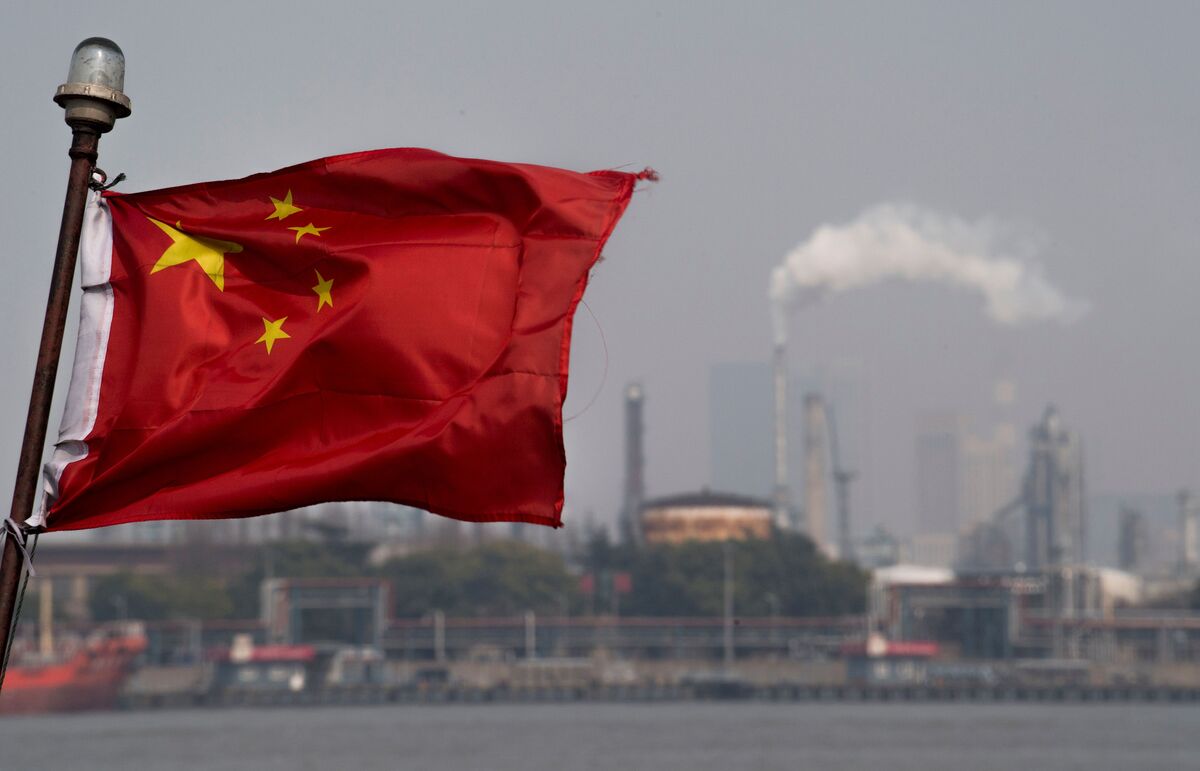

rongsheng refinery start up made in china

SINGAPORE, Oct 14 (Reuters) - Rongsheng Petrochemical, the trading arm of Chinese private refiner Zhejiang Petrochemical, has bought at least 5 million barrels of crude for delivery in December and January next year in preparation for starting a new crude unit by year-end, five trade sources said on Wednesday.

Rongsheng bought at least 3.5 million barrels of Upper Zakum crude from the United Arab Emirates and 1.5 million barrels of al-Shaheen crude from Qatar via a tender that closed on Tuesday, the sources said.

Rongsheng’s purchase helped absorbed some of the unsold supplies from last month as the company did not purchase any spot crude in past two months, the sources said.

Zhejiang Petrochemical plans to start trial runs at one of two new crude distillation units (CDUs) in the second phase of its refinery-petrochemical complex in east China’s Zhoushan by the end of this year, a company official told Reuters. Each CDU has a capacity of 200,000 barrels per day (bpd).

Zhejiang Petrochemical started up the first phase of its complex which includes a 400,000-bpd refinery and a 1.2 million tonne-per-year ethylene plant at the end of 2019. (Reporting by Florence Tan and Chen Aizhu, editing by Louise Heavens and Christian Schmollinger)

SINGAPORE, Dec 31 (Reuters) - Zhejiang Petroleum & Chemical Co Ltd, one of two new major refineries built in China in 2019, said on Tuesday it has started up the remaining units in the first phase of its refinery and petrochemical complex.

The company, 51% owned by private chemical group Zhejiang Rongsheng Holdings, said it has started test production at ethylene, aromatics and other downstream facilities, without giving further details.

Zhejiang Petrochemical started a first 200,000 barrels per day (bpd) crude processing unit in late May, following on from the start of a 400,000-bpd refinery owned by another private chemical major Hengli Petrochemical.

The newly started units at Zhejiang Petrochemical should include a second 200,000-bpd crude unit, a 1.2 million tonnes per year (tpy) ethylene unit and a 2 million tpy paraxylene unit, according to several industry sources with knowledge of the plant’s operations.

Podcast: China"s petrochemical refiners are making their presence felt way beyond the country"s borders. How will this impact global supply, demand, and trade balances? Will global operating rates be reduced?

Textile giants Rongsheng and Hengli have shaken up China"s cozy, state-dominated oil market this year with the addition of close to 1mn b/d of new crude distillation capacity and vast, integrated downstream complexes. Petrochemical products, rather than conventional road fuels, are the driving force for this new breed of private sector refiner. And more are on their way.

Tom: And today we are discussing the advent of petrochemical refineries in China, refineries that have been built to produce mainly petrochemical feedstocks. Just a bit of background here, these two big new private sector firms, Rongsheng and Hengli, have each opened massive, shiny new 400,000 b/d refineries in China this year. Hengli at Changxing in Northeast Dalian and Rongsheng at Zhoushan in Zhejiang Province on the East coast. For those unfamiliar with Chinese geography, Dalian is up by China"s land border with North Korea and Zhoushan is an island across the Hangzhou Bay from Shanghai. And the opening of these two massive new refineries by chemical companies is shaking up China"s downstream market. But China is a net exporter of the core refinery products, gasoline, diesel, and jet. So, building refineries doesn"t sound like a purely commercial decision. Is it political? What"s behind it? How will it affect the makeup of China"s petrochemical product imports?

Chuck: And clearly, the driver here for Rongsheng and Hengli, who as Tom mentioned, are chemical companies, they are the world"s largest producers of purified terephthalic acid, known as PTA, which is the main precursor to make polyester, polyester for clothing and PET bottles. And each of them were importing massive amounts of paraxylene, paraxylene being the main raw material to make PTA. And paraxylene comes from the refining of oil. And really the alternate value for paraxylene or its precursors would be to blend into gasoline to increase octane. So, when looking to take a step upstream in terms of reverse or vertical integration, they"ve quickly found themselves not just becoming paraxylene producers, but in fact becoming refiners of crude to begin with, which of course, is quite complex and it involves all kinds of co-products and byproducts. And as many know, the refining of oil, the primary driver there, as Tom has mentioned, is to produce motor fuels. So, we"re reversing this where the petrochemicals become the strategic product and we look to optimize or maybe even limit the amount of motor fuels produced.

Tom: And presumably then, the creation of so much petrochemical feedstock production capacity is going to have a pretty major impact on global supply-demand and trade balances.

Chuck: And margins, of course, as well because no one wants to shut down their unit just to accommodate the new Chinese production. And what remains to be seen is global operating rates for these PX units will be reduced to maybe unsustainable levels. And as margins come down, they"ll be down for everyone, but the most efficient suppliers or producers will be the ones that survive. And in the case of Hengli and Rongsheng, low feedstock costs, if you"re driving down the cost of paraxylene, you take the benefit on the polyester side because now you have very competitive or very low-priced feedstock.

Tom: That"s a really interesting point actually. Looking at it from a refining economics point of view, if you were trying to diversify your revenue stream, for example, you probably wouldn"t want to increase your gasoline production. And gasoline margins in Europe are barely breaking even, they"re about $4 a barrel. In China, gasoline crack spreads are actually negative. So, fine, they"re self-sufficient in the paraxylene they need for weaving, but are they just... the refiners themselves, Hengli and Changxing, are they now just soaking up losses from the sales of their transport fuels? I think they may be initially, but they"re not just giving their gasoline away, obviously, these refineries were conceived as viable commercial concerns. Hengli anticipates profits, I think, of around 12 billion Yuan per year from its Changxing refinery giving a payback period on that investment of around five years. And each company, interestingly enough, has a distinct marketing strategy for their transport fuel.

Rongsheng is trying to build itself into a retail brand around Shanghai and the Zhejiang area. And Hengli is trying to muscle into the wholesale market on a national level, so it"s gonna be selling products across China. And in that respect, as we were discussing earlier, in fact, Rongsheng appears to have an advantage because where it"s located on the East Coast of China, that region is net short still of transport fuels, but Hengli in the Northeast, that"s a very competitive refining environment. It"s a latecomer to an already pretty saturated market: PetroChina, a state-owned oil giant, is a huge refiner up in Northeast China with its own oil fields, so a ready-made source of low-cost crude. And it"s also very close to the independent sector refining hub in Shandong Province, which is the largest concentration of refineries in China. So, I think there are definite challenges for them on the road fuel front, even if it sounds like they"re going to be pretty competitively placed further downstream in the paraxylene market.

Chuck: Well, and beyond paraxylene, they are looking at...to maximize paraxylene, not to get too technical, but you wanna split the naphtha into two different qualities and the high N+A, or the heavier naphtha is what yields the most paraxylene per ton of feed. But then you"re left with a lighter paraffinic naphtha, which is not particularly good to blend into gasoline. And so, therefore, both are building ethylene steam crackers using that naphtha and then taking the ethylene down into polyethylene plastics. Not strategic markets for these two players necessarily, but China also has massive deficits in terms of meeting its domestic polyethylene demand. China is the largest importer of polyethylene and polypropylene. So, these projects will help offset some of that as well. But I"m concerned, you mentioned about the road fuels and if they are making retail gasoline, one needs octane, and it"s precisely the precursors to the paraxylene that are needed, you have to buy those away from the chemical sector in order to blend up to the appropriate octane level. Is there a chance that they might be able to export fuels products or is that left to maybe some of the other established refining players in China?

Tom: Well, that"s one of the peculiarities of the Chinese market. As private sector companies, neither Rongsheng nor Hengli are allowed currently to export transport fuels. That"s a legacy concern of the Chinese government to ensure energy self-sufficiency downstream to make sure there"s adequate supply on the domestic market of those fuels. So, that is a real impediment for them. And when they ramp up production of gasoline, diesel, and jet, they are driving down domestic prices and they are essentially forcing product into the seaborne market produced by other refineries. So, in that respect, the emergence of Hengli in Northeast China on PetroChina"s doorstep has created a huge new sense of competition for PetroChina in particular. And I think certainly when you look at their recent financial data, it"s quite clear that they are struggling to adapt to the new environment in which it"s essentially export or die, because these new, massive refineries are crushing margins inside China.

I think globally it"s increasingly a competitive environment for road fuels. China is already a net exporter of over 1mn b/d combined of gasoline, diesel, and jet. It"s the fastest-growing exporter of those fuels in the world. But over-supply is also percolating through into the seaborne market: Indian diesel exports are rising; everyone is trying to desperately seek out net short regions and they"re having to ship product further and further overseas. And we"re seeing a situation emerge now in China where these refineries are importing crude perhaps from Latin America and they"re exporting finished products to those same markets from which they took the crude. It"s a tricky arbitrage, one would imagine.

Chuck: And going back specifically to the Hengli and Rongsheng projects, it"s interesting to note, again, going to an order of magnitude or perspective, Hengli is producing or has capacity to produce 4.5 million tons of paraxylene. And in phase one, Rongsheng will have capacity to produce 4 million tons. And I know those are just large numbers, but again, bear in mind that last year, global demand was 43.5 million. So, effectively, these two plants, they could account for 20% of global demand. Just these two projects themselves to give you an idea of just how massive they are and how impactful they can be. Impactful or disruptive, it remains to be seen.

Tom: A sign it doesn"t do things by halves. Although that said, one of the interesting things they have done is essentially halved their transport fuel yields. So, where in a conventional refinery, your combined output of gasoline, diesel, and jet, those core products, might be in the region of 80%, when you look at these new refineries, they"ve really cut that back down to 40% or 50%. And there are new petrochemical refineries springing up, and it"ll be very interesting to see how disruptive those are to the petrochemical market. But in the conventional refining market, they are, I think under pressure to do even more to reduce their exposure to already weakened gasoline and diesel markets. I mean, Shenghong — this new textile company who"s starting up another massive new conventional refinery designed to produce petrochemical products in 2021, I think — they"ve managed to reduce that combined yield to around 30%. They"ve reduced that from an original blueprint.

Chuck: It"s remarkable, but just a note of caution, there have been other petrochemical and refinery projects built recently in Saudi Arabia and in Malaysia, in particular, with established engineering and established chemical and refining companies. And they"ve had trouble meeting the targeted dates for startup and it"s one thing to be mechanically complete, it"s another thing to be operationally complete. But both Hengli and Rongsheng have amazed me at how fast they were able to complete these projects. And by all reports so far, they are producing very, very effectively, but it does remain to be seen why these particular projects are able to run whereas the Aramco projects in Malaysia and in Rabigh in Saudi Arabia have had much greater problems.

Tom: It sounds like in terms of their paraxylene production, they are going to be among the most competitive in the world. They have these strategies to cope with oversupplied markets and refined fuels, but there is certainly an element of political support which has enabled them to get ahead of the pack, I guess. And suddenly in China, Prime Minister Li Keqiang visited the Hengli plant shortly after it came on stream in July, and Zhejiang, the local government there is a staunch backer of Rongsheng"s project. And Zhoushan is the site of a national government initiative creating oil trading and logistics hub. Beijing wants Zhoushan to overtake Singapore as a bunkering location and it"s one of the INE crude futures exchanges, registered storage location. So, both of these locations in China do enjoy a lot of political support, and there are benefits to that which I think do allow them to whittle down the lead times for these mega projects.

Chuck: Exactly. And there are projects downstream as well to add additional PTA capacity to consume much of this additional paraxylene, but there will be some lag effect as well. But to the extent that both of these firms and these projects are integrated, they stand to benefit by either profiting on the PTA and the polyester, the downstream or upstream on PX depending on market conditions.

So, thank you for joining us today, and it"ll be interesting to follow all of these developments because there still are so many moving parts. And you can follow this on the petroleum side with China Petroleum, the publication in which Tom edits out of London or some of our petrochemical reports. We do daily assessments on the paraxylene markets as well as monthly outlooks, which include global price forecasts. And we have databases which show supply, demand, and trade flows, etc. And then also please tune in for future episodes of the "China Connection." And we thank you for your time and attention.

The company, 51% owned by private chemical group Zhejiang Rongsheng Holdings, said it has started test production at ethylene, aromatics and other downstream facilities, without giving further details.

Zhejiang Petrochemical started a first 200,000 barrels per day (bpd) crude processing unit in late May, following on from the start of a 400,000-bpd refinery owned by another private chemical major Hengli Petrochemical.

The newly started units at Zhejiang Petrochemical should include a second 200,000-bpd crude unit, a 1.2 million tonnes per year (tpy) ethylene unit and a 2 million tpy paraxylene unit, according to several industry sources with knowledge of the plant"s operations.

The construction works started recently. The volumes from the additional capacity are expected to be available from the end of 2021 and are dedicated to mainly serve European customers as well as the rapidly growing Asian market.

"We want to meet our customers" growing demand for high-quality, sustainable and high-performance technologies in the best possible way now and in future. To achieve that, we continuously invest in expanding our capacities and production technologies. To this end, we acquired an innovative process approach for producing MSA from Grillo-Werke AG in mid 2019 to strengthen our own R&D activities and to accelerate the development of a new manufacturing process for methane sulfonic acid. In doing so, we support as reliable partner the growth of our customers across the world," said Ralph Schweens, President Care Chemicals, BASF.

As MRC wrote previously, BASF, the world"s petrochemical major, restarted its No. 1 steam cracker on September 30, 2019, following a maintenance turnaorund. The plant was shut for maintenance in mid-August, 2019. Located at Ludwigshafen in Germany, the No. 1 cracker has an ethylene production capacity of 235,000 mt/year and a propylene production capacity of 125,000 mt/year.

According toMRC"s ScanPlast report, Russia"s estimated PE consumption totalled 1,904,410 tonnes in the first eleven months of 2019, up by 6% year on year. Shipments of all PE grades increased. PE shipments increased from both domestic producers and foreign suppliers. The PP consumption in the Russian market was 1,161,830 tonnes in January-November 2019, up by 7% year on year. Deliveries of all grades of propylene polymers increased, with the homopolymer PP segment accounting for the largest increase.

Meanwhile, feedstock consumption at China"s independent refineries in eastern Shandong province fell a marginal 0.4% year on year to 121.3 million mt in 2021, data from local information provider JLC showed. However, crude feedstock consumption fell 4.6% to 111.53 million mt over the same period as fewer crude import quotas were allocated to Shandong"s independent refineries in 2021, with four receiving no allocation in the last batch announced in mid-October. To address the feedstock shortage, fuel oil and bitumen blend were imported and cracked as supplement feedstocks in 2021, with 8.5 million mt cracked by Shandong independent refineries in the year, surging from a small volume the year before.

The integrated Zhejiang Petroleum & Chemical refinery continued to raise its crude throughput to around 2.84 million mt in December, up 7.2% from 1.72 million mt in November, which was up 54% from October, according to JLC data. The refinery ramped up throughput after it was allocated more quotas in late October.

The Hengli Petrochemical (Dalian) Refinery in Liaoning province also raised its throughput by 3.6% month on month to 1.7 million mt in December. This comes after the completion of the maintenance at its secondary units, according to refinery sources.

However, Shandong independent refineries have gradually started to cut crude throughput from around Jan. 22 in response to a directive to cap utilization below 70% during the Winter Olympics, as Beijing aims to ensure that emissions remain under control, refinery sources told S&P Global Platts. But some refinery sources believe the overall impact will not be much more than what occurs every year since the Winter Olympics will be held around the Lunar New Year holidays, when independent refineries are forced to cut crude throughput due to logistics and manpower constraints.

In other news, Sinopec"s Hainan Petrochemical refinery in southern China is expected to export about 50,000 mt of refined oil products in January 2022, according to a refinery source. This was down 55% from 110,000 mt planned for export in December 2021.

PetroChina"s West Pacific Petrochemical Corp. refinery will skip gasoil exports in January after skipping them in December and November due to good demand in the domestic market.

PetroChina"s flagship refinery Dalian Petrochemical in northeastern Liaoning province will raise its gasoline exports to 160,000 mt in January, according to sources with knowledge of the matter. This will be about 357% higher than its planned exports in December. Dalian will double jet fuel exports to 80,000 mt in January, from 40,000 mt last month. Dalian plans to process around 1.3 million mt of crudes in January, translating to 75% of its nameplate capacity, stable on the month.

** Sinochem has been in the process of starting up its 12 million mt/year CDU and related refining units at its Quanzhou Petrochemical facility in southern Fujian province, according to a source with knowledge of the matter Jan. 19. The refining and petrochemical units were shut at around Dec. 1, 2021 for maintenance, which lasted for about 40-50 days, according to the maintenance schedule. The refinery will likely process about 450,000 mt to 500,000 mt of crudes for the remainder of February, compared with around 1.2 million mt during normal months.

** Sinopec"s Guangzhou Petrochemical restarted its 8 million mt/year CDU on Dec. 21 following the completion of a scheduled maintenance which started late October, a company source said. With its resumption, the refiner lifted December throughput to 840,000 mt from 440,000 mt in November, the source said. Moreover, the S-zorb that caught fire Nov. 27 during maintenance was fixed and resumed operation, the source added.

** Sinopec"s Fujian Refining and Chemical Co. refinery in southeastern Fujian province has been in the process of restarting from a scheduled maintenance this week, according to a source with knowledge of the matter Jan. 19. The refinery was expected to return to normal operations around Jan. 20, about nine days behind schedule, mainly due to the slow progress in procuring some parts, the source added. The 4 million mt/year crude distillation unit, as well as some secondary units, including the aromatics units, were to be restarted along the way. Following the restart of the CDU, the crude throughput at the refinery will likely increase to around 750,000 mt in January, or 63% of its nameplate capacity. This compares with a run rate of 56%, or 660,000 mt, in December 2021.

** Japan"s ENEOS said Dec. 28 it plans to shut the sole crude distillation unit at its Marifu refinery in the west in late January for scheduled maintenance until early March 2022.

** Idemitsu Kosan restarted the sole 160,000 b/d crude distillation unit at its Aichi refinery in central Japan on Dec. 5 after completing planned maintenance, a spokesperson said Dec. 20.

** PetroChina"s Yunnan Petrochemical refinery in southwestern Yunnan province, has shut its 4 million mt/year residual hydrogenation unit and some of its relative downstream facilities due to a blast. The blast hit the residual hydrogenation unit Dec. 13 morning, according to a press release issued by the Anning city local government in Yuannan. A refining engineer said the closure of residual hydrogenation unit would cut about 30% of the refinery"s daily production.

** Sinopec"s Hainan Petrochemical refinery in southern China plans to completely shut for scheduled maintenance over March-April 2022, a source with the refinery said. This is a routine maintenance that is normally carried out by Chinese refineries every three to four years, according to the source. Sinopec Hainan refinery last carried out complete maintenance over November 2017-January 2018.

** Japan"s ENEOS said it will decommission the 120,000 b/d No. 1 CDU at its 270,000 b/d Negishi refinery in Tokyo Bay in October 2022. It will also decommission secondary units attached to the No. 1 CDU, including a vacuum distillation unit and fluid catalytic cracker. ENEOS will also decommission a 270,000 mt/year lubricant output unit at the Negishi refinery.

** Sinopec is looking to launch its 2 million mt/year crude distillation unit expansion at Luoyang Petrochemical in central China in January, with a new crude pipeline able to supply sufficient feedstock, a refinery source said late December. "We have reconfigured an existing crude pre-treater into a 2 million mt/year CDU to increase the primary capacity to 10 million mt/year. The start-up will be in the next month with the crude pipeline having been put into use in November," the refinery source said. The expansion was initially set to be put into use in H2 2020, but was delayed to H1 2021 due to construction of the 10 million mt/year Rizhao-Puyang-Luoyang crude pipeline and weak demand in oil product market, Platts reported. The source said the expansion needs more crude supplies discharged from Rizhao port in Shandong province and transmitted through the Rizhao-Puyang-Luoyang crude pipeline.

** Chinese Sinopec"s refinery Zhenhai Refining and Chemical currently has a 27 million mt/year refining capacity and a 2.2 million mt/year ethylene plant, after its phase 1 expansion project of 4 million mt/year crude distillation unit and a 1.2 million mt/year ethylene unit was delivered end-June.

** PetroChina"s Guangxi Petrochemical in southern Guangxi province plans to start construction at its upgrading projects at the end of 2021, with the works set to take 36 months. The projects include upgrading the existing refining units as well as setting up new petrochemical facilities, which will turn the refinery into a refining and petrochemical complex. The project will focus on upgrading two existing units: the 2.2 million mt/year wax oil hydrocracker and the 2.4 million mt/year gasoil hydrogenation refining unit. For the petrochemicals part, around 11 main units will be constructed, which include a 1.2 million mt/year ethylene cracker.

** Sinopec"s Changling Petrochemical in central Hunan province plans to start construction for its newly approved 1 million mt/year reformer in 2021 and to bring its port upgrading project online by end-December.

** China"s privately held refining complex, Shenghong Petrochemical, is likely to start feeding crudes into its newly built 16 million mt/year crude distillation unit, according to a company source in early January. The refinery initially planned to start up at the end of August, but this was postponed to the end of December due to slower-than-expected construction work, and then again to around the Lunar New Year. The construction of the complex started in December 2018. Located in the coastal city of Lianyungang in Jiangsu province, the company"s 16 million mt/year CDU is the country"s single biggest by capacity.

** Chinese privately owned refining and petrochemical complex Zhejiang Petroleum & Chemical has fully started up commercial operation at it 400,000 b/d Phase 2 refining and petrochemical project, parent company Rongsheng Petrochemical said in a document Jan. 12. There are two crude distillation units in the Phase 2 project, each with a capacity of 200,000 b/d. ZPC started trial run at one of the CDUs in November 2020. Due to tight feedstock supplies, the refiner could not feed the other CDU until the end of November 2021, when it gained crude import quota for the project. The nameplate capacity of the company doubled to 800,000 b/d in Phase 2. It will run four CDUs at about 82% of nameplate capacity in January. Rongsheng said Phase 2 adds 6.6 million mt/year aromatics and 1.4 million mt/year ethylene production capacity.

** Saudi Aramco continues to pursue and develop the integrated refining and petrochemical complex in China with Norinco Group and Panjin Sinchen. The joint venture plans to build an integrated refining and petrochemical complex in northeast China"s Liaoning province Panjin city with a 300,000 b/d refinery, 1.5 million mt/year ethylene cracker and a 1.3 million mt/year PX unit.

** Honeywell said China"s Shandong Yulong Petrochemical will use "advanced platforming and aromatics technologies" from Honeywell UOP at its integrated petrochemical complex. The complex will include a UOP naphtha Unionfining unit, CCR Platforming technology to convert naphtha into high-octane gasoline and aromatics, Isomar isomerization technology. When completed Yulong plans to produce 3 million mt/yr of mixed aromatics. Shandong"s independent greenfield refining complex, Yulong Petrochemical announced the start of construction work at Yulong Island in Yantai city at the end of October 2020.

Construction work is expected to be completed in 24 months. The complex has been set up with the aim of consolidating the outdated capacities in Shandong province. A total of 10 independent refineries, with a total capacity of 27.5 million mt/year, will be mothballed over the next three years. Jinshi Petrochemical, Yuhuang Petrochemical and Zhonghai Fine Chemical, Yuhuang Petrochemical and Zhonghai Fine Chemical will be dismantled, while Jinshi Asphalt has already finished dismantling.

** PetroChina officially started construction works at its greenfield 20 million mt/year Guangdong petrochemical refinery in the southern Guangdong province on Dec. 5, 2018.

** China"s coal chemical producer Xuyang Group has announced plans to build a greenfield 15 million mt/year refining and petrochemical complex in Tangshang in central Hebei province.

Saudi Aramco today signed three Memoranda of Understanding (MoUs) aimed at expanding its downstream presence in the Zhejiang province, one of the most developed regions in China. The company aims to acquire a 9% stake in Zhejiang Petrochemical’s 800,000 barrels per day integrated refinery and petrochemical complex, located in the city of Zhoushan.

The first agreement was signed with the Zhoushan government to acquire its 9% stake in the project. The second agreement was signed with Rongsheng Petrochemical, Juhua Group, and Tongkun Group, who are the other shareholders of Zhejiang Petrochemical. Saudi Aramco’s involvement in the project will come with a long-term crude supply agreement and the ability to utilize Zhejiang Petrochemical’s large crude oil storage facility to serve its customers in the Asian region.

Phase I of the project will include a newly built 400,000 barrels per day refinery with a 1.4 mmtpa ethylene cracker unit, and a 5.2 mmtpa Aromatics unit. Phase II will see a 400,000 barrels per day refinery expansion, which will include deeper chemical integration than Phase I.

The startup took only about three days to complete. The liquids ethylene cracker is part of ZPC’s grassroots integrated refining and petrochemical complex which broke ground in 2016.

Stan Knez, President of TechnipFMC Process Technology, commented: “We are very pleased with the successful startup of the ZPC cracker. This is a great milestone for the complex and another example of our proven ethylene technology”.

(1) ZPC: Zhejiang Petroleum & Chemical Co., Ltd, established in Zhoushan, Zhejiang on June 18, 2015, is a mixed-ownership enterprise jointly formed by the private enterprise Rongsheng Petrochemical Co., Ltd.(holding 51% of shares), provincial state-owned enterprise Zhejiang Juhua Investment Co., Ltd.(holding 20% of shares), the private enterprises Zhejiang Tongkun Investment Co., Ltd.(holding 20% of shares) and Zhoushan Marine Comprehensive Development and Investment Co., Ltd.(holding 9% of shares), which will be the first kind of mixing economy enterprise in China in the Refinery and Petrochemical Industry. ZPC’s first phase project includes 20 million tons per year refinery and 1400 KTA Ethylene Complex.

Were the extra barrels needed to satisfy unusually strong refinery demand? A desire to stockpile supply for later consumption? Or perhaps add more cushion to strategic reserves?

Plans for a joint Saudi Arabia-China refining and petrochemical complex to be built in northeast China that were shelved in 2020 are now being discussed again, according tosources close to the deal. The original deal for Saudi Aramco and China’s North Industries Group (Norinco) and Panjin Sincen Group to build the US$10 billion 300,000 barrels per day (bpd) integrated refining and petrochemical facility in Panjin city was signed in February 2019. However, in the aftermath of the enduring low prices and economic damage that hit Saudi Arabia as a result of the Second Oil Price War it instigated in the first half of 2020 against the U.S. shale oil threat, Aramco pulled out of the deal in August of that year.

The fact that this landmark refinery joint venture is back under serious consideration underlines the extremely significant shift in Saudi Arabia’s geopolitical alliances in the past few years – principally away from the U.S. and its allies and towards China and its allies. Up until the 2014-2016 Oil Price War, intended by Saudi Arabia to destroy the then-nascent U.S. shale oil sector, the foundation of U.S.-Saudi relations had been the deal struck on 14 February 1945 between the then-U.S. President Franklin D. Roosevelt and the Saudi King Abdulaziz. In essence, but analyzed in-depth inmy new book on the global oil markets,this was that the U.S. would receive all of the oil supplies it needed for as long as Saudi had oil in place, in return for which the U.S. would guarantee the security both of the ruling House of Saud and, by extension, of Saudi Arabia.

After the end of the 2014-2016 Oil Price War, Saudi Arabia had not only lost the upper hand in global oil markets that it had established alongside other OPEC member states with the 1973 Oil Embargo but it had also prompted a catastrophic breach of trust with its former allies in Washington. Consequently, the U.S. changed the effective terms of 1945 to: the U.S. will safeguard the security both of Saudi Arabia and of the ruling House of Saud for as long as Saudi not only guarantees that the U.S. will receive all of the oil supplies it needs for as long as Saudi has oil in place but also that Saudi Arabia does not attempt to interfere with the growth andprosperity of the U.S. shale oil sector. Shortly after that (in May 2017), the U.S. assured the Saudis that it would protect them against any Iranian attacks, provided that Riyadh also bought US$110 billion of defense equipment from the U.S. immediately and another US$350 billion worth over the next 10 years. However, the Saudis then found out that none of these weapons were able to prevent Iran from launchingsuccessful attacksagainst its key oil facilities in September 2019, or several subsequent attacks.

Concomitant with this weakening of relations between Saudi Arabia and the U.S. came a drift towards Russia first and then China. Given the reputational damage done to the perceived power of Saudi Arabia and its OPEC brothers by their inability to destroy or disable the growing threat from U.S. shale oil to their former dominance in the global oil markets, their attempts to pull oil prices back up to levels at which they could begin to repair thedamage done to their economiesby the 2014-2016 Oil Price War towards the end of 2016 also failed. At that point, fully cognisant of the enormous economic and geopolitical possibilities that were available to it by becoming a core participant in the crude oil supply/demand/pricing matrix, Russia agreed to support the OPEC production cut deal in what was to be called from then-on ‘OPEC+’, albeit in its own uniquely self-serving and ruthless fashion, again analyzed in-depth inmy new book on the global oil markets.

Given Russia’s significant leverage in the Middle East by dint of its pivotal position in making the OPEC deal credible in terms of being able to affect global oil prices, China also began to more aggressively leverage its own power with the group and in the region by dint of its being the world’s biggest net importer of crude oil and its increasing use of checkbook diplomacy. Nowhere were the two elements more in evidence than in China’s offer to buy the entire 5 percent stake of Aramco in a private placement. This was designed to enable Saudi Crown Prince Mohammed bin Salman to save face, given hisunsuccessful attempts from 2016 to 2020to persuade serious Western investors to have any significant part in the company’s initial public offering. Shortly after the offer was made,China was referred toby Saudi’s then-vice minister of economy and planning, Mohammed al-Tuwaijri, as: “By far one of the top markets” to diversify the funding basis of Saudi Arabia. He added that: “We will also access other technical markets in terms of unique funding opportunities, private placements, panda bonds and others.” In a similar vein, andjust last year, Saudi Aramco’s chief executive officer, Amin Nasser, said: “Ensuring the continuing security of China’s energy needs remains our [Saudi Aramco’s] highest priority — not just for the next five years but for the next 50 and beyond.”

Later, the first discussions about the joint Saudi-China refining and petrochemical complex in China’s northeast began, with a bonus for Saudi Arabia being that Aramco was intended to supply up to 70 percent of the crude feedstock for the complex that was to have commenced operation in 2024. This, in turn, was part of a multiple-deal series that also included three preliminary agreements to invest in Zhejiang province in eastern China. The first agreement was signed to acquire a 9 percent stake in the greenfield Zhejiang Petrochemical project, the second was a crude oil supply deal signed with Rongsheng Petrochemical, Juhua Group, and Tongkun Group, and the third was with Zhejiang Energy to build a large-scale retail fuel network over five years in Zhejiang province.

This latest Aramco-Norinco-Panjin Sincen deal, though, carries with it even broader ramifications of a much more overtly testing nature for U.S. President Joe Biden in terms of where he draws the line on supposed allies blurring trade considerations and security considerations. All Chinese companies function as part of the State apparatus – without any exception – and Norinco has the added troubling element for the U.S. that it is one of China’s major defense contractors, specializing in the full range of research, development, and production of military equipment, technology, systems, and weapons. This runs alongside ongoing concerns from Washington about Saudi Arabia’s on again-off again agreement with Russia tobuy its S-400 missile defense system, and much more recent news in December 2021 that Saudi Arabia is now actively manufacturing itsown ballistic missiles with the help of China.

The changing roles played by China’s independent refineries are reflected in their relations with Middle East suppliers. In the battle to ensure their profitability and very survival, smaller Chinese teapots have adopted various measures, including sopping up steeply discounted oil from Iran. Meanwhile, Middle East suppliers, notably Saudi Aramco, are seeking to lock in Chinese crude demand while pursuing new opportunities for further investments in integrated downstream projects led by both private and state-owned companies.

Four years later, the NDRC adopted a different approach, awarding licenses and quotas to teapot refiners to import crude oil and granting approval to export refined products in exchange for reducing excess capacity, either upgrading or removing outdated facilities, and building oil storage facilities.[10] But this partial liberalization of the refining sector did not go exactly according to plan. Swelling with new sources of feedstock that catapulted China into the position of the world’s largest oil importer, teapots increased their production of refined fuels and, benefiting from greater processing flexibility and low labor costs undercut larger state rivals and doubled their market share.[11]

2021 marked the start of the central government’s latest effort to consolidate and tighten supervision over the refining sector and to cap China’s overall refining capacity.[14] Besides imposing a hefty tax on imports of blending fuels, Beijing has instituted stricter tax and environmental enforcement[15] measures including: performing refinery audits and inspections;[16] conducting investigations of alleged irregular activities such as tax evasion and illegal resale of crude oil imports;[17] and imposing tighter quotas for oil product exports as China’s decarbonization efforts advance.[18]

The politics surrounding this new class of greenfield mega-refineries is important, as is their geographical distribution. Beijing’s reform strategy is focused on reducing the country’s petrochemical imports and growing its high value-added chemical business while capping crude processing capacity. The push by Beijing in this direction has been conducive to the development of privately-led mega refining and petrochemical projects, which local officials have welcomed and staunchly supported.[20]

Yet, of the three most recent major additions to China’s greenfield refinery landscape, none are in Shandong province, home to a little over half the country’s independent refining capacity. Hengli’s Changxing integrated petrochemical complex is situated in Liaoning, Zhejiang’s (ZPC) Zhoushan facility in Zhejiang, and Shenghong’s Lianyungang plant in Jiangsu.[21]

As China’s independent oil refining hub, Shandong is the bellwether for the rationalization of the country’s refinery sector. Over the years, Shandong’s teapots benefited from favorable policies such as access to cheap land and support from a local government that grew reliant on the industry for jobs and contributions to economic growth.[22] For this reason, Shandong officials had resisted strictly implementing Beijing’s directives to cull teapot refiners and turned a blind eye to practices that ensured their survival.

But with the start-up of advanced liquids-to-chemicals complexes in neighboring provinces, Shandong’s competitiveness has diminished.[23] And with pressure mounting to find new drivers for the provincial economy, Shandong officials have put in play a plan aimed at shuttering smaller capacity plants and thus clearing the way for a large-scale private sector-led refining and petrochemical complex on Yulong Island, whose construction is well underway.[24] They have also been developing compensation and worker relocation packages to cushion the impact of planned plant closures, while obtaining letters of guarantee from independent refiners pledging that they will neither resell their crude import quotas nor try to purchase such allocations.[25]

To be sure, the number of Shandong’s independent refiners is shrinking and their composition within the province and across the country is changing — with some smaller-scale units facing closure and others (e.g., Shandong Haike Group, Shandong Shouguang Luqing Petrochemical Corp, and Shandong Chambroad Group) pursuing efforts to diversify their sources of revenue by moving up the value chain. But make no mistake: China’s teapots still account for a third of China’s total refining capacity and a fifth of the country’s crude oil imports. They continue to employ creative defensive measures in the face of government and market pressures, have partnered with state-owned companies, and are deeply integrated with crucial industries downstream.[26] They are consummate survivors in a key sector that continues to evolve — and they remain too important to be driven out of the domestic market or allowed to fail.

In 2016, during the period of frenzied post-licensing crude oil importing by Chinese independents, Saudi Arabia began targeting teapots on the spot market, as did Kuwait. Iran also joined the fray, with the National Iranian Oil Company (NIOC) operating through an independent trader Trafigura to sell cargoes to Chinese independents.[27] Since then, the coming online of major new greenfield refineries such as Rongsheng ZPC and Hengli Changxing, and Shenghong, which are designed to operate using medium-sour crude, have led Middle East producers to pursue long-term supply contracts with private Chinese refiners. In 2021, the combined share of crude shipments from Saudi Arabia, UAE, Oman, and Kuwait to China’s independent refiners accounted for 32.5%, an increase of more than 8% over the previous year.[28] This is a trend that Beijing seems intent on supporting, as some bigger, more sophisticated private refiners whose business strategy aligns with President Xi’s vision have started to receive tax benefits or permissions to import larger volumes of crude directly from major producers such as Saudi Arabia.[29]

The shift in Saudi Aramco’s market strategy to focus on customer diversification has paid off in the form of valuable supply relationships with Chinese independents. And Aramco’s efforts to expand its presence in the Chinese refining market and lock in demand have dovetailed neatly with the development of China’s new greenfield refineries.[30] Over the past several years, Aramco has collaborated with both state-owned and independent refiners to develop integrated liquids-to-chemicals complexes in China. In 2018, following on the heels of an oil supply agreement, Aramco purchased a 9% stake in ZPC’s Zhoushan integrated refinery. In March of this year, Saudi Aramco and its joint venture partners, NORINCO Group and Panjin Sincen, made a final investment decision (FID) to develop a major liquids-to-chemicals facility in northeast China.[31] Also in March, Aramco and state-owned Sinopec agreed to conduct a feasibility study aimed at assessing capacity expansion of the Fujian Refining and Petrochemical Co. Ltd.’s integrated refining and chemical production complex.[32]

Commenting on the rationale for these undertakings, Mohammed Al Qahtani, Aramco’s Senior Vice-President of Downstream, stated: “China is a cornerstone of our downstream expansion strategy in Asia and an increasingly significant driver of global chemical demand.”[33] But what Al Qahtani did notsay is that the ties forged between Aramco and Chinese leading teapots (e.g., Shandong Chambroad Petrochemicals) and new liquids-to-chemicals complexes have been instrumental in Saudi Arabia regaining its position as China’s top crude oil supplier in the battle for market share with Russia.[34] Just a few short years ago, independents’ crude purchases had helped Russia gain market share at the expense of Saudi Arabia, accelerating the two exporters’ diverging fortunes in China. In fact, between 2010 and 2015, independent refiners’ imports of Eastern Siberia Pacific Ocean (ESPO) blend accounted for 92% of the growth in Russian crude deliveries to China.[35] But since then, China’s new generation of independents have played a significant role in Saudi Arabia clawing back market share and, with Beijing’s assent, have fortified their supply relationship with the Kingdom.

Smaller Chinese independents have been less fortunate, hit hard not just by tougher domestic regulation but by soaring crude oil prices.[36] US-led sanctions flowing from the war in Ukraine have compounded the pressure on teapots, which prior to the conflict had sourced about a fifth of their crude oil from Russia. Soaring oil tanker freight rates and the refusal of Chinese banks to issue letters of credit for Russian crude have choked off much of this supply, though some private refiners have compensated by using cash transfers to pay for Russian ESPO blend crude.[37]

Meanwhile, though, enticed by discounted prices Chinese independents in Shandong province have continued to scoop up sanctioned Iranian oil, especially as their domestic refining margins have thinned due to tight regulatory scrutiny. In fact, throughout the period in which Iran has been under nuclear-related sanctions, Chinese teapots have been a key outlet for Iranian oil, which they reportedly unload from reflagged vessels representing themselves as selling oil from Oman and Malaysia.[38] China Concord Petroleum Company (CCPC), a Chinese logistics firm, remained a pivotal player in the supply of sanctioned oil from Iran, even after it was blacklisted by Washington in 2019.[39] Although Chinese state refiners shun Iranian oil, at least publicly, because of US sanctions, private refiners have never stopped buying Iranian crude.[40] And in recent months, teapots have been at the forefront of the Chinese surge in crude oil imports from Iran.[41]

As Chinese private refiners’ number, size, and level of sophistication has changed, so too have their roles not just in the domestic petroleum market but in their relations with Middle East suppliers. Beijing’s import licensing and quota policies have enabled some teapot refiners to maintain profitability and others to thrive by sourcing crude oil from the Middle East. For their part, Gulf producers have found Chinese teapots to be valuable customers in the spot market in the battle for market share and, especially in the case of Aramco, in the effort to capture the growth of the Chinese domestic petrochemicals market as it expands.

Chinese private petrochemical group Zhejiang Rongsheng Holding has entered into a framework of agreement with China Shipbuilding Group to build a VLCC fleet.

Under the agreement, Rongsheng will set up a joint venture with CSSC Shipping and order VLCCs with China Shipbuilding Group. The ships will be used for oil transportation from the Middle East to Zhoushan to support the development of Rongsheng’s new petrochemical plant.

Mohammed bin Salman will meet Chinese President Xi Jinping, who has made stepping up China"s presence in the Middle East a key foreign policy objective, despite its traditional low-key role there. China has given few details about the visit.

Saudi Aramco, the world"s top oil exporter, will sign a memorandum of understanding (MOU) to build a refinery and petrochemical project in the northeastern Chinese province of Liaoning in a joint venture with China"s defence conglomerate Norinco, said three sources with knowledge of the matter.

Aramco is also expected to formalise an earlier plan to take a minority stake in Zhejiang Petrochemical, controlled by private Chinese chemical group Zhejiang Rongsheng Holding Group, said two sources with knowledge of this particular deal. Zhejiang Petrochemical is building a refinery and petrochemical complex in the eastern Chinese province of Zhejiang.

The investments could help Saudi Arabia regain its place as the top oil exporter to China, which it has relinquished to Russia for the past three years. Saudi Aramco is poised to bolster its market share by signing supply agreements with non-state Chinese refiners.

Under that earlier MOU, the companies agreed to build a refinery capable of processing 300,000 barrels per day of crude and a facility that would make 1 million tonnes per year of ethylene, a building block for petrochemicals, at an estimated cost of over $10 billion.

The agreement follows an earlier MOU that Aramco signed in October to invest in Zhejiang"s project, which is planned as a refinery to process 400,000 bpd of crude and associated petrochemical facilities in the city of Zhoushan, south of Shanghai.

8613371530291

8613371530291