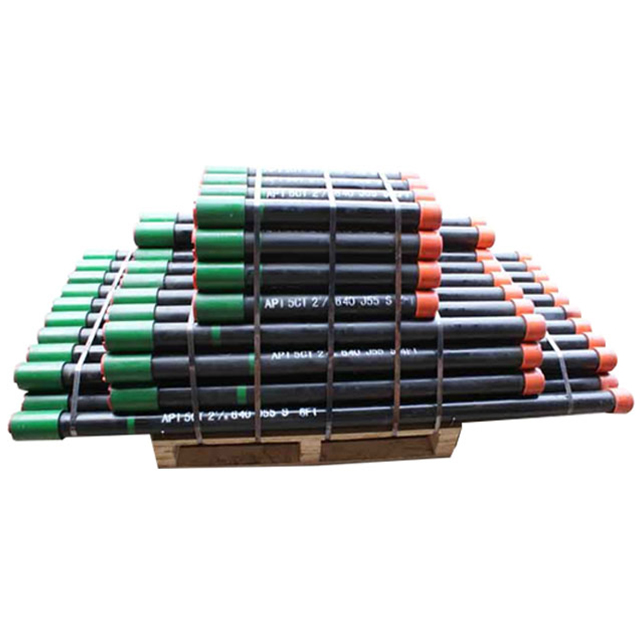

pup joint oil field pricelist

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for pup joint drill pipe at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale pup joint drill pipe you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the pup joint drill pipe from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then pup joint drill pipe that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of pup joint drill pipe at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale pup joint drill pipe that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

A premium provider of oil field equipment and service parts, Parveen Industries Pvt. Ltd is focused on high-quality manufacturing of premium-grade oil and gas field equipment that exceeds international standards. At its eight large-scale facilities, Parveen manufactures products that not only support the existing oil and gas industry but drive forward industry-wide innovation.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

We care about your needs, we pay attention to the quality of Steel Pipe Seamless Nipple & Pup Joint; Oil OCTG Casing & Tubing Pup Joint Oilfield Services J55/K55/N80/L80/P110/C95/T95/80s, your satisfaction is our eternal pursuit, quality and integrity is our goal. We strictly and seriously fulfill our contracts, keep our promises and strengthen our network system of after-sales service. We set up a sense of quality service and do our best to do the entrusted project of each contracted customer.

Flow iron pup joints from Cameron deliver maximum total lifecycle cost savings, even in the oil and gas industry’s most demanding applications. For all of your flow iron requirements, from high-stage-count hydraulic fracturing to cementing, well testing, and even abrasive flowback, you can count on Cameron for high reliability and low cost.

Cameron offers flow iron pup joints in standard 2- and 3-in sizes and lengths from 2 to 10 ft with 1502 hammer wing unions and nonpressure seal threads (NPST).

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

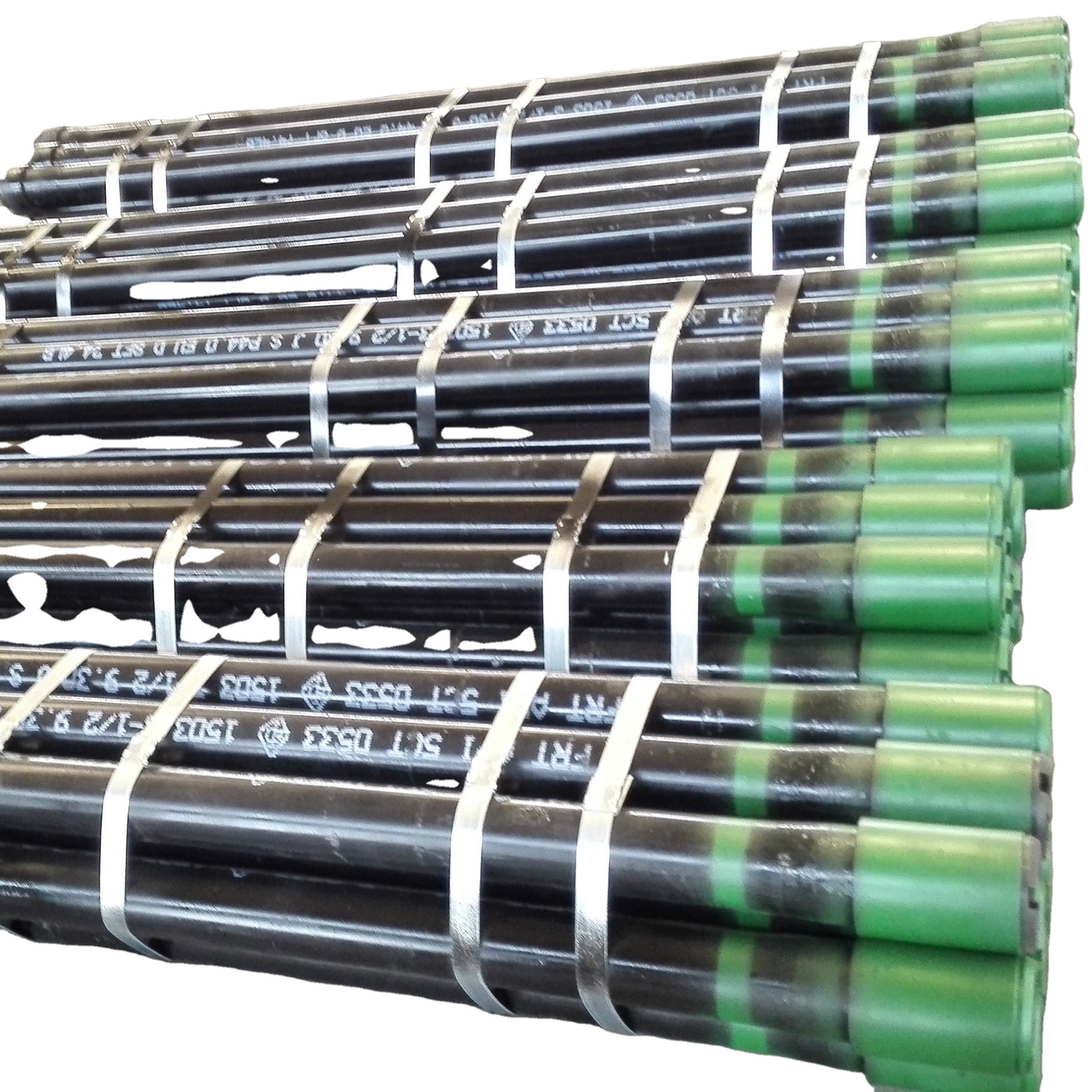

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

Prithviraj Industries manufactures Pup Joints up to 20, 000 psi cold working pressure in sizes: 1, 11 /2, 2, 3, and 4-inch bore sizes, lengths to 20 feet.

Shreeraj Industries offers NPST (Non-pressure Seal Thread) Pups in size 1-3 Fig 602 and 1502. The NPST connection offers a light weight pup capable of 6000-15000 CWP with a connection that isolates the thread from fluid’s flowpath. This connection is permanent and is well suited to abrasive applications where a weldedread more...

- Grant Prideco pup joints are manufactured from the same material as our drill collars. Heat-treatment processes ensure a hardness range of 285-341 Brinell. Charpy V minimum impact strength of 40 ft-lb at 70° F are guaranteed one inch below the surface.

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

Blaze Sales & Service has been outfitting the oil and natural gas industry with top quality Oilfield and downhole equipment supply and services. Offering sales, rental, replacement and repair services, we cater to a broad range of customer needs. From downhole equipment, 1502 plug valve, flow iron, pup joint, plug valve and trash catcher manifold, plug and gate valve, ridge plug, hydraulic packers, cement retainers, 1502 swivel joint, 1502 Chiksan, 10K needle valve, 15k needle valve, pressure gauge, Needle valves, Auto clave fitting, High pressure adapters and Changeover and crossover adapters, flowback and frac to coil tubing, workover rigs and supply stores, we deliver leading equipment that exceeds industry standards and regulations.

Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. These are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Blast joints manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customer’s request. Typical lengths are 10" and 20".

Octg refers to Oil Country Tubular Goods which refer to the pipe and tube products that are used in the petroleum industry. Octg are primarily of three kinds. They are:Drill pipes

Supply of Octg depends upon a number of factors. Octg Supply also takes in casings, tubing, drill pipes, pup joints, drill collars, HDD rods, crossovers and other related premium tubular products and many other Octg accessories. The accessories of Octg take into account of the Supply of the following:Pup joints

Octg also takes in production pipes as well as structural pipes. Octg Supply of the former takes into account production casing, production rods as well as production tubing, whereas Octg Supply of the latter takes into account structural casing, structural rods as well as structural tubing. Supply of the Oil Country Tubular Goods primarily includes 3 kinds of seamless tubes that are generally delivered in tempered and quenched condition. Supply of Country Tubular Goods comprises the casing pipe, drill pipe and tubing. Now, take a look at the different kinds of Octg supplies.

Types of the Oil Country Tubular Goods SuppliesThe first and foremost category in this regard is the drill pipe, the Supply of which is available in most Octg Supply firms. These are in fact heavy as well as seamless tubes which rotate the drill bit as well as enable the circulation of the drilling fluid. The tool joints are often towed along with the joints of pipes that are 30 ft or 9m in terms of length.

Thirdly, Oil Country Tubular Goods supplies consist of the tubing which refers to the pipe through which the gas or oil is produced from the well bore. Generally, the tubing joints are more or less 30ft or 9 m in length along with a connection by a thread on either end.

Oil Country Tubular Goods take in drill pipes and production tubes that can be supplied in a good variety of designs, sizes and metallurgical combinations and are manufactured out of seamless pipes that have a high quality and are connected with the required specifications of API or Application Programming Interface. Oil Country Tubular Goods can be supplied by different kinds of suppliers according to the following:Specifications

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

8613371530291

8613371530291