kemper integral pup joint in stock

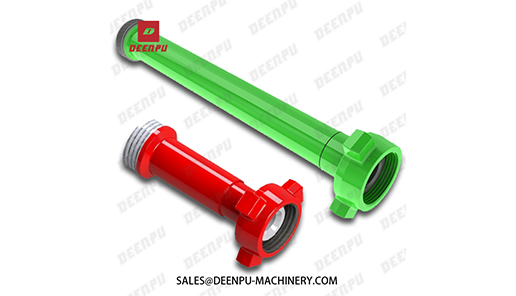

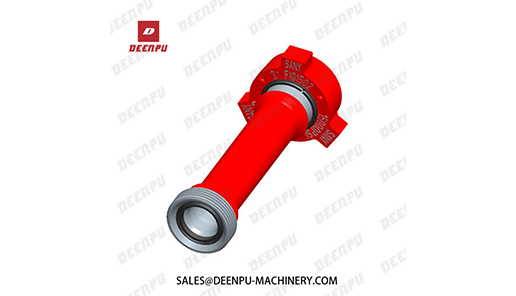

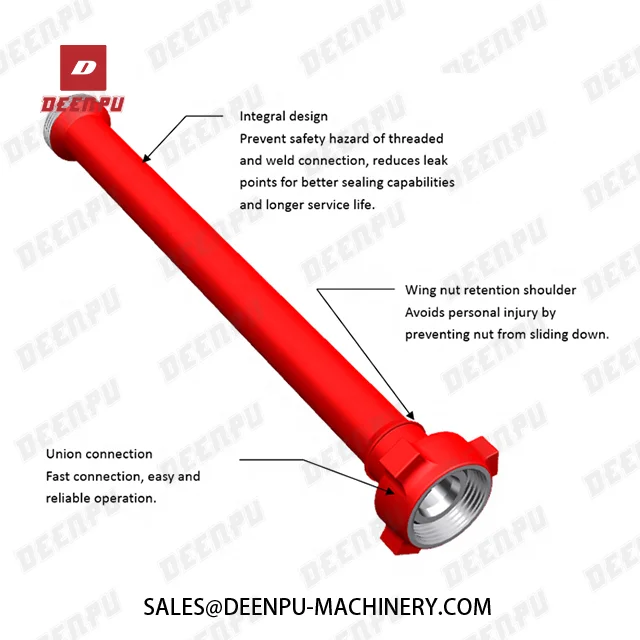

High pressure Pup joint is a kind of pressure pipe with hammer union end or flange end connection,the high pressure pup joint can be made integral or weld type which end connection is welded to pipe. Cost of Intergal type is higher than welded type.

Hammer union end connection pup joint is designed to interchangable with weco wing union, including Fig100, Fig206, Fig207, Fig602, Fig1002, Fig1502, Fig2002, Fig2202 and etc.

Flange end connection pup joint is designed according to API 6A or ASME standard. Working pressure of pup joint is from 2,000 psi to 20,000psi.Manufacturing theory is according to API 16C. Our company supply high pressure weco pup joints with four types:

Pup joints size : 1″~4″, Working pressure: 7MPa~150MPa, Length of the pup joint: 1m. , 1.5m, 2m, 2.5m, 2.8m. High-pressure straight pipes of various sizes and pressures as well as acidic environments are available upon request. Application: Fracturing manifold, cementing manifold, maintenance manifold, test manifold, high-pressure well service flowlines, fracturing flowlines, well testing flowlines, cementing and circulating flowlines etc.

Black Gold Pump & Supply, Inc. stocks more than 5,000 parts, including the unions, fittings and clutches our oil and gas field clients require. The Kemper Valve & Fittings Corporation, has been making pipe unions for 40 years and are best known for their line of oil field hammer unions.

Kemper Valve & Fittings Corporation, one of the largest manufacturers of oil field hammer unions in North America, also manufactures valves and other flow line products used throughout the oil and gas industry.

Kemper products are supplied for the following applications:Unions - Oil field unions, Hammer-Seal unions, Seal-O-Grip connections and industrial unions

Over the past ten years Kemper has developed some new product lines such as plug valves, swivel joints, pup joints, hose loops, check valves, pressure relief valves and high-pressure fittings are now being produced.

SASCOM has been sole distributor in Saudi Arabia for Kemper products since 1999. SASCOM supply customers from its ready stocks a variety of Unions classified as:

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

Here at OSR we sell new and refurbished swivel joints, pup joints, plug valves, mainfolds, plug catchers, etc. We also do repairs on all name brand swivel joints, plug valves, manifolds, etc. All of our refurbished and repaired flowiron comes with (3rd party) flowiron inspection reports and tested in shop with test reports, banded, and painted

Flow line check valves, code red/black/silver swivels, integral and NPST pup joints, Integral fittings, pressure relief valves, plug valves, oilfield unions, hammerseal unions, seal-o-grips, 602/1002/1502, hose loops, manifolds, chokes, trash catchers.

comHammerUnionsIntegralFittingsPupJ ointsSwivelJ ointsButterflyValvesUnionCrossoversHoseLoopsHammerSealSeal-O-GripOver 35 years of manufacturing and marketingflow control products for the oilfieldOilfield Hammer Unions ................................Swivel Joints - Code Red .............................Swivel Joints - Code Silver ...........................Pup Joints ......................................................Hose Loops ...................................................Integral Flow Line Fittings.............................Well Service Manifold Trailers.......................Hammerseal Unions ..................................Seal-O-Grip Connections ..........................Industrial Unions ............................................Body-Style Butterfly Valves ...........................Wafer and Lug-Style Butterfly Valves ...........Non-Freeze Tank Valves ...............................GW-178 Pressure Transducer .....................DNV Certifications List ..................................Page 3Page 7Page 8Page 9Page 10Page 11Page 12Page 13Page 13Page 14Page 15Page 16Page 17Page 17Page 18Kemper Valve & Fittings Corporation, one of the largest manufacturers of OilfieldHammer Union in the USA, also manufactures valving and other flowline prod-ucts used throughout the Oilfield.ManufacturingPO Box 400Wauconda, Illinois 60084Local: 847-526-2166Toll Free: 800-323-1659Fax: 847-526-2241Distribution Sales5650 Guhn Road Suite 110Houston, Texas 77040Local: 713-462-1665Toll Free: 800-231-2724Fax: 713-462-1626Stimulation Sales2733 Industrial DrSulphur, OK 73086Local: 580-622-2048Fax: 580-622-2058Inquiries: sales@kempervalve.com http://www.kempervalve.comManufacturing: 1-800-323-1659 Sales: 1-800-231-2724INDEX2Figure 100 Figure 200 Figure 300 Figure 400Figure 600 Figure 1002 Figure 1502OILFIELD UNIONS3e r u g i Fr e b m u Nd r a d n a t Se c i v r e Sr o l o Ce d o C- s b u S () t u Ng n i k r o W d l o C k c o h S - n o N) i s p ( g n i t a R e r u s s e r P) s e h c n I ( e z i S e p i P l a n i m o Nd r a d n a t Se c i v r e SH2Se c i v r e S1 - 1 4 / 1 - 1 2 / 1 2 - 2 2 / 1 3 4 5 6 8 0 1 2 1P W C t s e T P W C t s e T0 0 1 0 0 0 1 0 0 5 1 ! ! ! ! ! ! !1 0 1 0 0 0 1 0 0 5 1 !0 0 2 0 0 0 2 0 0 0 3 0 0 0 2 0 0 0 3 ! ! ! ! ! ! ! ! ! ! !1 0 2 0 0 0 2 0 0 0 3 0 0 0 2 0 0 0 3 !6 0 2 0 0 0 2 0 0 0 3 0 0 0 2 0 0 0 3 ! ! ! ! ! ! ! ! ! !7 0 2 0 0 0 2 0 0 0 3 0 0 0 2 0 0 0 3 ! ! !1 1 2 0 0 0 2 0 0 0 3 ! !0 0 3 0 0 0 2 0 0 0 3 !0 0 4 0 0 0 4 0 0 0 6 0 0 0 4 0 0 0 6 ! ! ! ! !2 0 4 0 0 0 4 0 0 0 6 0 0 0 4 0 0 0 6 !0 0 6 0 0 0 6 0 0 0 9 ! ! ! ! !G e r u g i F 0 0 0 6 0 0 0 9 0 0 0 6 0 0 0 9 ! ! !2 0 6 0 0 0 6 0 0 0 9 0 0 0 6 0 0 0 9 ! ! ! ! ! !2 0 0 1 0 0 0 0 1 0 0 0 5 1 0 0 5 7 0 0 0 2 1 ! ! ! ! ! ! !3 0 0 1 0 0 5 7 0 0 0 2 1 0 0 0 5 0 0 5 7 ! ! ! !2 0 5 1 0 0 0 5 1 0 0 5 2 2 0 0 0 0 1 0 0 0 5 1 ! ! ! ! ! !2 0 0 2 0 0 0 0 2 0 0 0 0 3 !2 0 2 2 0 0 0 5 1 0 0 5 2 2 !Sales: 1-800-231-2724 Manufacturing: 1-800-323-1659OILFIELD HAMMER UNIONSFigure 200. 2000-psi NSCWP unions are available in 1-inch through 10-inch. These unions are compact andpopular for low pressure rig piping. They also meet mostrequirements in the medium pressure ranges for air, wa-ter, oil or gas service. Available in butt-weld Schedule40. Also available with stainless steel subs.FOR ALL PRESSURE CLASSES consult factory for NON-STAN-DARD END CONNECTIONS such as 8 or 10-RND EUE, NUE, TUBING,CASING, and NON-STANDARD BUTT-WELD SCHEDULES.SOLID SUBS, GAGE SUBS, and NON-PRESSURE SEAL UNIONS arealso available upon request.NSCWP- Non-Shock Cold Working PressureFigure 100. 1000-psi NSCWP unions are available in 2-inch through 8-inch. Recommended for low-pressuremanifolds and applications where working pressures donot exceed 1000-psi. Figure 100 Unions are made fromtough, impact resistant ductile iron, with precisely manu-factured ball-cone (male-to-female) seats.FIGURE 201. 2000-psi NSCWP unions are available in 1,1, 2, 2 and 3-inch line pipe thread (NTP) sizes and arealso available in 2 and 2 8 round EUE thread sizes.These unions feature the effective and dependable flat-face/o-ring sealing design. They seal equally well in lowor high pressure vapor or liquid service, and the standardNBR O-Ring can be substituted with the elastomer ofchoice for severe service conditions or other special appli-cations. The flat-face design also permits straight awaylateral breakouts of short rigid piping sections, withoutthe need to spread the pipe.Figure 206. 2000-psi NSCWP unions are available in 1-inch through 10-inch. These unions are fitted with an o-ring in the male sub seating surface for enhanced sealing.Available in butt-weld Sch. 40. Also available with stain-less steel subs.4Manufacturing: 1-800-323-1659 Sales: 1-800-231-2724Figure 207. 2000-psi NSCWP unions are available in 3, 4and 6-inch. These unions are fitted with a nitrile o-ring in ablanking cap for effective closure. With the cap removed,the female sub will make up to hose, pipe, or tubing fittedwith a Figure 200 or 206 male sub and nut. Recom-mended for air, water, oil or gas service. Available in butt-weld Sch. 40.Figure 400. These unions are available in 2, 3, 4 and 6inch 4000-psi and 12 inch 2500-psi NSCWP. All threeparts are made from steel forgings with heavy walls andrugged design. They feature ball and cone sealing for easyalignment and dependable seals. Also available in butt-weld schedule 80.Figure 600. 6000-psi NSCWP unions are available in1, 1 , 1 , 2, and 4inch sizes. These unions have abronze seat insert to provide an additional hardness dif-ferential across the seats for enhanced sealing.Figure 211. 2000-psi NSCWP Insulating Unions are avail-able in 2 and 3-inch sizes. The insulated design elimi-nates metal to metal contact across the union, while dualabrasion resistant precision molded elastomers provide apositive seal. Recommended where electrolytic corrosionprevention is a problem, or to statically isolate sections ofpiping. Replacement seal kits are available to extend ser-vice of the union.OILFIELD HAMMER UNIONSNSCWP- Non-Shock Cold Working Pressure5Sales: 1-800-231-2724 Manufacturing: 1-800-323-1659Figure 602. 6000-psi NSCWP unions are available in 1,1, 1, 2, 3 and 4-inch sizes. These unions feature aresilient nitrile seal ring that helps sealing and protectsthe steel-to-steel seating of the union. Recommended formanifold and truck-mounting where size and weight arecritical. Fig. 602 unions are also available as non-pres-sure seal unions, and in butt-weld Sch. 80, Sch. 160 andXXH, or prepped for sour gas service.Figure 1002. These unions are available in 1 thru 4 inch10,000-psi and 5 and 6 inch 7,500-psi NSCWP. Theseunions also have a resilient nitrite seal ring (5-inch and 6-inch have nitrile o-ring). They are made from alloy steeland are used primarily by service companies in applica-tions such as cementing, fracturing and acidizing. De-signed for high-pressure systems, including truck-mountedsystems, Fig. 1002 unions also are available as non-pressure seal unions, and in butt-weld Sch. 160 or XXH,or prepped for sour gas service.Figure 1502. These 15,000 psi NSCWP unions are avail-able in 1, 1, 2, 3 and 4 inch sizes, with a replaceableresilient nitrite seal ring. Alloy steel construction, heavywalls, and rugged design have made these unions popu-lar with the service companies for working pressures upto 15,000 psi. Fig. 1502 unions also are available as non-pressure seal unions, and in butt-weld Sch. 160 or XXH,or prepped for sour gas service.Figure 1003. These unions are available in 3 inch 10,000psi and 4 and 5 inch 7500 psi NSCWP. Recommendedfor air, water, oil, mud or gas service where alignment ofpiping is a problem. Especially suitable for high pressuremanifolding and drilling rig use. This union incorporates aball seat that provides for 7 of misalignment or angularadjustment from center, for a total of 15 misalignmentcapability. In addition to the steel-to-steel seating of theunion, a nitrile o-ring assures a pressure tight connectionin any position of misalignment.All Kemper o-ring and seal rings are available in standardNitrile material or upon request, Viton or Highly SaturatedNitrile.OILFIELD HAMMER UNIONS6Manufacturing: 1-800-323-1659 Sales: 1-800-231-2724SWIVEL J OINTS" Extra High Pressure Long Radius Swivel Joints, Figure 1502 & 1002, in 1, 2, 3 and now 4 sizes." For test lines, fracturing, acidizing, cementing, and well servicing up to 15,000 psi CWP." Swivel Joints can be custom configured in any style on short order." Manufactured to the highest quality standards in the industry." Optimal combination of core strength and case hardness, without sacrificing ductility." Full traceability, including low temperature charpy impact values, included." Maintenance, re-build and re-certification is available through our Sulphur, Oklahoma division.7Style 100 M x MStyle 30 M x FStyle 80 M x FStyle 60 M x MStyle 100 M x FSales: 1-580-622-2048 Manufacturing: 1-800-323-1659SWIVEL J OINTS - 6000 CWP" High Pressure Swivel Joints 6000 psi CWP (Code Working Pressure) in 1 and 2 LPT sizes." For test lines, fracturing, acidizing, cementing, and well servicing up to 6,000 psi CWP." Swivel Joints can be custom configured in any style for quick delivery." Manufactured to the highest quality standards in the industry." Full traceability, including low temperature charpy impact values, included." Material Traceability Reports included at no extra charge." Maintenance, re-build and re-certification is available through our Sulphur, Oklahoma division. Style 103 Swivels, 2 Elbows Style 20 1 Swivel Style 301 Swivel, 1 Elbow Style 401 Swivel, 2 Elbows Style 502 Swivels, 2 Elbows Style 602 Swivels, 1 Elbow Style 803 Swivels, 3 Elbows Style 702 Swivels, 3 Elbows8Manufacturing: 1-800-323-1659 Sales: 1-800-231-27249PUP J OINTSKemper Non-Pressure Seal Pup Joints are available in 1, 2 3 and 4 nominal sizes. These Pup Joints are factoryfabicated, 100% hydrostatically tested at 1.5 times the rated cold working pressure, and certified for service.Standard lengths range from 1 foot up to 20 feet at cold working pressure from 6,000 psi (Code Silver) 10,000 psi (CodeBlack) to 15,000 psi (Code Red).Non-Standard lengths in any quantity are available with minimal lead time for custom requirements. Please consult thefactory for details.Kemper 2 15,000 psi (Code Red) Integral alloy steel Pup Joints are available in lengths up to 10 feet. They feature anentirely one piece, seamless upset-forged construction, made for use where welded or threaded connections are causefor concern. These Pups can be used with the complete range of high pressure and abrasive oilfield fluids. 3 KemperIntegral Pup Joints will be available soon!E Z I S A1A2A3A4A5A6" 2 " 0 . 2 " 0 . 4 " 0 . 5 " 0 . 6 " 0 . 8 " 0 . 0 1" 3 " 0 . 2 " 0 . 3 " 0 . 4 A / N A / N A / NSales: 1-580-622-2048 Manufacturing: 1-800-323-1659" Extra High Pressure Cementing/Circulating Hose Loops, Figure 1502 & 1002, in 2 and 3 sizes." For test lines, fracturing, acidizing, cementing, and well servicing up to 15,000 psi CWP." Hose Loops can be custom ordered in non-standard lengths." Manufactured to the highest quality standards in the industry." Optimal combination of core strength and case hardness, without sacrificing ductility." Full traceability, including low temperature charpy impact values, included." Maintenance, re-build and re-certification is available through our Sulphur, Oklahoma division.10CEMENTING / CIRCULATING STEEL HOSE LOOPSE Z I S A1A2A3B" 2 " 7 5 " 0 6 " 2 7 " 9 6 . 0 1" 3 " 7 5 " 0 6 A / N " 8 3 . 6 1Manufacturing: 1-800-323-1659 Sales: 1-580-622-2048Forged alloy steel body precision machined with integral 2, 3 or 4 figure 1502 Kemper hammer union ends availablefor standard service (15,000 psi CWP) or sour gas service (10,000 psi CWP). Kemper union connections are availablein combinations to suit any installation, and are delivered complete with full material traceability test reports, includingcharpy impact values at no extra cost. Both Tees and Ells are supplied with seals and detachable hammer lug nuts, andcushion ells can be ordered for flow-back service from the factory.INTEGRAL FITTINGS11Sales: 1-580-622-2048 Manufacturing: 1-800-323-1659E Z I S A B C" 2 8 3 . 6 8 3 . 6 5 7 . 2 1" 3 0 0 . 8 0 0 . 8 0 0 . 6 1" 4 3 1 . 6 5 2 . 8 0 5 . 6 1Manufacturing: 1-800-323-1659 Sales: 1-580-622-204812 KEMPERMANIFOLDTRAILERSKemper Well ServiceManifold Trailersdramatically reduce thehookup and breakout laborof any frac job, withtimesavings of up to 50%over conventional hookupsManifold Trailer fabricationsto exact customerspecifications or standardmodels are fabricated andequipped with KemperHammer Union Integral orNon-Pressure Seal Flow-Line, Swivel Joints, Tees,Laterals, Check Valves,Butterfly Valves andHammer Unions. All UnionEnd Connections aresupplied with blanking capsfor protection of theenvironment duringtransport.For more detailedinformation or forquotations, please contactBuddy Wood at the KemperValve Sulphur, Oklahomafacility.Hammerseal UnionsJoin drilling mud tanks in a hurryEven if tanks arent aligned perfectly, you can hammer these tough unionstight to a non-leak seal. The external threaded female portion of theHammerseal welds to a stub pipe at the tank wall. A smaller O.D. connect-ing pipe extends through the female portion, the o-ring and then the nutportion of the union. When the internally threaded nut component is ham-mered tight onto the female, the o-ring is squeezed to an oblong cross-section to seal up to 150 psi against the O.D. of the connecting pipe.3 Hammerseal Available Consult factory*Schedule 80 Butt-WeldSeal-O-Grips are speedy connect-and-disconnect for mud suction and re-turn lines or low-pressure fluid lines. A tight seal is maintained even if thepipe is mis-aligned within certain limits (see table). Available for size popularoilfield line pipe sizes: 4, 6, 8, 10, 12 and 16-inch.Seal-O-Grip steel (ASTM A216 Grade WCB) welds in place on mud tanks,pipe and other fittings. Oil-resistant inflatable tube is heavy duty, abra-sion-resistant, designed for 200 psi maximum air pressure. (Tube inflationpressure must exceed fluid line pressure by 50 psi for line pressures up to150 psi.)Seal-O-Grip ConnectionsProvide air-inflatable tight seal between mud tanksABe p i P e n i Le z i S) s e h c n i (p i r G - O - I a e Se t e I p m o C y I b m e s s A e I b a t a I f n Iy I n O e b u T m u m i x a Mt n e m n g i I A - s i Me c n a r e I o Tp i r G - O - I a e S) s e h c n i ( s n o i s n e m i Dt r a Pr e b m u N . x o r p p A) s b I ( t W t r a Pr e b m u N . x o r p p A) s b I ( t W A B C D E F G4 0 8 4 P 3 . 5 T - 0 8 4 P 8 . 7 2 3 / 9 1 - 4 2 3 / 9 1 - 4 6 1 / 1 - 5 4 / 3 - 5 8 / 5 - 6 3 2 / 1 - 16 0 8 6 P 0 . 3 2 T - 0 8 6 P 4 . 1 4 1 4 / 3 - 6 6 1 / 5 1 - 6 8 8 / 5 - 8 4 / 1 - 0 1 4 28 0 8 8 P 0 . 7 2 T - 0 8 8 P 6 . 1 4 1 4 / 3 - 8 6 1 / 5 1 - 8 8 / 1 - 0 1 4 / 3 - 0 1 4 / 1 - 2 1 4 20 1 0 8 0 1 P 0 . 1 3 T - 0 8 0 1 P 4 . 2 4 1 6 1 / 5 1 - 0 1 8 / 1 - 1 1 8 / 1 - 2 1 4 / 3 - 2 1 2 / 1 - 4 1 4 / 1 - 4 22 1 0 8 2 1 P 5 . 8 3 T - 0 8 2 1 P 2 . 3 4 1 6 1 / 5 1 - 2 1 8 / 1 - 3 1 8 / 3 - 3 1 4 1 2 / 1 - 6 1 4 / 1 - 4 26 1 0 8 6 1 P 5 . 6 4 T - 0 8 6 1 P 5 . 3 4 1 4 / 1 - 6 1 4 / 1 - 6 1 4 / 1 - 7 1 4 / 1 - 8 1 4 / 1 - 0 2 8 / 1 - 5 2I a n i m o Nd I e i f I i O e z i Sg n i t c e n n o Ce p i Pe z i S I a n i m o Ne p i P d I e i f I i O *t n e n o p m o C e I a Mo t s d I e Wy I b m e s s A e t e I p m o C y I n O g n i R - Oy I b m e s s Ar e b m u N. x o r p p At h g i e W) . s b I (t r a Pr e b m u N. x o r p p At h g i e W) . s b I (h c n I - 4) . D . O " 2 / 1 - 4 (h c n I - 6 A 0 0 4 S P 2 2 R O 0 4 S P 0 5 . 0h c n I - 6) . D . O " 8 / 5 - 6 (h c n I - 8 A 0 0 6 S P 7 3 R O 0 6 S P 5 7 . 0h c n I - 8) . D . O " 8 / 5 - 8 (h c n I - 0 1 A 0 0 8 S P 2 4 R O 0 8 S P 0 0 . 1h c n I - 0 1) . D . O " 4 / 3 - 0 1 (h c n I - 2 1 A 0 0 1 S P 3 5 R O 0 1 S P 5 2 . 1h c n I - 2 1) . D . O " 4 / 3 - 2 1 (h c n I - 4 1 A 0 2 1 S P 1 6 R O 2 1 S P 0 5 . 1g n i s a c h c n I - 3 1) . D . O " 8 / 3 - 3 1 (d r a d n a t S - n o N A 0 3 1 S P 3 5 R O 3 1 S P 0 6 . 1h c n I - 4 1) . D . O " 4 1 (h c n I - 6 1 A 0 4 1 S P 3 8 R 0 4 1 S P 5 7 . 1h c n I - 6 1) . D . O " 6 1 (h c n I - 8 1 A 0 6 1 S P 9 9 R O 6 1 S P 0 0 . 2I.D. BodyFG 2I.D. TubeCDE13Sales: 1-800-231-2724 Manufacturing: 1-800-323-1659All Kemper Industrial Unions are manufac-tured from carbon steel to meet ASTM A105.INDUSTRIAL UNIONS3000# UnionsBronze-to-SteelSizes: , thru 2-inch3000# AAR UnionsSteel-to SteelMSS SP-83 DimensionalThreaded or Socket WeldSizes: , thru 3-inch3000# UnionsBronze-to BronzeSizes: , thru 2 inch.3000# Hi-Speed UnionsSteel-to SteelSizes: thru 3-inch3000# Hi-Speed Lug Nut UnionsFlat Face O-RingSizes: , thru 3-inch3000# Hi-Speed Lug Nut UnionsInsulated Male End PieceSizes: thru 3-inch.3000# Hi-Speed Lug Nut UnionsSteel-to-SteelSizes: thru 3 inch3000# Hi-Speed UnionsInsulated Male End PieceSizes: thru 3 inch3000# Hi-Speed UnionsFlat Face O-RingSizes: thru 3 inch3000# Orifice UnionsSizes: , thru 2 inch3000# Tabbed Orifice UnionsSizes: thru 2-inch3000# Male and Female UnionsSizes: , thru 2-inch*Across Nut FlatsMSS-SP-83 Dimensions and Weights14s e i t r e p o r P n o i t c e t o r P c i d o h t a Cs n o i n U d e t a I u s n I r e p m e K I I a f oy t r e p o r P y t i I i b a p a Ce r u t a r e p m e T 0 2 o0 0 3 o t FoFe v i s s e r p m o C e t a m i t l Uh t g n e r t si s p 0 0 0 , 0 3) % ( n o i t p r o s b A l i O & r e t a W e l b i g i l g e Nl a m r e h T f o t n e i c i f f e o C r e n i Ln o i s n a p x E0 1 x 86 -. x a Md a o l r e d n U n o i t a m r o f e D i s p 0 0 0 , 4 @ % 5 . 0e z i S) s e h c n i ( ) s e h c n i ( s n o i s n e m i D 0 0 1 / t W) s b I (A B C D*4 / 1 5 6 . 1 4 / 1 8 7 . 5 7 3 . 1 4 38 / 3 0 1 . 2 8 / 3 9 0 . 1 0 8 . 1 2 72 / 1 0 1 . 2 2 / 1 5 2 . 1 0 8 . 1 9 64 / 3 5 3 . 2 4 / 3 0 5 . 1 0 2 . 2 7 1 11 0 6 . 2 1 1 8 . 1 6 5 . 2 7 6 14 / 1 - 1 0 0 . 3 4 / 1 - 1 7 1 . 2 6 0 . 3 0 5 22 / 1 - 1 8 1 . 3 2 / 1 - 1 4 4 . 2 2 4 . 3 3 2 32 2 5 . 3 2 7 9 . 2 9 0 . 4 0 0 52 / 1 - 2 1 1 . 4 2 / 1 - 2 3 6 . 3 8 8 . 4 4 1 83 7 4 . 4 3 1 3 . 4 5 7 . 5 5 7 1 1Manufacturing: 1-800-323-1659 Sales: 1-800-231-2724Specify Kemper Model B butterfly valves for flow controlincluding severe service in waterflood projects, tank batteryhook-ups and any fluid control system requiring bubble-tightseal at cold working pressures up to and including 150 lbs.W.O.G.NPT screwed ends and external marking of each valve to in-dicate flow direction simplify correct field installation accord-ing to fluid flow. Provisions are made for easy padlocking ofthe valves in either open or closed position.Corrosion protection is provided by electroless nickel platingto the interior and exterior of the valve bodies and the stan-dard Aluminum-Bronze Disc adds to the life of the valve. The416 stainless steel valve stems are designed to withstand thetorque ratio built into the handle and extension.Positive seal in the closed position is assured by high tensile,nitrile o-rings. This material is wear-resistant in the presenceof hydrocarbons and abrasive fluids. Special elastomers, suchas Viton, EPDM and others, are available on request. Thestem, disc and o-ring are replaceable in the field.FEATURES of Kemper Model BMODEL B, BODY STYLE BUTTERFLY VALVESUnidirectional in 2, 3 or 4 Sizes15s e h c n I n i s n o i s n e m i Dn o i s n e m i DI o b m y S h c n I - 2e v I a V h c n I - 3e v I a V h c n I - 4e v I a VA 4 / 1 - 4 8 / 1 - 5 8 / 1 - 5B 3 8 / 1 - 4 2 / 1 - 5C 8 / 7 - 4 4 / 1 - 6 8 / 3 - 6D 8 8 8E 6 1 / 5 - 2 8 / 5 - 2 4 / 3 - 3Sales: 1-800-231-2724 Manufacturing: 1-800-323-1659(A) Top plate, integral with body, is standard-drilled toaccept power operators.(B) Handle for manual operation easily locked in anyone of ten positions; full open, eight throttling orcompletely closed. Opening stops stamped intoindex plate for durability.(C) Upper stem bushing is wear and corrosion-resis-tant, absorbs operator side-thrust.(D) Upper stem packing seals off line materials, retainspressure or holds vacuum.(E) Lugs tapped UNC on standard 125 and 150 psiANSI bolt circle.(F) Ductile iron body tolerates rough treatment in ad-verse conditions.(G) Resilient butterfly seat is smooth-surfaced Nitrile,EDPM, or Highly Saturated Nitrile for easy openingor closing with minimum wear.(H) Disc screws of 316 stainless steel make disassem-bly and seat replacement or other field repairs fastand easy.(I) Seal-against-flange is integral with resilient butter-fly seat. Eliminates separate o-ring.(J) Disc of carbon steel, aluminum bronze or CF8Mstainless steel is precision finished to seat accu-rately in leak-tight shut-off.(K) Stainless steel 303 stem is highly polished, extendsthrough body cavity to pivot firmly in recess in bodybase.(L) Initial seal-off line materials and pressure is pro-vided by contoured disc-edge in firm contact withresilient seat. Additional seal is accomplished byclose grip of seat material where the stem extendsthrough a hole in the seat that is smaller diameterthan the stem.(M) Optional grease fittings available on Kemper but-terfly valves for easy lubrication of valve stem insevere service conditions.BUTTERFLY VALVESKemper Butterfly Valves control oilfield fluids dependably and are rated at200 psi working pressureWafer Style Lug Style16e v I a V ) s e h c n i ( s n o i s n e m i D y I n O e p y T - g u Le z i S A B C D E F G H J K L" 2 8 / 1 - 2 8 / 1 - 4 6 1 / 5 1 - 3 8 / 5 - 1 4 2 / 1 4 / 1 - 1 1 1 4 / 3 - 4 1 1 - 8 / 5 4" 3 8 / 1 - 3 8 / 3 - 5 8 / 7 - 4 4 / 3 - 1 4 2 / 1 4 / 1 - 1 1 1 6 1 1 - 8 / 5 4" 4 8 / 1 - 4 8 / 7 - 6 6 2 4 8 / 5 4 / 1 - 1 1 1 2 / 1 - 7 1 1 - 8 / 5 8" 5 8 / 1 - 5 4 / 3 - 7 2 / 1 - 6 8 / 1 - 2 4 4 / 3 4 / 1 - 1 1 1 2 / 1 - 8 0 1 - 4 / 3 8" 6 8 / 1 - 6 4 / 3 - 8 2 / 1 - 6 8 / 1 - 2 4 4 / 3 4 / 1 - 1 1 1 2 / 1 - 9 0 1 - 4 / 3 8" 8 8 / 1 - 8 1 1 6 1 / 5 - 8 2 / 1 - 2 6 8 / 7 4 / 1 - 1 2 / 1 - 6 1 4 / 3 - 1 1 0 1 - 4 / 3 8" 0 1 8 / 1 - 0 1 8 / 3 - 3 1 9 2 / 1 - 2 6 8 / 1 - 1 2 / 1 - 1 2 / 1 - 6 1 4 / 1 - 4 1 9 - 8 / 7 2 1" 2 1 2 3 / 3 - 2 1 6 1 / 1 - 6 1 2 3 / 9 - 0 1 3 6 8 / 1 - 1 2 / 1 - 1 2 / 1 - 6 1 7 1 9 - 8 / 7 2 1ACDMGHJKILFEBEFCA BJ-Bolt CircleK-Bolt Dia.L-No. of LugsLug BodyGHDManufacturing: 1-800-323-1659 Sales: 1-800-231-2724New design, piston-type transducer converts mud pressure to hy-draulic fluid pressure, withstands pressure fluctuations with less riskof failure than diaphragm design. Maximum instrumentation ca-pacity in minimum space with eight (not just two) NPT plugs. Easyconnections. Additional connections available on request. Stan-dard 2 male line pipe thread for easy installation in manifolds.Flange or union connection available on request. Working pres-sure 0 to 5,000 psi (0 to 351.5 kg/cm2). Test pressure 10,000 psi(703kg/cm2). WOG needle valve (10,000 psi) provides for hydraulicfluid installation and bleed-off. Oil-resistant piston gives long ser-vice in oil base or acid fluids.GW 178 Pressure Transducers (Assembly GW178)Protect gauges and instruments in mud systemsThe only precision-manufactured non-freezestorage tank valves in 2-inch, 3-inch and 4-inch sizes. These valves operate in extremelycold climates when other tank valves freezeup. The stainless steel valve stem meetsmost corrosive service requirements. Adjust-able gland prevents leaking and extends thewear-life of the gland packing. Heavy dutynitrile valve seat and nitrile gland packing tol-erate hydrocarbon liquids for long periods with-out deterioration. Standard line pipe connec-tions permit easy make-up at the tank con-nection and valve outlet. Operating pres-sures to 150 psi (10.5 kg/cm2) valve rating.High torque handwheel makes opening andclosing easy at all times. Complete valves andindividual parts available. All sizes also avail-able with flange connections.Non-Freeze Tank ValvesGive trouble-free service in cold country17EIGHT NPT PIPE CONNECTIONS5 O.D.CYLINDERBODY2 LINEPIPEMALETHREAD21 3/8CBGIEAFPISTONCOMPLETETEFLONSEALRINGSSET OFPISTONRUBBERSONLYe t e I p m o Ce v I a VE V L A V E Z E E R F - N O Ns e h c n I n i s n o i s n e m i D. o N t r a P e v I a Ve z i S A B C D E F G H I0 0 2 F - N 2 2 2 8 / 5 - 0 1 4 / 1 - 9 2 4 / 1 - 2 5 4 / 1 - 3 1 8 / 1 - 2 8 / 3 - 20 0 3 F - N 3 5 2 2 1 0 1 3 8 / 3 - 3 5 4 / 1 - 5 1 8 / 1 - 3 2 / 1 - 30 0 4 F - N 4 2 / 1 - 9 2 4 1 2 1 4 4 / 1 - 4 7 8 / 1 - 8 1 4 / 1 - 4 2 / 1 - 4TEFLONSEALRINGSNEEDLEVALVESales: 1-800-231-2724 Manufacturing: 1-800-323-16594" Figure 1002 w/ Butt Weld Ends4" Figure 1002 w/ LPT Ends5" Figure 1002 w/ Butt Weld Ends5" Figure 1002 w/ w/ LPT Ends6" Figure 1002 w/ Butt Weld Ends1" Figure 1502 w/ Butt Weld Ends1" Figure 1502 w/ LPT Ends1 " Figure 1502 w/ Butt Weld Ends1 " Figure 1502 w/ LPT Ends2" Figure 1502 w/ Butt Weld Ends2" Figure 1502 w/ LPT Ends3" Figure 1502 w/ Butt Weld Ends3" Figure 1502 w/ LPT Ends4" Figure 1002 w/ Butt Weld Ends4" Figure 1502 w/ Detachable Nut, Butt Weld Ends4" Figure 1502 w/ Non-Pressure Seal Threaded Ends5" Figure 1002 w/ Butt Weld Ends5" Figure 1003 (Misaligning) w/ Buttweld Ends5" Figure 1502 w/ Butt Weld EndsTYPE APPROVAL CERTIFICATIONS1 " Figure 602 w/ Butt Weld Ends1 " Figure 602 w/ LPT Ends1 " Figure 602 w/ Butt Weld Ends1 " Figure 602 w/ LPT Ends2" Figure 602 w/ Butt Weld Ends2" Figure 602 w/ LPT Ends3" Figure 602 w/ Butt Weld Ends3" Figure 602 w/ LPT Ends4" Figure 602 w/ Butt Weld Ends4" Figure 602 w/ LPT Ends1 " Figure 1002 w/ Butt Weld Ends1 " Figure 1002 w/ LPT Ends1 " Figure 1002 w/ Butt Weld Ends1 " Figure 1002 w/ LPT Ends2" Figure 1002 w/ Butt Weld Ends2" Figure 1002 w/ LPT Ends3" Figure 1002 w/ Butt Weld Ends3" Figure 1002 w/ LPT EndsManufacturingPO Box 400Wauconda, Illinois 60084Local: 847-526-2166Toll Free: 800-323-1659Fax: 847-526-2241Distribution Sales5650 Guhn Road Suite 110Houston, Texas 77040Local: 713-462-1665Toll Free: 800-231-2724Fax: 713-462-1626Stimulation Sales2733 Industrial DrSulphur, OK 73086Local: 580-622-2048Fax: 580-622-2058Inquiries: sales@kempervalve.com http://www.kempervalve.com18The following Kemper Hammer Union products have received Det Norske Veritas Type Approval Certification.Type Approval assures you can use these products with reference to the Certificate in DNV overseen fabricationprojects without the need for individual item project approvals. Please consult with the factory foradditional Type Approved products, and soon for ABS Type Approved product listings.Manufacturing: 1-800-323-1659 Sales: 1-800-231-272419DRILLING CONTRACTORSNOMAC CHEASAPEAKEENSCO DRILLINGGREYWOLF DRILLINGHELMERICH & PAYNENABORS INDUSTRIESPARKER DRILLINGROWAN INDUSTRIESSUNFLOWER OFFSHORESANTA FE DRILLINGOEMSCAN RIGCOPPER STATES RUBBERGATES RUBBERTESCO CORPORATIONVARCO DRILLING SYSTEMSDISTRIBUTORSNATIONAL OILWELLRED MAN PIPE & SUPPLYWILSON / SMITH INTLSERVICE COMPANIESAMERICAN ENERGY SERVICESCUDD PUMPING SERVICESHALLIBURTONRIG MANUFACTURERSDRECOIRI INTERNATIONALSTATE OWNED COMPANIESARAMCO SAUDI ARABIAPEMEX MEXICOPDVSA VENEZUELAWHEREVER IN THE WORLD OIL AND GAS EXPLORATION AND PRODUCTION ISUNDERWAY, KEMPER OILFIELD FLOW CONTROL PRODUCTS WILL BE FOUND. HEREIS A PARTIAL LIST OF COMPANIES THAT USE KEMPER PRODUCTS WORLD WIDE.ManufacturingPO Box 400Wauconda, Illinois 60084Local: 847-526-2166Toll Free: 800-323-1659Fax: 847-526-2241Distribution Sales5650 Guhn Road Suite 110Houston, Texas 77040Local: 713-462-1665Toll Free: 800-231-2724Fax: 713-462-1626Stimulation Sales2733 Industrial DrSulphur, OK 73086Local: 580-622-2048Fax: 580-622-2058Inquiries: sales@kempervalve.com http://www.kempervalve.com

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

Oilfield Hammer Unions ................................Swivel Joints - Code Red ..............................Swivel Joints - Code Silver ............................Pup Joints ......................................................Hose Loops ...................................................Integral Flow Line Fittings .............................Integral Manifold Fittings ...............................Union Bulls, CrossOvers and Swages...........Check Valves & Pressure Relief Valves.........Well Service Manifold Trailers........................ReBuild / ReCertification Facilities.................Mobile ReBuild / ReCert Teams.....................DNV Certifications List ..................................

Kemper Valve & Fittings Corporation, one of the largest manufacturers of Oilfield Hammer Unions in the USA, has expanded our product offerings to include flow line fittings and fabrications specifically for the Stimulation and Service market. See our companion brochure Oilfield Service and Distribution Products for other Kemper Products.

8613371530291

8613371530291