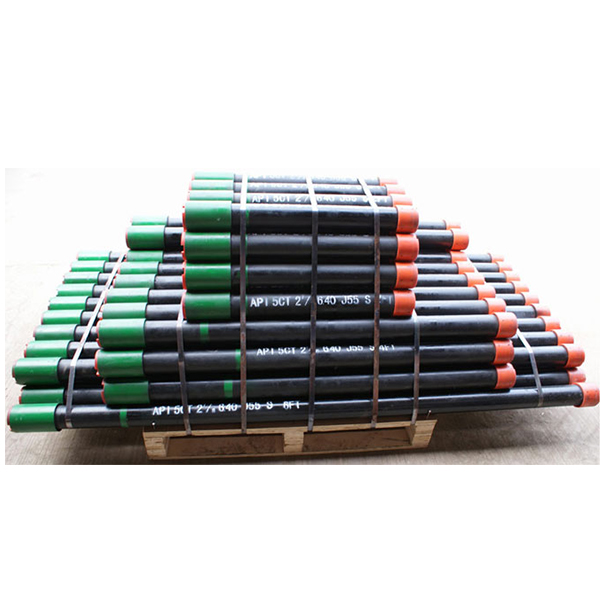

pup joint yield strength api factory

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Pup joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup joints are heat-treated to 110,000 psi minimum yield. All connections are phos-coated to impede galling during initial make-up. They are available in standard lengths of 5′, 10′, 15′ and 20′ with other configurations upon request.

Pup joints are commonly used to adjust the length of the drill string to the elevation of rotary table for easy surface handling and drilling practices. They undergo the same stresses as drill pipe and their performance depends primarily on their superior mechanical properties.

API 5CT J55 and K55 casing and tubing are relatively low grade material pipe among all API 5CT pipes, they have same chemical composition and same yield strength 379-552 Mpa but in different tensile, J55 tensile strength minimum 517 Mpa which K55 is 655 Mpa. J55/K55 are lower grade than N80, L80, P110 or T95, so they are a cheaper option material and widely used in non corrosive oil well installation without high strength requirement.

API 5CT defines delivery conditions for steel casing and tubing pipes used for oil wells installation, it covers pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.

As we know steel casing pipe is considered as a pipe pile that will stabilize the oil well. Casing is installed in oil well downhole to provide structural integrity to the wellbore and bear external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It needs to take pressure from its own weight and withstand the torque and transaxial pressure placed on it while running downhole.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

Every step of production process is performed with the highest degree of accuracy to meet or exceed API Specifications as well as the Industry Standards.

It is a short drill pipe used to adjust the overall length of drill string. The surface of Drill Pipe Pup joint looks like a smaller version of joint of drill pipe.

The minimum yield strength of Drill Pipe Pup Joint is 120000 PSI, just like the Tool Joint of the Drill Pipe. We manufacture Drill Pipe Pup Joints of all sizes, grades, and thread profiles to meet any custom requirements.

All our products have passed the ISO certification and API certifications.We have become the reliable exporter of Drill Pipe Pup Joint in India. Our products are tested numerous times under technical guidance and are made from best quality material.

For couplings, pup joints and accessories the analyses requested shall be furnished by the steel manufacturer or processor and shall be taken from material in tubular or bar form.

For Groups 1, 2 and 3, when requested by the purchaser, the manufacturer shall furnish a report giving the heat analysis of each heat of steel used in the manufacture of API 5CT CASING TUBING, coupling stock and couplings furnished on the purchase agreement. In addition the purchaser, upon request, shall be furnished the results of quantitative | analyses for other elements used by the manufacturer to control mechanical properties.

For Grade Q125, the manufacturer shall furnish a report giving the heat analysis of each heat of steel used in the manufacture of API 5CT CASING PIPE, coupling stock and couplings furnished on the purchase agreement. The report shall I include quantitative analyses for other elements used by the manufacturer to control mechanical properties.

One tensile test shall be made as a control on each heat of steel used by the manufacturer for the production of API 5CT CASING PIPE under this International Standard. For electric-welded pipe, these tensile tests shall be made on either the skelp or the finished API 5CT CASING PIPE , at the option of the manufacturer.

The lengths for testing shall be selected at random and, when more than one test is required, the selection procedures shall provide samples representing the start and end of the heat-treat cycle (as applicable) and front and back ends of the tubes. When more than one test is required, the test specimens shall be from different lengths, except for upset API 5CT CASING PIPE the test specimens may be taken from both ends of one length.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

The primary use of the pup joint is to adjust the overall length of the drill string to land at a specific depth while staying within the working area of the Kelly.

Command Tubular pup joints are manufactured from the highest quality API seamless tubing, per API specifications 5CT latest edition and are machined from integral bars of chromium molybdenum alloy steel. Pup joints with tool joint OD less than

6 7/8” have minimum yield strength of 110,000 psi. Pup joints with tool joint OD less than 6 7/8” or larger have minimum yield strength of 100,000 psi. Our pup joints are available from 2 feet to 25 feet in lengths however, standard lengths are 5, 10, 15 and 20 feet. Additional sizes are available upon request and can be ordered to match standard drill pipe dimensions.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Pup Joints are short drill pipe used to adjust the length of the drill string and are available in standard lengths of 5", 10", 15", 20" and can be ordered to match other drill ...

8613371530291

8613371530291