power tong test stand for sale

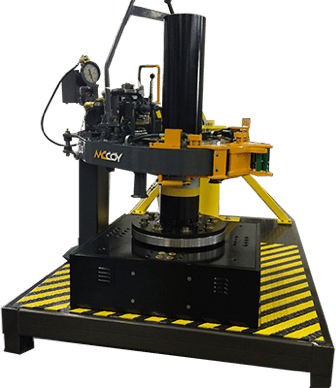

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

Before your tongs see any action, it’s essential to perform a tong test. Our tong testing stand allows you to test both hydraulic casing and tubing power tongs. Tong testing works by resisting the torque applied by the power tongs through a test mandrel. The tong test stand can be used for tool testing, certifying torque requirements, as well as training personnel on new, or unfamiliar equipment.

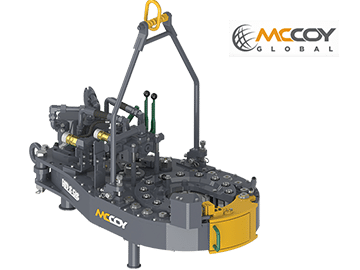

The Power Tong and Back-up Test Stand is a facility designed for testing all combinations of powered tubular make-up equipment to a maximum size of 30” diameter.

Handling tools play a critical role in modern drill pipe operations. They are used for suspending, moving, and rotating tubulars in and around the well centre and on the drill floor. At Oil Baron Supply, we pride ourselves in only selling high-quality API 7K and API 8C oilfield tools and equipment. We carry a wide range of oilfield tools for sale and rent, including: elevators, power tongs, power units, tong test stands, casing running tools, casing tools and rotary tools. We can repair, recertify and test all of our drill pipe and casing handling equipment including inspecting, welding, machining, MPI and load tests. Oil Baron Supply stocks and distributes for several manufactures including Mud King Products, Hamburg Oil Tools, TEDA and Cavins.

Blow Out Preventer (BOP) test stumps are often used for manufacturers to test their BOP or drillers testing operations at off-shore and on-shore drilling rig. BOP TEST STUMP is designed and manufactured in accordance with API 6A or API 16A standard.we provide all sizes and pressure ratings BOP TEST STUMP used for BOP test.

Basic material of construction is alloy steel. For corrosion resistance, we can overlay 316 SS or Inconel 625 on the ring groove to improve product life if required.CCSC"s customizable BOP TEST STUMP allow customers to design their ideal product for reliable and consistent performance.

The tong should be secured for both make-up or break-out operation, by utilizing the snub line. If this is not done, the tong may be thrown against operator causing physical harm.

When using the mechanical shift lever to change speeds, the power tong must first come to a complete stop before shifting. When using tongs hydraulic shift two-speed motor to change speeds, the tong may be shifted "On the Run."

Eckel tongs have proven to basically to last forever with minimal maintenance as all they are manufactured with the highest quality of steel. Using Eckel equipment tells your customer that you have the highest quality equipment on the market.

Tong size is determined by range of tubulars you will run. For example a 5-1/2 Hydra-Shift® is capable of running tubulars 5-1/2-inches and smaller while the 14 UHT is capable of running tubulars 14-inches and smaller. It is important not to use a large range of sizes with just one tong. If you have a 10-3/4 Standard and you regularly run 4-1/2-inch tubing with this tong, you might consider using a smaller tong.

PSI pressure determines the maximum torque the tong will safely be able to reach. Eckel rates all their tongs at the industry standard 2500 PSI. A competitor with a similar size tong may show more or the same torque as an Eckel tong due to a higher PSI from the power unit (which is in fine print) in an effort to fool you, thinking there tong is equal to the industry standard (Eckel tong.)

Gallons Per Minute determines the rotational speed of the tong. A low GPM will cause the tong to operate at a lower speed while a high GPM will result in the tong to rotate at a higher speed. Eckel offers an RPM (Revolutions per minute) Control which is a flow divider to decrease the amount of hydraulic fluid that reaches the tong if needed, the remaining fluid is returned to the power unit reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM of the tong.

Field tests have shown depending on several factors most power units used in above 32 degrees Fahrenheit conditions no matter if your hydraulic oil tank holds 200 gallons of oil, will exceed 150 degrees during a short 8 hour job. Most power units without hydraulic oil coolers exceed 170 degrees which is way past the recommended guide lines.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Harrington"s SHLT2 are designed to test manual hoists and DHLT2 are able to test manual and powered hoists. Both of our hoist load testers are able to perform load tests of up to 10 Ton and were designed to test hoists in accordance with ANSI/ASME B30.16 and B30.21 requirements. Testing of load carrying parts becomes effortless with these reliable testers.

At the heart of this innovative hydraulic motor is a patented vane-crossing-vane design, a revolutionary concept in hydraulic power transmission. The design is a bi-rotational power converter utilizing working vanes in the rotating member and sealing vanes in the stationary member, or stator.

With 10 rotor vanes working in four cavities, the motor provides an uninterrupted torque output regardless of angular position. This design thus delivers 40 power strokes per revolution, providing higher average torque with low torque ripple.

The stator vanes function as seals between high- and low-pressure ports within the stator. This allows for more displacement in the stator, giving the Rineer vane motor an optimum power-to-weight ratio. The result: The torque curves are virtually flat with starting and stall torque equal to 90 to 94 percent of theoretical torque.

8613371530291

8613371530291