anson pup joint manufacturer

Pup joint is kind of pipe without non-standard length to adjust the length of tubular strings to its exact requirement. API casing and tubing pup joint are produced according to API SPEC 5CT standard. Beyond the standard of oil casing pipe is called pup joint, the main oil casing pup joint material: J55, K55, N80, L80, C90, T95 and P110. Anson steel is a professional pup joint manufacturers in the steel line with good reputation.

Pup joints are non-standard lengths of piping applied to adjust the height of full length casing, tubing, line pipe, drill pipe or casing strings, for instance, in the acidic operating environment in the high pressure discharge line, input line, a temporary flow line, well testing and other high voltage transmission line on oil and natural gas pipelines. Meanwhile API pup joint is also cementing and fracturing equipment delivery high pressure fluid control products.

Pup joint is made of high strength steel, with a special toughening process. It uses Acme threaded connection, making it with the demolition convenient, fast, reliable connection, and reliable. Multiple seal design and high precision, to ensure the sealing performance of Pup joint.

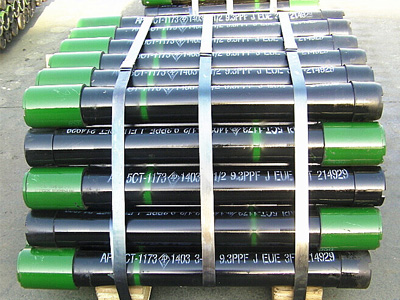

Anson Steel manufactures all range of tubing pup joint and casing pup joint as per API specifications in all groups for casings and tubing. All of our pup joints meet the American Petroleum Institute (API) Specifications 5CT. The tubing and casing pup joints are subjected to be phosphated to prevent rusting and coated on thread by VCI oil. The range of couplings extends from 2 3/8" to 20", under grades H-40, J-55, K-55, L-80, N-80, C90, T95, P-110, Q125 etc.

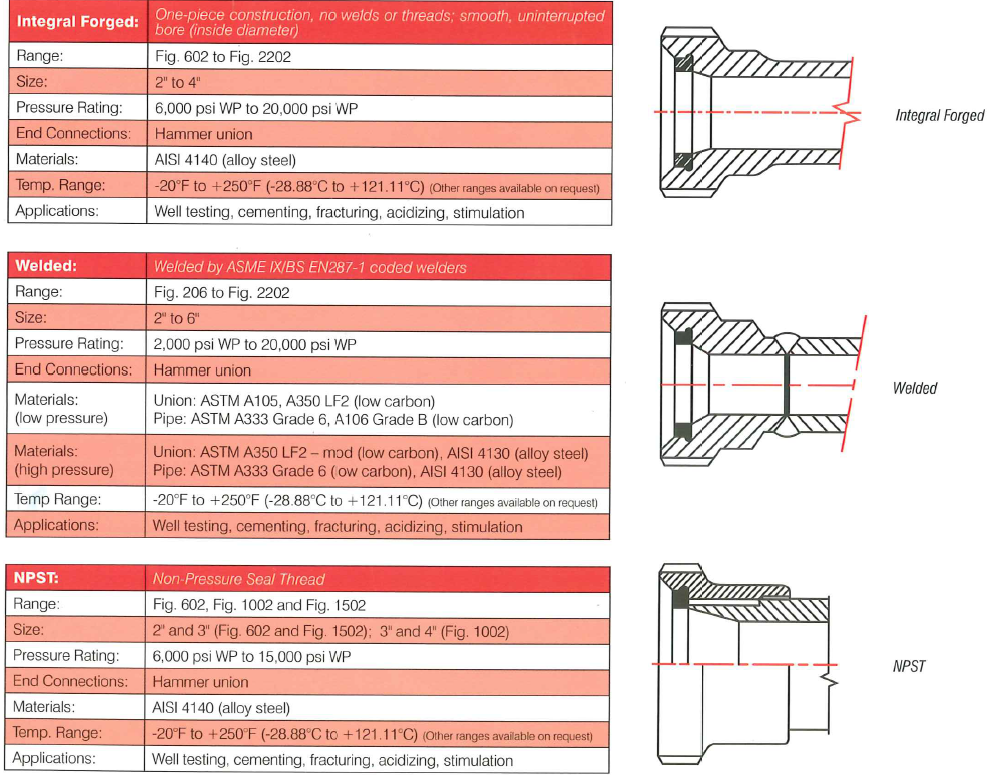

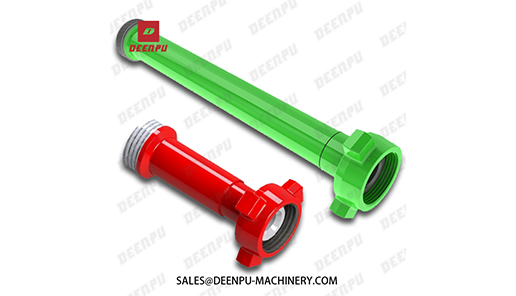

The high pressure pup joint is forged by high quality structural alloy steel. Terminal union is forged together with pipe, which is able to avoid disassembling and ensure good sealing, small weight, convenient use and fast installation. Except for integral pup joints, Anson steel is also supplying pressure thread sealing pup joint, non-pressure thread sealing pup joint and welding pup joint. Therefore, we have enough stock in different types and sizes to meet customers’ different requirements. Choose a good pup joints supplier, choose a best start for your business! Henan Anson Steel is your trustable supplier and manufacturer in the international trade.

ANSON API.6A ‘Top Entry’ Check Valves are manufactured to a high specification from closed die forged steel bodies with 17/4 ph stainless steel internals.

ANSON API.6A ‘Top Entry’ Check Valves are manufactured to a high specification from closed die forged steel bodies with 17/4 ph stainless steel internals.

Pup Joints are used interconnecting pipe work between major equipment. PYZS offers the industry"s wide range of pup joints including forged integral, welded, threaded and NPST styles. All Anson brand pup joints are available for standard or sour gas service.

The Longlife swivel joint is a long radius journal bearing design that increases the swivel design life and greatly reduces maintenance time. The swivel elbows are a forged one-piece construction, fully heat treated and subject to a full MPI inspection to ASTM E709.

ANSON elbows provide a 45 or 90 degree bend option for customers. For portable flowline, the most common end configuration is male x female hammer union connection. Elbow construction can either be forged or welded. Manifold elbows are also available in long sweep, full flow, and block configurations with butt weld ends.

ANSON steel cementing and circulating hoses incorporate the unique NOV ANSON Longlife swivel joint suitable for use up to 15,000 psi working pressure or code silver threaded swivel joints for use up to 6,000 psi working pressure. Hoses can be supplied in standard service or sour gas trim with fully traceable material certification.

ANSON fittings encompass over 2,500 designs that include union ended tees, laterals, wye’s, goat heads, crowsfoot, union crossovers, hub crossovers, and flange crossovers. Also available are ANSON full flow and block manifold fittings: elbows (long sweep, double back, and block), tees and crosses (long sweep, full flow, and block), laterals, and goosenecks. Most fittings are manufactured from closed die forgings offering high material integrity.

Mission offers the industry’s most extensive range of pup joints, including forged integral, welded, threaded, and NPST styles. All ANSON pup joints are available for standard or sour gas service (NACE MR-01-75/ISO 15156) and are supplied with full material traceability and certification.

ANSON hammer lug unions are available in hydrogen sulphide trim (Sour Gas, H2S) with either threaded or butt weld ends. Sour gas unions are manufactured in accordance with NACE Standard MR-01-75 (Latest Revision). All unions are subjected to rigorous inspection checks throughout manufacture. Sour gas unions have their batch numbers prefixed by letters S G and, for ease of identification, are painted olive green.

ANSON hammer lug unions are available in all Fig. numbers as butt weld unions as an alternative to the Standard API threaded end. The only exception to this being the Fig. 50 which is available as socket weld only. When ordering butt weld unions please state the pipe schedule required.

ANSON lip and ‘O’ ring type seals are available for standard service in nitrile and for sour gas service in fluoroelastomer. Manufacture is closely monitored to guarantee the correct shore hardness and composition.

ANSON flowheads offer compact design resulting in reduced overall size and weight therefore increasing ease of operation. All valve seat pockets can be CRA625 inlaid to offer increased service life. The flowheads can be supplied complete with a string swivel if required. ANSON string swivels allow rotation around the string and eliminate torque transfer. They are complete with locking keys to prevent string thread back-out. Excessive testing including high temperature cyclic and slurry testing is carried out for ANSON swivels.

ANSON flowheads are available with working pressures from 2,000 psi through to 15,000 psi, temperatures from -75 ̊F (-59.4 ̊C) to 400 ̊F (204.4 ̊C) and sizes up to 9” API. All API 6A material classes are available in product specification levels (PSL 1, 2, 3 an 4).

Pup joint is kind of pipe without non-standard length to adjust the length of tubular strings to its exact requirement. API casing and tubing pup joint are produced according to API SPEC 5CT standard. Beyond the standard of oil casing pipe is called pup joint, the main oil casing pup joint material: J55, K55, N80, L80, C90, T95 and P110. Anson steel is a professional pup joint manufacturers in the steel line with good reputation.

Grade:J55/K55/N80/L80/P110/C95OD of Tubing Joint:From 2-3/8"(60.3mm) to 4.5"(114.60mm);Pipe end:EUE/NUEOD of Casing Joint:From 4-1/2"(114.3mm) to 20"(508mm);Threads:BTC, LTC, STC.Length:2,3,4,6,8,10 12 ft (with other lengths available upon request)Surface treatment:coatingPacking:according to customer specific requirements, or by wooden case or wooden pallet

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

The present invention relates to a pup joint and, more particularly, to a pup joint which includes means for maintaining the wing nut and retainer segments in a position adjacent the male sub at all times.

Pup joints are relatively small lengths of pipe used in the oilfield industry to conduct fluids from one piece of equipment to another. Typical pup joints comprise a length of pipe having a male sub located at one end, a female sub located at the other end and a wing nut for connecting the male end of one pup joint to the female end of another pup joint. The male sub includes a spherical sealing surface, and the female sub includes a mating conical sealing surface and a set of external threads. The wing nut is retained on the pup joint by means of a shoulder or a set of retainer segments and engages the threads of the female sub to secure two pup joins together.

Maintaining the wing nut and retainer segments adjacent the male sub end has been somewhat of a challenge in prior art pup joints. In certain prior art pup joints constructed of heavy-wall tubing, the wing nut and retainer segments are held in place by means of an interference fit with the male sub tubing. In lighter weight pup joints, however, this interference fit does not exist. Therefore, when a pup joint is held in a non-horizontal position, the wing nut is permitted to slide down the pup joint, thus creating difficulties during installation.

Therefore, it is an object of the present invention to provide a pup joint which includes means for maintaining the wing nut and retainer segments adjacent the male sub.

According to the present invention, this and other objects and advantages are achieved by providing a pup joint comprising a length of pipe, a female sub integral with one end of the pipe and having external threads formed thereon, a male sub integral with the other end of the pipe, a wing nut for threadedly connecting the male sub to the female sub, a set of retainer segments for retaining the wing nut on the pup joint, and a retention shoulder extending radially outwardly from the male sub to maintain the wing nut and retainer segments on the male sub. In a preferred embodiment of the invention, the pipe and the male and female subs are comprised of a single forging, and the retention shoulder is formed by machining the male sub. The retention shoulder therefore provides a means for preventing the wing nut and retainer segments from sliding down the pup joint.

Referring to FIG. 1, a prior art pup joint 10 is shown which comprises a length of pipe 12, an integrally formed male sub 14 at one end of pipe 12 and an integrally formed female sub 16 at the other end of pipe 12. Male sub 14 includes a spherical sealing surface 18, while female sub 16 includes a mating is conical sealing surface 20. Female sub 16 also includes a set of threads 22 formed on an exterior surface thereof, and pup joint 10 further comprises a wing nut 24 having a set of internal threads 26 formed therein for engaging the threads 22 of a female sub 16 of another pup joint 10. Nut 24 is retained on pup joint 10 by means of retainer segments 28, which simultaneously engage a rearward shoulder 30 extending radially inwardly from the interior surface of nut 24 and a forward shoulder 32 extending radially outwardly from the exterior surface of male sub 14 to thereby prevent nut 24 from pulling off of pup joint 10 (to the right in FIG. 1) when nut 24 is threaded onto the female sub of another pup joint. In each of the embodiments described herein, it should be recognized that the pup joint, including the length of pipe and the male and female subs, includes a fluid flow passage extending completely longitudinally therethrough.

Referring to FIG. 2, another prior art pup joint, indicated generally at 34, is shown which comprises a length of pipe 36, a male sub 38 and a female sub 40. In this pup joint, male sub 38 and female sub 40 are threaded onto corresponding ends of pipe 36. Prior to threading male sub 38 onto pipe 36, a wing nut 42 is assembled over pipe 36. Wing nut 42 comprises a rearward shoulder 44 extending radially inwardly from an interior surface 46 thereof, and wing nut 42 is retained on pup joint 34 by means of the engagement of rearward shoulder 44 with a forward shoulder 48 of greater diameter than rearward shoulder 44 extending radially outwardly from male sub 38.

Referring to FIG. 3, the pup joint of the present invention, indicated generally at 110, is shown to comprise a length of pipe 112, a male sub 114 located at one end of pipe 112 and a female sub 116 located at the other end of pipe 112. Male sub 114 and female sub 116 may either be formed integral with pipe 112 as a single forging or manufactured individually and then threaded onto the ends of pipe 112. Male sub 114 comprises an enlarged diameter section 118 and a spherical sealing surface 120. Female sub 116 comprises an enlarged diameter section 122 having external threads 124 formed thereon and a conical sealing surface (not shown) adapted to mate with spherical sealing surface 120 of another pup joint 110.

Referring to FIG. 4, pup joint 110 also comprises a wing nut 126 having internal threads 128 designed to engage the threads 124 of another pup joint 110 to thereby secure two pup joints 110 together. Nut 126 is retained on pup joint 110 by means of one or more retainer segments 130. Retainer segments 130 comprise an inner diameter corresponding generally to the outer diameter of enlarged diameter section 118, a front face 132 and a rear face 134. When nut 126 and retainer segments 130 are assembled on male sub 114, front face 132 engages an annular forward shoulder 136 extending radially outwardly from enlarged diameter section 118 of male sub 114 and rear face 134 engages a rearward shoulder 138 extending radially inwardly from an inner surface 140 of nut 126 to thereby prevent nut 126 from pulling off of pup joint 110 (to the right in FIG. 4) when nut 126 is threaded onto the female sub of another pup joint.

According to the present invention, pup joint 110 is also provided with a retention shoulder 142 extending radially outwardly from enlarged diameter section 118 of male sub 114. Retention shoulder 142 comprises an outside diameter which is greater than the inside diameter of retainer segments 130. Rearward shoulder 138 of nut 126 is restricted from movement relative to retainer segments 130 by a retainer ring 131 located in a corresponding groove in retainer segments 130. In an embodiment of the invention wherein retention segments 130 are not employed, such as in conjunction with the pup joint 34 described in reference to FIG. 2, retention shoulder 142 comprises an outside diameter which is greater than the diameter of rearward shoulder 138 of nut 126. Therefore, nut 126 and retainer segments 130 (or nut 126 alone) are preventing from sliding off of male sub 114 and down pipe 112 (to the left in FIG. 4) when pup joint 110 is oriented in a non-horizontal position.

Referring to FIG. 5, pup joint 110 is preferably constructed of a single forging 144 comprising identical upset ends 146,148. Upset end 146 is machined into male sub 114, and retention shoulder 142 is formed by turning down large diameter section 118. Upset end 148 is likewise machined into female sub 116. This method of manufacture simplifies the forging process. In addition, this method of manufacture results in a retention shoulder which cannot be removed or otherwise defeated in the field.

FMC Technologies’ new lightweight pup joints with integral Weco® wing union end connections enable faster, easier make-up and break-out of temporary flowlines than ever before. Available in lengths up to 12 feet, these alloy-steel pup joints efficiently handle a complete range of well servicing fluids at cold working pressures up to 15,000 psi. FMC Technologies’ pup joints are also available for sour gas services at working pressures up to 10,000 psi.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

8613371530291

8613371530291