drill pipe pup joint dimensions made in china

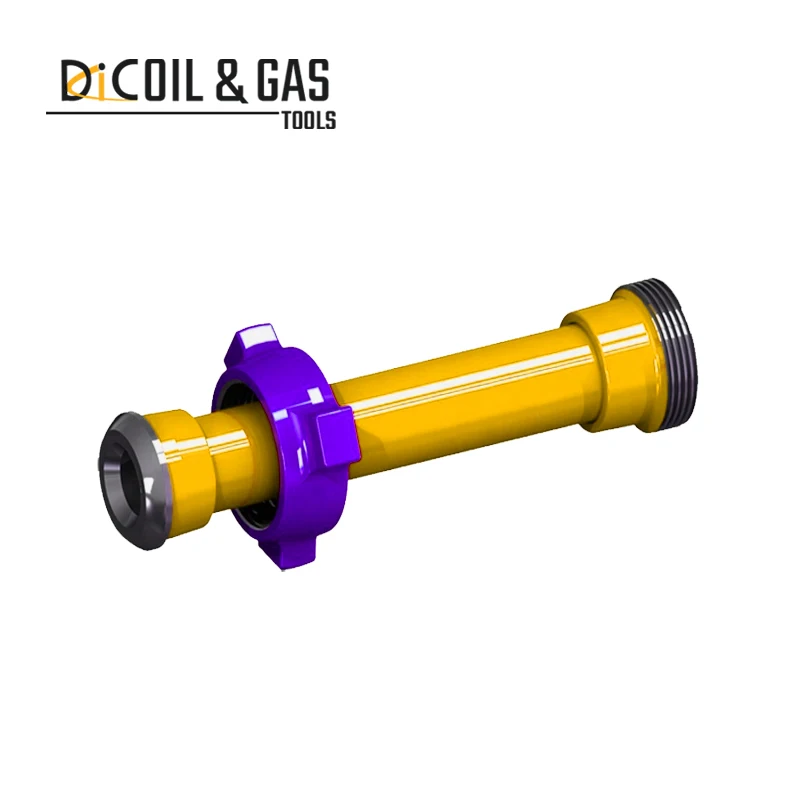

The drill pipe joint is an important connecting part of the oil drill pipe and drilling tool, and is widely used in the oil drilling industry. Our pup joint drilling is finished with high-quality and unique materials for excellent durability and precise dimensional accuracy. The threads on the fittings are cut on a CNC machine, which ensures high precision of the threads and prolongs the service life of the fittings. Considering the specificity in practical applications, we use phosphate coating or copper plating to enhance the wear and chemical resistance of the joint. This pup joint drilling has good mechanical strength and comprehensive performance and meets international standards, it can be widely used in oil, natural gas, sewage treatment and other industries.

Outside Diameter of Tubing Joint: From 2-3/8"(60 3mm) to 4.5"(114.60mm) Pipe End: EUE/NUE Outside Diameter of Casing Joint: From 4-12"(114 3mm) to 20*(508mm)

PUP JOINT DRILLING, PUP JOINT INC, PUP JOINT, PUP JOINT OIL AND GAS, NPST PUP JOINT, API PUP JOINT DIMENSIONS, PUP JOINTS FOR SALE. DRILL, API, API 5CT, CASING, EUE, PIPELINES, TUBING,

Hot Tags: pup joint drilling, China, suppliers, manufacturers, factory, low price, for sale, in stock, made in China, ERW Structural Pipe, Socket Weld Cap, Class150 Blind Flange, Api 5l Line Pipe, Steel Pipe Reducer, Oil Casing and Tubing

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

A pup joint is a pipe of non-standard length used to adjust the length of tubular strings to its exact requirement.Pup Joints are short drill pipe used to adjust the length of the drill string and are available in standard lengths of 5′, 10′, 15′, 20′ and can be ordered to match other drill pipe dimensions.

API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing.Premium pup joints are also available with premium connections and in API or exotic alloy grades

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Pup Joints are short drill pipe used to adjust the length of the drill string and are available in standard lengths of 5", 10", 15", 20" and can be ordered to match other drill ...

Drill pipe joint is an important connecting component of petroleum drilling pipe drill, which is widely used in oil drilling industry. The market demand is big, has broad prospects for development, Goldenman company with its unique perspective, to create a modern international joint industry as the goal, take on the hard road of entrepreneurship. In the increasingly competitive market economy situation, the courage to struggle and thrive.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

It is produced according to API 5CT Specification. Our precision-engineered pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. As a tubing pup joints manufacturer in China, we also provide API 5CT casing pup joint which is the accessory of the casing strings.

Our tubing pup joints have passed the ISO9001:2000 international quality management system certification and the API certificate of the American Petroleum Institute.

1.Before sale, our company can provide samples and plans for clients according to the given budget. The costs should be borne by clients. We also provide some wearing-parts of the tubing pup joint like thread protector.

2.The delivery time depends on the order quantity. The minimum quantity is 20 t. We provide the pup joints to clients and positively cooperate with the third party on the supervision and inspection arranged by the clients.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API...

Tubing coupling is a type of drilling tool used in oil field. It is mainly used for connecting oil pipes. This pipe coupling has solved the problem that the existing couplings tend to crack due ...

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API Spec5CT specification. The steel grades of the products of this kind are J55, K55, N80 and L80 P110. These products feature high corrosion resistance and long running life. As a pup joints supplier, we also produce the API 5CT tubing pup joint which is the fitting of the tubing strings. And we promise that all our casing pup joints are in high quantity.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API...

Line pipe is a tube made of high strength carbon steel. It is typically manufactured according to the API 5L metallurgical specification developed by the American Petroleum Institute (API) ...

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order.

Pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing, and casing pup joint is the same as casing.

and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are

1. Introduction of pup joint The pup joint is fixed length tubing or casing. The thread is EUE, NUE, NEW VAM. The Length is from 1feet to 10feet. 2. Specification 3. Property of material

Tianjin Soright is one of the largest api 5ct tubing/casing pup joints manufacturers and suppliers in China, who can offer you the free sample and the quotation consultation service. Welcome to buy the low price and high quality products made in China from us.

DP-Master is committed to the continuous improvement of our manufacturing processes and to the development and training of employees to ensure that we deliver the highest quality products on time, competitively and with excellent standards of service. We will continue to engineer and test new products to ensure that we can provide the market with a complete range of first-class products capable of being used in the most challenging drilling environments. Our Technical Support & Services Group will continue to expand the licensee network for the repairs of our premium connections around the world. We will strive to exceed our customer’s expectations.

API Coupling refers to the steel couplings that used in connecting casing pipe and tubing. Also known by OCTG coupling, it is usually manufactured in seamless type, material grade same with the pipe body (API 5CT K55/J55, N80, L80, P110 etc), same PSL or providing higher grades than requested. Same heat treatment also applicable, except there is an special requirements.

As we know steel pipe coupling is a short pipe or tube that with threads on both ends, used to connect pipelines. So It is a kind of pipe fittings that with threaded connection, the advantage is easy for pipeline maintenance or to replace the broken pipe.

With this purpose, API 5CT standard coupling plays an important feature in connecting casing and tubing line pipes. On the contrary, the biggest different with general steel pipe coupling is: API coupling manufacturing processes is more rigorous, requires a precisely control in the different processes as blew listed.

As we told, one of the important figure of API coupling, that it shall be made of seamless, another is the same grade as the casing or tubing pipe body, and these materials are used for manufacturing the blank coupling.

Regular couplings diameters complied with API 5CT Tables C.32 to C.35 or Tables E.32 to E.35. Coupling bearing contact face inside and outside edges shall be rounded or broken, but shall not significantly reduce the width of the bearing face (dimension b), since less thickness will not be safe to support the pipe weight. The ends of couplings shall be faced exactly at right angles to the axis.

Special-clearance coupling dimensions and tolerances shall comply to as given in Tables C.33 and C.35 or Tables E.33 and E.35 and as shown on Figures D.3 and D.5. Color identification see clause 11.

Reducing coupling are used to connect two pipes of different diameter with the same or different types of thread on the two ends, and shall be furnished when specified on the agreements. The minimum length and minimum diameter of reducing couplings shall be sufficient to accommodate the specified size and type of threads.

There are couplings for casing and couplings for tubing, the function is the same that to connect the pipe each other. On the other hand, still there are some differences between the two.

Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.

The oil tubing coupling can solve the problem of fatigue fracture in the existing coupling due to stress concentration. Oil tubing end is connected to the inside wall of the coupling in a tapered thread. The coupling body end and oil tubing are connected with same thread pitch flat thread. The coupling is not easy to produce fatigue fracture, and has good connection effect. It can prevent the accident of oil well pipe string break effectively.

Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

(NOTE Couplings with API threads may not have a leak resistance as high as the internal yield pressure of the pipe body, due to inadequate bearing pressure between the coupling and pin.)

API 5B covers dimensions, tolerances, and marking for API threads and the gauges that control the acceptance criteria for the threads. It includes thread element gauges, instruments, and requirements for the inspection of threads for line pipe, casing and tubing (round threads), and buttress casing connections. Thread dimensions shown without specifications (or shown as NA) are not subject to inspection of diameter, ovality, and addendum. Thread dimensions shown without tolerances are related to the basis for connection design and are not subject to measurement to determine acceptance of product.

Premium connection is a higher class connection type for used to connect casing or tubing pipelines. The reason to use premium connection is due to it’s high seal performances, high strength, and longer durability.

For Group 1, 2 and 3, Unless specified in the purchase agreement, coupling dimensions and tolerances shall be complied to API 5CT table C.32 to C.35 or tables E.32 to E.35.

8613371530291

8613371530291