pup joint houston tx manufacturer

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

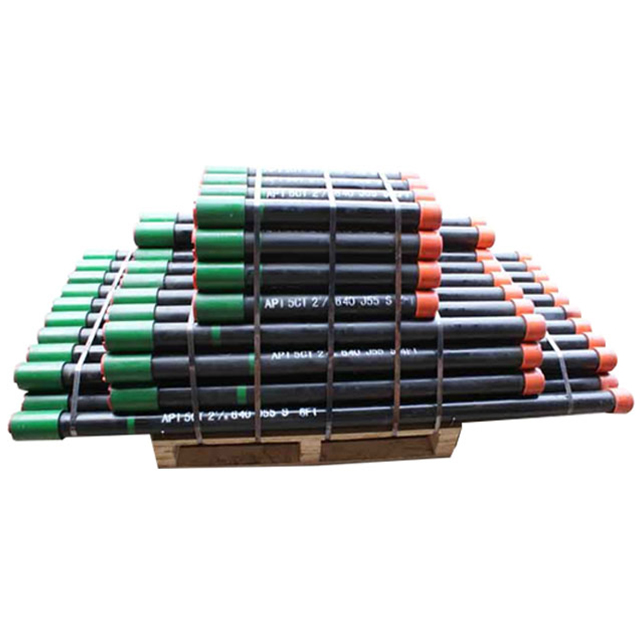

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Stewart Tubular Products will manufacture Pup Joints to any length – inch or metric. Typical lengths are 2’, 4’, 6’, 8’ and 10’. Either API or proprietary threaded connections may be provided. Pup Joints manufactured by Stewart Tubular Products are available in all API and proprietary grades of steel, stainless steel and CRA steel.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

Built in 2012, Command Tubular’s primary manufacturing facility is located in New Caney, Texas with a secondary repair/service facility in Houston, Texas. The New Caney facility is located on 15 acres with 68,000 ft2 of manufacturing area and can produce approximately 12,000 net tons of drill stem products per year. With an OD range of 2 3/8” – 6 5/8” and lengths from Range 1, Range 2 to custom Range 3, this facility was designed to meet the highest of customer specifications. With an industry reputation for quality, we guarantee that our materials and final products will perform better than API and ISO standards bringing our customer’s added value every step of the way.

These J55, L80, N80Q & P110 pup joints are manufactured from seamless Grade J-55, L80 N80Q and P110 mechanical tubing. The API 5CT tubing pup joint is mainly used to adjust the height of the tubing strings. It is also used to adjust the depth of down-hole tools.

manufacture Pup Joints 2’-20’ API threads LC, SC & BC and we install hangers, running tools and float equipment with customer or manufacturer third parties welcome.

We provide pup joints in several sizes, grades, and thread profiles. These pup joints are used as interconnecting pipework between equipment and adjust the length of tubular strings to its exact requirement. They are used to reach an exact reservoir depth, for setting packers at an exact location within the borehole, to space out your string prior to hanging it and more.

At W74 Oil Tools, our pup joints meet all certifications and specifications. Due to their shorter length, they are easier to handle and to use while out on in the field. In addition to their durability and quality, our oilfield pup joints also provide the same performance as the tubing, casing, or drill pipe that they’re attached to. To learn more about our selection of pup joints or to discuss your project needs, please feel free to contact our team today! We proudly serve and support oilfield sites across the Odessa, Midland, and Houston, TX area.

As one of the world’s largest and most respected commercial heat treating companies, TSC has the resources and expertise to consistently meet the rigorous specifications for OCTG products. TSC"s product list includes: tubing, casing, mechanical tubing, coupling material, drill stems, pup joints, drill pipe, horizontal directional drilling stems, and heavy weight drill pipe. TSC offers a wide array of processing for tubing and casing with outside diameter’s ranging from 1.315” to 10.000” and wall thicknesses up to 2.000” thick.

As one of the world’s largest and most respected commercial heat treating companies, TSC, Inc. has the resources and expertise to consistently meet the rigorous specifications for OCTG products. TSC, Inc.’s product list includes: tubing, casing, mechanical tubing, coupling material, drill stems, pup joints, drill pipe, horizontal directional drilling stems, and heavy weight drill pipe. TSC, Inc. offers a wide array of processing for tubing and casing with outside diameter’s ranging from 1.315” to 10.000” and wall thicknesses up to 2.000” thick.

Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. These are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Blast joints manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customer’s request. Typical lengths are 10" and 20".

Integral → The pup joints are one-piece construction made from alloy steel and feature wing union end connections that eliminate welds and threads. The pup joints are capable of handling a variety of fluids and a working pressure of 15,000 psi. Available in lengths up to 15 feet, they are pressure rated to 10,000 psi for sour gas service.

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

Our representatives are the largest manufacturers of API Pup Joints in North America. All our Pup Joints are manufactured with the highest quality, with API specification 5CT latest edition, and with full traceability. All alloys Pup Joints are made with Quench and Temper processes were in our own treatment lines.

Oilfield supplier Tejas Tubular Products, Inc. manufactures American Petroleum Institute (API) tubing, couplings, and pup joints, among other products. Currently, the company is embarking on its third endeavor with robotics to improve upon the speed and safety of manufacturing. This includes the invention and application of new technology to help the robots operate at full potential.

In 2014, Maximo was honored with the Male Hispanic Entrepreneur of the Year award, issued by the Houston Hispanic Chamber of Commerce in recognition of his outstanding contributions to the Houston business community. “I am completely humbled by this experience,” he said at the time, “and would like to thank the Tejas Tubular Team for making this possible.”

Manufacturing takes place at an electric resistance welded (ERW) tubing plant in Stephenville and two casing plants that found homes in Houston and New Carlisle, Indiana. These are joined by the original plant, also located in Houston, which is capable of producing an array of joints, couplings, tubing, and oil field drill pipe.

Along with futuristic coupling production, is Tejas Tubular’s automated pup joint processing line. A pup joint is used to supplement a length of tubing to meet the exact requirements of each drilling job. As customers require very specific measurements, the company has taken it upon itself to improve the production process and keep all of its aspects in-house. All pup joints are hydro tested for leaks and steel strength with modernized equipment. This is followed by a magnetic particle inspection, a form of non-destructive testing that uses magnetic fields to identify shallow and sub-surface defects.

Next, is more quality assurance through another means of non-destructive stress testing known as a full-body ultrasonic inspection which uses ultrasonic frequencies to detect cracks, pits, and imperfections. This above all else provides the most accurate assessment of a pup joint’s structural integrity. With all of these tests done in-house and the full-body ultrasonic being unique to Tejas Tubular, the company can provide the best possible product in record time.

8613371530291

8613371530291