what is a pup joint used for brands

CountryAfghanistanAland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo (Brazzaville)Congo (Kinshasa)Cook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHondurasHong Kong S.A.R., ChinaHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyIvory CoastJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao S.A.R., ChinaMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth KoreaNorwayOmanPakistanPalauPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaSaint BarthélemySaint HelenaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth KoreaSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVaticanVenezuelaVietnamWallis and FutunaWestern SaharaYemenZambiaZimbabwe

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

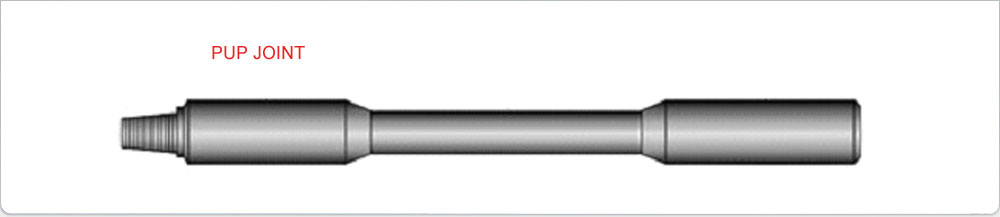

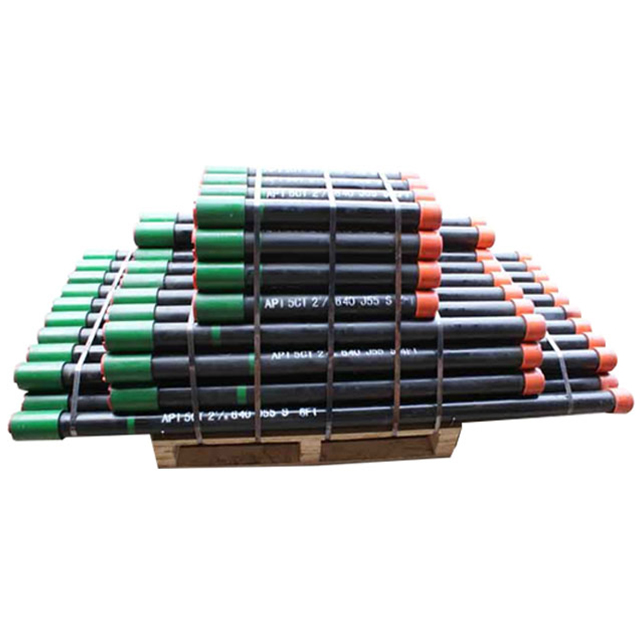

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

Swages are generally Box x Pin with a transition on the outside diameter and the inside diameter of the swage to assure that there are no sharp corners to set up an area of stress risers. When stress risers occur, there is a chance that the part could fail due to the fact that the part would be prone to crack in these areas.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

A lift sub falls under the drill string accessory tool category and utilized to mobilize various tools during drilling or fishing operations. Lift Sub are manufactured to the following specs connections, lengths, weights and material grade.

A circulating sub falls under the downhole accessory tool category that regulates flow rates, especially drilling in slimhole wells or wellbore cleanout projects. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Circulating Sub/Swages are manufactured from AISI 4140/4145. They typically are female hammer union on the top end and an IF pin on the bottom end, but can be manufactured with any size and style connection.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

A side-entry sub falls under the drilling tool accessory category to allow various drilling, fishing, wireline operations through drill pipe without interference from the rig"s top drive unit. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Side Entry Subs are manufactured from AISI 4140/4145. They are manufactured from one piece. They are typically rotary shouldered pin by box with 2” 1502 female hammer union, but can be manufactured with any size and style connection.

These can be made Rotary Shoulder Box Up x Pin Down with the ½ union on the side, we can build with any combination of the connections placed anywhere on the sub. All of Crossover’s Side Entry Subs are Integral manufactured which means that the sub is one piece and has no heat affected zone from welding the ½ union onto the body.

The style shown is built from one piece of 4145M bar stock and the excess material milled away and then threaded. There are also Lift Caps which are Cast Steel Castings and are threaded with the correct thread, but the rest of the plug is casts to create the bail.

Some customers request Lift Caps with Pad Eye for lifting. These are also made out 4145M and can be manufactured to fit any of several shackles. They can be built with either the pin or the box facing down.

Crossover Pipe Scrubbing Wire Brush is used to brush and clean the ID of the casing and remove scale, rust, mud residue, and any other particles of debris.

These brushes are generally run on Rotary Shoulder Drill String to Brush the inside of Casing Down Hole. These brushes will remove rust, scale and other contaminates that build up on the inside diameter (ID) of the casing. Usually run in preparation of running a packer or some other piece of equipment that needs a fairly uniform ID to set.

Crossover Inside BOP Valves are manufactured from AISI 4145. Crossover"s one piece design is much more robust than the traditional two piece construction design. Crossover"s one piece design typically allows for standard connection OD"s and shorter overall length parts. This eliminates the service break which allows for quicker disassembly.

Crossover"s Drop-in Check Valve is a retrievable check valve. It is retrievable by means of a retrievable tool (gravel girdie) run in on wireline. When needed the check valve is pumped down the drill string to the landing sub. The dogs are locked in place with pressure from below the valve. The check valve will open to allow circulation and close when circulation is stopped.

A washover pipe is Casing or Pipe shorter in length than a standard tubular string. Made of large-diameter pipe with a cutting surface at the tip, washover pipe is run in the well and then the cutting edge grinds the fish to a smooth surface and continues normal operations. Washover Pipe is manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

15.2. Company Profiles [Company Overview, Product Portfolio, Financial Information, (Subject to Data Availability), Business Strategies / Recent Developments]

Pup Joints are joints of tubing or drill pipe that are reduced in length. Pup Joints can range anywhere from 2 feet to 25 feet. They are very similar to standard joints of drill pipe and tubing except in most cases they have a reduced inside diameter matching that of the tool joint inside diameter.

A pup joint is a pipe of basically a type of non-standard length, which is used to adjust the length, specifically tubular strings to its customization requirement. Furthermore, API casing and tubing pup joints are manufactured generally according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. It is also used to adjust the height of full-length casing and tubing. These joints are mainly used as a depth identifier, such as the drill string, production tubing, or casing. A pup joint offers a wide range of applications in the energy sector, including renewable, coal, and gas, such as interconnect flowline, full traceability, and customized length adjustment according to their needs.

The COVID-19 has extremely affected the economy in the world in a negative way, hence the pup joint market also got affected abruptly and experienced a slowdown in the generation of revenue. There were strict regulations by governments of various countries, which caused reduction in demand for pup joints in the current scenario. Furthermore, industries are focusing on innovations during the lockdown situation, such that it could help gain attention of majority of the players during the forecast period.

The key factors affecting the industry include the recent technological advancements in drilling techniques, and quicker industrialization in the developing countries, is anticipated to boost the industry in the forecast period. Furthermore, the rise in the population which would boost in the demand for the natural gas and the oil are anticipated to help the pup joint market flourish in the next few years. The growth in the demand for high-grade pup joints within various industry verticals would boost the market in the coming years. Additionally, the growth in the energy consumption, economic development of the shipping industry, and surge in the seaborne trade are the major factors that propel the demand for pup joints in the next few years.

Major companies are focusing on the up gradation according to the need in the market in the coming years. The key players are focusing on bringing up the products which are the need of the hour which would help the industry in the next few years. For instance, Ace Oil Tools had launched its new Ace Splice Clamp (ASC) to the completions market. Allowing multiple lines to be spliced with a single clamp, the ASC is a “sub-less” downhole product that protects the control lines during completion.

Combining the functionality of a shrouded crimp clamp with a splice sub into one single product, the Ace Splice Clamp accepts a flat pack control line assembly. The design protects bare control lines and houses the splice blocks. The splice blocks can be provided by different vendors installing monitoring devices or can be hydraulically operated. By attaching the ASC to the tubing or a pup joint, the Ace Splice Clamp provides the same reliability and functionality that is usually offered by subs. The boost in the number of launches would help the industry propel in the coming years.

The boom in the demand for the pup joint to be utilized for the untapped business, are the main arena focused by the key players, and hence are bringing up the advancements in the coming years. The major players are focusing over bringing up increase in the number of acquisitions, such that there is an increase in the revenue generation, by utilizing the distribution channels of the acquired companies. This would help the industry propel in the next few years.

For instance, Forum Energy Technologies, Inc. (FET) announced the acquisition of SVP Products Inc., a leading provider of high pressure flow control equipment and products utilized in hydraulic fracturing and flow back of oil and gas wells. The company sells Forum’s Wood Flowline and Phoinix product lines, including swivels, plug valves, relief valves, chokes, pup joints and manifold trailers from three facilities in North, East and West Texas.

SVP also performs critical repair and recertification services of these products from its stores as well as from its fleet of mobile units. SVP’s customer relationships and service capabilities strengthen Forum’s Production and Infrastructure division, which provides completion products, engineered process and production systems, measurement and monitoring systems, construction and field services, and a full range of valve and other flow control products.

Key benefits of the report:This study presents the analytical depiction of the global pup joint industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global pup joint market share.

The report provides a detailed global pup joint market analysis based on competitive intensity and how the competition will take shape in coming years.

Key Market Players Anvil International, AZZ Inc., Dmh United Steel Industry Co., Ltd, Forum Energy Technologies, Inc., National Oilwell Varco, Oil Country Tubular Limited, Sledgehammer Oil Tools Pvt. Ltd, Stewart Tubular Products, Texas Pipe Works Inc., TPS-Technitube Röhrenwerke GmbH.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly�s, subs and pup joints, and pipes.

In most completions, the length of tubing available at surface is not enough for proper wellhead installation and operation. Pup joints and varying lengths of tubing are used to adjust the production string length as close as possible to the desired value. Then, the adjustable union or joint is installed, rotationally adjusted, and locked to the desired makeup length. In dual completions, the tool can be used to adjust the length of the short string.

The adjustable, telescoping action of the union or joint allows it to be set and locked at any desired position within its adjustment length while maintaining pressure integrity in the tubing string. Once the tool is in place, the desired amount of tension, weight, and rotational torque can be applied through it to the tubing.

Forum’s high-grade swivels enhance tool string rotation without transferring torque to the components above. Even under high tension levels, they decouple the tool string from the wireline to permit unrestricted rotation and prevent torque build-up. All of our swivels feature durable exteriors and internal precision features that adjust to the temperature and pressure fluctuations of well environments.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pup joints are a type of non-standard length pipe which is often utilized to adjust tubular strings to individual requirements. API casing and tubing pup joints are manufactured according to API Spec 5CT with API monogrammed, seamless oil country tubing. These joints are also used to adjust the height of full-length tubing and casing and are mainly applied as depth markers for drill strings, Products on tubing, or casing. A pup joint is widely used in the energy sector, including renewable electricity, coal, and gas. These applications include interconnecting flow lines, full traceability, and customized lengths based on the client"s requirements.

Further, the Pup Joint market is segmented by Product Type, Technology, End-User, and geography. Based on Product Type, the Pup Joint market is segmented under Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. Based on the Technology, the Pup Joint market is segmented under Hot Rolled and Cold Rolled. Based on End-User, the Pup Joint market is segmented under Chemical Industry, Mining,Oil & Gas, Construction, and Others. By geography, the market covers the following regions: North America, Europe, Asia-Pacific, South America, and Middle East & Africa. For each segment, the market sizing and forecasts have been done on the basis of value (in USD Million).

The key factors affecting the industry include technological advancements in drilling techniques and faster industrialization in developing countries. In addition, the rise in population will lead to an increase in the demand for natural gas and oil, which will help the pup joint market flourish during the forecast period. Growth in the demand for high-grade pup joints within various industry verticals is expected to boost the market growth during the forecast period. Additionally, the increase in energy consumption, economic development of the shipping industry, and surge in seaborne trade are the major factors driving the market.

The majority of major companies are focusing on upgrading their equipment according to market needs in the coming years. Key players are focusing on developing products that would benefit the industry in the next few years. As an example, Ace Oil Tools introduced its new Ace Splice Clamp (ASC) to the completions market. The ASC allows multiple lines to be spliced with a single clamp and protects control lines during the completion process. Ace Splice Clamps attach to tubing or pup joints, providing the same reliability and functionality that is usually offered by submersibles. The increase in launches will help the industry to grow during the forecast period.

Renewable offshore wind energy is becoming increasingly affordable, environmental-friendly and cost-effective. It will help to reduce greenhouse gases. During the forecast period, renewable energy is expected to be more affordable than existing oil and gas sources. It will act as a restraint on the global pup joint market.

A boom in demand for pup joints to be used for untapped businesses is where key players are focusing their efforts. This is leading to advancements in the coming years and giving opportunities to key players. To increase revenue generation, major players are focusing on acquiring more companies so that they can use the distribution channels of the acquired companies. This is a significant opportunity for key players.

COVID-19 has greatly affected the world economy in a negative way, which is why the pup joint market suffered a decrease in revenue. The government of several countries implemented strict regulations on pup joints, which greatly negatively affected the market. Moreover, the lockdown situation is causing industries to focus on innovations, which could help gain the attention of the majority of players during the forecast period.

By Product Type,the Pup Joint Market is segmented into Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. The Tubing Pup Joint segment had the highest market share in 2021. Because these pup joints are also used to handle production tubing accessories, the tubing pup joint segment is expected to have a huge demand. A tubing pup joint is a short piece of tubing that is used for spacing.

By Technology, the Pup Joint Market is segmented into Hot Rolled and Cold Rolled. The Hot Rolled segment had the highest market share in 2021.The most common type of pup joint is the hot-rolled pup joint. Steel is heated to a high temperature and then rolled into a cylindrical shape. This type of pup joint has higher tensile strength, but it is also less corrosion resistant.

By End-User, the Pup Joint Market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. The Oil & Gas segment had the highest market share in 2021, and it will boost the market growth during the forecast period.As various emerging economies rely on petroleum-based products, dependence on oil & gas has increased. Petroleum is used to make various chemical products, including fertilizers, pharmaceuticals, and solvents. Private and public companies are showing interest in exploring new oil reserves to meet future demand. Investment by major companies in oil exploration is expected to boost the market for pup joint ventures.

The North America region held the highest market share in 2021.The pup joint industry is the leading revenue generator for the North American market. The growing demand for energy from the oil & gas and chemical industries in this region is driving the growth of this market. As a result of technological advancements and an increase in foreign direct investment for various exploration projects, manufacturers are also entering new markets in developing countries like Mexico and Canada.

The South America region has witnessed a fast-growing market during the forecast period. A major factor that will boost this market"s growth is the increasing demand from various industries, such as oil & gas, chemical, mining, and construction. In addition, the growing infrastructure development in countries like Brazil and Mexico is driving this market"s growth.

The market is characterized by the existence of a number of well-known firms. These companies control a large portion of the market, have a wide Product Type portfolio, and have a global presence. In addition, the market comprises small to mid-sized competitors that sell a limited variety of items, some of which are self-publishing organizations.

The market"s major companies have a significant impact because most of them have extensive global networks through which they can reach their massive client bases. To drive revenue growth and strengthen their positions in the global market, key players in the market, particularly in North America and Europe, are focusing on strategic initiatives such as acquisitions, new collection launches, and partnerships.

The objective of the report is to present a comprehensive analysis of theGlobalPup Joint market to the stakeholders in the industry. The report provides trends that are most dominant in the GlobalPup Joint market and how these trends will influence new business investments and market development throughout the forecast period. The report also aids in the comprehension of theGlobalPup Joint Market dynamics and competitive structure of the market by analyzing market leaders, market followers, and regional players.

The qualitative and quantitative data provided in theGlobalPup Joint market report is to help understand which market segments, regions are expected to grow at higher rates, factors affecting the market, and key opportunity areas, which will drive the industry and market growth through the forecast period. The report also includes the competitive landscape of key players in the industry along with their recent developments in theGlobalPup Joint market. The report studies factors such as company size, market share, market growth, revenue, Product Type Typeion volume, and profits of the key players in theGlobalPup Joint market.

The report provides Porter"s Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals exist, who they are, and how their Product Type Type quality is in theGlobalPup Joint market. The report also analyses if theGlobalPup Joint market is easy for a new player to gain a foothold in the market, do they enter or exit the market regularly, if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political variables help in figuring out how much a government can influence theGlobalPup Joint market. Economic variables aid in the analysis of economic performance drivers that have an impact on theGlobalPup Joint market. Understanding the impact of the surrounding environment and the influence of environmental concerns on the GlobalPup Joint market is aided by legal factors.

Transparency Market Research delivers key insights on the global pup joint market. In terms of revenue, the global pup joint market is estimated to expand at a CAGR of ~7%during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in the global pup joint market report.

In the report, TMR predicts that the global pup joint market would be largely driven by factors such as increase in demand for oil & gas and increase in number of explorations. Rise in demand for high-grade pup joints, use of advanced drilling technology, and penetration in developing nations are set to drive the global pup joint market during the forecast period.

According to the pup joint market report, the product type segment includes crossover pup joint, drill pipe pup joint, and tubing pup joint; the technology segment includes hot rolled and cold rolled; the end use segment includes oil & gas, chemical industry, mining, construction, and others. Based on product type, drill pipe pup joint accounts for major share. Increase in drilling activities in various countries contributes maximum to this segment. The segment is projected to expand at a significant rate in the near future.

The oil & gas segment holds maximum share in the global pup joint market. Economic growth and high demand for electricity has increased the demand for offshore exploration and production activities worldwide.

Volatility in raw material prices has an obvious impact on pup joint manufacturers. Fluctuating prices of raw materials have impact on the production of pup joints.

Geopolitical situations such as the ongoing troubles in Iran, and Venezuela and Qatar’s exit from OPEC is likely to influence oil and gas supply. Renewable and alternative energy coupled with government pressure and environmental legislation is another threat to traditional oil & gas companies. Government and private companies are showing keen interest in exploring new oil reserves to meet future demands.

Rising demand for oil & gas is set to increase drilling activities. New drilling technologies such as horizontal drilling and hydraulic fracturing is expected to have a positive impact on the oil & gas market. These factors are expected to drive the demand for pup joints during the forecast period.

Middle East & Africa holds a major share of the global pup Joint market followed by Europe. Key players largely depend on geographical expansion, promotions, and technological advancements to cater to customer demand and gain a competitive edge in the global pup joint market.

Middle East & Africa accounted for approximately 30% share of the global pup joint market in 2018, followed by North America and Europe. It is anticipated to maintain its dominance in the market during the forecast period. Domestic production capacity is increasing in several countries; exploring undeveloped sites and exploring new sites for drilling is projected to generate more options for business growth.

Key players operating in the global pup joint market include Anvil International, AZZ Inc., Dmh United Steel Industry Co., Ltd, Forum Energy Technologies, Inc., National Oilwell Varco, Oil Country Tubular Limited, Sledgehammer Oil Tools Pvt. Ltd, Stewart Tubular Products, Texas Pipe Works Inc., and TPS-Technitube Röhrenwerke GmbH.

Transparency Market Research registered at Wilmington, Delaware, United States, is a global market research firm that offers Market Analysis Reports and business consulting. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

8613371530291

8613371530291