power tong test stand brands

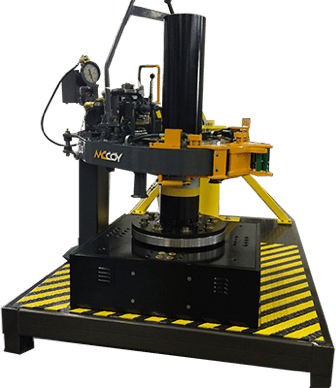

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

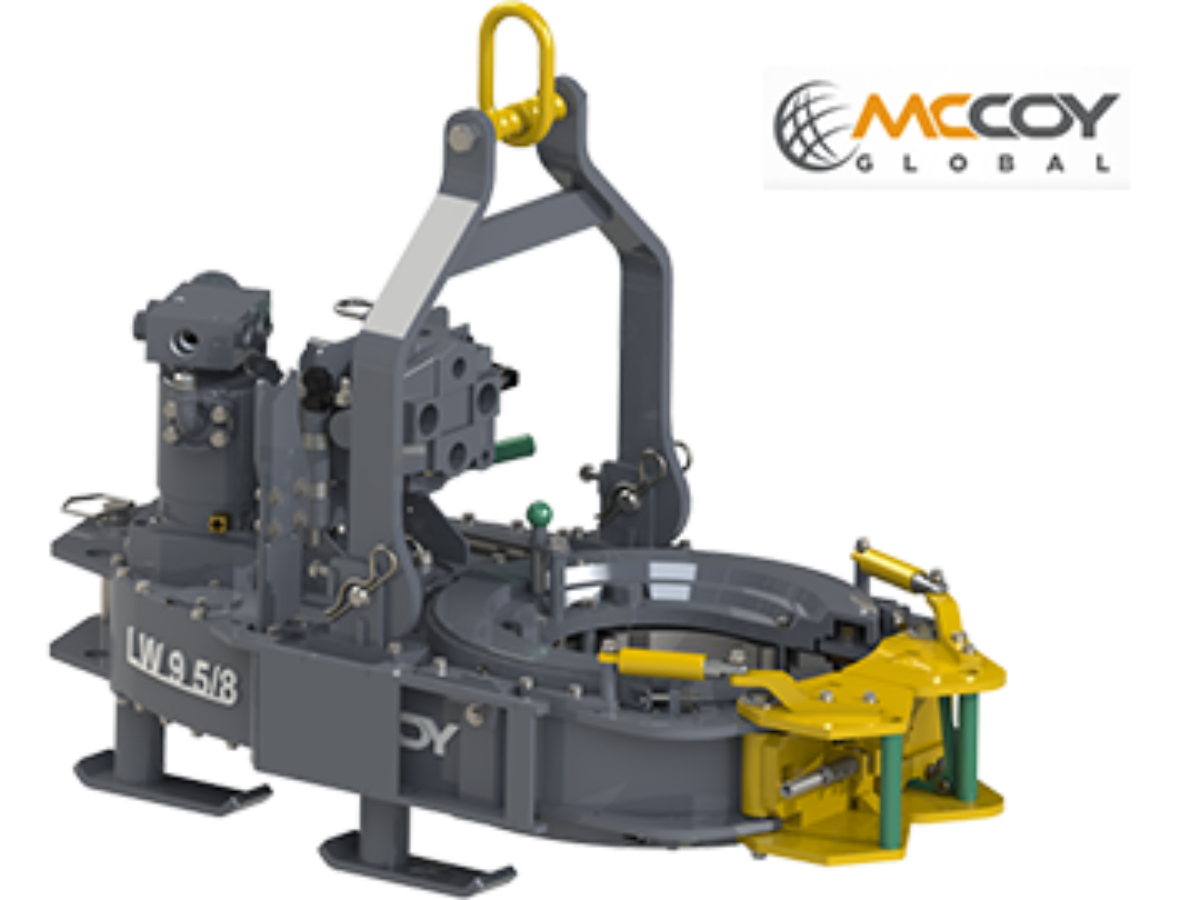

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

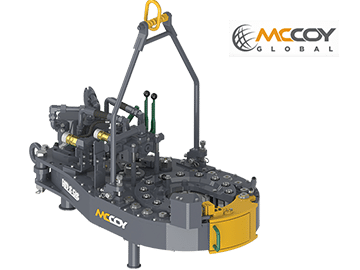

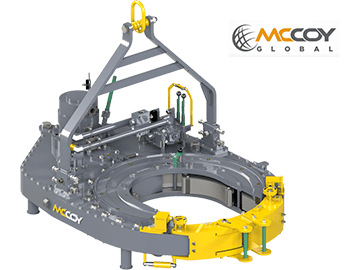

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

Casing tong handling tools (CTHTs) improve safety and efficiency by reducing the time to complete casing running operations. The CTHT automatically moves the casing tongs to and from well center, which decreases the personnel required to make up casing on the rig floor. Additionally, the CTHT increases the speed of running the casing tong to and from well center. Operations are faster and more consistent, from shift to shift, crew to crew.

The CTHT is an upgrade to an existing offshore drilling rig. This tool lifts and handles casing tongs, ranging in size from 7 5/8 in to 30 in, to and from the well center during casing running operations. And it can be used on any Cameron SmartRacker vertical pipe handling system or any other brand of column racker.

Our casing and tubing running services are the right choice for efficient casing and tubular running. When you need expert handling of standard or exotic chrome tubulars—for any job-from the simplest to the most challenging—we havethe answer that reduces down time and costs, backed by 45 years of operating experience.

The Derrickman™ casing alignment tool eliminates the risks of personnel working at height with a hydraulically powered stabbing arm and the stabberless T-CAT™ casing alignment tool, operated remotely from the rig floor.

Our Leadhand™ tong manipulating systemmoves the hydraulically powered tong to and from the well centerline mechanically, without the need for manual handling. The system facilitates a one-man tong operation, removing multiple personnel from the dangers of the well center.

We have the most comprehensive and robust suite of casing and tubing tongs available. These tong systems are complimented by self-contained hydraulic power units in a variety of diesel and electric configurations. We are able to provide zone-rated units for operation in hazardous areas, custom built, and certified to the highest industry standards.

Our tong systems cover a wide range of sizes and torque capacities from small tubing through large-diameter casing. Integrated hydraulic backups maximize safety, accuracy, and efficiency. All of our power tongs are compatible with ourSalvo torque-turn monitoring systemfor control and accuracy of makeup.

Tubing power tong (Inner curved cam clamp) is used for quick make-up/ break-out in well service operations. The tong is equipped with hydraulic backup tong and use inner curved cam to clamp.

2. Advantage of Model XQ89/3YE; Low speed, rated speed is 28 rpm. Dies of backup tong can clamp the underside of tubing coupling, so as to reduce distortion of tubing coupling to prevent conglutination of thread.

ZQ drill pipe power tong is an ideal well head tool for oil drilling, widely applied for making-up and breaking-out in offshore and onshore drilling operations and well service operations. Open-throat design of the ZQ series allows the tongs to escape from drilling pipe freely with high mobility. The tong is a combination of spinning tong and torque tong. It substitutes cathead, manual tong and rotary rope in making-up and breaking-out.

At the heart of this innovative hydraulic motor is a patented vane-crossing-vane design, a revolutionary concept in hydraulic power transmission. The design is a bi-rotational power converter utilizing working vanes in the rotating member and sealing vanes in the stationary member, or stator.

With 10 rotor vanes working in four cavities, the motor provides an uninterrupted torque output regardless of angular position. This design thus delivers 40 power strokes per revolution, providing higher average torque with low torque ripple.

The stator vanes function as seals between high- and low-pressure ports within the stator. This allows for more displacement in the stator, giving the Rineer vane motor an optimum power-to-weight ratio. The result: The torque curves are virtually flat with starting and stall torque equal to 90 to 94 percent of theoretical torque.

8613371530291

8613371530291