rongsheng petrochemical singapore pte ltd free sample

The moomoo app is an online trading platform offered by Moomoo Technologies Inc. Securities, brokerage products and related services available through the moomoo app are offered by including but not limited to the following brokerage firms: Moomoo Financial Inc. regulated by the U.S. Securities and Exchange Commission (SEC), Moomoo Financial Singapore Pte. Ltd. regulated by the Monetary Authority of Singapore (MAS), Futu Securities International (Hong Kong) Limited regulated by the Securities and Futures Commission of Hong Kong (SFC) and Futu Securities (Australia) Ltd regulated by the Australian Securities and Investments Commission (ASIC).

Registered with the Monetary Authority of Singapore (MAS), moomoo SG is a Capital Markets Services Licence (Licence No. CMS101000) holder with the Exempt Financial Adviser Status. Moomoo SG has been admitted as Clearing Member of The Central Depository (Pte) Ltd (CDP) , Trading Member of Singapore Exchange Securities Trading Limited (“SGX-ST”), Trading and Clearing Member of Singapore Exchange Derivatives Trading Limited (“SGX-DT”), and Depository Agent of CDP.

RONGSHENG PETROCHEMICAL CO., LTD. is a China-based company principally engaged in the research, development, manufacture and distribution of chemicals and chemical fibers. The Company’s main products include aromatics, phosphotungstic acid (PTA), polyethylene terephthalate (PET) chips, terylene pre-oriented yarns (POYs), terylene fully drawn yarns (FDYs) and terylene draw textured yarns (DTYs), among others. The Company distributes its products in domestic market and to overseas markets.

With the entire phase 2 project online, ZPC expects to lift its combined petrochemicals product yield to 71% from 65% for the phase 1 refinery, according to the source.

"Petrochemical contributes most of the companies" profit with healthy demand growth while the stakeholders have feedstock demand for their textile plants too," the source said.

Zhejiang Petroleum, a joint venture between ZPC"s parent company Rongsheng Petrochemical and Zhejiang Energy Group, planned to build 700 gas stations in Zhejiang province by end-2022 as domestic retail outlets of ZPC.

Established in 2015, ZPC is a JV between textile companies Rongsheng Petrochemical, which owns 51%, Tongkun Group, at 20%, as well as chemicals company Juhua Group, also 20%. The rest 9% stake was reported to have transferred to Saudi Aramco from the Zhejiang provincial government. But there has been no update since the agreement was signed in October 2018.

Oil prices tell some of the story. Early last year, as the economy froze up and people stayed home, crude prices crashed, dragging chemical prices down with them. Petrochemical volumes, however, were relatively strong because some products, such as polyethylene, saw an uptick in demand.

For instance, more than a dozen members of the Global Top 50 have major plastics recycling initiatives. A similar number of companies are looking to make ammonia and hydrogen via water electrolysis rather than from natural gas. Still others are overhauling basic petrochemical processes to make them more energy efficient. Dow, Shell, Sabic, and BASF, for example, are developing ethylene crackers that run on renewable electricity.

Despite the year’s volatility, the survey was marked by few changes. Companies heavily laden with petrochemical operations generally saw declines in sales and fell in the ranking. Companies that make industrial gases or agricultural chemicals tended to rise.

Three companies in the Global Top 50 a year ago didn’t make it this year. Ecolab fell off the list because it divested an oil-field chemical business. SK Innovation and PTT Global Chemical were both victims of declines in petrochemical sales.

Now that it is breaking out chemical sales again, Shell rejoins the Global Top 50 this year after a 5-year hiatus. Rongsheng Petrochemical, which makes polyester chemicals, debuts this year. The former DowDuPont agricultural chemical business, Corteva Agriscience, made the cut as well.

Saudi Arabia’s state oil company, Saudi Aramco, completed its purchase of a 70% stake in the petrochemical maker Sabic in June 2020. The purchase was meant to diversify Aramco, which today depends heavily on oil and gas. But soon after the deal closed, the firms announced they were reevaluating the scope of a planned complex that was to convert 400,000 barrels per day of crude oil into 9 million metric tons (t) per year of petrochemicals. Their new, more modest plan is to build an ethylene cracker and derivatives units that will be integrated with existing Aramco refineries. In another instance of Sabic and Aramco working together, the companies shipped 40 t of ammonia to a power plant in Japan last September. The ammonia is considered “blue” because carbon dioxide emitted during its manufacture was captured and used for enhanced oil recovery and methanol production in Saudi Arabia. In another strategic move, Sabic carved out a stand-alone business that includes its polyphenylene oxide, polyetherimide, and compounding units. The company got the businesses with its purchase of GE Plastics in 2007. Sabic had sought to combine them with Clariant’s masterbatch business, but those talks broke down in 2019.

The $9.4 billion petrochemical complex that Formosa Plastics is planning in St. James Parish, Louisiana, is in hot water. It faces fierce opposition both locally from community organizations worried about pollution and nationally from environmental groups that wish to stop the mounting production of plastics. Sharon Lavigne, head of the local group Rise St. James, recently received the prestigious Goldman Environmental Prize for her efforts, a sign that the Formosa project has high-profile opposition. The project also faces practical hurdles. Notably, the US Army Corps of Engineers suspended a permit for the facility in November. Formosa Plastics had better luck in Point Comfort, Texas, where it started up an ethylene cracker and low-density polyethylene unit last year.

Most large chemical companies nowadays are plunging into plastics recycling to counter public backlash, and LyondellBasell Industries is at the front of the pack. CEO Bob Patel is one of the founders of the Alliance to End Plastic Waste, formed by industry to address the recycling problem. And Lyondell has its own initiatives. It and the waste management firm Suez bought the plastics recycler Tivaco and are combining it with Quality Circular Polymers, a recycling venture Lyondell and Suez started in 2018. Quality Circular has some high-profile clients. For example, Samsonite is using its resin for a line of sustainable suitcases. Meanwhile, Lyondell continues to grow its core petrochemical business, often on the cheap. In December, the firm bought, for the bargain price of $2 billion, a 50% interest in a new ethylene cracker and two polyethylene plants that the struggling Sasol had built. Similarly, it bought into an ethylene cracker joint venture already under construction in China.

PetroChina will bring a pair of unique petrochemical projects—which cost a total of $2.5 billion—on line later this year. The company is building ethylene crackers in Tarim and Changqing, China, that will use ethane sourced from domestic natural gas fields as their feedstock. These projects wouldn’t be unusual in the US or the Middle East, where oil and natural gas are cheap and plentiful, but ethylene crackers in resource-constrained China are mostly fed with naphtha derived from imported oil. The country also sources petrochemical feedstocks from coal. Both routes to ethylene are relatively expensive and put China at a competitive disadvantage.

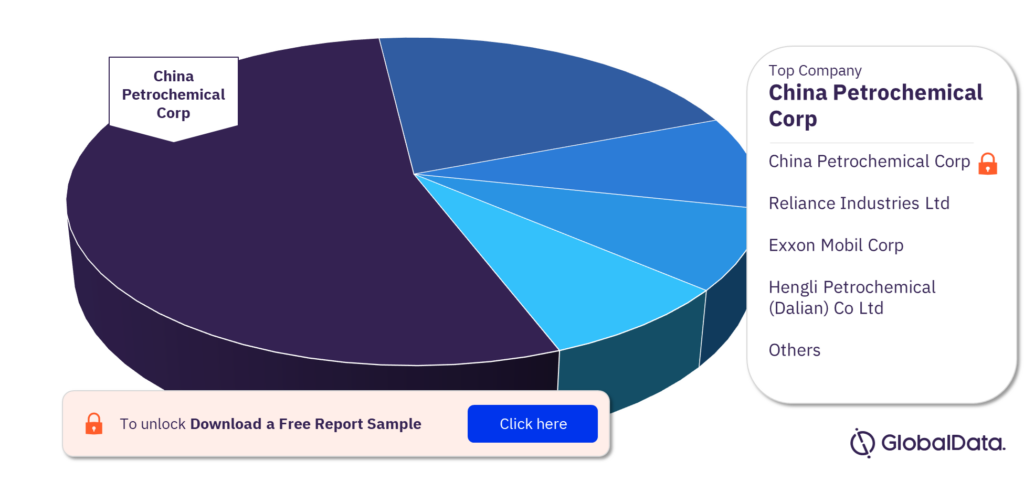

Hengli Petrochemical’s growth has been amazing. Last year, the company came out of nowhere to debut at 26 in the Global Top 50. In 2020, and despite the COVID-19 pandemic, the Chinese petrochemical maker’s chemical sales grew by a whopping 46%. Construction at an almost unbelievable pace is responsible for this growth. In 2020 alone, Hengli started two large production lines for purified terephthalic acid (PTA), a polyester raw material, in Dalian, China. The lines, which use technology from Invista, bring Hengli’s PTA capacity to 12 million metric tons (t) per year. In November, Hengli signed a licensing agreement, also with Invista, for two more PTA lines at its site in Huizhou, China. In addition, the company plans to build a plant in Dalian to make a biodegradable plastic from PTA, adipic acid, and 1,4-butanediol. Hengli says the plant will have 450,000 t of annual capacity, a large figure for a biodegradable plastic.

The Japanese chemical maker has emphasized green projects of late. In June, it signed an agreement to use Ginkgo Bioworks’ synthetic biology capabilities to improve the production of an undisclosed biobased chemical and to make other Sumitomo Chemical products. Sumitomo’s similar relationship with Zymergen resulted in a biobased film for displays and touch screens. Sumitomo is also building a pilot plant in Chiba, Japan, that will make ethylene from ethanol supplied by Sekisui Chemical. In addition, Sumitomo is planning a facility in Singapore that will make methanol from carbon dioxide and hydrogen. To investigate even more technologies with low environmental impact, Sumitomo is building a research facility in Chiba.

Many people would think of Dow and BASF as the technology giants in industrial chemistry. But Braskem, a Brazilian petrochemical maker, is a technological heavy hitter too. It is partnering with the University of Illinois Chicago on a route to ethylene based on the electrochemical reduction of carbon dioxide from flue gas. At its chlor-alkali complex in Maceió, Brazil, Braskem will host a pilot plant to make ethylene dichloride using a novel process developed by the start-up Chemetry. In this energy-saving process, called eShuttle, chloride ions react with cuprous chloride (CuCl) to form cupric chloride (CuCl2), which reacts with ethylene to form the polyvinyl chloride raw material. In Pittsburgh, Braskem recently completed a $10 million expansion of its technology and innovation center to allow work on recycling, 3D printing, and catalysis.

In June 2020, Bayer attempted to ensure its financial stability by settling 125,000 lawsuits claiming its Roundup glyphosate herbicide, which it acquired with its 2018 purchase of Monsanto, contributed to defendants’ non-Hodgkin lymphoma. Bayer is now trying to limit future liability related to the product. It is considering withdrawing glyphosate from the residential lawn and garden market, which has spurred the “overwhelming majority of claimants,” the company says. Bayer may form a scientific panel to review Roundup-related safety information, and it is launching a new website where it will host studies related to the product.

The Chinese polyurethane raw materials supplier bucked the general trend of sales decline in 2020 with a nearly 8% increase in chemical sales and a 10% rise in profits. After a weak first half of the year, demand bounced back in the second half, the company says. The COVID-19 “pandemic in China was rapidly and effectively controlled,” Wanhua Chemical says in its annual report. “Domestic market demands and the downstream export overseas were resumed rapidly, and growth of prices of chemical products was recovered.” Wanhua sought to build a beachhead in the US with a $1.25 billion project to build a methylene diphenyl diisocyanate plant in Louisiana. But US-China trade friction and a jump in construction costs appear to have prompted the firm to shelve the initiative.

Recent years have seen Chinese petrochemical producers, often involved in the polyester supply chain, join the Global Top 50. Hengli Petrochemical is one of those firms. And now Rongsheng Petrochemical is another. The company is one of the largest producers of purified terephthalic acid in the world, with 13 million metric tons of capacity at plants in Dalian, Ningbo, and Hainan, China. It also makes polyester resin and fiber. It is an investor in Zhejiang Petrochemical, a large oil refinery and petrochemical complex that is currently starting up.

Sustainability continues to be a focus for the Austrian petrochemical maker. In June, the company signed an agreement to buy oil from Renasci Oostende Recycling, which uses a thermal process to break down postconsumer plastic. Borealis will turn this feedstock into plastics again at its complex in Porvoo, Finland. Borealis also started up a demonstration unit at its polyethylene plant in Antwerp, Belgium, to test a heat-recovery technology developed by the start-up Qpinch. The technology is modeled on the adenosine triphosphate–adenosine diphosphate cycle in biology. Separately, Borealis put its fertilizer business up for sale in February.

Sasol ended a saga in November when it started up a low-density polyethylene plant in Lake Charles, Louisiana. The unit was the last of the plants the South African company built as part of a $12.8 billion petrochemical complex. The project went $4 billion over budget, leading to the ouster of its co-CEOs. To strengthen its balance sheet, Sasol aims to divest $6 billion in assets. To that end, the company formed a joint venture with LyondellBasell Industries to run the ethylene cracker and two polyethylene plants it built in Lake Charles, essentially selling half these operations for $2 billion. Sasol is keeping alcohols, ethylene oxide and ethylene glycol, and ethoxylation plants at the site. Separately, Sasol sold its 50% interest in the Gemini HDPE high-density polyethylene joint venture with Ineos for $400 million.

Rongsheng Petro Chemical Company Limited manufactures and sales purified terephthalic acid (PTA) and polyester drawn yarn related products. The Company"s main products are PTA and polyester full drawn yarn (FDY), polyester pre-oriented yarn (POY), polyester drawn textured yarn (DTY), various polyester filament and polyethylene terephthalate (PET) slices.

Rongsheng Petrochemical Co., Ltd. is one of the leading enterprises in China"s petrochemical-chemical fiber industry. Mainly engaged in the production and sales of petrochemical and chemical fiber-related products, with a complete industrial chain of crude oil-aromatic hydrocarbons (PX), olefin-refined terephthalic acid (PTA), ethylene glycol (MEG)-polyester-spinning (POY, FDY)-(DTY). It is one of the world"s largest PTA producers. The company adheres to quality creation, the products have passed ISO9001, ISO14001, OHSAS18001, Oeko-Tex Standard 100 certification and Carbon Footprint Certification. Rongsheng has established a high-tech research and development center, academician expert workstation, enterprise technology center, postdoctoral scientific research workstation, etc. Vigorously promote the research and development of new products and technologies.

Rongsheng is a member of the National Chemical Fiber Industry Standardization Committee, which presided over and participated in the drafting of a number of product industry standards.

Podcast: China"s petrochemical refiners are making their presence felt way beyond the country"s borders. How will this impact global supply, demand, and trade balances? Will global operating rates be reduced?

Textile giants Rongsheng and Hengli have shaken up China"s cozy, state-dominated oil market this year with the addition of close to 1mn b/d of new crude distillation capacity and vast, integrated downstream complexes. Petrochemical products, rather than conventional road fuels, are the driving force for this new breed of private sector refiner. And more are on their way.

Tom: And today we are discussing the advent of petrochemical refineries in China, refineries that have been built to produce mainly petrochemical feedstocks. Just a bit of background here, these two big new private sector firms, Rongsheng and Hengli, have each opened massive, shiny new 400,000 b/d refineries in China this year. Hengli at Changxing in Northeast Dalian and Rongsheng at Zhoushan in Zhejiang Province on the East coast. For those unfamiliar with Chinese geography, Dalian is up by China"s land border with North Korea and Zhoushan is an island across the Hangzhou Bay from Shanghai. And the opening of these two massive new refineries by chemical companies is shaking up China"s downstream market. But China is a net exporter of the core refinery products, gasoline, diesel, and jet. So, building refineries doesn"t sound like a purely commercial decision. Is it political? What"s behind it? How will it affect the makeup of China"s petrochemical product imports?

Chuck: And clearly, the driver here for Rongsheng and Hengli, who as Tom mentioned, are chemical companies, they are the world"s largest producers of purified terephthalic acid, known as PTA, which is the main precursor to make polyester, polyester for clothing and PET bottles. And each of them were importing massive amounts of paraxylene, paraxylene being the main raw material to make PTA. And paraxylene comes from the refining of oil. And really the alternate value for paraxylene or its precursors would be to blend into gasoline to increase octane. So, when looking to take a step upstream in terms of reverse or vertical integration, they"ve quickly found themselves not just becoming paraxylene producers, but in fact becoming refiners of crude to begin with, which of course, is quite complex and it involves all kinds of co-products and byproducts. And as many know, the refining of oil, the primary driver there, as Tom has mentioned, is to produce motor fuels. So, we"re reversing this where the petrochemicals become the strategic product and we look to optimize or maybe even limit the amount of motor fuels produced.

Tom: And presumably then, the creation of so much petrochemical feedstock production capacity is going to have a pretty major impact on global supply-demand and trade balances.

Chuck: And margins, of course, as well because no one wants to shut down their unit just to accommodate the new Chinese production. And what remains to be seen is global operating rates for these PX units will be reduced to maybe unsustainable levels. And as margins come down, they"ll be down for everyone, but the most efficient suppliers or producers will be the ones that survive. And in the case of Hengli and Rongsheng, low feedstock costs, if you"re driving down the cost of paraxylene, you take the benefit on the polyester side because now you have very competitive or very low-priced feedstock.

Rongsheng is trying to build itself into a retail brand around Shanghai and the Zhejiang area. And Hengli is trying to muscle into the wholesale market on a national level, so it"s gonna be selling products across China. And in that respect, as we were discussing earlier, in fact, Rongsheng appears to have an advantage because where it"s located on the East Coast of China, that region is net short still of transport fuels, but Hengli in the Northeast, that"s a very competitive refining environment. It"s a latecomer to an already pretty saturated market: PetroChina, a state-owned oil giant, is a huge refiner up in Northeast China with its own oil fields, so a ready-made source of low-cost crude. And it"s also very close to the independent sector refining hub in Shandong Province, which is the largest concentration of refineries in China. So, I think there are definite challenges for them on the road fuel front, even if it sounds like they"re going to be pretty competitively placed further downstream in the paraxylene market.

Tom: Well, that"s one of the peculiarities of the Chinese market. As private sector companies, neither Rongsheng nor Hengli are allowed currently to export transport fuels. That"s a legacy concern of the Chinese government to ensure energy self-sufficiency downstream to make sure there"s adequate supply on the domestic market of those fuels. So, that is a real impediment for them. And when they ramp up production of gasoline, diesel, and jet, they are driving down domestic prices and they are essentially forcing product into the seaborne market produced by other refineries. So, in that respect, the emergence of Hengli in Northeast China on PetroChina"s doorstep has created a huge new sense of competition for PetroChina in particular. And I think certainly when you look at their recent financial data, it"s quite clear that they are struggling to adapt to the new environment in which it"s essentially export or die, because these new, massive refineries are crushing margins inside China.

Chuck: And going back specifically to the Hengli and Rongsheng projects, it"s interesting to note, again, going to an order of magnitude or perspective, Hengli is producing or has capacity to produce 4.5 million tons of paraxylene. And in phase one, Rongsheng will have capacity to produce 4 million tons. And I know those are just large numbers, but again, bear in mind that last year, global demand was 43.5 million. So, effectively, these two plants, they could account for 20% of global demand. Just these two projects themselves to give you an idea of just how massive they are and how impactful they can be. Impactful or disruptive, it remains to be seen.

Tom: A sign it doesn"t do things by halves. Although that said, one of the interesting things they have done is essentially halved their transport fuel yields. So, where in a conventional refinery, your combined output of gasoline, diesel, and jet, those core products, might be in the region of 80%, when you look at these new refineries, they"ve really cut that back down to 40% or 50%. And there are new petrochemical refineries springing up, and it"ll be very interesting to see how disruptive those are to the petrochemical market. But in the conventional refining market, they are, I think under pressure to do even more to reduce their exposure to already weakened gasoline and diesel markets. I mean, Shenghong — this new textile company who"s starting up another massive new conventional refinery designed to produce petrochemical products in 2021, I think — they"ve managed to reduce that combined yield to around 30%. They"ve reduced that from an original blueprint.

Chuck: It"s remarkable, but just a note of caution, there have been other petrochemical and refinery projects built recently in Saudi Arabia and in Malaysia, in particular, with established engineering and established chemical and refining companies. And they"ve had trouble meeting the targeted dates for startup and it"s one thing to be mechanically complete, it"s another thing to be operationally complete. But both Hengli and Rongsheng have amazed me at how fast they were able to complete these projects. And by all reports so far, they are producing very, very effectively, but it does remain to be seen why these particular projects are able to run whereas the Aramco projects in Malaysia and in Rabigh in Saudi Arabia have had much greater problems.

Tom: It sounds like in terms of their paraxylene production, they are going to be among the most competitive in the world. They have these strategies to cope with oversupplied markets and refined fuels, but there is certainly an element of political support which has enabled them to get ahead of the pack, I guess. And suddenly in China, Prime Minister Li Keqiang visited the Hengli plant shortly after it came on stream in July, and Zhejiang, the local government there is a staunch backer of Rongsheng"s project. And Zhoushan is the site of a national government initiative creating oil trading and logistics hub. Beijing wants Zhoushan to overtake Singapore as a bunkering location and it"s one of the INE crude futures exchanges, registered storage location. So, both of these locations in China do enjoy a lot of political support, and there are benefits to that which I think do allow them to whittle down the lead times for these mega projects.

So, thank you for joining us today, and it"ll be interesting to follow all of these developments because there still are so many moving parts. And you can follow this on the petroleum side with China Petroleum, the publication in which Tom edits out of London or some of our petrochemical reports. We do daily assessments on the paraxylene markets as well as monthly outlooks, which include global price forecasts. And we have databases which show supply, demand, and trade flows, etc. And then also please tune in for future episodes of the "China Connection." And we thank you for your time and attention.

Although many capital projects suffered setbacks and delays during the COVID-19 pandemic, new refining and petrochemicals capacity additions are being built around the world. These projects are enabling refiners and petrochemicals producers to satisfy increasing demand for clean transportation fuels and petrochemical products.

Using Gulf Energy Information’s Global Energy Infrastructure database, the editors of Hydrocarbon Processing have selected 11 nominees for the 2021 Top Projects awards. The winners and nominees of this prestigious award will have a considerable impact on the hydrocarbon processing industry, whether though capital cost, satisfying domestic or regional demand, diversifying product offerings, increasing operational efficiency, mitigating emissions and increasing energy efficiency, and/or producing cleaner fuels and petrochemical products. The winners of this prestigious award over the past several years have included:

The 11 projects nominated this year span the globe and represent nearly $76 B in capital investments. Once completed, the nominees’ facilities will add more than 2.1 MMbpd of additional refining capacity and a significant amount of new petrochemicals production capacity—more than 5 MMtpy of ethylene capacity, 9.5 MMtpy of ethylene derivatives capacity and nearly 8 MMtpy of aromatics capacity.

Over the past two months, hundreds of Hydrocarbon Processing readers voted online to select the top refining and petrochemical projects of 2021. The following sections present the results of the reader poll, along with details of the Top Project winners and the nominees’ projects.

Zhejiang Petrochemical Co. Ltd.—a JV of Zhejiang Rongsheng Holding Group Co. Ltd., Juhua Group Corp., Tongkun Group Co. Ltd. and Zhoushan Marine Comprehensive Development Investment Co. Ltd.—is building one of the largest integrated facilities in the world. The integrated refining and petrochemical complex is being built approximately 280 km south of Shanghai on Zhoushan Island.

PetroChina is investing more than $10 B to build a refining and integrated complex in Jieyang. The capital-intensive project includes the construction of a 400,000-bpd refinery that will provide feedstock for integrated petrochemical units. The petrochemical units will produce 1.2-MMtpy of ethylene and 2.6-MMtpy of aromatics. Operations are scheduled to begin around mid-2022.

The $2.6-B, two-phase project is part of the country’s development program to process natural gas from Kazakhstan’s Tengiz field into high-value petrochemical products. The integrated complex is being built in Kazakhstan’s National Industrial Technopark in the country’s Atyrau region. Phase 1 includes the construction of a nearly 630,000-tpy propane dehydrogenation unit to produce 500,000 tpy of PP. Phase 2 includes the construction of a gas separation plant to supply ethane to a downstream 1.25-MMtpy PE unit. Phase 1 of the complex is scheduled to begin operations in 1Q 2022. At the time of this publication, the ethane cracker and derivative units were scheduled to begin operations by the end of the year.

Nigerian business mogul Aliko Dangote plans to construct the largest privately-owned refinery in Africa. The Dangote Industries Ltd. (DIL) integrated complex will be constructed in Lekki, Lagos State, Nigeria, and will include a petrochemical complex and fertilizer facility. The project will be the first of its kind in Nigeria.

The $15-B, 650,000-bpd refinery will include a petrochemical plant that will produce 750,000 tpy of polypropylene (PP), along with a fertilizer plant that will produce 2.8 MMtpy of urea and ammonia for the nation’s agricultural sector. The refinery will produce gasoline, diesel, aviation fuel and slurry to be used as a raw material for carbon black.

The more than $10.4-B integrated complex consists of a 320,000-bpd refinery and integrated petrochemicals production complex. In addition of producing ultra-low-sulfur fuels, the refinery will provide feedstock for the integrated petrochemicals production units. These units will produce 1.1 MMtpy of ethylene and 2.8 MMtpy of aromatics. Commercial operations are expected to begin in 1Q 2022.

The nearly $7-B project is being developed by OQ8, a JV between OQ Group and Kuwait Petroleum International. The project, which is the cornerstone of the Duqm Special Economic Zone, consists of a 230,000-bpd full conversion hydrocracking/coking refinery and petrochemicals complex. The refinery is scheduled to be completed in 2022, followed by the petrochemicals complex in 2025. The petrochemicals complex includes a 1.6-MMtpy ethylene plant, a 280,000-tpy PP plant, a 480,000-tpy HDPE plant and an aromatics plant.

Zhenbang Fibre, Zhejiang Hengyi, Wankai New Materials, Thai PET Resin Co., Ltd., TEIJIN, SK Chemicals, Sinopec Yizheng Chemical Fibre, Since CR Chemicals, Selenis, Sanfangxiang Group, SABIC, Rongsheng petrochemical, Petroquimica Suape, OCTAL, NEO GROUP, Nan Ya Plastics, M&G Chemicals, Lotte Chemical, KoKsan, JBF, Indorama Ventures, Far Eastern New Century Corporation, Far Eastern Industry, EIPET, Eastman, DuPont, Dhunseri Petrochem & Tea, DAK

Any questions regarding this Policy and our privacy practices should be sent by e-mail to privacy@gtreview.com or by writing to Data Protection Officer at, Exporta Publishing & Events Ltd, 4 Hillgate Place, London, SW12 9ER, United Kingdom. Alternatively, you can telephone our London headquarters at +44 (0) 20 8673 9666.

Established in 2002 and with offices in London and Singapore, Exporta Publishing & Events Ltd is the world’s leading trade and trade finance media company, offering information, news, events and services for companies and individuals involved in global trade.

We also collect certain personal data from other group companies to whom you have given information through their websites (including, by way of example, Exporta Publishing & Events Ltd and subsidiaries, in accordance with the purposes listed below). Should we discover that any such personal data has been delivered to any of the Sites, we will remove that information as soon as possible.

The Data Protection Act 1998 described how organisations – including Exporta Publishing & Events Ltd – must collect, handle and store personal information. These rules apply regardless of whether data is stored electronically, on paper or on other materials. To comply with the law, personal information collected must be stored safely, not disclosed unlawfully and used fairly.

On some Sites, Exporta Publishing & Events Ltd collects personal data such as your name, job title, department, company, e-mail, phone, work and/or home address, in order to register you for access to certain content, subscriptions and events. In addition, we may also store information including IP address and page analytics, including information regarding what pages are accessed, by whom and when.

Users have the opportunity to set their computers to accept all cookies, to notify them when a cookie is issued, or not to receive cookies at any time. Selecting not to receive means that certain personalised services Exporta Publishing & Events Ltd offers cannot then be provided to that user.

E-mail tracking is a method for monitoring the e-mail delivery to those subscribers who have opted-in to receive marketing e-mails from GTR, including GTR Africa, GTR Asia, GTR Americas, GTR Europe, GTR Mena, GTR eNews, Third party e-mails and GTR Ventures.

So that we can better understand our users’ needs, we track responses, subscription behaviour and engagement to our e-mails – for example, to see which links are the most popular in newsletters. They enable us to understand the consumers journey through metrics including open rate, click-through rate, bounces and unsubscribes. Any other purposes for which Exporta Publishing & Events Ltd wishes to use your personal data will be notified to you and your personal data will not be used for any such purpose without obtaining your prior consent.

Any questions regarding consents and opt-outs should be sent by e-mail to privacy@gtreview.com or by writing to Data Protection Officer at, Exporta Publishing & Events Ltd, 4 Hillgate Place, London, SW12 9ER, United Kingdom. Alternatively, you can telephone our London headquarters at +44 (0) 20 8673 9666.

Services on the Internet are accessible globally so collection and transmission of personal data is not always limited to one country. Exporta Publishing & Events Ltd may transfer your personal data, for the above-listed purposes to other third parties, which may be located outside the European Economic Area and/or with a different level of personal data protection. However, when conducting transfers, we take all necessary steps to ensure that your data is treated reasonably, securely and in accordance with this Privacy Statement.

Everyone who works for or with Exporta Publishing & Events Ltd has some responsibility for ensuring data is collected, stored and handled appropriately. Each team handling personal data must ensure that it is handled and processed in line with this policy and data protection principles. However, the following people have key areas of responsibility.

The Data Controller is Exporta Publishing & Events Ltd. Exporta Publishing & Events Ltd is subject to the UK Data Protection Act 1998 and is registered in the UK with the Information Commissioner`s Office.

Exporta Publishing & Events Ltd allows you to challenge the data that we hold about you and, where appropriate in accordance with applicable laws, you may have your personal information:

In certain circumstances, the Data Protection Act allows personal data to be disclosed to law enforcement agencies without the consent of the data subject. Under these circumstances, Exporta Publishing & Events Ltd, will disclose requested data. However, the Data Controller will ensure the request is legitimate, seeking assistance from the board and from the company’s legal advisors where necessary.

8613371530291

8613371530291