kemper integral pup joint supplier

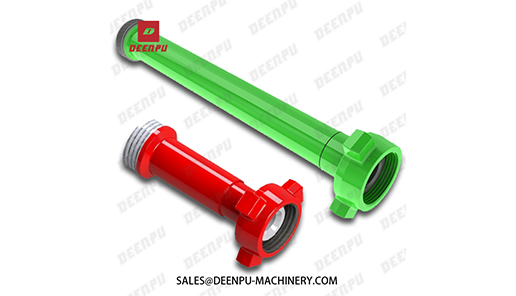

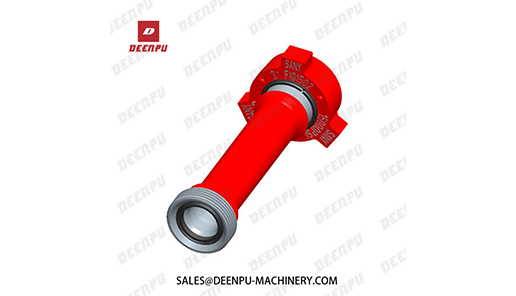

High pressure Pup joint is a kind of pressure pipe with hammer union end or flange end connection,the high pressure pup joint can be made integral or weld type which end connection is welded to pipe. Cost of Intergal type is higher than welded type.

Hammer union end connection pup joint is designed to interchangable with weco wing union, including Fig100, Fig206, Fig207, Fig602, Fig1002, Fig1502, Fig2002, Fig2202 and etc.

Flange end connection pup joint is designed according to API 6A or ASME standard. Working pressure of pup joint is from 2,000 psi to 20,000psi.Manufacturing theory is according to API 16C. Our company supply high pressure weco pup joints with four types:

Pup joints size : 1″~4″, Working pressure: 7MPa~150MPa, Length of the pup joint: 1m. , 1.5m, 2m, 2.5m, 2.8m. High-pressure straight pipes of various sizes and pressures as well as acidic environments are available upon request. Application: Fracturing manifold, cementing manifold, maintenance manifold, test manifold, high-pressure well service flowlines, fracturing flowlines, well testing flowlines, cementing and circulating flowlines etc.

Over the past ten years Kemper has developed some new product lines such as plug valves, swivel joints, pup joints, hose loops, check valves, pressure relief valves and high-pressure fittings are now being produced.

SASCOM has been sole distributor in Saudi Arabia for Kemper products since 1999. SASCOM supply customers from its ready stocks a variety of Unions classified as:

Black Gold Pump & Supply, Inc. stocks more than 5,000 parts, including the unions, fittings and clutches our oil and gas field clients require. The Kemper Valve & Fittings Corporation, has been making pipe unions for 40 years and are best known for their line of oil field hammer unions.

Kemper Valve & Fittings Corporation, one of the largest manufacturers of oil field hammer unions in North America, also manufactures valves and other flow line products used throughout the oil and gas industry.

Kemper products are supplied for the following applications:Unions - Oil field unions, Hammer-Seal unions, Seal-O-Grip connections and industrial unions

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

Flow line check valves, code red/black/silver swivels, integral and NPST pup joints, Integral fittings, pressure relief valves, plug valves, oilfield unions, hammerseal unions, seal-o-grips, 602/1002/1502, hose loops, manifolds, chokes, trash catchers.

Integral Pup Joints are used for transporting high-pressure flow in fracturing, cementing, maintenance, and test manifolds. These are made from high-quality alloy steel, integrally constructed, forged-ended features seamless upset construction. Standard integral pup joints are available in different models, pressure, and temperature rating.

Kemper Valve & Fittings Corporation is a rapidly growing and leading provider ofoilfield valves, hammer unions, swivel joints, oilfield flowline components, manifoldsand complete rebuild / recertification services. This brochure outlines the productsthat are specifically designed and sold to the well servicing segment of the oil industry.See our companion brochure Oilfield Service and Distribution Products for additionalproducts that are distributed through leading oilfield supply stores in North America.

INDEXPlug Valves .................................................................................Check, Pressure Relief and Rupture Disc Valves .........................Manifold Trailers and Dual Choke Manifolds ..............................Union Bulls, Crossovers, Swages and Crosses..............................Wyes and Chokes ........................................................................Integral Flow Line Fittings ...........................................................Integral Manifold Fittings ...........................................................Pup Joints ...................................................................................Hose Loops .................................................................................Swivel Joints - Code Red .............................................................Swivel Joints - Code Silver ..........................................................Oilfield Hammer Unions .............................................................Rebuild / Recertification Services ..............................................

PLUG VALVES - LOW TORQUEKemper Low Torque (LT) Plug Valves are field tested and provide flow control for oilfield applications such as:Cementing, Fracturing, Aciding, Coiled Tubing, Sand Control and Manifold Trailers. The valves are offered with industrystandard Male and Female End connections and have a Standard Service Rating of 15,000-psi NSCWP. Additionally, HeavyDuty Connections are available for only the 3 valve. Other connections are available - consult factory.The valve incorporates a bottom entry design that allows for maintenance of the valve without having to remove thevalve from the existing piping.Note: This should only be done after system pressure has been relieved otherwise serious injury can result.

The valve is designed with repair in mind for even the harshest applications. Each valve uses a set of replaceable wearinserts (2). This minimizes body erosion, allowing the valve to be inexpensively repaired with replacement wear items(Inserts, Plug, and Seals) and for re-use of the costly valve body. Repair Kits, Seal Kits and individual parts are stockedthroughout the Kempers distribution network.Each valve is serialized and pressure tested to 1.5 times NSCWP. All supporting documentation, including MTRs andHydrostatic test reports, is available at any time for no additional cost.Kemper Low Torque Plug Valves are available in 1, 2, 3 and 3 Heavy Duty. 4 will be available soon. Valve actuationoptions Bar Nut, Gear Op, Hydraulic, and Pneumatic. Hydraulic Power units are also available for remote valveactuation for safety and emergency situations. Consult the factory for availability.

FLOWLINE CHECK, PRESSURE RELIEFAND RUPTURE DISC VALVESKemper Dart Style Check Valves provide flowbackprotection in well service applications such as:Acidizing, Cementing, Fracturing, Sand Control and Well Kill.Available in 1, 1, 2 and 3 models withpressure ratings from 6,000-psi to 15,000-psiNSCWP. These spring-loaded dart checks assure flowback protection up to 15,000-psi. Kempers unique,modular design allows the valve to be assembled forstandard or reverse flow. Easy replacement of worncomponent parts increase the service life of the valve.

Kemper Pressure Rupture Disc Valves providesafe, over-pressure protection for treating lines,reciprocating pumps, pressure vessels and othere q u i p m e n t o p e ra t i n g u n d e r h i g h p re s s u re .Available in 2 models only with operational pressureranges from 150 to 15,000-psi for standard service.

Kemper Pressure Relief Valves provide safe, over-pressureprotection for reciprocating pumps, treating lines, pressurevessels and other equipment operating under high pressure.These valves make use of the systems own hydraulic forcesto open at the preset pressure. They will stay open whilefluid flow is gradually diverted out the discharge port until thesystem pressure drops below the preset limit. When thepredetermined and adjustable blowdown pressure is reached, thevalve will automatically and smoothly close. Exclusive Kemperdischarge flow recirculation design assures minimal hydraulicshock to the pumping device or treating iron during valve closure.Kemper Relief Valves are available in 1, 2 and 3 models withoperation pressure ranges from 150 to 15,000-psi for standardor sour service.

Kemper Well Service Manifold Trailers dramatically reduce the hookup and breakout labor of any frac job, with time savingsof up to 50% over conventional hook-ups. Manifold Trailers can be chosen from a set of standard models or fabricated to exactcustomer specifications. They can be equipped with Kemper Hammer Union Integral or Non-Pressure Seal Flowline, Swivel Joints,Tees, Laterals, Check Valves, Butterfly Valves and Hammer Unions. All Union End Connections are supplied with blanking caps forprotection of the environment during transit.NEW - Kemper now offers manifold trailers with Helical Wire Rope Isolators (see picture above right) in an improved mountingconfiguration that in conjunction with Kempers exclusive Extra Heavy Duty Union connection, results in a new mounting systemthat offers longer life and smoother operation. This is ideal for the vigorous Frac pump wing up connection. Kemper has manysuccessful field installations both new build and retro-fits. Kemper strongly recommends the use of this system for ManifoldTrailers with extreme service conditions.Kemper Manifold trailers are available in ratings of 6,000-psi, 10,000-psi and 15,000-psi and have proven to be effective in avariety of field applications. Trailer lengths include 30, 42 and 53 in 1 and 2 axle configurations. They can have from 3 to 8pump hook-ups per side, depending on length. Piping is available in 3 and 4 nominal pipe diameters. Components are alsoavailable in the 3 Heavy Duty configuration (recommended).Every trailer comes with Hose Racks, but many other options are available including Pup Joint Racks, Swivel Joint Racks, SolarPowered Lights, Cranes and Hydraulic Feet. All these options help you to customize the trailer to your specific needs. Eachcomponent on the trailer is serialized and pressure tested to 1.5 times NSCWP. In addition, after assembly, each trailer is testedfor 30 minutes at NSCWP to insure the integrity of the connections and proper sealing of the components. All supportingdocumentation, including MTRs and Hydrostatic test reports, is available at any time for no additional cost.Dual Choke Manifolds (DCM) are available in 2 Figure 1502,5 valve and 9 valve configurations. Other Figures and sizesavailable consult factory for availability. A variety of manifoldsare offered in many configurations: two (2) Adjustable Chokes,one (1) Adjustable Choke and one (1) Positive Choke; with orw/out gage ports, 1 or Adj Choke; 1 or 2 Plug Valves;other valves. Other non-DCM available: 4 valve both boxed andunboxed.Every component used in the DCM, as well as the DCMassembly itself, are serialized and pressure tested to 1.5 timesNSCWP (2 tests).All supporting documentation, including MTRs and Hydrostatictest reports, is avaiable at any time for noadditional cost.5

Kemper Integral Hammer Union Bulls and Crossovers are manufactured to the same stringentspecifications for material, heat treatment and dimensional tolerance as our KemperHammer Unions. Standard lengths and Union Figure number combinations are stocked forimmediate delivery. Custom combinations or lengths can be delivered to order with minimal lead times.

Kemper Integral Hammer Union Swages can replace couplings or nipples in oilfield service,stimulation and test systems where Hammer Union pipe connector modularity isessential. Standard API thread types and Union Figure Number combinations are stocked forimmediate delivery. Custom combinations can be delivered to order with minimal lead times.NOTE: Kemper Hammer Union Crossovers and Swages with Male Union Ends aresold with the Hammer Lug Nut and / or Segmented Rings at no extra charge.

Kemper Crosses are field tested and provide the necessaryconnections for demanding applications. They arem a n u fa c t u re d f ro m h i g h st re n gt h a l l o y ste e l a n d h e attreated to exacting requirements for strength and longevity.Crosses are available in 2 industry standard Male and FemaleEnd connections Figure 1502, 1002 and 602 configurations withcorresponding standard service ratings of 15,000-psi, 10,000-psi and6,000-psi. Sour gas service is also available at de-rated pressures.Crosses are serialized and pressure tested to 1.5 timesNSCWP. All supporting documentation, including MTRs andHydrostatic test reports, is available at any time for no additional cost.6

WYE AND CHOKESKemper Wyes are field tested and provide a utility for applications where flow needs to besplit. They are manufactured from high strength alloy steel and heat treated to exactingrequirements for strength and longevity.Wyes are available in 2 with industry standard Male and Female End connections inFigure 1502, 1002 and 602 configurations with corresponding standard service ratings of15,000-psi, 10,000-psi and 6,000-psi. Sour Gas service is also available at de-rated pressures.Wyes are serialized and pressure tested to 1.5 times NSCWP. All supporting documentation,including MTRs and Hydrostatic test reports, is available at any time for no additional cost.

Kemper Adjustable and Positive Choke Systems are field tested and provide control in Fracturing and Flowbackapplications up to 15,000-psi CWP. Both chokes are offered with 2 industry standard Male and Female End connections,have a Standard Service Rating of 15,000-psi NSCWP and are suitable for many types of manifold applications.For the Adjustable Choke, a simple clockwise turn of the hand wheel increases fluid flow restriction/pressure while acounterclockwise turn decreases fluid flow restriction/pressure. The Adjustable Chokes hand wheel is rotated until the desiredsystem pressure is reached and can be verified from gages directly installed in the T of the Adjustable Choke. Finding the equivalentbean size at this point is as easy as directly reading (in 64ths) the value from the indicator hub on the stem at the top of the bonnet.Note: The Adjustable Choke is not to be used as a shut off valve.

Chokes are serialized and pressure tested to 1.5 times NSCWP. All supporting documentation, including MTRs andHydrostatic test reports, is available at any time for no additional cost.Both Kemper Adjustable and Positive Chokes are available in 2 connections. 3 is possible consult factory. Fully-linedcarbon seats/beans; Gage ports available in NPT or Autoclave. Complete chokes and repair parts are stocked throughoutKempers distribution network. Adjustable Choke 1 & seats. Positive Choke various bean sizes available in 64th increments.7

Forged alloy steel body precision machined with integral 1, 1, 2, 3 or 4 Figure 1502 Kemperhammer union ends available for standard service (15,000-psi CWP) or sour gas service (10,000-psi CWP).Also available in Figure 602 or 1002 union connections. Both Tees and Ells are supplied with seals anddetachable hammer lug nuts. Cushion Ells can be ordered for flowback service from the factory. Allsupporting documentation, including MTRs and Hydrostatic test reports, is available at any time for no additional cost.

For applications where fluid turbulence or abrasiveness canbe a problem through short radius 90 ells. Our one piecehammer union integral Long Radius Elbow will turnthese fluids easily. Using the same centralized boreas our Long Radius Swivel Joints assures an even wallthickness through the bend for maximum erosionresistance. These elbows can be made with hammer unionthread-to-nut, nut-to-nut or thread-to-thread ends in anycombination of Figure 602, 1002 or 1502. Also availableprepped for sour gas service compliant to N.A.C.E. MR-01-75.8

INTEGRAL MANIFOLD FITTINGSKemper integral manifold Tees and Laterals are ideally suited for ground and truck manifold applications. Theselarge bore integral fittings are made from forged alloy steel and have integral union end connections. The endconnections are precision machined to fit industry common Kemper Hammer Unions and are available in sizes:2, 3 and 4 and figures: 602, 1002, and 1502. Many combinations of size and figures are available. EXTRAHEAVY DUTY connections are available but only for 3 1502. See below for more information on this connection.Kemper integral manifold fittings are available for either standard service (up to 15,000-psi CWP) or sour gas service (up to10,000-psi CWP). All integrals are 100% hydrostatic pressure tested before leaving factory and have material traceability.

EXTRA HEAVY DUTY CONNECTION (EHD) Kemper has engineered an exclusive large bore connection that can easily be used onboth integral manifold Tees, Laterals and Plug Valves. The 3 1502 EHD can stand up to the forces derived from the frac pump inletthat normally overstresses standard 3 1502 connections used in 4 trailer mounted manifolds. The added strength of the 3 1502EHD is a direct result of the 75% increase in critical wall thickness along with the extended thread length of the Hammer Lug Nutconnection. The Extra Heavy Duty connection will outperform the standard 3 1502 connection AND is strongly recommendedfor truck manifold applications. The EHD is available in both standard and sour gas service but ONLY in 3 1502 connections.Note: When connecting the EHD connection to a 3 Code Red Swivel Joint, an EHD no. 8 pc Swivel Component must beused to mate with the EHD Lateral, Tee, or Plug Valve. Plug Valves and other fittings are available with EHD connections toallow direct connection and increased strength to all trailer mounted connections attached to the frac pump. See page 5with the heading Manifold Trailers and Dual Choke Manifolds for recommended frac pump hookups.

Kemper Non-Pressure Seal Pup Joints are available in 1, 1, 2, 3 and 4 nominal sizes. All supportingdocumentation, including MTRs and Hydrostatic test reports, is available at any time for no additional cost.Standard lengths range from 1 foot up to 20 feet at CWPs of 6,000-psi (Code Silver), 10,000-psi (Code Black) and15,000-psi (Code Red).Non-standard lengths in any quantity are available with minimal lead time for custom requirements. Please consultthe factory for details.

Kemper Integral Pup Joints feature an entirely one piece, seamless upset-forged construction and are utilized whenwelded or threaded connections are cause for concern. They are available in 2, 3 and 4 15,000-psi (Code Red) inlengths up to 10 feet. These Pups can be used with the complete range of high pressure and abrasive oilfield fluids.

Extra High Pressure Long Radius Swivel Joints, Figure 1502 & 1002, in 1, 1, 2, 3 and 4 sizes.For test lines, fracturing, acidizing, cementing and well servicing up to 15,000-psi CWP.Swivel Joints can be custom configured in any style for quick delivery.Manufactured to the highest quality standards in the industry.Optimal combination of core strength and case hardness without sacrificing ductility.All supporting documentation, including MTRs and Hydrostatic test reports, is available at any time for no additional cost.Maintenance, rebuild and recertification are available through our Service facilities.

High Pressure Swivel Joints - 6,000-psi CWP (Cold Working Pressure) in , 1, 1, 1 and 2 LPT sizes.For test lines, fracturing, acidizing, cementing and well servicing up to 6,000-psi CWP.Swivel Joints can be custom configured in any style for quick delivery.All supporting documentation, including MTRs and Hydrostatic test reports, is available at any time for no additional cost.Hose Loops factory built to customer specification and certified for service.Maintenance, rebuild and recertification is available through our Service facilities.

KEMPER REBUILD - RECERTIFICATION FACILITIESKemper Rebuild and Recertification Facilities provide complete management, rebuild andrecertification of frac iron, such as: Swivel Joints, Pup Joints, Plug Valves, Check Valves and Relief Valves. Theseservices will significantly increase the life of your equipment and maximize the return on your originalinvestment. Kemper can provide programs for periodic managed inspection and refurbishment of allflow and manifold iron. We utilize our Iron Management System to record all the details of the servicework we perform, providing you with detailed reports upon completion of the job. Please contact us forquotations regarding your inspection and maintenance requirements at any of the following locations:Sales & Service2733 Industrial DriveSulphur, OK 73086Local: 580-622-2048Toll Free: 888-533-3722Fax: 580-622-2058

MOBILE REBUILD - RECERTIFICATION TEAMSKempers Mobile Rebuild Teams provide flowline and valve maintenance, repair, UT andhydrostatic testing at whatever location required to return your iron investment to productivity.These teams are scheduled out of our Sulphur, OK location and we will spend as much time on-site asneeded. Every piece of your equipment will be properly assessed, rebuilt and recertified for service.Equipment not suitable for rebuild service will be documented and segregated for your disposition.

8613371530291

8613371530291