power tong services quotation

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

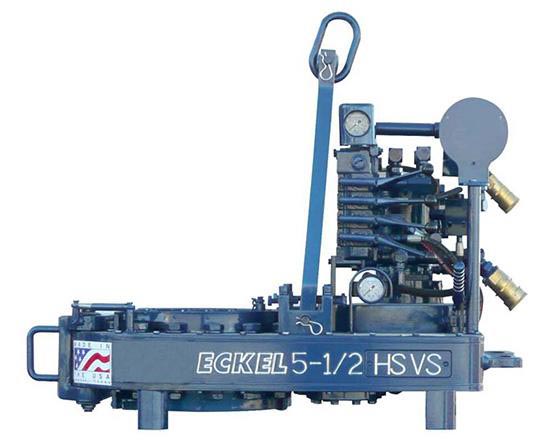

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

After each job make the following checks and take appropriate corrective action.Check cam follower or dumbbell rollers for wear or breakage, and replace if necessary. Clean heads and head sliding surfaces of foreign debris and grease lightly. Check grease in tong case, repack if necessary. Refer to the operation manual for proper greasing.

Our power tongs are built to last. With 1 motor options for the 6 1/4” hydraulic power tong, you crew can reach rated torque at 2500 psi. Which means, the tools can reach their rated torque dependably on ever single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Our power tongs are built to last. With 3 motor options for the 13 5/8” hydraulic power tong, you crew can reach rated torque at 3000 psi, 2250 psi, or 2000psi. Which means, the tools can reach 35,000 ft-lb of torque on every single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

Our goal at GOM Energy Services LLC is to deliver safe and reliable equipment our customers can depend on in the field. We will work with our clients to design products which will decrease non-productive time and in turn reduce money going out the door and away from the bottom line. Our products can and will help your company do those very things as well as add a best in class product to your portfolio as a tubular running and handling service company.

The team at GOM Energy Services is comprised of over 48 years experience in the oil and gas industry. Our main goal is to produce user friendly, field effective, and cost efficient equipment. Customer service is and always will be our #1 priority! On behalf of GOM Energy Services LLC and the team here I thank you for spending time learning about our product.

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

Key offers a broad range of squeeze services, including running squeeze, hesitation squeeze, high/low pressure squeeze, low pressure squeeze, packer/retainer squeeze, and Bradenhead squeeze.

Whether re-entering an existing wellbore or sidetracking around a stuck bottom hole assembly, our equipment and services have proven to reduce trips, milling time and

Fishing Services are used to remove wellbore obstructions. Key is highly capable of providing Fishing services for cased and open-hole applications. Our tool fleet ranges

The SmartTong® system takes the guesswork out of rod connections. As the world’s first computer-controlled connection service, algorithms ensure correct circumferential displacement on every connection

R.D.O.T is a small but ambitious Company specializing in Hydraulic Handling Tools. Our core business is the Sales, Supply & Service of Hydraulic Power Tongs.

GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA P[OWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS GILL

At R.D.O.T we are uniquely able to work on everything from Sucker Rod Tongs, the familiar 58-93R up to and including Snubbing and Casing Tongs. From a simple service to a complete custom Slant Rig Configuration R.D.O.T has the experience and skill to fulfill your requirements. Our in house test bench allows us to test up to 3500 psi @ 36 gallons a minute.

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

These gauges (CTT101 Series) display the amount of torque in foot pounds per joint when using power tongs to run oilfield tubular. They are available for all makes and models of power tongs and even dual scale variations are available. The systems come with either compression or tension-type load cells, which provide precision checks of make up torque for all oilfield tubular.

The CTT100 Series Tong Line Pull Systems are available from 10,000 to 30,000 single line pull for use in all torquing applications. The universal tong line pull system can be used with a veriety of tong systems and can be moved from rig to rig as needed. When you need a gauge to work in most of your tong applications with a variety of tong handle lenghts, you can trust taht the CTT100 series will provide the best measurement you can get.

Model XQ89/3C Hydraulic Power Tong is a special device for Well Service, which is used to make up and break out tubing thread. It is a improved new product based on Model XQ89/3B hydraulic power tong. Driving by hydraulic motor with low speed and large torque, model“H”manual control valve simply matching with oil motor. It’s a lighter hydraulic power tong for well service .

●The tong head uses inner curved roller climbing and cliping mechanism and needn’t to change any part during making up or breaking out the tubing thread which diameter is “27/8″”or“31/2″”.

●The new type hydraulic Backup tong and master tong form a combined tong . Operating the manual control valve of master tong, the combined tong clipping and unloosing simultaneously.

Matherne Instrumentation’s power tong system is designed to assure uniform and proper make-up of the string by indicating accurate torque applied to each joint when running pipe or casing.

The system can help reduce drill collar and tool joint failure resulting from improper make-up. The system includes a 6” tong torque indicator with bracket, a standard 5 ft. hose, and a tension or compression load cell.

The convenient mounting design allows the gauge to be mounted in a driller’s console, in a weight indicator box, locally on the power tong, or stand alone. The 6” dial face is available with combination dual scales for added versatility.

8613371530291

8613371530291