pup joint manufacturer lsaw steel pipes for sale

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

In the face of fierce market competition, we will definitely start from the customer"s point of view. It is the corporate mission to make safer, more reliable and more stable X56 Line Pipe, Rectangular Steel Pipe, Galvanized Steel Pipe for you! In order to enable each employee to have a deep understanding of the concept of company rules and implement them in their daily work, we have formulated a code of conduct as a specific standard. Our company adheres to the pioneering spirit of openness, self-correcting spirit of tolerance, and spirit of integrity to abide by promises. We work together to build an excellent team, which yearns for the new goals set by our company and can perform well even in the new environment.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

We care about your needs, we pay attention to the quality of Steel Pipe Seamless Nipple & Pup Joint; Oil OCTG Casing & Tubing Pup Joint Oilfield Services J55/K55/N80/L80/P110/C95/T95/80s, your satisfaction is our eternal pursuit, quality and integrity is our goal. We strictly and seriously fulfill our contracts, keep our promises and strengthen our network system of after-sales service. We set up a sense of quality service and do our best to do the entrusted project of each contracted customer.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

Eastern Steel Manufacturing Co.,Ltd is a leading manufacturer and distributor of seamless steel pipe, welded steel pipe, OCTG products and fittings. We supply first-step processing, semi-finished parts and finished parts to help our clients meet fabrication requirements beyond their capacity or to improve operations by moving forward the pre-production processing.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

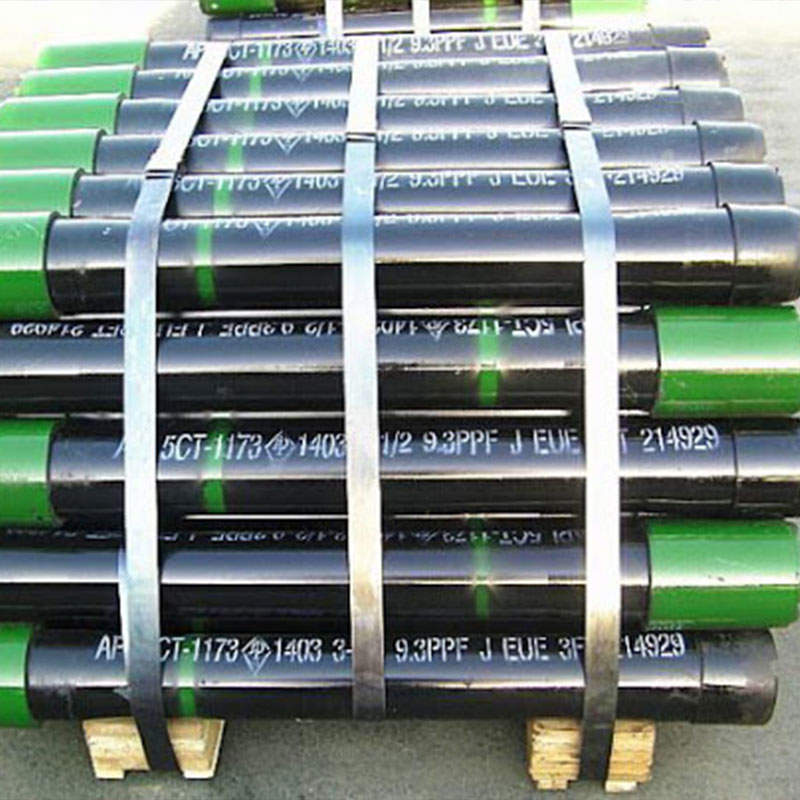

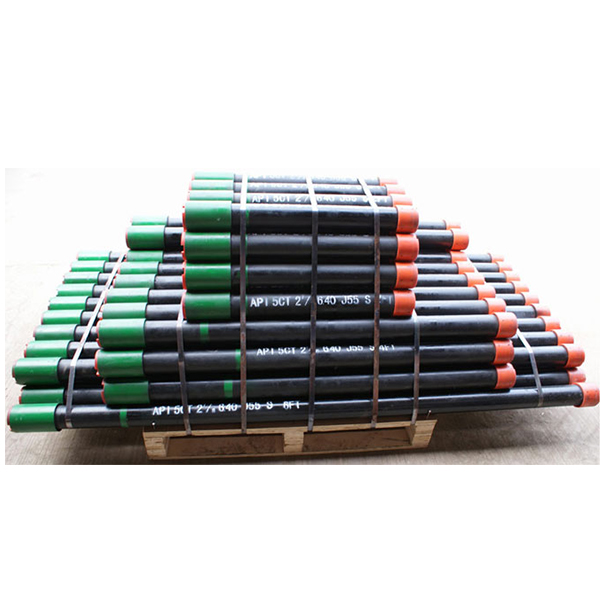

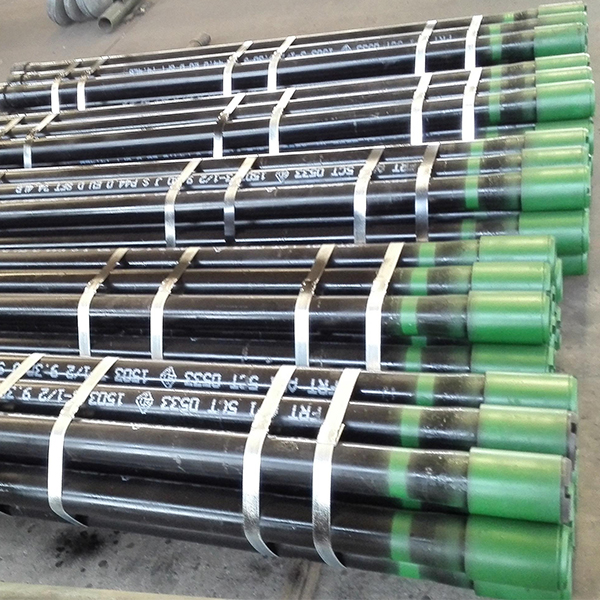

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Project of LSAW Line Pipe Client: PDVSA from Venezuela Location: Pto. Cabello, Venezuela Delivery Quantity: 23500 m API 5L Pipe Year Completed: 2011 Material Description of Line Pipe Project WELDED LINE PIPE, WELDED LSAW, WELDING METHOD LONGITUDINAL, MATERIAL CARBON STEEL, OUTSIDE DIAMETER 24 in, NOMINAL WEIGHT 171.29 lb/ft, WALL THICKNESS 0.688 in, STANDARD AND GRADE […]

Project of Welded ERW Line Pipe Client: PDVSA from Venezuela Location: Pto. Cabello Delivery Quantity: 7600 m Year Completed: 2014 Material Specification of the Purchase Order Material PO text LINE PIPE, WELDED ERW, MATERIAL CARBON STEEL, OUTSIDE DIAMETER 16 in, NOMINAL WEIGHT 82.77 lb/ft, WALL THICKNESS 0.500 in, STANDARD AND GARDE API 5L X65M, ENDS […]

Project of ASTM A572 Steel Plate Client: Client from Saudi Arabia Location: Dubai, Saudi Arabia Delivery Quantity: 350 MT Year Completed: 2014 Material Order Specification Material Carbon Low Alloy Steel Plate, standard and grade ASTM A572 Grade 50 / ASTM A709 Grade 345, sizes in 6mm, 8mm, 9.5mm 12.5mm, 16mm, 20mm, 25mm and etc. Want […]

Project of LSAW Line Pipe Client: PDVSA from Venezuela Location: Pto. Cabello, Venezuela Delivery Quantity: 23500 m API 5L Pipe Year Completed: 2011 Material Description of Line Pipe Project WELDED LINE PIPE, WELDED LSAW, WELDING METHOD LONGITUDINAL, MATERIAL CARBON STEEL, OUTSIDE DIAMETER 24 in, NOMINAL WEIGHT 171.29 lb/ft, WALL THICKNESS 0.688 in, STANDARD AND GRADE […]

Project of Welded ERW Line Pipe Client: PDVSA from Venezuela Location: Pto. Cabello Delivery Quantity: 7600 m Year Completed: 2014 Material Specification of the Purchase Order Material PO text LINE PIPE, WELDED ERW, MATERIAL CARBON STEEL, OUTSIDE DIAMETER 16 in, NOMINAL WEIGHT 82.77 lb/ft, WALL THICKNESS 0.500 in, STANDARD AND GARDE API 5L X65M, ENDS […]

Project of Spiral Welded Line Pipe Client: Pdvsa from Venezuela Location: Maracaibo, Venezuela Delivery Quantity : 3000m Spiral Welded Steel Pipe in API 5L X60 PSL1 Year Completed: 2014 SSAW Pipe Material Specification WELDED LINE PIPE SSAW, SPIRAL WELDED LINE PIPE, MATERIAL CARBON STEEL, OUTSIDE DIAMETER 30 in, NOMINAL WEIGHT 138.29 lb/ft, WALL THICKNESS 0.438 […]

Project of Pdvsa for Steel Casing Pipe Client: PDVSA from South America Destination Port: Guanta, Venezuela Location: South America Delivery Quantity: 280,000 FT Year Completed: 2014 Material Specification of API 5CT N80 Casing Pipe ITEM 1: API 5CT CASING PIPE SEAMLESS, NON SLOTTED, MATERIAL CARBON STEEL, EXTERNAL DIAMETERS 7 in, NOMINAL WEIGHT 23.00 lb/ft, ENDS […]

Project Description of Steel Pipe Accessories Client: Client from Venezuela Project Location: South America Delivery Quantity: 4,800 units including steel elbows, steel tees, reducers, caps and nipples Year Completed: 2014 Steel Pipe Fittings Order Specification STEEL ELBOW 45 DEGREE AND 90 DEGREE, SIZES FROM 1 1/2 in to 8 in, THICKNESS SCH 40, SCH STD, […]

Project of ASTM A572 Steel Plate Client: Client from Saudi Arabia Location: Dubai, Saudi Arabia Delivery Quantity: 350 MT Year Completed: 2014 Material Order Specification Material Carbon Low Alloy Steel Plate, standard and grade ASTM A572 Grade 50 / ASTM A709 Grade 345, sizes in 6mm, 8mm, 9.5mm 12.5mm, 16mm, 20mm, 25mm and etc. Want […]

Project of Stainless Steel Plate 304 Client: Client from Peru Location: Callo, Peru Delivery Quantity: 80 MT Year Completed: 2013 Material Specification of Purchase Order Stainless Steel Plate in coil 304 2B, stainless steel coil 304 2B, thickness 5mm, width 1500mm, quantity 80MT.

Project of ASTM A516 GR70 Client: South of America Location: Exported to South of America Surface Area: 520 MT Year Completed: 2013 Material Specification of the Boiler Steel Plate

Project of Chequered Steel Plate Client: Client from Asia Location: Singapore Delivery Quantity: 260MT Year Completed: 2015 Material Specification of the Purchase Order Chequered steel plate, material standard ASTM A36, carbon steel, thickness 6mm, width 1000mm, length 2000mm. Quantity 260MT.

The drill pipe joint is an important connecting part of the oil drill pipe and drilling tool, and is widely used in the oil drilling industry. Our pup joint drilling is finished with high-quality and unique materials for excellent durability and precise dimensional accuracy. The threads on the fittings are cut on a CNC machine, which ensures high precision of the threads and prolongs the service life of the fittings. Considering the specificity in practical applications, we use phosphate coating or copper plating to enhance the wear and chemical resistance of the joint. This pup joint drilling has good mechanical strength and comprehensive performance and meets international standards, it can be widely used in oil, natural gas, sewage treatment and other industries.

Outside Diameter of Tubing Joint: From 2-3/8"(60 3mm) to 4.5"(114.60mm) Pipe End: EUE/NUE Outside Diameter of Casing Joint: From 4-12"(114 3mm) to 20*(508mm)

PUP JOINT DRILLING, PUP JOINT INC, PUP JOINT, PUP JOINT OIL AND GAS, NPST PUP JOINT, API PUP JOINT DIMENSIONS, PUP JOINTS FOR SALE. DRILL, API, API 5CT, CASING, EUE, PIPELINES, TUBING,

Hot Tags: pup joint drilling, China, suppliers, manufacturers, factory, low price, for sale, in stock, made in China, ERW Structural Pipe, Socket Weld Cap, Class150 Blind Flange, Api 5l Line Pipe, Steel Pipe Reducer, Oil Casing and Tubing

Steel pipe is a building material made from an alloy of iron and carbon. It is widely used in the construction industry, but can also be found in a variety of manufacturing and industrial

applications. In plumbing systems, steel pipe can be used to transport liquids and gases for commercial and residential buildings, as well as in municipal water supplies. This material also acts as a

There are several different types of steel pipe available for use in various applications. The most common is carbon pipe, which is so named because it contains no other alloys. Carbon pipe is

widely available and relatively affordable, making it a popular choice for very large projects such as pipelines. Stainless steel pipe is made from an alloy of steel and chromium, and is one of the

more expensive types of pipe on the market. It offers a high level of corrosion-resistance, which allows smaller and thinner pipes to be used, even in highly corrosive or acidic scenarios.

tools, playing the function of adapting and connecting of drill string components used in oil, gas and geological drilling. The pup joint is needed if the threads of the upper and bottom drill tools

steel or stainless steel pipes. Because line pipe needs to withstand high pressures, there are important tests done on line pipe to ensure it meets all of the requirements of steel chemistry,

walls, laboratories, and commercial and industrial structures. The pipes transport fluids including water, natural gas, waste and air. Three manufacturing methods exist to produce steel pipes.

Seamless steel pipes are produced using an extrusion mold. Welded steel pipes are produced by rolling a sheet of steel into a tube and welding the seam. These pipes are less expensive. The third

and pushed or pulled over a form until the steel is shaped into a hollow tube. The seamless pipe is then finished to dimensional and wall thickness specifications in sizes from 1/8 inch to 36 inch

molybdenum, nickel, silicon and tungsten. To increase the chemical resistance and make it harder, some part of elements like manganese, phosphorous and sulfur is also added to it. At DRLIPRL Steel,

is rapidly increasing. Contact us to meet your need for alloy steel pipes for we specialize in engineered alloy steel. Making no compromise with quality and performance, we provide you alloy pipes

(EFW), and Double Submerged Arc Welded (DSAW) carbon steel pipe along with their respective flanges and fittings. We also carry A139 - Grade Band A252 Grades 2 & 3 spiral weld pipe along with

(EFW), and Double Submerged Arc Welded (DSAW) carbon steel pipe along with their respective flanges and fittings. We also carry A139 - Grade Band A252 Grades 2 & 3 spiral weld pipe along with

manufacturer to produce several sorts of sucker rod such as Grade HLHYKDD with different properties consisting of high strength and toughness, anti-corrosion and surface spray, used in major oilfield

protects the steel from corrosion. It is most commonly used for outdoor construction like fences and handrails, or for some interior plumbing. It is also sometimes called galvanized iron pipe.

pipe. A small amount of adhesive is typically placed on the threads before screwing them together, in order to reinforce the connection. If no threads are available, the pipes and fittings can be

welded together, although caution should be taken because the heat from welding can release dangerous zinc fumes into the air. Pipes can be cut using a cutoff saw or hacksaw.

A wide variety of api l80 oil pipe pup joints options are available to you, such as energy & mining, construction works .You can also choose from 6 months, 3 years api l80 oil pipe pup joints,As well as from provided, {2}, and {3}. and whether api l80 oil pipe pup joints is kazakhstan, russia, or egypt.

Core JFE Group company for spiral steel business, boasting the largest spiral steel pipe manufacturing plant and steel pipe column manufacturing plants in the industry

Manufacturing processes for round, angle, rectangular steel pipe and mainly manufactures steel pipe for mechanical structures , mostly for automotive parts (final demand).

Carbon steel pipe for general construction, angle steel pipe for general construction, carbon steel pipe for cold drawing, carbon steel pipe for mechanical structures, alloy steel pipe for mechanical structures, carbon steel pipe for plumbing, carbon steel pipe for high-pressure services, material pipes, columns, products conforming to overseas standards (ASTM, BS, DIN)

Cast fittings, steel pipe fittings, ductile fittings, mechanical parts, copper alloy fittings, stainless steel fittings, resin pipe and fittings, flexible plumbing materials, prefab plumbing processes

Processing of special joints and PUP joints for oil well pipe in 13% Cr steel. Manufactures special steel pipe, e.g., insulated double-pipe for hot springs in Japan and geothermal wells, slit pipe, and original design casings.

Manufacture of couplings for oil well pipe and special steel pipe for hot springs, geothermal, civil engineering works, and building materials, steel pipe threading, slits, hole processing, cutting, hot springs drilling, etc.

Sale of general steel, civil engineer material products for roads and buildings, steel plate fusion cutting, welding, machining, and cold-drawing of steel pipe.

Sale and processing of general steel and steel pipe, steel processing (medium-thickness steel plate shearing, fusion cutting, welded structures, machining), steel pipe processing (cold-drawing), construction for bridges and steel structures.

Zinc coating for various kinds of steel structures, zinc coating of steel pipe and steel materials, various kinds of painted steel pipe, various kinds of powder coating

Steel pipe for plumbing, steel pipe for special applications, general steel pipe for general construction, cast iron pipe, resin pipe, cast iron pipe, copper pipe, SUS pipe, metal pipe joints, resin pipe joints, valves, flanges, etc.

As one of the leading octg manufacturers and suppliers in China, we warmly welcome you to buy high-grade octg for sale here from our factory. All our products made in China are with high quality and low price. Tubing and Casing Coupling, Api 5l Line Pipe, LSAW Structural Pipe

For oil well tubing pup joints, WORLD IRON&STEEL can provide various cut-to-length oil well tubing pup joint accessories of API standard type (EU, NU, SC, LC, BC, etc.) and BSIG special type according to individual requirements of customers. According to the needs of on-site use, the pup joints can be processed into pup joints with couplings, double male buckle pup joints, conversion pup joints with different buckle types, conversion pup joints with different outer diameter specifications, etc.

Covering all steel grades of API standards (H40, J55, K55, N80, L80, C90, T95, P110, C110, Q125), BISG enterprise standard corrosion-resistant pipe steel grades, and anti-collapse product steel grades

The tubing pup joint offers high strength design to ensure excellent performance for joints of API 5CT drill pipe and tubing. World iron&steel manufacture, supply, sell OCTG, pipe, collar, joints and other accessories in various sizes and specifications, if you are looking for this material, please contact us or get a quotation. Not only do we have all kinds of sizes, but we also have all kinds of sizes that are hard to find.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

8613371530291

8613371530291