power tong test stand price

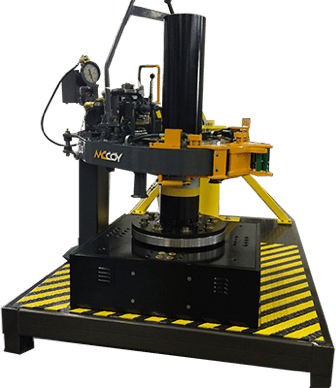

Before your tongs see any action, it’s essential to perform a tong test. Our tong testing stand allows you to test both hydraulic casing and tubing power tongs. Tong testing works by resisting the torque applied by the power tongs through a test mandrel. The tong test stand can be used for tool testing, certifying torque requirements, as well as training personnel on new, or unfamiliar equipment.

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

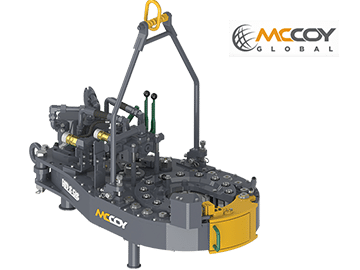

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Casing tong handling tools (CTHTs) improve safety and efficiency by reducing the time to complete casing running operations. The CTHT automatically moves the casing tongs to and from well center, which decreases the personnel required to make up casing on the rig floor. Additionally, the CTHT increases the speed of running the casing tong to and from well center. Operations are faster and more consistent, from shift to shift, crew to crew.

The CTHT is an upgrade to an existing offshore drilling rig. This tool lifts and handles casing tongs, ranging in size from 7 5/8 in to 30 in, to and from the well center during casing running operations. And it can be used on any Cameron SmartRacker vertical pipe handling system or any other brand of column racker.

Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells.

The tong should be secured for both make-up or break-out operation, by utilizing the snub line. If this is not done, the tong may be thrown against operator causing physical harm.

When using the mechanical shift lever to change speeds, the power tong must first come to a complete stop before shifting. When using tongs hydraulic shift two-speed motor to change speeds, the tong may be shifted "On the Run."

Eckel tongs have proven to basically to last forever with minimal maintenance as all they are manufactured with the highest quality of steel. Using Eckel equipment tells your customer that you have the highest quality equipment on the market.

Tong size is determined by range of tubulars you will run. For example a 5-1/2 Hydra-Shift® is capable of running tubulars 5-1/2-inches and smaller while the 14 UHT is capable of running tubulars 14-inches and smaller. It is important not to use a large range of sizes with just one tong. If you have a 10-3/4 Standard and you regularly run 4-1/2-inch tubing with this tong, you might consider using a smaller tong.

PSI pressure determines the maximum torque the tong will safely be able to reach. Eckel rates all their tongs at the industry standard 2500 PSI. A competitor with a similar size tong may show more or the same torque as an Eckel tong due to a higher PSI from the power unit (which is in fine print) in an effort to fool you, thinking there tong is equal to the industry standard (Eckel tong.)

Gallons Per Minute determines the rotational speed of the tong. A low GPM will cause the tong to operate at a lower speed while a high GPM will result in the tong to rotate at a higher speed. Eckel offers an RPM (Revolutions per minute) Control which is a flow divider to decrease the amount of hydraulic fluid that reaches the tong if needed, the remaining fluid is returned to the power unit reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM of the tong.

Field tests have shown depending on several factors most power units used in above 32 degrees Fahrenheit conditions no matter if your hydraulic oil tank holds 200 gallons of oil, will exceed 150 degrees during a short 8 hour job. Most power units without hydraulic oil coolers exceed 170 degrees which is way past the recommended guide lines.

K&S Power Tongs committs to providing quality casing services in a safe, reliable, cost efficient and timely manner. Safety is everyone’s full time job and we are committed to the prevention and elimination of all safety nad health hazards. All operators are specially trained and industry safety certified. Safety is never compromised. Unsafe acts are never tolerated and our employees are held accountable to work safe.

K&S Power Tongs offers coventional and integral power tong services, volant casing running tools, computer torque-turn systems, power thread washing, thread inspection, handling equipment rentals and light oilfield hauling.

As shown in Figure 1, power tong head torque check system of the present invention comprises detection module 11, Data Enter module 12, data receiver display module 13, data processing chart display module 14 and calibration certificate generation module 15.

Data processing chart display module 14 is for comparing process to the actual torque value of the binding clip of power tong detected by detection module 11 and the standard torque value of this binding clip of power tong, calculate the error of actual torque value and standard torque value, by the standard torque value of this binding clip of power tong, the actual torque value of the binding clip of power tong that detection module 11 detects, error between actual torque value and standard torque value, matching relationship between the standard torque value of this binding clip of power tong and its hydraulic system pressure and the matching relationship between the actual torque value of this binding clip of power tong and its hydraulic system pressure are reflected in calibration chart, and by these calibration result information displaying in software display interface.

Preferably, for the Power Tong installing different tubing, the detection module in power tong head torque check system of the present invention has following three kinds of embodiments.

As shown in Figure 2, the detection module in this embodiment is applicable to carry out verification to the power tong head torque of installing drilling tool and detects.This detection module comprises simulation tubing and torque sensor, and wherein, simulation tubing comprises simulation tubing top connection 21 and simulation tubing lower sub 22; Torque sensor comprises sensor body 23 and torque gauge 24, torque gauge is set in the middle part of sensor body 23, and sensor body 23 being arranged in a part of two parts of torque gauge 24 both sides for detection link 231, another part is coupling shaft 232.Simulation tubing top connection 21 is the top connection of simulation drilling tool, and simulation tubing lower sub 22 is the lower sub of simulation drilling tool, and simulation drilling tool top connection and the lower sub of simulation drilling tool are tubular structure.Simulation drilling tool top connection to be set in sensor body on the detection link 231 on 23, and the internal diameter of this simulation drilling tool top connection equals the diameter detecting link 231; The lower sub of simulation drilling tool is set on the coupling shaft 232 in sensor body 23, and the internal diameter of this simulation drilling tool lower sub equals the diameter of coupling shaft 332.The external diameter of torque gauge 24 equals to simulate the external diameter of drilling tool top connection and the external diameter of simulation drilling tool lower sub.Certainly, this power tong head torque calibration equipment also can verify the power tong head torque of installation two sections of unequal drilling tools of external diameter.Preferably, non-contact torque sensor selected by torque sensor, and the sidewall of detection link 231 in its sensor body 23 is provided with keyway or key (not shown), like this, when using this detection module to verify power tong head torque, the moment of torsion that binding clip of power tong is applied in the top connection of simulation drilling tool is delivered on torque gauge 24 by keyway or key, binding clip of power tong can be measured by torque gauge 24 and be applied to the actual torque of simulating in drilling tool top connection, and then draw the matching relationship of the reality between the hydraulic pressure of this power tong head torque and Power Tong and binding clip moment of torsion.Preferably, detecting key on link 231 sidewall can one optionally in flat key, screw key, spline or square key.Certainly, torque sensor also can select foil gauge torque sensor, utilizes foil gauge on being positioned in its sensor body 23 detection link 231 sidewall to realize the transmission of moment of torsion.

As shown in Figure 3, the power tong head torque that the detection module in this embodiment is applicable to installing oil pipe or sleeve pipe verifies.The difference of this embodiment and the first embodiment is, simulation tubing is simulation oil pipe or analog casing, wherein, simulation tubing top connection 21 is simulation oil pipe (sleeve pipe) top connection, simulation tubing lower sub 22 is simulation oil pipe (sleeve pipe) lower sub, and the external diameter of simulation oil pipe (sleeve pipe) top connection equals the external diameter of simulating oil pipe (sleeve pipe) lower sub, the internal diameter of simulation oil pipe (sleeve pipe) top connection equals the internal diameter of simulating oil pipe (sleeve pipe) lower sub.The end of one end that simulation oil pipe (sleeve pipe) top connection is connected with the detection link 231 in sensor body 23 is provided with circular inner edge boss 211, and the internal diameter of this inner edge boss 211 equals the diameter detecting link 231; The end of one end that simulation oil pipe (sleeve pipe) lower sub is connected with the coupling shaft 232 in sensor body on 23 is provided with circular inner edge boss 221, and the internal diameter of this inner edge boss 221 equals the diameter of coupling shaft 232.Linked together by inner edge boss 211 and detection link 231 in simulation oil pipe (sleeve pipe) top connection, after simulation oil pipe (sleeve pipe) lower sub is linked together by inner edge boss 221 and coupling shaft 232, the external diameter being set in the torque gauge 232 in sensor body 231 is less than the external diameter of simulation oil pipe (sleeve pipe) top connection, and have spacing between the inwall of the sidewall of detection link 231 and simulation oil pipe (sleeve pipe) top connection, there is spacing between the sidewall of coupling shaft 232 and the inwall of simulation oil pipe (sleeve pipe) lower sub.Preferably, the external diameter of torque gauge 232 equals to simulate the internal diameter of oil pipe (sleeve pipe) top connection and the internal diameter of simulation oil pipe (sleeve pipe) lower sub.Preferably, the sidewall detecting link 231 is provided with keyway or the key of transmitting torque and connecting analog oil pipe (sleeve pipe) top connection.

As shown in Figure 4, the power tong head torque that the detection module in this embodiment is also applicable to installing oil pipe or sleeve pipe verifies.The difference of this embodiment and the second embodiment is, the external diameter of the simulation tubing top connection 21 in this embodiment is less than the external diameter of simulation tubing lower sub 22.

Preferably, as shown in Figure 1, Data Enter module 12 comprises parameter input unit 121 and Detection Information input block 122; Wherein, parameter input unit 121 is for inputting the device name of Power Tong to be verified, specifications and models, factory number and manufacturing firm, and the range of Power Tong, accuracy class and indicating value permissible error scope; Detection Information input block 122 is for information, the certificate number of input power pincers affiliated unit, calibration date, calibration location, environment temperature, ambient humidity, identifier, check people, Approved by, and the device name of detection module, device numbering, verification certificate number and verification certificate the term of validity.Like this, the essential information of Data Enter module 12 typing Power Tong, to ensure the information match in verified Power Tong and calibration certificate, is convenient to the calibration certificate that relevant staff consults Power Tong.

Preferably, as shown in Figure 1, data receiver display module 13 comprises data receipt unit 131 and data display unit 132, and the data that data receipt unit 131 detects for receiving detection module 11, the data that data display unit 132 first receives data receipt unit 131 judge and error correction, then the authentic and valid data obtained are shown in the display interface of this power tong head torque check system.Like this, data receiver display module 13 can be avoided the data receiving transmission distortion or the partial data collected by detection module 11 that receives to be shown in the lower display interface of power tong head torque check system as authentic and valid data, and then avoid data processing chart display module 14 effective for non-genuine data to be processed as authentic and valid data.Preferably, carry out data transmission between detection module 11 and data receiver display module 13 by RS232 bus, the data detected to avoid detection module 11 are the distortion because being subject to outer signals interference when being transferred to data receiver display module 13.Preferably, adopt event-driven explanation to realize avoiding data to leak to the data collection that detection module 11 detects and adopt, and then make data receiver display module 13 can receive all data messages being transferred to data receiver display module 13 by detection module 11.Like this, data acquisition program response in time and reliability is high.

Preferably, as shown in Figure 1, data processing chart display module 14 comprises data processing unit 141 and chart display unit 142.Wherein, the actual torque value of binding clip of power tong that data processing unit 141 pairs of detection modules 11 detect and the standard torque value of this binding clip of power tong compare, and calculate the error between the actual torque value of this binding clip of power tong and standard torque value.Chart display unit 142 is by the standard torque value of binding clip of power tong, error between the actual torque value of this binding clip of power tong that the actual torque value of this binding clip of power tong that detection module 11 detects and data processing unit 141 calculate and standard torque value is reacted in calibration chart with data mode, matching relationship between the actual torque value of the matching relationship between the standard torque value of this binding clip of power tong and its hydraulic system pressure and this binding clip of power tong and its hydraulic system pressure is reacted in calibration chart with the form of calibration curve, and this calibration chart is presented in the display interface of this power tong head torque check system.This calibration chart can matching relationship between the standard torque value of matching relationship clearly between the reaction power pincers actual torque value of binding clip and its hydraulic system pressure and this binding clip of power tong and its hydraulic system pressure.Like this, the user that this calibration chart can be this Power Tong reaches expection torque value in the process using this Power Tong provides important reference frame.

Preferably, as shown in Figure 1, certificates constructing module 15 comprises calibration certificate generation unit 151 and data saving unit 152.Wherein, the data that the information of Data Enter module 12 typing, data receiver display module 13 receive by calibration certificate generation unit 151 and data processing chart display module 14 process the data preparation obtained and integrate and be filled up in calibration certificate template, generate calibration certificate.Preferably, calibration certificate substrate interface is presented on computing machine foreground, is convenient to detect operating personnel and audits check and correction.Preferably, calibration certificate template is word document form, is so both convenient to Rapid input and the Mass production of information, is convenient to again to detect operating personnel and after calibration certificate generates, carries out error correction to the information in calibration certificate and revise.The data that calibration certificate inteilectual becomes the calibration certificate of generation in unit 151, the information of Data Enter module 12 typing, data receiver display module 13 to receive by data saving unit 152 and data processing chart display module 14 process the data obtained and are saved in memory device.Preferably, in preservation process, calibration certificate filename is numbered corresponding with certification of proof, and under the unification of the calibration certificate of all generations is saved in TorqueTestData folder content, so that relevant staff has access to inquiry in the later stage.

Existing composition graphs 1 and Fig. 5 illustrate the process that this power tong head torque check system verifies power tong head torque, and concrete steps are as follows:

Step 502: to the device name of typing Power Tong in Data Enter module 12, specifications and models, factory number and manufacturing firm and range, accuracy class and indicating value permissible error scope on the display interface of this power tong head torque check system, this Power Tong affiliated unit information, certificate number, calibration date, calibration location, environment temperature, ambient humidity, identifier, check people, Approved by and the term of validity of the device name of detection module, device numbering, verification certificate number and verification certificate;

Step 503: start detection module 11 pairs of Power Tongs verify, receives by data receiver display module 13 data that detection module 11 detects, and tests the data detected;

Step 505: in the actual torque value of the binding clip of power tong detected in the 141 pairs of steps 503 of the data processing unit in data processing chart display module 14 and step 502, the standard torque value of the binding clip of power tong of typing compares, and calculates error therebetween;

Step 506: the matching relationship that the chart display unit 142 in data processing chart display module 14 gathers between the standard torque value of matching relationship between the actual torque value of binding clip of power tong and its hydraulic system pressure and this binding clip of power tong and its hydraulic system pressure forms calibration curve, by this calibration curve, the standard torque value of this Power Tong, the actual torque value of this Power Tong and the error between the actual torque value of this Power Tong and standard torque value are reflected in calibration chart, and this calibration chart is presented in the display interface of this power tong head torque check system,

A3: We has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

A4: Generally, it will take 35 working days after receiving your deposit payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have standard machines in stock.

8613371530291

8613371530291