pup joint schlumberger factory

In most completions, the length of tubing available at surface is not enough for proper wellhead installation and operation. Pup joints and varying lengths of tubing are used to adjust the production string length as close as possible to the desired value. Then, the adjustable union or joint is installed, rotationally adjusted, and locked to the desired makeup length. In dual completions, the tool can be used to adjust the length of the short string.

The adjustable, telescoping action of the union or joint allows it to be set and locked at any desired position within its adjustment length while maintaining pressure integrity in the tubing string. Once the tool is in place, the desired amount of tension, weight, and rotational torque can be applied through it to the tubing.

A joint of tubing or casing included in the string at a known position to provide a reference point for further operations. A short pup joint that registers clearly in a collar locator log is a common flag joint.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly�s, subs and pup joints, and pipes.

Through our subsidiary HOWCO, SCOA provides oil field equipment and services from companies such as Schlumberger, Baker Hughes, Cameron, FMC, and others. The market size of oil field service related businesses is much bigger than that of OCTG distribution.

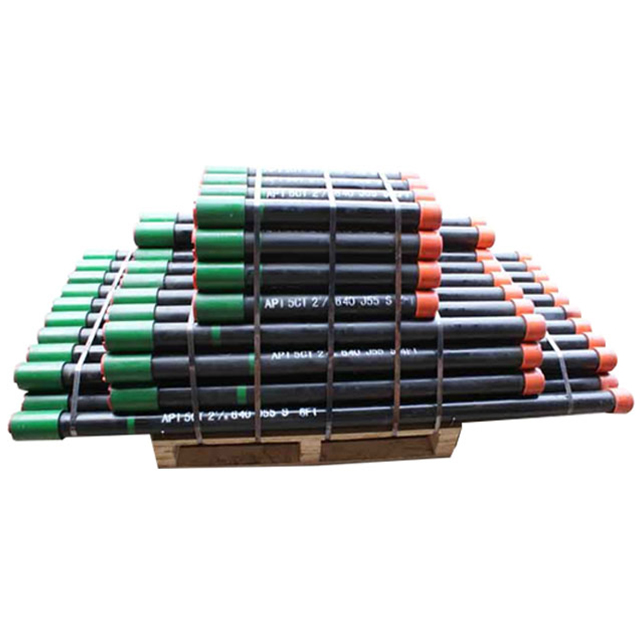

API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling

API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling API 5CT Oil Pipe Carbon Steel 3-1/2" NU Tubing Pup Joint With Coupling

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

A fourth aspect of the present invention relates to a gas or oil tubing collar or pup joint, said joint having tubing engagement means that connectably engage a first well

A pup joint is essentially the same as the collar joint but with the addition of an extended length of pipe between the tubing engagement means that connect to the first and second tubing respectively.

It is envisaged that the alloy could be melted so as to supplement the seal formed by the interaction between the tubing engagement means and the tubing engaged by the collar or pup joint, which is preferably achieved by co-operating screw threads provided by the tubing and the tubing engagement means. Alternatively the alloy may only be employed when a leak is discovered at the collar joint.

Preferably each of the alloy rings is mounted within recess in the collar joint. In this way the alloy does not obstruct the insertion of tubing into the collar.

It is envisaged that when the collar joint is being used to connect two sections of tubing in a substantially vertical plane the alloy ring will be retained in a recess above the tubing engaging means so that when the alloy is melted it will flow downwards under gravity into the join formed between the tubing and the tubing engaging means (e.g. screw thread).

Advantageously the pup joint may further be provided with a temporary plug in the form of a burst disc. In this way the pup joint can be used to provide a temporary zo plug within the well.

The ability to provide temporary, non-permanent, well plugs is desirable during completion. The above mentioned collar joint provides this functionality during the construction of a well.

Figure 16 shows a diagrammatic cross-sectional representation of an embodiment of the collar joint provided by the fourth aspect of the present invention;

Figure 17 shows a diagrammatic cross-sectional representation of the embodiment of figure 16 being heated to cause the alloy to flow into the join between the tubing and the collar joint.

In the shown example the tubing 1 is attached to the top of the tubing 6. It is envisioned that advantageously the tubing 1 of the present invention may be connected to existing production tubing 6 using the collar joint of the present invention shown in figures 16 and 17, although this is not considered essential. It is appreciated that alternative approaches to deploying a series of sections of well tubing can be employed in concert with the present invention.

Figures 16 and 17 provide cross-sectional views of an embodiment of a collar joint 40 according to a fourth aspect of the present invention. The collar joint is provided with a first tubing engagement means 41a and a second tubing engagement means 41b, both in the form of inwardly facing screw threads. As will be appreciated from figure 17 in particular the screw thread 41a and 41b engage with complementary screw threads 46 and 46a on tubing sections 45 and 45a.

Although the screw threads of the collar joint are shown as facing inwards it is envisioned that the screw orientation of the screw threads on the collar and the tubing could be reversed without departing from the present invention (i.e.

In the embodiment being described the collar joint is provided with two separate rings 42 and 43 or eutectic/bismuth alloy, one for each screw thread. The upper alloy ring 42 is located in a recess (shown as 47 in figure 12) located above the upper screw thread 41a of the collar joint 40. The lower alloy ring 43 is located in a recess (shown as 48 in figure 12) above the lower screw thread 41b.

In the event that the joint between the adjacent sections of tubing 45, 45a develops a leak heater 49 is deployed via the tubing 45 to a point that is adjacent the collar joint 40 via a standard delivery means 50 (e.g. wire line). Once in place the heater 49 can be operated to heat the alloy rings, which can then flow under gravity into the screw threaded joint located below the respective recesses 47, 48. The alloy is then allowed to cool and expand within screw threaded region to enhance the seal formed.

Although the alloy rings are intended for use only when a leak develops at a joint it is also envisaged that the alloy may be deployed even when there is not leak with the sole purpose of providing an enhanced seal at a joint section.

8613371530291

8613371530291