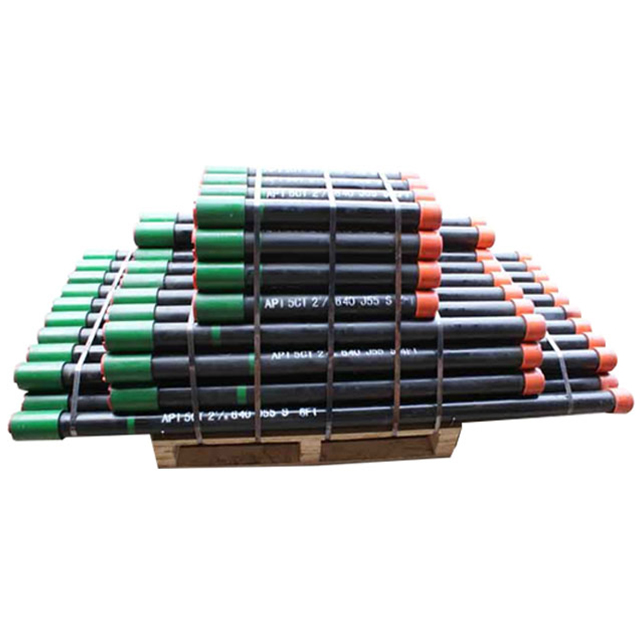

pup joint octg in stock

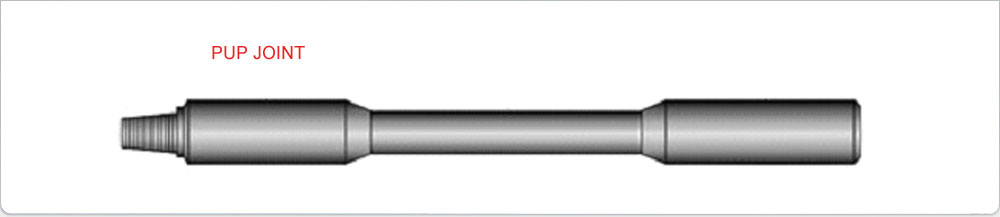

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

OCTG Pup Joints is one kind of common accessories for connection with casing and tubing. Threaded pup joints are divided into male threaded ends, single male threaded and Female threaded. The size and material is the same as the casing or tubing.

China N80 Pup Joint Manufacturer Derbo Supplies N80 Pup Joint, Hot Rolled, 1.66 Inch, EUE 2.40lb/ft, Oiled, Painting Finish, for Oil & Gas Industries.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Cressman Tubular carries a full range of both ERW and seamless OCTG tubing and casing stocks from 1.315 through 20 inches in grades to HCP110 and chrome product to 28% CR. From both foreign and domestic sources, we offer most customer requested industry options including both internal and external coatings, special clearance couplings, flush joints, gas-tight and semi-premium connections along with our traditional API end finishes.

Other “critical need” oilfield-related products are available on short notice through exclusive relationships with specialized industry partners. Cressman Tubular provides new and used, inspected drill pipe with varying tool joint options as well as sucker rods, pup joints and OCTG couplings.

Blast joints are commonly used in casing perforating operations. Their key characteristic is that they have the OD of the coupling and the ID of the tubing, which results in a high wall thickness. Thus, Blast Joints are more resistant to the erosion and wear which mainly occurs in high velocity flow areas in the casing annulus, which are often referred to as blast. They increase the safety and reliability of operations by reducing the risks of leakages.

Both proprietary and API standard accessories are available, including marker joints and pup joints. Many of these products are in stock and ready to deliver making your project as time efficient as possible.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

We care about your needs, we pay attention to the quality of Steel Pipe Seamless Nipple & Pup Joint; Oil OCTG Casing & Tubing Pup Joint Oilfield Services J55/K55/N80/L80/P110/C95/T95/80s, your satisfaction is our eternal pursuit, quality and integrity is our goal. We strictly and seriously fulfill our contracts, keep our promises and strengthen our network system of after-sales service. We set up a sense of quality service and do our best to do the entrusted project of each contracted customer.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

A pup joint is a pipe without standard length. API SPEC 5CT pup joints are used to adjust the height of full length tubing or casing strings to exact requirement. They are also applied to adjust the depth of downhole tools. In order to cater to the needs of customers, JST is offering a broad range of API SPEC 5CT OCTG pup joints.

2.With our sophisticated manufacturing facility, we produce these joints by using high grade raw materials (which are sourced from vendors of high repute) and cutting edge technology to ensure their sturdy design and longer functionality.

Jiangyin Changjiang Steel Tube Making Factory is a leading manufacturer and supplier of seamless steel pipes and various special pipes in China. We mainly manufacture structure pipe, fluid pipe, high pressure boiler pipe, API pipe, marine pipe, alloy pipe, tubing, casing, line pipe, OCTG pup joint (such as API SPEC 5CT pup joint), etc. Our company sets up a steel tube technology R & D center with advanced pipe testing equipment. Through strict testing process, we are able to produce high quality steel pipes for customers. Our products have been exported to the Middle East, CIS, Southeast Asia, Africa, South America, North America, Europe, Australia and many other countries and regions.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

OCPL offers a wide range of OCTG Casing Pup Joints, with both API and premium threads, manufactured at our select API spec. 5CT compliant steel mills.

NOTE:OCTG casing to suit Coupled; Semi-Flush and Flush connections, with casing ID to suit your poundage (including clearance couplings & special drift ID).

Swivel Joints and Blast Saves are our widely recognized premium solutions for ensuring the best performance, endurance and quality in intelligent completion design. With dual metal-to-metal seals, they are available in a range of sizes, metallurgies and steel grades, and their upper and lower ends can be customized for many of our premium connections.

Our Swivel Joint premium connectors are designed to solve alignment problems during dual completion or intelligent completion installations. Furthermore, our Swivel Joints Torque Transmission (TT) can withstand torque in excess of the maximum make-up torque of premium connections.

8613371530291

8613371530291