perforated pup joint quotation

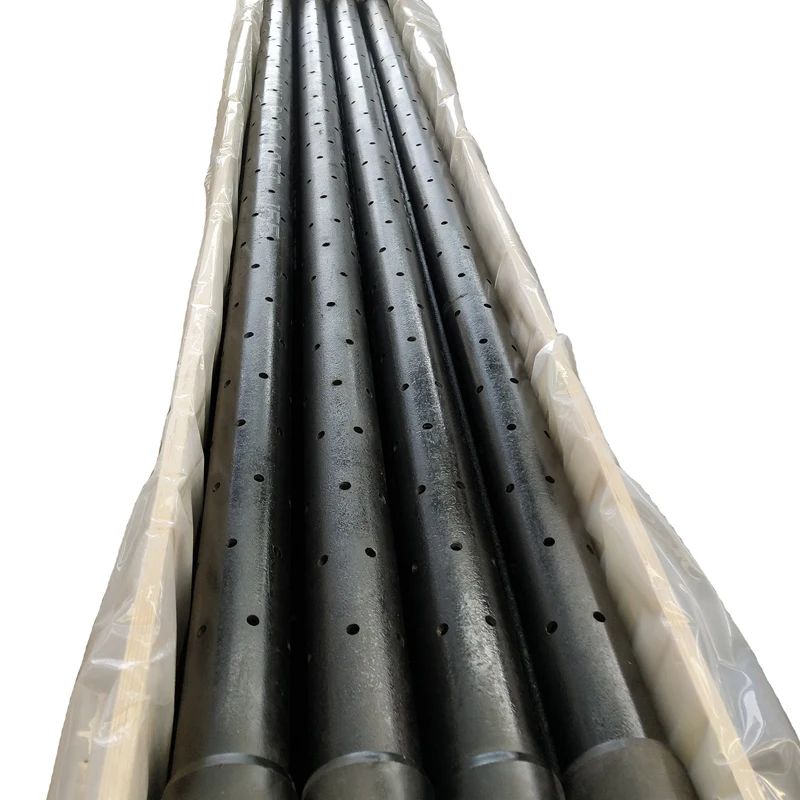

Pipe system involves various components, including perforated pup joints and are made from different materials. We offer wholesale perforated pup joints to create a smooth channel for the pipe systems in both commercial and residential areas.

We are Supplier and Exporter of Perforated Pup Joints in UAE. It is usually installed between the bottom of two nipples of a completion. It allows unrestricted fluid or gas flow, which increases the accuracy and reliability of acquired downhole production data.

We supply all sizes, grades, and thread profiles to meet custom requirements. The perforated pup joints are sometimes also known as the perforated production tube. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

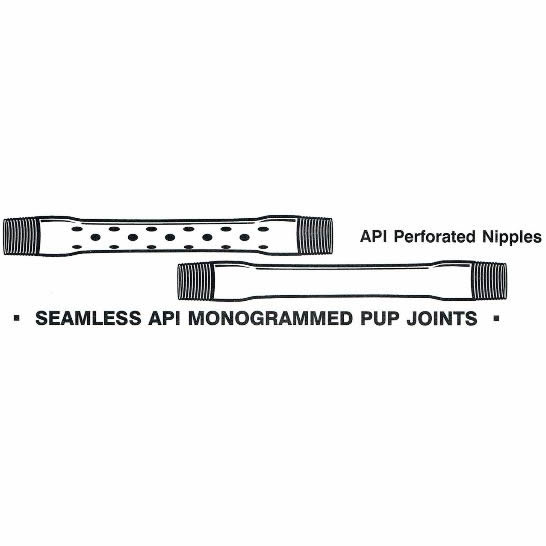

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Round Pup Joint Tubing Hot Rolled Non Secondary Anti Corrosion Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. O.D. ... Read More

Economical Steel Oil Pipe Stock J55 , Crossover Pup Joints For Oil Field Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole ... Read More

Tubular Pup Joint Tubing Non Standard Length Harshest Chemicals Resistant Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole ... Read More

Industrial Crossover Pup Joints Anti Corrosion Petroleum Machinery Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. ... Read More

J55 Pup Joint Tubing Round Shape Thick Wall Non Secondary Condition Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. ... Read More

API 5CT TUBING PUP JOINT 2-7/8" J55 Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. TUBING PUP JOINT O.D. 2 3/8" END ... Read More

Tool Pup Joint Tubing American Petroleum Institute Certified NUE EUE End Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole ... Read More

Spec 5CT Oil Gas Pipe , Integral Pup Joint Prime API Monogrammed Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. ... Read More

Alloy P110 Pup Joint Tubing Bulk 2-7/8" For Pipe Connector Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. TUBING PUP ... Read More

Threaded Pup Joint Tubing K55 , Oil Supply Pipe For Well Drilling Pup Joints are used to adjust the height of full length tubing or casing strings. They are also used to adjust the depth of downhole tools. ... Read More

In wells flowing large volumes, a restriction in the tubing such as a gauge hanger, could cause false pressure readings. Vibrations due to flow could also cause extensive damage to delicate gauges, therefore a perforated pup joint (approx. 10ft length) set above the bomb hanger nipple would allow flow to pass unrestricted over the gauges and hanger, thus giving a more accurate pressure/temperature recording within the

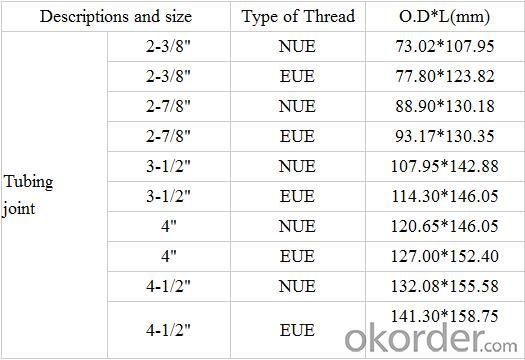

Global Steel distributes casing markers, pup joints and tubing pup joints which are manufactured according to API 5CT. Pup joints are available in 2 ft (0.61m), 4 ft (1.22m), 6 ft (1.83m), 8 ft (2.44m) and 10 ft (3.05m) lengths external upset (EUE). Casing marker joints are available in longer lengths (custom lengths as requested). Grades range from J55 and P110 to L80. Premium connections and threads are also available upon request. Fully detailed Mill Test Reports (MTRs) are available.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

Our range of products include Blank Adapter SH-500-A, Box-Box Flow Coupling SH502-FC, Combination Adapter SH-500-A, Combination Flow Coupling SH502-FC, Coupled Pup Joint SH503-PJ and Open Hole Hydraulic Set Packer SH518-OHP.

The Bullnose is a blanking device used at the end of the string. Its primary function is to prevent flow from entering the bottom end of the string, whilst its rounded nose design provides a positives guide while running in hole. Bull noses come in standard tool joint thread configurations and can be modified on location to best fit the application for which they are being used.

Integral → The pup joints are one-piece construction made from alloy steel and feature wing union end connections that eliminate welds and threads. The pup joints are capable of handling a variety of fluids and a working pressure of 15,000 psi. Available in lengths up to 15 feet, they are pressure rated to 10,000 psi for sour gas service.

8613371530291

8613371530291