haas rotary table pricelist

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

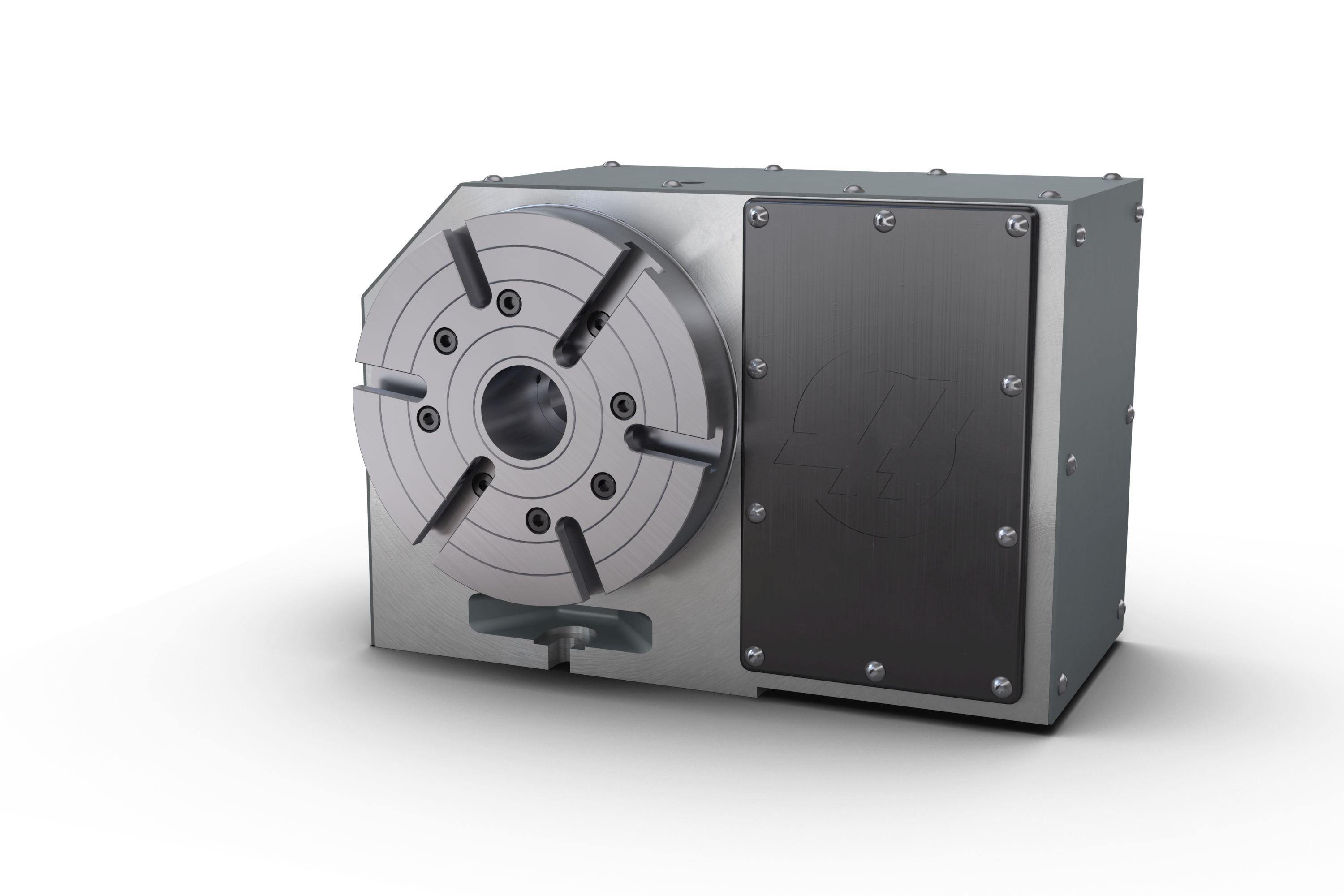

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high speed of the ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

... fixtures, the HRT series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

For holding medium to large parts or fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures can easily be bolted to the table using the six precision T-slots, and large through-holes allow for bar feeding and special fixture-locating requirements.

Requires a Haas mill with 4th-axis drive and software version 18.00 or later for full 4th-axis operation, or a rotary control box for stand-alone operation.

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

In order to participate in the auction, all BIDDERS must provide AUCTIONEER a 25% deposit in cash, cashier’s check, or company check accompanied by a bank letter of guarantee of unqualified payment to AUCTIONEER, or a wire transfer (with a wire transfer fee included) of BIDDER’S maximum expected spending inclusive of taxes and fees. Credit cards are not acceptable form of payment and will not be accepted.The final payment in full of BIDDER’S invoice must be received by AUCTIONEER within the first banking day 24 hours after the auction or BIDDER will be in default of AGREEMENT. AUCTIONEER will charge BIDDERS a taxable surcharge BUYERS PREMIUM on AUCTIONEER’S invoice to BIDDER. BIDDER shall provide proof satisfactory to AUCTIONEER of BIDDER’Sentitlement to claim exemption from sales tax. BIDDER’S proof of any claimed tax exemption must be representative of the same industry as the LOTS purchased. In the absence of proof satisfactory to AUCTIONEER, BIDDER shall pay all taxes. AUCTIONEER is not responsible for any Department of Motor Vehicle fees, taxes, registration, licensing, penalties, smog certificate, or any other fees. Certain vehicles as announced and/or noted in the auction catalog or on BIDDER’S invoice will be sold “AS IS” with a Bill of Sale only. Each titled item will be charged a $75 title transfer fee. If available to AUCTIONEER, titles will be sent to BIDDER approximately 7-30 business days after receipt of payment from BIDDER to AUCTIONEER. Sales tax on Motor Vehicles is the responsibility of BIDDER to be remitted to BIDDER’S appropriate state Department of Motor Vehicles. All vehicles are sold “AS IS, WHERE IS, WITH NO WARRANTIES EXPRESSED OR IMPLIED”. It is the BIDDER’S responsibility to inspect the vehicle to verify accurate description, model, year, mileage, condition and any and all details pertaining to the vehicle. AUCTIONEER is not responsible for any inaccuracies regarding LOTS of any kind INCLUDING THE DESCRIPTIONS ON THE FINAL INVOICE.

Should any pits, floor bolts or hazards of any type exist after removal of equipment, it is BIDDER’Sresponsibility, at BIDDER’S cost, to reasonably safe guard these areas using generally accepted safety practices, such as safety tapes, pipes or bars welded in place or suitable safety barriers acceptable to AUCTIONEER. All floor bolts and/or anchoring fasteners are to be cut flush to the floor and the area left broom clean and all debris removed. It is the responsibility of BIDDER to be sure that power to the LOTSis off and then to safely disconnect all electrical wiring and utility piping from the LOTSand to cap at the first electrical or air junction of the LOTS.

In 1988 Haas introduced the VF-1, a machine designed by machinists for machinists Since the VF1 Haas has continued to provide CNC mills for numerous applications. Today Haas Automation is the leader in North American CNC machine sales. In the world of CNC, Haas is so popular that "Haas CNC For Sale" is the most searched for CNC-related term in search engines today.

Haas CNC are made in Oxnard, California, USA, and has become the most trusted brand in the industry. As of 2018, they continue to sell thousands of machines each month and even have backlogs in their delivery because of the demand and momentum in the United States. One of the most popular models made by Haas is the Haas VF2. The Haas VF2 on haascnc.com. The VF2 has remained so popular, that they"ve made the same model for over 10 years. Haas is a great brand for companies looking for economical machines that they would like to support themselves. Haas supports its customers with online resources to encourage shops to maintain and repair their own Haas CNC as much as is reasonable.

The Haas control makes Haas CNC easy to operate. Even models going back to the year 2000 had Haas-only features like Word Processor Editing to help operators easily make changes. On their milling machines, they had features like one-touch, multi-function jog-handle and quick code programming even on machines made 18 years ago. They provide a robust dependable control that is integrated with the Haas CNC machine. They do not rely on third-party CNC suppliers. Haas machines have dedicated keypads with a full array of keys including a complete alphanumeric keypad with all common functions clearly labeled for operator use. Operators do not need to remember any encrypted codes. Keep in mind, if you are buying an older Haas, its very likely that the control can be updated. Haas supports their equipment no matter what the age and provides updates to all Haas CNC machine owners.

As computer technology advances, Haas makes itscontrols even faster and smarter. Their goal is to keep the spindle turning which keeps the cash flowing into your pocket. Contact your local Haas distributor or visit the Haas website for information on updating an older Haas machine. Newer models have: HaasConnect Remote Monitoring, Ethernet connectivity, DWO/TCPC (Dynamic Work Offsets and Tool Center Point Control), User-Definable Macros, WiFi Connectivity, and Expandable Memory.

You will find the used Haas mills are sold as VF Series, as universal machines (UMC), Haas mini mills (MINI MILL) and drill/tap/mill (DT & DM). There are also machine series designed for specific applications, like the mold machines (VM) and tool room mills (TM). For small parts in tight spots, the compact CNC vertical mill (CM) may fit the bill. For the largest applications, cutting plate and sheet Haas offers the Gantry series (GR). The Haas VR Series ended in 2013 but is still widely available used.

Haas VF Vertical Mill VF1, VF1YT, VF2, VF2TR, VF2YT, VF2SS, VF2SSYT, VF3, VF3SS, VF3SSYT, VF3YT/50, VF4, VF4SS, VF5, VF5/50, VF5XT VF5SS, VF6, VF6/50, VF6SS, VF7, VF9, VF10, VF11, VF12 1990 - 2019

Horizontal mills have the spindle on the horizontal axis and are used for making much larger parts than the vertical milling machines. Differentiators between various Haas horizontal machines are similar to those of vertical milling machines. Size, spindle speed, horsepower and the design of the tool changing system all make an impact on the speed and complexity of part that can be made on horizontal milling machines. Haas offers the EC series which can make parts up to 10,000 lbs. Haas offers two basic sizes of horizontal milling machines, 64 x 50 x 32 and 64 x 50 x 40. The additional 8 is on the ZT variation of their EC. Look for EC-1600, EC-1600ZT or for both 5 Axis and the extra size, the EC-1600ZT-5AX.

Haas makes a full line of Used Haas lathe turning centers (CNC lathes) including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis models and Y-axis capabilities.

Hass offers rotary products that add 4th and 5th axis capabilities to many of their machines. T-slotted rotary tables allow for flexible fixturing for machining round parts and odd-shaped parts. Model numbers for these rotary tables usually begin with HRT. Their 5-axis rotary tables and add a 3+2 position or full 5-axis motion. The models of tilting indexers include the T5C, T5C2, T5C3, and T5C4. The TR70, TRT100, TRT160, and TRT210 are models of tilting rotaries. Prices for these begin around $20,000 for new. Indexers have model numbers like HA5C, HA5C-T, HA5CS, HA5C2, HA5C3 and more. They can be single-spindle or multi-spindle and have new prices ranging from $8,000 to $13,000. When buying used Haas CNC, sometimes you"ll find that rotary table and/or indexers included. If one of these accessories is included, then the price will be proportionately higher in most cases.

Haas provides extensive online resources for training and support. They have troubleshooting guides, how-to procedures, mill operator manuals and lathe operator mills readily available on their website. You can watch videos for troubleshooting as well as service and maintenance and get regular tips on how to best operate and care for your Haas machines. In addition, operators can search from alarm codes for all kinds of resources. They also have an extensive network of service technicians at their Haas Factory Outlets and recommend that certain machine repairs be done only by authorized personnel.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Europe and America: the best selling brands in the Chinese market are Haas and Lehmann. Haas is mainly configured on its machine tools, other brands of machine tools are rarely installed. Lehmann is positioned at the high end and mainly cooperates with some high-end machine tools. In addition, it is also used in some occasions with high accuracy requirements, but the demand is small

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

8613371530291

8613371530291