pup joint manufacturing inc price

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

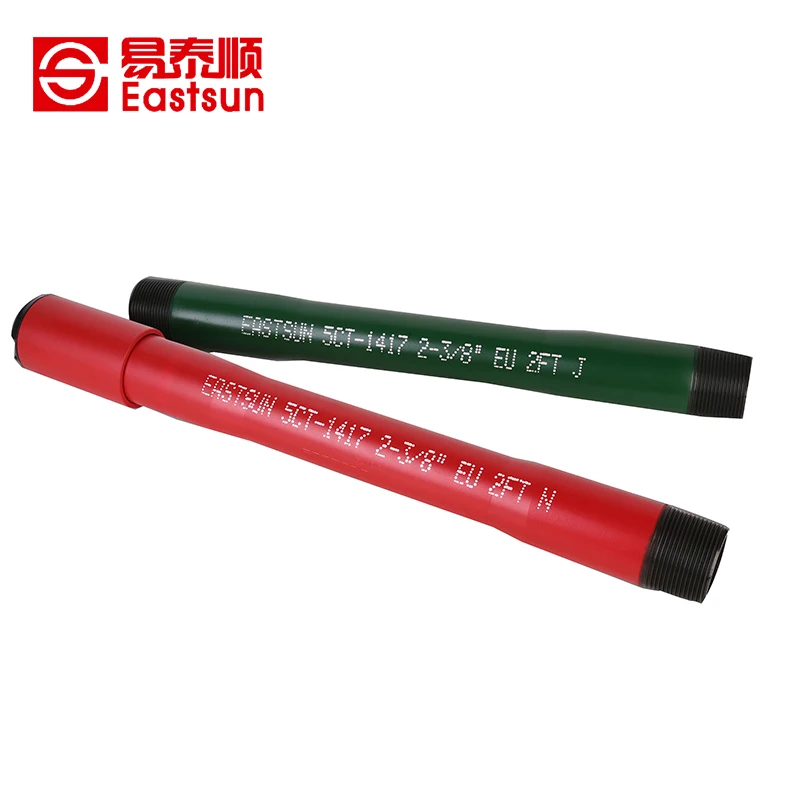

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

Prithviraj Industries manufactures Pup Joints up to 20, 000 psi cold working pressure in sizes: 1, 11 /2, 2, 3, and 4-inch bore sizes, lengths to 20 feet.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

Transparency Market Research delivers key insights on the global pup joint market. In terms of revenue, the global pup joint market is estimated to expand at a CAGR of ~7%during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in the global pup joint market report.

In the report, TMR predicts that the global pup joint market would be largely driven by factors such as increase in demand for oil & gas and increase in number of explorations. Rise in demand for high-grade pup joints, use of advanced drilling technology, and penetration in developing nations are set to drive the global pup joint market during the forecast period.

According to the pup joint market report, the product type segment includes crossover pup joint, drill pipe pup joint, and tubing pup joint; the technology segment includes hot rolled and cold rolled; the end use segment includes oil & gas, chemical industry, mining, construction, and others. Based on product type, drill pipe pup joint accounts for major share. Increase in drilling activities in various countries contributes maximum to this segment. The segment is projected to expand at a significant rate in the near future.

The oil & gas segment holds maximum share in the global pup joint market. Economic growth and high demand for electricity has increased the demand for offshore exploration and production activities worldwide.

Volatility in raw material prices has an obvious impact on pup joint manufacturers. Fluctuating prices of raw materials have impact on the production of pup joints.

Rising demand for oil & gas is set to increase drilling activities. New drilling technologies such as horizontal drilling and hydraulic fracturing is expected to have a positive impact on the oil & gas market. These factors are expected to drive the demand for pup joints during the forecast period.

Middle East & Africa holds a major share of the global pup Joint market followed by Europe. Key players largely depend on geographical expansion, promotions, and technological advancements to cater to customer demand and gain a competitive edge in the global pup joint market.

Middle East & Africa accounted for approximately 30% share of the global pup joint market in 2018, followed by North America and Europe. It is anticipated to maintain its dominance in the market during the forecast period. Domestic production capacity is increasing in several countries; exploring undeveloped sites and exploring new sites for drilling is projected to generate more options for business growth.

Key players operating in the global pup joint market include Anvil International, AZZ Inc., Dmh United Steel Industry Co., Ltd, Forum Energy Technologies, Inc., National Oilwell Varco, Oil Country Tubular Limited, Sledgehammer Oil Tools Pvt. Ltd, Stewart Tubular Products, Texas Pipe Works Inc., and TPS-Technitube Röhrenwerke GmbH.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

These J55, L80, N80Q & P110 pup joints are manufactured from seamless Grade J-55, L80 N80Q and P110 mechanical tubing. The API 5CT tubing pup joint is mainly used to adjust the height of the tubing strings. It is also used to adjust the depth of down-hole tools.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Moreover, Pup Joint Market trends report provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector. In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Pup Joint market in any manner.

The information for each competitor includes, Company Profile, Main Business Information, SWOT Analysis, Sales, Revenue, Price and Gross Margin, Market Share, etc.

Among other players domestic and global, Pup Joint market share data is available for global, North America, Europe, Asia-Pacific, Middle East and Africa and South America separately. Research analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Due to the COVID-19 pandemic, the global Pup Joint market size is estimated to be worth USD million in 2022 and is forecast to a readjusted size of USD million by 2028 with a CAGR of during the review period. Fully considering the economic change by this health crisis, Hot Rolled accounting for of the Pup Joint global market in 2021, is projected to value USD million by 2028, growing at a revised CAGR in the post-COVID-19 period. While Oil and Gas segment is altered to an CAGR throughout this forecast period.

The oil and gas segment holds maximum share in the global pup joint market. Economic growth and high demand for electricity has increased the demand for offshore exploration and production activities worldwide.

In terms of production side, this report researches the Pup Joint capacity, production, growth rate, market share by manufacturers and by region (region level and country level), from 2017 to 2022, and forecast to 2028.

In terms of sales side, this report focuses on the sales of Pup Joint by region (region level and country level), by company, by Type and by Application. from 2017 to 2022 and forecast to 2028.

Pup Joint market is segmented by Type and by Application. Players, stakeholders, and other participants in the global Pup Joint market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on production capacity, revenue and forecast by Type and by Application for the period 2017-2028.

Pup Joint Market Size [2023-2028] research report mainly introduces the statistical scope of the report, market division standards, and market research methods. Also focuses executive summary of different market segments (by region, product type, application, etc.), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Pup Joint Market and its likely evolution in the short to mid-term, and long term. Pup Joint Market Report makes a detailed analysis of the market"s competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Researcher"s latest report provides a deep insight into the global Pup Joint market share covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, Porter’s five forces analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Pup Joint Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

Pup Joint market growth is split by Type and by Application. For the period 2017-2028, the growth among segments provides accurate calculations and forecasts for sales by Type and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each application, including -

Regional analysis is another highly comprehensive part of the research study of the global Pup Joint market analysis presented in the report. This section sheds light on the sales growth of different regional and country-level Pup Joint markets. For the historical and forecast period 2015 to 2025, it provides detailed and accurate country-wise volume analysis and region-wise market size analysis of the global Pup Joint market.

Since the outbreak of COVID-19, the world economy continues to suffer from a series of destabilizing shocks, many companies experienced bankruptcy and a sharp decline in turnover. After more than two years of pandemic, global economy began to recover, entering 2023, the Russian Federation’s invasion of Ukraine and its global effects on commodity markets, supply chains, inflation, and financial conditions have steepened the slowdown in global growth. In particular, the war in Ukraine is leading to soaring prices and volatility in energy markets, with improvements in activity in energy exporters more than offset by headwinds to activity in most other economies. The invasion of Ukraine has also led to a significant increase in agricultural commodity prices, which is exacerbating food insecurity and extreme poverty in many emerging market and developing economies.

● What is current market status of Pup Joint industry? What is market competition in this industry, both company, and country wise? What is market analysis of Pup Joint market by taking applications and types in consideration?

● What are projections of global Pup Joint industry considering capacity, production and production value? What will be the estimation of cost and profit? What will be market share, supply and consumption?

With tables and figures helping analyses worldwide Global Pup Joint Market Forecast provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Pup joints are nonstandard pipes used to adjust the length of the tubular string to meet the exact requirements. In addition, the pup joints are used to change the length of the drill string for drilling operations and easy surface handling. The appearance of the pup joints is largely determined by their mechanical properties.

Further, thePup Joint marketis segmented by product type, Technology, End-User, and geography. On the basis of product type, the Pup Joint market is segmented under Crossover Pup Joint, Tubing Pup Joint. Based on the Technology, the market is segmented under the Hot Rolled and Cold Rolled. Based on End-User, the market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. By geography, the market covers the major countries in North America, i.e., the US, Canada, and Mexico. For each segment, the market sizing and forecasts have been done on the basis of value (in USD Million).

Increasing consumption of natural gas and oil, technological advancements in drilling techniques, and fast-growing industrialization are the major factors contributing to the market growth. The rise in demand for high-grade pup joints from several end-use industries is expected to drive the use of pup joints. Demand for pup joints is expected to rise because of the growing demand for energy and significant investments in exploring onshore and offshore reserves by the oil & gas and mining industries. Increased energy consumption, the economic development of the shipping industry, and increased seaborne trade are the major factors driving the demand for pup joints during the forecast period.

The decline in petroleum production may hinder the market"s growth. Renewable energy will be more affordable than existing oil and gas sources during the forecast period, which will restrain the market for pup joints.

Key players are concentrating on developing more companies to use the distribution channels of the developed companies to increase revenue generation. Key players are focusing on improving product quality and offering customized products according to the application. This is a significant opportunity for key players.

Due to COVID-19, the major end-user industries of pup joints were affected, which will hinder the demand for pup joints since the oil & gas industry is the largest end-user. COVID-19 has had a significant impact on the downstream oil & gas industry due to the significant drop in prices and reduced demand caused by the economic slowdown, which affected production rates in many countries. However, major countries such as the US and Canada implement dynamic and diverse approaches to navigate and deal with what is happening due to COVID-19. As a result, the market will experience moderate growth during the forecast period. The United States is a major revenue generator in the North American pup joint market.

With changes in energy arrangements and expanding political pressures, the market interest in pup joints and comparable items is changing. Government and privately owned businesses are showing a clear interest in finding new oil stores to meet future needs. Ventures by significant oil exploration companies are likely to support the pup joint market.

By Product Type,the Pup Joint Market is segmented into Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. The Tubing Pup Joint had the highest market share in 2021. Tubing pup joints are likely to have a huge demand because they are also used to handle production tubing accessories. Tubing pup joints are tubing that is short in size and operated for spacing.

By Technology, the Pup Joint Market is segmented into Hot Rolled and Cold Rolled. The Hot Rolled segment had the highest market share in 2021. Under high temperature and pressure processing conditions, the steel tube can be completely devoid of air bubbles, cracks, and porosity. It has a good mechanical effect and excellent intensity.

By End-User, the Pup Joint Market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. The Oil & Gas segment had the highest market share in 2021. The oil & gas business has been positively impacted by the introduction of several drilling technologies. Due to the reliance on petroleum-based products by various emerging economies, oil & gas dependence has increased. Petroleum is used to make a variety of chemical products, such as fertilizers, pharmaceuticals, and solvents. To meet future demand for oil, both private and public companies are seeking to explore new oil reserves.

The objective of the report is to present a comprehensive analysis of theNorth AmericaPup Joint market to the stakeholders in the industry. The report provides trends that are most dominant in the North AmericaPup Joint market and how these trends will influence new business investments and market development throughout the forecast period. The report also aids in the comprehension of theNorth AmericaPup Joint Market dynamics and competitive structure of the market by analyzing market leaders, market followers, and regional players.

The qualitative and quantitative data provided in theNorth AmericaPup Joint market report is to help understand which market segments and regions are expected to grow at higher rates, factors affecting the market, and key opportunity areas, which will drive the industry and market growth through the forecast period. The report also includes the competitive landscape of key players in the industry along with their recent developments in theNorth AmericaPup Joint market. The report studies factors such as company size, market share, market growth, revenue, Product Type, and profits of the key players in theNorth AmericaPup Joint market.

The report provides Porter"s Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals exist, who they are, and how their Product Type quality is in theNorth AmericaPup Joint market. The report also analyses if theNorth AmericaPup Joint market is easy for a new player to gain a foothold in the market, do they enter or exit the market regularly, if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political variables help in figuring out how much a government can influence theNorth AmericaPup Joint market. Economic variables aid in the analysis of economic performance drivers that have an impact on theNorth AmericaPup Joint market. Understanding the impact of the surrounding environment and the influence of environmental concerns on the North AmericaPup Joint market is aided by legal factors.

The drill pipe joint is an important connecting part of the oil drill pipe and drilling tool, and is widely used in the oil drilling industry. Our pup joint drilling is finished with high-quality and unique materials for excellent durability and precise dimensional accuracy. The threads on the fittings are cut on a CNC machine, which ensures high precision of the threads and prolongs the service life of the fittings. Considering the specificity in practical applications, we use phosphate coating or copper plating to enhance the wear and chemical resistance of the joint. This pup joint drilling has good mechanical strength and comprehensive performance and meets international standards, it can be widely used in oil, natural gas, sewage treatment and other industries.

Outside Diameter of Tubing Joint: From 2-3/8"(60 3mm) to 4.5"(114.60mm) Pipe End: EUE/NUE Outside Diameter of Casing Joint: From 4-12"(114 3mm) to 20*(508mm)

PUP JOINT DRILLING, PUP JOINT INC, PUP JOINT, PUP JOINT OIL AND GAS, NPST PUP JOINT, API PUP JOINT DIMENSIONS, PUP JOINTS FOR SALE. DRILL, API, API 5CT, CASING, EUE, PIPELINES, TUBING,

Hot Tags: pup joint drilling, China, suppliers, manufacturers, factory, low price, for sale, in stock, made in China, ERW Structural Pipe, Socket Weld Cap, Class150 Blind Flange, Api 5l Line Pipe, Steel Pipe Reducer, Oil Casing and Tubing

8613371530291

8613371530291