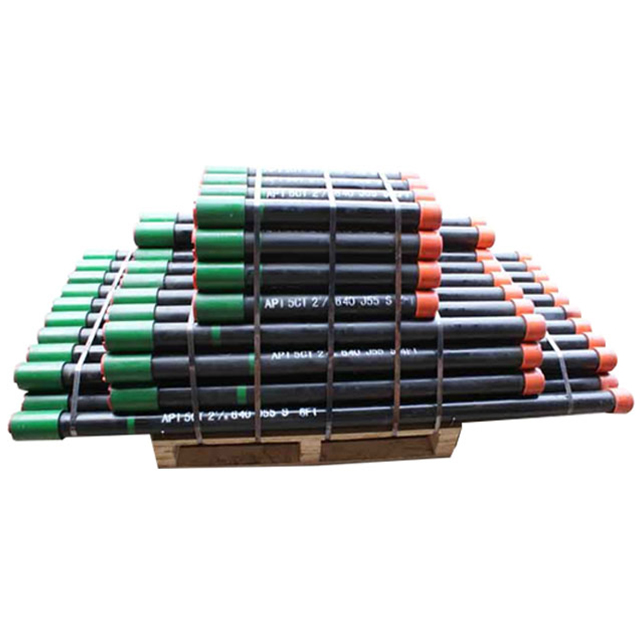

pup joint manufacturer lsaw steel pipes free sample

A wide variety of api l80 oil pipe pup joints options are available to you, such as energy & mining, construction works .You can also choose from 6 months, 3 years api l80 oil pipe pup joints,As well as from provided, {2}, and {3}. and whether api l80 oil pipe pup joints is kazakhstan, russia, or egypt.

We have become one of the leading 309 Stainless Steel Plate, 310 Stainless Steel Plate, 316 Stainless Steel Plate companies in China with its strong technical strength and abundant talents. Since the establishment of our company, thanks to the support and love of the vast number of new and old customers, our service team is growing and the service field is constantly expanding. Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. In the increasingly fierce market competition now, we have won a broad market development space for the company since we insist on continuous development and management, with good and thoughtful service and sincere cooperation.

We will comprehensively increase the pace of corporate internal restructuring, improve product innovation technology to create Ms Casing Black Spiral Steel Pipes with Polyethylene Coated for Pile/Building Material/Foundation Works and Water/Oil /Gas Pipeline that meet customer needs. We will continue to uphold the customer first, integrity-based concept, strive to forge ahead, to provide customers with more intimate service. With a group of engineers and technicians with rich practical experience as the core, we provide customers with a variety of localized solutions and quality after-sales service.

BS1387 ERW Welded Pipe is a high-frequency resistance welded steel pipe. Unlike ordinary steel pipes, the weld is formed by melting the base material of the steel strip body, and its mechanical strength is better than that of general welded pipes. It is mainly used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction, etc.

BS1387 ERW Welded Pipe uses high-quality raw materials and advanced manufacturing technology, so it has the characteristics of uniform wall thickness, anti-backlog and high performance. Compared with ordinary steel pipes, it has a better surface, and has better properties in terms of hardness, tensile and impact.

NDT test(x-ray,UT,RT,)Hydro static test, Impact Test,Mechacical&Chemical testPlain End, Beveled End, TreadedRound Pipes, Black Pipes, Zinc Coated Pipe

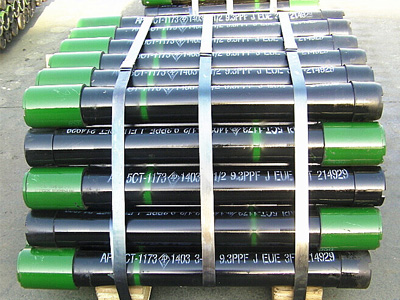

Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.

API Spec.5CT includes an illustration of API tubing joint connections. All three connections have tapered and round thread forms with either 8 or 10 threads/in., depending on the size. When casing is used as tubing, long-thread coupling/short-thread coupling and buttress-thread coupling connections can be specified.

According to API 5CT standard, steel material used for making the pipe billet supplied shall be grain refining treatment. This steel shall contain one or more grain refining elements, such as a certain amount of aluminum, niobium, vanadium or titanium, so that the austenite grains of the steel Grain refinement.

A separately heat treated coupling blank is acceptable. If the finishing temperature is higher than the upper critical temperature of the treated steel and the pipe is air cooled, it shall be considered to be normalized.

Flat end pipe is a pipe supplied with unmachined threads, and It may upset or not , but it shall comply with all requirements of a specific steel grade in this standard.

Steel grade H40, J55, K55 or M65 casings are available in short or long threads. However, if the purchaser requests a long threaded casing, it should be specified on the order.

The “round” or “bullet-nose” type of pipe end may be provided by the manufacturer or specified by the purchaser to replace the conventional corner breaks on the threaded ends of external upset tubing. The improved end should be rounded so that the coating is applied and the inner and outer surfaces are rounded and smooth, without sharp corners, burrs.

Product threading, gauging practice and thread inspection shall be in accordance with API Spec 5B. The product end shall not be hammered, but may be slightly shaped to meet the requirements of thread machining. For steel grades of C90 and higher strength, such forming shall only be carried out with the consent of the purchaser.

All product ends shall be free of burrs on the inside and outside edges. And sand blasting shall be applied to both male and female threads of C110 steel grade.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

API 5L pipe is carbon steel pipe used for oil and gas transmissions, it includes the pipes manufactured in seamless and welded (ERW, SAW). Materials covers API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 onshore, offshore and sour services. API 5L the implementation standard of steel pipe for pipeline transportation system and specification for line pipe.

Manufacturing Types: Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW

In API SPEC 5L 46th Edition, it is defined the scope as:”Requirements for the manufacture of two product specification level (PSL1 and PSL2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries. This standard is not applicable to cast pipe.”

In a word, API 5L pipe is the carbon steel pipe applied to the oil and gas transmission system. Meanwhile other fluids like steam, water, slurry also could adopt the API 5L standard for the transmission purposes.

Besides Seamless and ERW, SAW manufacturing technologies, in the earliest years the API 5L steel pipe also could be made in furnace lap-welded (deleted in API 5L in 1962).

As the development of pipeline steel plate making technology, pipe forming and welding technology also has been much improved, so a lot of ERW pipe and SAW pipe used in the pipeline constructions. Specially for the big diameter steel pipe, SAW pipe gains a great advantage. With less raw material cost, simplified and uniform production procedures, welded steel pipe has taken the first place in oil and gas line pipe industries.

API 5L steel line pipe adopts different steel grades, generally are Gr. B, X42, X46, X52, X56, X60, X65, X70, X80. Some manufacturers are capable of manufacturing steel grade up to X100 and X120. As the steel line pipe grades higher, more strictly control on the carbon equivalent control, and higher mechanical strength performances.

c. Al ≤ 0.060%; N ≤ 0.012%; Al/N ≥ 2:1 (titanium-killed or titanium-treated steel not applicable); Cu ≤ 0.35% (Cu ≤ 0.10% if agreed); Ni ≤ 0.30%; Cr ≤ 0.30%; Mo ≤ 0.15%; B ≤ 0.0005%.

a. Jointers need not be hydrostatically level, provided that the portions of pipe used in making the jointers were successfully hydrostatically tested prior to the joining operation.

In 2007, ISO and API did a joint release for ISO 3183:2007/API SPEC 5L 44th, to complete a international standard worldwide. Until 2012, United States claimed about the intellectual property right, so API terminated the cooperation with ISO, and no longer making standards for ISO. But the latest version of ISO 3183:2012 or API 5L 2012 still a union achievement, except API LOGO and onshore line pipe specification for European, the other content was all the same.

Therefore, API 5L steel pipe should have high strength, high toughness and brittle fracture, and good weld ability, and suitable for sour services and in H2S environment with anti-corrosion performances.

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion.

We produce small & large turned parts and machined parts, Precision CNC Turned Parts by CNC Turning & Milling. Metal stamping Parts, Deep Drawing Parts, Metal parts welding and forming, Pipe Bending & fabricating components, Cold & Hot Forged Parts from Stainless Steels, Carbon steels, Brass & Copper, Aluminum Alloys. And produce Plastic injection molded parts, Plastic extrusion profiles and tubes.

We are working metal parts & plastic parts for various industries, custom produce a wide variety of machine parts and hardware components according customer’s drawing or sample, such as metal shafts, steel rods, bushings, Sleeves, Flanges, tubes, pipe coupling, fittings of valves; Metal stamping brackets, frames, clamps, casing, housing; deep drawn components; tube bending components; cold & hot forging parts, studs, bolts, screws, nuts, pins; steel wire forms, metal springs and all kinds metal components, plastic injection molded parts, plastic extrude profiles and pipes…

Our world is based on high tech seamless pipes that can withstand the toughest conditions, day in, day out. We promise highest performance based on the core values customization, innovation, sustainability and responsibility.

EUE Pup Joints are manufactured in nominal diameters of 2" and 4 1/2" with a length in use from 1 to 12 feet and under API 5CT application regulations.

While many pipe manufacturing methods exist, the most prominent discussion in the industry compares electric resistance welded (ERW) vs. seamless (SMLS) steel pipe.

Both ERW and seamless steel pipe manufacturing methods have been in use for decades; over time, the methods used to produce each have advanced. So which is better?

Welded pipe starts out as a long, coiled ribbon of steel called a skelp. The skelp is cut to the desired length, resulting in a flat rectangular sheet. The width of that sheet’s shorter ends will become the pipe’s outside circumference, a value that can be used to calculate its eventual outside diameter.

Seamless piping begins as a solid cylindrical hunk of steel called a billet. While still hot, billets are pierced through the center with a mandrel. The next step is rolling and stretching the hollow billet. The billet is precisely rolled and stretched until it meets the length, diameter and wall thickness as specified by the customer order.

Generally, welded pipe was considered inherently weaker because it included a weld seam. Seamless pipe lacked this perceived structural flaw and was considered safer. While it’s true that welded pipe does include a seam that makes it theoretically weaker, manufacturing techniques and quality assurance regimens each have improved to the extent that welded pipe will perform as desired when its tolerances aren’t exceeded. While the apparent advantage is clear, a critique of seamless piping is that the rolling and stretching process produces an inconsistent wall thickness compared to the more precise thickness of steel sheets destined for welding.

The industry standards that govern the manufacture and specification of ERW and seamless steel pipe still reflect those perceptions. For example, seamless piping is required for many high-pressure, high-temperature applications in the oil & gas, power generation and pharmaceutical industries. Welded piping (which is generally cheaper to produce and is more widely available) is specified across all industries as long as the temperature, pressure and other service variables do not exceed parameters noted in the applicable standard.

In structural applications, there’s no difference in performance between ERW and seamless steel pipe. While the two can be specified interchangeably, it wouldn’t make sense to specify for seamless when cheaper welded pipe works equally well.

Also, a good grasp of industry standards could lead to cost savings. The A106 and A53 carbon steel pipe standards are a good example. In this article, we discuss how pipe complying with the former must be seamless while pipe complying with the latter can either be seamless or welded. For example, if an engineer must follow the A53 standard on a given project, he or she may still have the flexibility to choose which type to specify based on the specifics of the application.

American Piping Products stays fully-stocked with the best inventory of welded and seamless steel piping products in the industry. We source our stock from mills around the world, ensuring buyers get the pipe the need faster regardless of any applicable statutory restrictions.

In our steel pipe buyer’s guide, we’ll help you navigate the piping procurement process from start to finish to ensure you get what you need as quickly as possible when it’s time to buy. If a piping purchase is in your near future, request a quote. We’ll provide one that gets you exactly the products you need—fast.

8613371530291

8613371530291