what is a pup joint used for manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

CountryAfghanistanAland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo (Brazzaville)Congo (Kinshasa)Cook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHondurasHong Kong S.A.R., ChinaHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyIvory CoastJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao S.A.R., ChinaMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth KoreaNorwayOmanPakistanPalauPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaSaint BarthélemySaint HelenaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth KoreaSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVaticanVenezuelaVietnamWallis and FutunaWestern SaharaYemenZambiaZimbabwe

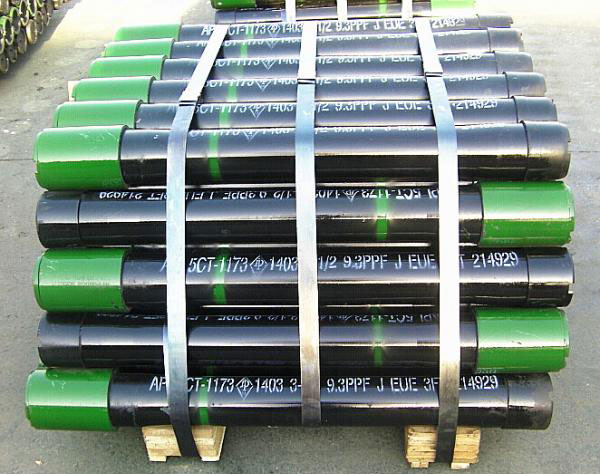

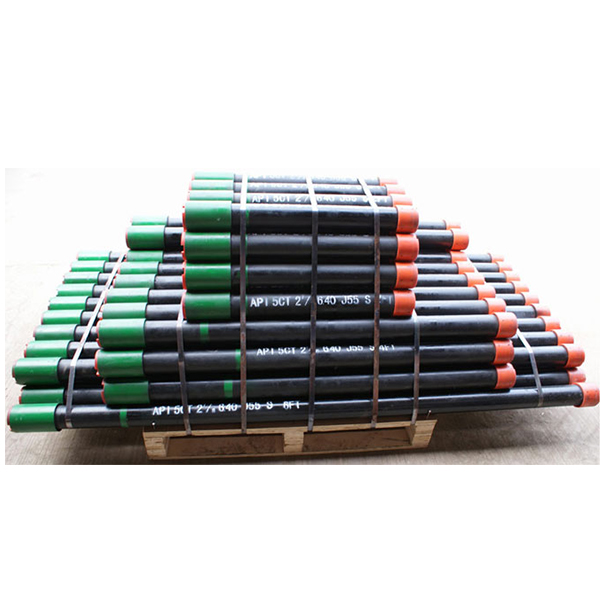

Pup joints are non-standard lengths of piping used to adjust the height of full length tubing, drill pipe, line pipe, or casing strings. Strings of pipe are assembled with standard length tubular goods that are typically 31 feet in length. As the drill string, production tubing, or casing is lowered into the well bore a pup joint is added to the pipe string in order to adjust the length of the string to its exact requirements.

Pup joints are offered in either two or five foot increments with custom lengths available on request. They are distinguished by the type of piping they are used with such as casing pup joints, tubing pup joints, or drill pipe pup joints. They are also distinguished by the nominal outside diameter of the pipe itself ranging from ¾” to 20″ or more dependent on the type of tubular goods they mate with.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

Stewart Tubular Products will manufacture Pup Joints to any length – inch or metric. Typical lengths are 2’, 4’, 6’, 8’ and 10’. Either API or proprietary threaded connections may be provided. Pup Joints manufactured by Stewart Tubular Products are available in all API and proprietary grades of steel, stainless steel and CRA steel.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API Spec5CT specification. The steel grades of the products of this kind are J55, K55, N80 and L80 P110. These products feature high corrosion resistance and long running life. As a pup joints supplier, we also produce the API 5CT tubing pup joint which is the fitting of the tubing strings. And we promise that all our casing pup joints are in high quantity.

The certificates we hold include License of the Business Corporation, Tax Registration Certificate, People’s Republic of China Organization Code Certificate, Registration Certificate of the Customs of the People’s Republic of China on Customs Declaration by Consignees and Consigners of Imported & Exported Goods, Registration Certificate of Foreign Trade Operator, API 5CT certificate, GOST certificate and quality management system certification.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API...

Line pipe is a tube made of high strength carbon steel. It is typically manufactured according to the API 5L metallurgical specification developed by the American Petroleum Institute (API) ...

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Prefabricated Pup joints & fittings are used for temporary operations and removable piping systems. Each component is fitted with wing union ends for fast and easy installation. Commonly used in upstream oil & gas well sites, it can be useful in all industrial applications.

Multiphase oil and gas well effluent, drilling fluids, water, chemicals, abrasive and corrosive fluids, cement, refined hydrocarbons, hydraulic oil, etc.

Each element is serialised and data is engraved onto individual stainless steel collar. Pressure rating is easily identified with stenciled or painted colour band(s) and rating markings.

Six combinations of equal tee fittings are available. When ordering tees, specify your requested position of male and female ends from left to right and perpendicular branch (M for male, F for female) as shown on figure: 1 x 2 x 3.

Special formats may be required in some piping systems such as wyes, laterals and crosses. FCE manufactures special fittings to client requirement comprising special shapes or specific materials.

FTE supplies racked containers to customer requirements which offer easier storage and ergonomic access. Proper racking also provides protection and an easier visual check of piping elements.

The tie-down clamp is one of the piping accessories supplied by Flow Test Equipment. The use of tie-down clamps may protect against severe damage and serious personal injury in case of unexpected failure under pressure and flowing conditions.

Incorrectly tighten union because of damaged threads makes the use and operation unsafe. Essential care by protecting threads during handling will improve your safety level. Hard plastic ACME thread protectors for wing unions are available.

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

It is produced according to API 5CT Specification. Our precision-engineered pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. As a tubing pup joints manufacturer in China, we also provide API 5CT casing pup joint which is the accessory of the casing strings.

Our tubing pup joints have passed the ISO9001:2000 international quality management system certification and the API certificate of the American Petroleum Institute.

1.Before sale, our company can provide samples and plans for clients according to the given budget. The costs should be borne by clients. We also provide some wearing-parts of the tubing pup joint like thread protector.

2.The delivery time depends on the order quantity. The minimum quantity is 20 t. We provide the pup joints to clients and positively cooperate with the third party on the supervision and inspection arranged by the clients.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API...

Tubing coupling is a type of drilling tool used in oil field. It is mainly used for connecting oil pipes. This pipe coupling has solved the problem that the existing couplings tend to crack due ...

We provide many of the most common tools and accessories used in OCTG. As a single source supplier, we added this capability to complement the full-length threading and ease the supply chain with a one-stop supplier.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

FLOAT EQUIPMENT, normally collars and shoes are housing of various sizes of casing supporting the cementing application in well construction. We manufacture to customer print all sizes and varieties of collars and shoes.

CROSSOVERS can be a critical element in well construction, completion and workover; to change size and thread connection for specific requirements without changing the entire well design. We manufacture crossovers of all sizes and with our thread licenses, matching and miss-matching connections to integrate most tools and accessories in the well. Refer to our quality page for specific applications and licenses.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly�s, subs and pup joints, and pipes.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

Swages are generally Box x Pin with a transition on the outside diameter and the inside diameter of the swage to assure that there are no sharp corners to set up an area of stress risers. When stress risers occur, there is a chance that the part could fail due to the fact that the part would be prone to crack in these areas.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

A lift sub falls under the drill string accessory tool category and utilized to mobilize various tools during drilling or fishing operations. Lift Sub are manufactured to the following specs connections, lengths, weights and material grade.

A circulating sub falls under the downhole accessory tool category that regulates flow rates, especially drilling in slimhole wells or wellbore cleanout projects. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Circulating Sub/Swages are manufactured from AISI 4140/4145. They typically are female hammer union on the top end and an IF pin on the bottom end, but can be manufactured with any size and style connection.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

A side-entry sub falls under the drilling tool accessory category to allow various drilling, fishing, wireline operations through drill pipe without interference from the rig"s top drive unit. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Side Entry Subs are manufactured from AISI 4140/4145. They are manufactured from one piece. They are typically rotary shouldered pin by box with 2” 1502 female hammer union, but can be manufactured with any size and style connection.

These can be made Rotary Shoulder Box Up x Pin Down with the ½ union on the side, we can build with any combination of the connections placed anywhere on the sub. All of Crossover’s Side Entry Subs are Integral manufactured which means that the sub is one piece and has no heat affected zone from welding the ½ union onto the body.

The style shown is built from one piece of 4145M bar stock and the excess material milled away and then threaded. There are also Lift Caps which are Cast Steel Castings and are threaded with the correct thread, but the rest of the plug is casts to create the bail.

Some customers request Lift Caps with Pad Eye for lifting. These are also made out 4145M and can be manufactured to fit any of several shackles. They can be built with either the pin or the box facing down.

Crossover Pipe Scrubbing Wire Brush is used to brush and clean the ID of the casing and remove scale, rust, mud residue, and any other particles of debris.

These brushes are generally run on Rotary Shoulder Drill String to Brush the inside of Casing Down Hole. These brushes will remove rust, scale and other contaminates that build up on the inside diameter (ID) of the casing. Usually run in preparation of running a packer or some other piece of equipment that needs a fairly uniform ID to set.

Crossover Inside BOP Valves are manufactured from AISI 4145. Crossover"s one piece design is much more robust than the traditional two piece construction design. Crossover"s one piece design typically allows for standard connection OD"s and shorter overall length parts. This eliminates the service break which allows for quicker disassembly.

Crossover"s Drop-in Check Valve is a retrievable check valve. It is retrievable by means of a retrievable tool (gravel girdie) run in on wireline. When needed the check valve is pumped down the drill string to the landing sub. The dogs are locked in place with pressure from below the valve. The check valve will open to allow circulation and close when circulation is stopped.

A washover pipe is Casing or Pipe shorter in length than a standard tubular string. Made of large-diameter pipe with a cutting surface at the tip, washover pipe is run in the well and then the cutting edge grinds the fish to a smooth surface and continues normal operations. Washover Pipe is manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

Integral Pup Joints are straight tubes with union connections on both ends, widely used for transporting high pressure flow in fracturing manifold, cementing manifold, maintenance manifold and test manifold.

Jereh Integral Pup Joints are forged from premium alloy steel, handled by advanced metal melting and heat treatment technology. Based on the analysis on weight and resistance to erosion, Jereh has improved wall thickness and inner diameter to extend service life.

Standard types are available with different models, pressure and temperature rating. Integral Pup Joints special for sour service are also developed in accordance to NACE MR0175. Customized service is also available.

8613371530291

8613371530291