haas 5th axis rotary table pricelist

Automatic Parts Loader, for use with Haas ST-10 through ST-25 CNC turning centers. Includes CNC Control Cabinet Cooler, Remote Jog Handle-Touch, and Auto Door when ordered with a machine; requires Remote Jog Handle and Auto Door when ordered separately. Units built after 06/01/2021 receive/require the Remote Jog Handle-Touch-XL. Note: The APL can only load/unload parts from the lathe main spindle. CE compliance requires the optional safety guard fencing.

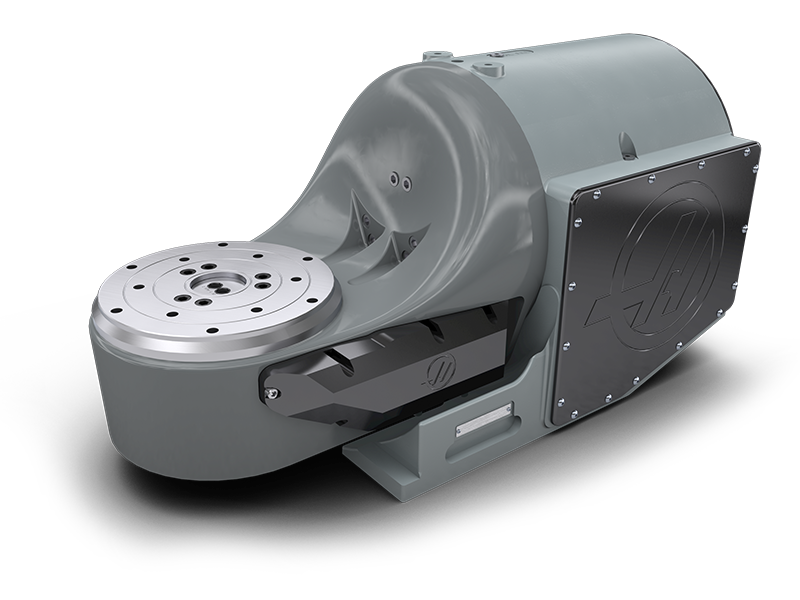

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

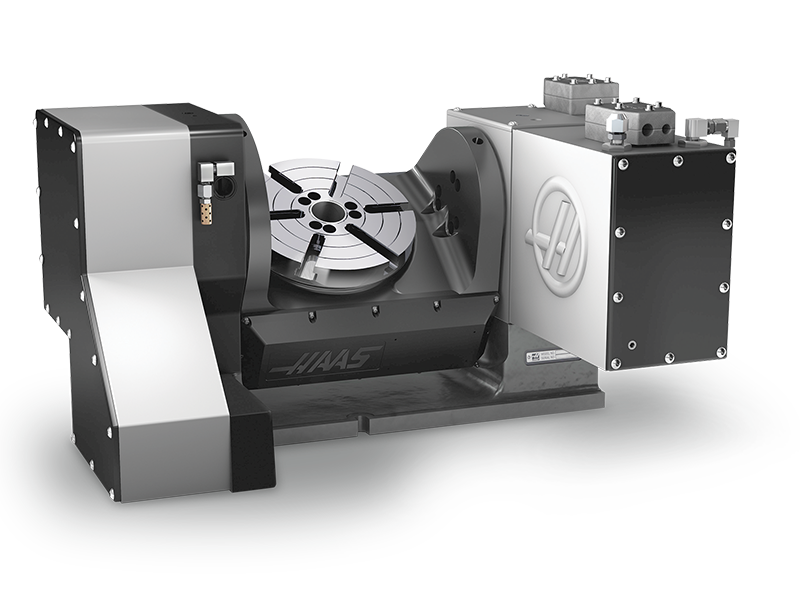

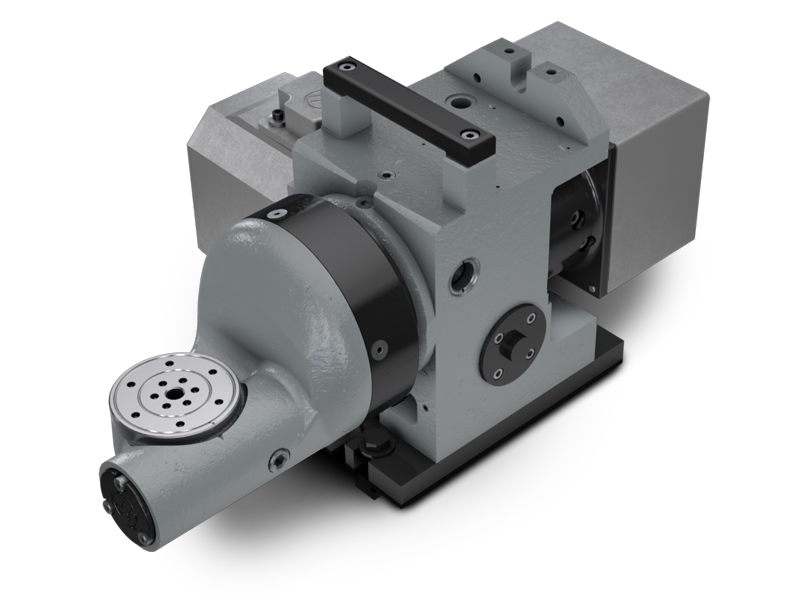

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises.

... 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version NGC 100.18.000.1030 or later to work with DWO/TCPC option. Consult your local ...

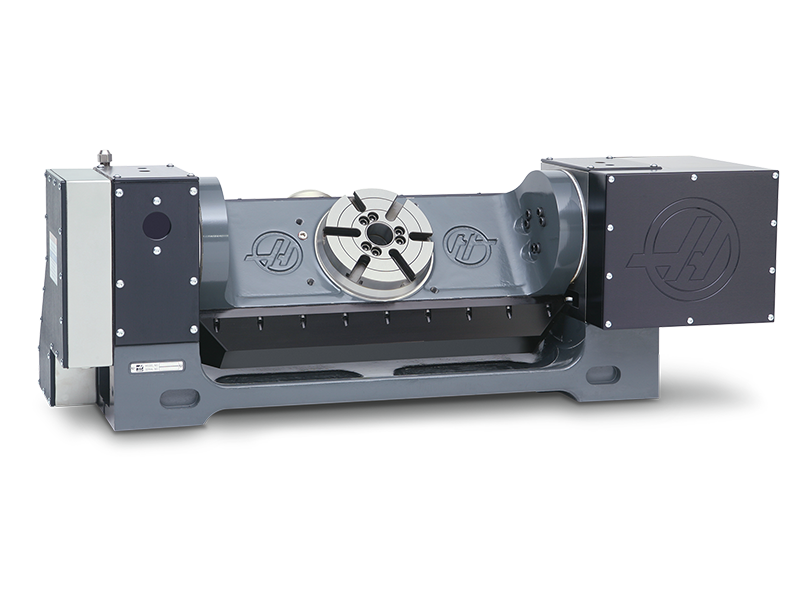

The TR160 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale ...

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The ...

... installed with the tilt axis parallel to the Y axis on VF-3 and larger VF Series machines, to allow more usable mill table space (extended Z-axis clearance options are ...

The TR210 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale ...

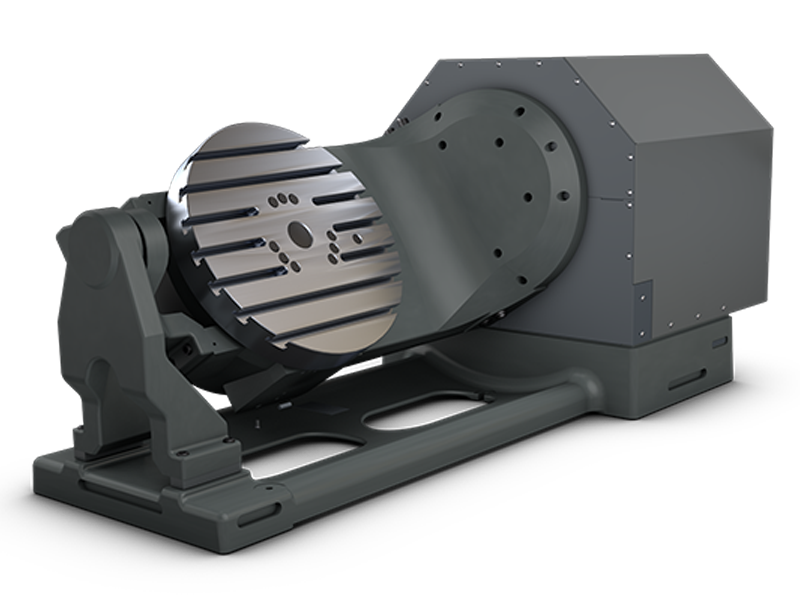

The TR310 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

Our new-design TRT310 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its compact size also provides greater mounting flexibility in mid-size mills. The unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises.

Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version NGC 100.18.000.1030 or later to work with DWO/TCPC option. Consult your local HFO for use on machines with a Classic Haas control.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Going from 3-axis machining to 4-axis and 5-axis machining can be intimidating. This short video shows how easy it is to transition from basic 3-axis milling to full 5-axis design and production.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Our control box is a cost-efficient solution for machining parts not needing true 5-axis, simultaneous motion. Add a single-axis controller with our 5th axis head turning your 4th axis machine into 4+1. Or add our dual-axis controller with our 5th axis head turning your 3 axis machine into 3+2.Either way, this allows you tomachine 5 sides of a part, thus reducing the number of machining operations and dramatically increasing efficiency and accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

In 1988 Haas introduced the VF-1, a machine designed by machinists for machinists Since the VF1 Haas has continued to provide CNC mills for numerous applications. Today Haas Automation is the leader in North American CNC machine sales. In the world of CNC, Haas is so popular that "Haas CNC For Sale" is the most searched for CNC-related term in search engines today.

Haas CNC are made in Oxnard, California, USA, and has become the most trusted brand in the industry. As of 2018, they continue to sell thousands of machines each month and even have backlogs in their delivery because of the demand and momentum in the United States. One of the most popular models made by Haas is the Haas VF2. The Haas VF2 on haascnc.com. The VF2 has remained so popular, that they"ve made the same model for over 10 years. Haas is a great brand for companies looking for economical machines that they would like to support themselves. Haas supports its customers with online resources to encourage shops to maintain and repair their own Haas CNC as much as is reasonable.

The Haas control makes Haas CNC easy to operate. Even models going back to the year 2000 had Haas-only features like Word Processor Editing to help operators easily make changes. On their milling machines, they had features like one-touch, multi-function jog-handle and quick code programming even on machines made 18 years ago. They provide a robust dependable control that is integrated with the Haas CNC machine. They do not rely on third-party CNC suppliers. Haas machines have dedicated keypads with a full array of keys including a complete alphanumeric keypad with all common functions clearly labeled for operator use. Operators do not need to remember any encrypted codes. Keep in mind, if you are buying an older Haas, its very likely that the control can be updated. Haas supports their equipment no matter what the age and provides updates to all Haas CNC machine owners.

As computer technology advances, Haas makes itscontrols even faster and smarter. Their goal is to keep the spindle turning which keeps the cash flowing into your pocket. Contact your local Haas distributor or visit the Haas website for information on updating an older Haas machine. Newer models have: HaasConnect Remote Monitoring, Ethernet connectivity, DWO/TCPC (Dynamic Work Offsets and Tool Center Point Control), User-Definable Macros, WiFi Connectivity, and Expandable Memory.

You will find the used Haas mills are sold as VF Series, as universal machines (UMC), Haas mini mills (MINI MILL) and drill/tap/mill (DT & DM). There are also machine series designed for specific applications, like the mold machines (VM) and tool room mills (TM). For small parts in tight spots, the compact CNC vertical mill (CM) may fit the bill. For the largest applications, cutting plate and sheet Haas offers the Gantry series (GR). The Haas VR Series ended in 2013 but is still widely available used.

Haas VF Vertical Mill VF1, VF1YT, VF2, VF2TR, VF2YT, VF2SS, VF2SSYT, VF3, VF3SS, VF3SSYT, VF3YT/50, VF4, VF4SS, VF5, VF5/50, VF5XT VF5SS, VF6, VF6/50, VF6SS, VF7, VF9, VF10, VF11, VF12 1990 - 2019

Horizontal mills have the spindle on the horizontal axis and are used for making much larger parts than the vertical milling machines. Differentiators between various Haas horizontal machines are similar to those of vertical milling machines. Size, spindle speed, horsepower and the design of the tool changing system all make an impact on the speed and complexity of part that can be made on horizontal milling machines. Haas offers the EC series which can make parts up to 10,000 lbs. Haas offers two basic sizes of horizontal milling machines, 64 x 50 x 32 and 64 x 50 x 40. The additional 8 is on the ZT variation of their EC. Look for EC-1600, EC-1600ZT or for both 5 Axis and the extra size, the EC-1600ZT-5AX.

Haas makes a full line of Used Haas lathe turning centers (CNC lathes) including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis models and Y-axis capabilities.

Hass offers rotary products that add 4th and 5th axis capabilities to many of their machines. T-slotted rotary tables allow for flexible fixturing for machining round parts and odd-shaped parts. Model numbers for these rotary tables usually begin with HRT. Their 5-axis rotary tables and add a 3+2 position or full 5-axis motion. The models of tilting indexers include the T5C, T5C2, T5C3, and T5C4. The TR70, TRT100, TRT160, and TRT210 are models of tilting rotaries. Prices for these begin around $20,000 for new. Indexers have model numbers like HA5C, HA5C-T, HA5CS, HA5C2, HA5C3 and more. They can be single-spindle or multi-spindle and have new prices ranging from $8,000 to $13,000. When buying used Haas CNC, sometimes you"ll find that rotary table and/or indexers included. If one of these accessories is included, then the price will be proportionately higher in most cases.

Haas provides extensive online resources for training and support. They have troubleshooting guides, how-to procedures, mill operator manuals and lathe operator mills readily available on their website. You can watch videos for troubleshooting as well as service and maintenance and get regular tips on how to best operate and care for your Haas machines. In addition, operators can search from alarm codes for all kinds of resources. They also have an extensive network of service technicians at their Haas Factory Outlets and recommend that certain machine repairs be done only by authorized personnel.

CharacteristicsNumber of axes5-axisSpindle orientationverticalOther characteristicsCNC, for aeronauticsRotational speed10,000 rpm (62,832 rad.min-1)X travel381 mm (15 in)Y travel356 mm (14 in)Z travel305 mm (12 in)

The UMC-350HD combines the 40-taper performance of our DM-1 Drill/Mill Center with the versatility of our TRT210 dual-axis rotary to create a lean-style UMC that’s perfect for 3+2 and simultaneous 5-axis machining of small parts.

The Stallion Tombstone provides manufacturers with the ultimate time saver. With 4 sides, handling and tool change time decreases substantially. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Tombstone minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary. Our smallest tombstone model, at 4", is perfect for machining small parts at large volume.

8613371530291

8613371530291