pup joint manufacturer spiral pipes factory

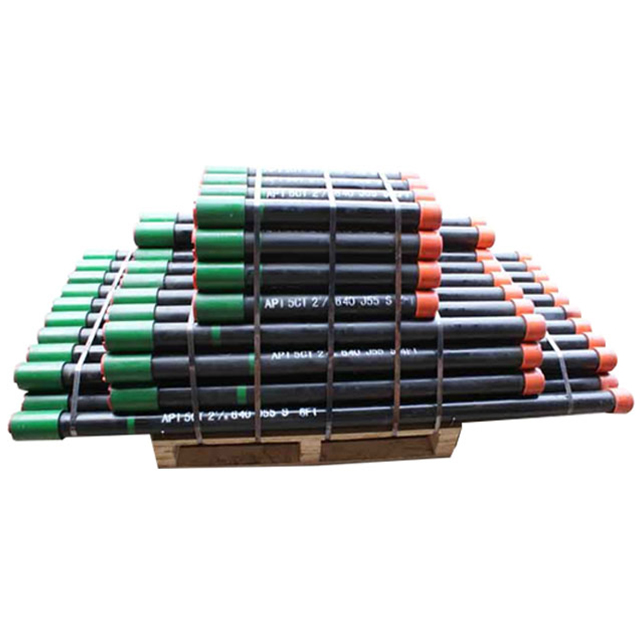

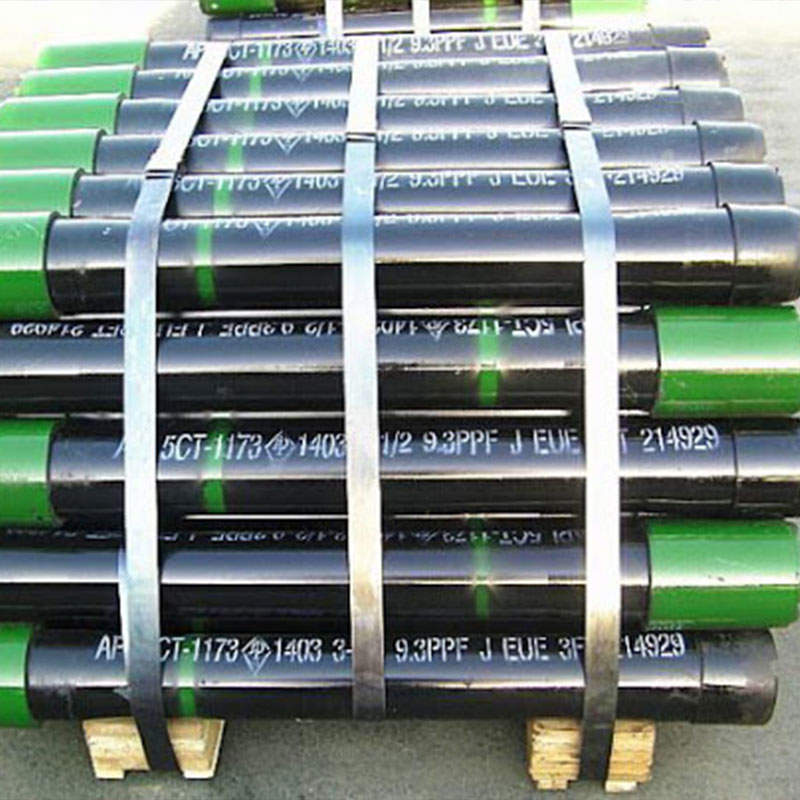

OCTG Pup Joints is one kind of common accessories for connection with casing and tubing. Threaded pup joints are divided into male threaded ends, single male threaded and Female threaded. The size and material is the same as the casing or tubing.

China N80 Pup Joint Manufacturer Derbo Supplies N80 Pup Joint, Hot Rolled, 1.66 Inch, EUE 2.40lb/ft, Oiled, Painting Finish, for Oil & Gas Industries.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

BRC INTERNATIONAL LLC is as a supply of high quality OCTG and Line Pipe in North America, South America, Europe and Middle East. Based in Houston Texas, BRC International LLC represents both domestic and foreign pipe manufacturers allowing us to offer entire range of OCTG and Line Pipe products. As a leading distributor of ERW and Seamless pipe, BRC International sets the goal to set competitive price and sets the industry standards in service and availability of Tubing and Casing products ranging from 2 -3/8” to 20” API5CT Grades J through Q125, Line Pipe ranging from ¼” to 110” API 5L and Drill Pipes ranging from 2-3/8” to 6-5/8” API 5DP, Grades E, X, G, S. BRC International built a reputation for expert knowledge in steel tubular products , strong support from world class manufacturers , Globally competitive pricing, 24/7 services by experienced professional for inquiries, order processing , monitoring of mill production and shipping status to meet scheduled deliveries of products. BRC Group of Companies is a supply home for high quality Tubular ranging from LSAW, Spiral, ERW and Seamless with size range covering from 1/8” to 110”. The company is placed uniquely in North American market with access to domestic & International Mills.

Pipe system involves various components, including pup joint pipe and are made from different materials. We offer wholesale pup joint pipe to create a smooth channel for the pipe systems in both commercial and residential areas.

Apart from materials, there are also other components of the pipe fittings to note. P-traps prevent odor by retaining a small pool of water to stop sewer gases from entering the bathroom. Pipe caps cover the end of pipes to stop the fluid flow and protect pipe threads.

The usage of the pipes plays a crucial role in the materials suitable. For manufacturing, pipes will need to be able to withstand the fluids conveyed. We provide solutions from pipe bends to copper pipe compression fittings for any piping system required.

For oil and gas reservoirs with high sulfur content that are likely to cause casing corrosion and cracking, GS has independently developed 80S/SS~110S/SS grades of oil well pipes with hydrogen sulfide stress corrosion resistance series, which have excellent mechanical properties and resistance to hydrogen sulfide stress corrosion cracking. Other grades mainly include 1%chrome, 3%chrome, 9% chrome, 13 chrome, super 13, etc.

Whole series of API SPEC 5CT oil tubing indicate the steel pipes produced as per API 5CT specification, used for exploiting resources such as petroleum and natural gas,etc. Oil tubing is used to extract oil and natural gas, casing is used as wall of oil and gas well bore.

Whole series of API SPEC 5CT casing pipe indicate the steel pipes produced as per API 5CT specification, used for exploiting resources such as petroleum and natural gas,etc. Tubing is used to extract oil and natural gas, casing is used as wall of oil and gas well bore.

Stainless steel pipe (Stainless Steel) is a hollow long cylindrical steel. Its scope of application is used as a pipeline for conveying fluids. It is mainly widely used in industrial pipelines such as petroleum, chemical, medical, food, light industry, mechanical instruments, etc. And mechanical structural parts, etc. Stainless steel pipes are made of acid-resistant and heat-resistant steel billets, which are heated, pierced, sizing, hot-rolled, and cut.

Core JFE Group company for spiral steel business, boasting the largest spiral steel pipe manufacturing plant and steel pipe column manufacturing plants in the industry

Carbon steel pipe for general construction, angle steel pipe for general construction, carbon steel pipe for cold drawing, carbon steel pipe for mechanical structures, alloy steel pipe for mechanical structures, carbon steel pipe for plumbing, carbon steel pipe for high-pressure services, material pipes, columns, products conforming to overseas standards (ASTM, BS, DIN)

Processing of special joints and PUP joints for oil well pipe in 13% Cr steel. Manufactures special steel pipe, e.g., insulated double-pipe for hot springs in Japan and geothermal wells, slit pipe, and original design casings.

Steel pipe for plumbing, steel pipe for special applications, general steel pipe for general construction, cast iron pipe, resin pipe, cast iron pipe, copper pipe, SUS pipe, metal pipe joints, resin pipe joints, valves, flanges, etc.

YUANTAI is a Professional China Manufacturer and Supplier of API 5CT PUP JOINTS supplier China, We Provide Custom Wholeslae API 5CT PUP JOINTS supplier China factory, Private Label API 5CT PUP JOINTS supplier China and API 5CT PUP JOINTS supplier China Contract Manufacturing, Contact us now to get the best quotation for API 5CT PUP JOINTS supplier China, We will respond in a timely manner, we are not the lowest price of API 5CT PUP JOINTS supplier China, but we will provide you with better service.

more expensive types of pipe on the market. It offers a high level of corrosion-resistance, which allows smaller and thinner pipes to be used, even in highly corrosive or acidic scenarios.

tools, playing the function of adapting and connecting of drill string components used in oil, gas and geological drilling. The pup joint is needed if the threads of the upper and bottom drill tools

steel or stainless steel pipes. Because line pipe needs to withstand high pressures, there are important tests done on line pipe to ensure it meets all of the requirements of steel chemistry,

walls, laboratories, and commercial and industrial structures. The pipes transport fluids including water, natural gas, waste and air. Three manufacturing methods exist to produce steel pipes.

Seamless steel pipes are produced using an extrusion mold. Welded steel pipes are produced by rolling a sheet of steel into a tube and welding the seam. These pipes are less expensive. The third

is rapidly increasing. Contact us to meet your need for alloy steel pipes for we specialize in engineered alloy steel. Making no compromise with quality and performance, we provide you alloy pipes

(EFW), and Double Submerged Arc Welded (DSAW) carbon steel pipe along with their respective flanges and fittings. We also carry A139 - Grade Band A252 Grades 2 & 3 spiral weld pipe along with

(EFW), and Double Submerged Arc Welded (DSAW) carbon steel pipe along with their respective flanges and fittings. We also carry A139 - Grade Band A252 Grades 2 & 3 spiral weld pipe along with

manufacturer to produce several sorts of sucker rod such as Grade HLHYKDD with different properties consisting of high strength and toughness, anti-corrosion and surface spray, used in major oilfield

pipe. A small amount of adhesive is typically placed on the threads before screwing them together, in order to reinforce the connection. If no threads are available, the pipes and fittings can be

welded together, although caution should be taken because the heat from welding can release dangerous zinc fumes into the air. Pipes can be cut using a cutoff saw or hacksaw.

We will comprehensively increase the pace of corporate internal restructuring, improve product innovation technology to create Ms Casing Black Spiral Steel Pipes with Polyethylene Coated for Pile/Building Material/Foundation Works and Water/Oil /Gas Pipeline that meet customer needs. We will continue to uphold the customer first, integrity-based concept, strive to forge ahead, to provide customers with more intimate service. With a group of engineers and technicians with rich practical experience as the core, we provide customers with a variety of localized solutions and quality after-sales service.

Backed by an industrial system with state-of-the-art R&D facilities and decades of metallurgy experience, we develop custom steel pipes, risers and services that meet deep and ultra-deep water needs.

We provide a range of steel tubes and pipes for refineries and processing plants as well as increased high temperature oxidation resistance and high thermal fatigue resistance.

We provide a wide range of cold-drawn and hot-rolled seamless tubes and components for car manufacturers and their suppliers for use in airbags, steering, chassis and suspensions, heavy trucks and trailers, transmission, ring gears and power train components.

8613371530291

8613371530291