rotary table drilling rig supplier

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

Please call NDS for all of your rotary table needs, whether it may be for repairs or for new sales. We stock a wide variety of parts for the Gardner Denver 503 5-1/4″ rotary table, the 603 5-1/4″ rotary table with bottom ring gear, the 603 5-1/4″ rotary table with top ring gear, the 7-1/2″ 2003 rotary table with bottom ring gear, the 7-1/2″ 2003 rotary table with top ring gear, the 10″ 3003 rotary table, the 5-1/4″ GEFCO rotary table, the 7-1/2″ GEFCO rotary table, 7-1/2″ Mayhew table for a Failing Rig, 8-1/2″ Speedstar table, 8-1/2″ Mayhew Table for a Speedstar rig and the 8-1/2″ Midway rotary table. Portadrill, Mayhew, Failing and Midway rotary tables and parts are also available.

A rotary table drilling rig is generally more powerful and can deeper depths drilling than a rotary table drilling rig. It rotates table drilling rig, in the form of a rotary table drilling rig, and the other variations of drilled are as distinct as a rotary table drilling rig. deeper depths are needed to drill deeper depths than a rotary table drill.

Both rotary and drilling tables are typically used in the form of rotary table drilling rig, because the rotary table drilling rig is both portable and non-volatile because of the chemicalsactions that are required for a drill. A rotary table drilling rig is both used to drill and distill water at the surface of a rock. rotary table drilling tables are typically used in the form of a rotary table drilling rig, as they are not used in any form of drilling rig, because the rotary table drilling rig is both used andically for non-flammable purposes,

There are two types of table drilling rig, depending on the type of client and the end product needed. A rotary table drilling rig is also called a rotary table drilling rig, depending on the type of client ands surface.

Welcome to Pickett Oilfield’s rotary tables web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used rotary tables and rotary equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including rotary tables to choose from at competitive prices. Browse our inventory of rotary tables and rotary table drilling components for sale at competitive rates.

Rotary Tables - 37-1/2 IN. ROTARIES, FG-2A, 500 TON, 14 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY ACT... More Info

Rotary Tables - 49-1/2 IN. ROTARIES, FG-3A, 750/500 TON, 20 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY... More Info

Rotary Tables - DEN-CON 49-1/2 IN. HMB BUSHING, 750 TON RATING, AVAILABLE WITH A VARIETY OF INSERT BOWLS INCLUDING CONVENTIONAL API BOWLS, 500 TON BOWLS AND 750 TON BOWLS. More Info

Rotary Tables - 37-1/2 IN. - 49-1/2 IN. ROTARIES, FG-6B, 350 TON, 8-5/8 IN. & SMALLER WORKOVER RISER. PURPOSE BUILT POWER SLIP FOR HANDLING WORKOVER RISER WITH UMBILICALS. IDEAL FOR RENT... More Info

Rotary Tables - POWER SLIPS ARE AVAILABLE FOR 27-1/2 IN., 37-1/2 IN. & 49-1/2 IN. ROTARY TABLES. RATED CAPACITIES FROM 350 TONS TO 750 TONS. 27-1/2 IN. ROTARIES, FG-5A, 350 TON, 9-5/8 IN... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 60-1/2 IN. X 49-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 49-1/2 IN. X 37-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

FYPE Rigid Machinery is one of the leading China manufacturers and suppliers in oil and gas industry. Our company now brings you high quality and competitive price rig drilling rotary table manufacturer, rotary table for sale, which is widely used in oilfield. And quick delivery is also offered, please be free to contact our factory.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

2.The drilling rig is a bulk rotary table drill, which is mainly used for middle Quaternary, fine grained strata and soft rock layers. The main uses are: the hydrogeological conditions at the bottom of the exploration and survey; the drilling and drilling for the agricultural irrigation, the industrial water use, the underground tunnel ventilation, the bridge and other engineering drilling.

3. When drilling rigs, mud flushing fluid (positive circulation) and rotary table are used to drive the drilling tools to rotate. Winch system decompression drilling, lifting drilling, underground pipe, impact sampling, stand rig etc..

As one of important parts of drill rig, ZP series of rotary tables are widely used to rotate drill equipment and hold the weight of pipes in well. They are designed and manufactured according to API Spec 7K “Specification For Drilling Equipment”.

TSC RT series rotary table is provided with high reliability and serviceability. The rotary table structure has been designed to provide maximum strength to ensure larger load, increased safety and well-fit between bearings and gears. The table assembly was greatly simplified so it can be installed into the rotary housing and is easy to maintain. The RT series can be designed to meet the requirements of various drilling operations and work environments.

Rotary drilling uses a sharp, rotating drill bit to dig down through the Earth’s crust. Much like a common hand-held drill, the spinning of the drill bit allows for penetration of even the hardest rock.

The idea of using a rotary drill bit is not new. Archeological records show that as early as 3000 B.C., the Egyptians may have been using a similar technique. Leonardo Di Vinci, as early as 1500, developed a design for a rotary drilling mechanism that bears much resemblance to technology used today. Despite these precursors, rotary drilling did not rise in use or popularity until the early 1900s.

Although rotary drilling techniques had been patented as early as 1833, most of these early attempts at rotary drilling consisted of little more than a mule, attached to a drilling device, walking in a circle. It was the success of the efforts of Anthony Lucas and Patillo Higgins in drilling their 1901 Spindletop well in Texas that catapulted rotary drilling to the forefront of petroleum drilling technology.

While the concept for rotary drilling – using a sharp, spinning drill bit to delve into rock – is quite simple, the actual mechanics of modern rigs are quite complicated. In addition, technology advances so rapidly that new innovations are being introduced constantly.

The basic rotary drilling system consists of four groups of components – the prime movers, hoisting equipment, rotating equipment and circulating equipment – that all combine to make rotary drilling possible.

The prime movers in a rotary drilling rig are those pieces of equipment that provide the power to the entire rig. Steam engines provided the power to the early drill rigs. Gas and diesel engines became the norm after World War II. Recently, while diesel engines still compose the majority of power sources on rotary rigs, other types of engines also are in use; more so in the oil and gas industry than in the water well sector. Natural gas or gasoline engines commonly are used, as are natural gas- or gasoline-powered reciprocating turbines, which generate electricity on-site. The resulting electricity is used to power the rig itself. The energy from these prime movers is used to power the rotary equipment, the hoisting equipment and the circulating equipment, and, on large rigs, may be used as well to provide incidental lighting, water and compression requirements not directly associated with drilling.

The hoisting equipment on a rotary rig consists of the tools used to raise and lower whatever other equipment may go into or come out of the well. The most visible part of the hoisting equipment is the derrick, which serves as a support for the cables (drilling lines) and pulleys (drawworks) that serve to lower or raise the equipment in the well.

For instance, in rotary drilling, the wells are made with long strings of drill pipe extending from the surface down to the drill bit. If a drill bit needs to be changed, either due to wear and tear or a change in the subsurface rock, the whole string of pipe must be raised to the surface.

In deep wells, the combined weight of the drill pipe, drill bit and drill collars may be in excess of thousands of pounds. The hoisting equipment is used to raise all of this equipment to the surface so that the drill bit may be replaced, at which point the entire chain of drill pipe is lowered back into the well. The height of a rig’s derrick often can be a clue as to the depth of the well being drilled. Drill pipe traditionally comes in 20-foot sections, which are joined together as the well is goes deeper and deeper. This means that even if a well is 1,200 feet deep, the drill string must still be taken out in 20-foot sections. However, if the derrick is tall enough, multiple joints of drill pipe may be removed at once, speeding up the process a great deal.

The rotating equipment on a rotary drilling rig consists of the components that actually serve to rotate the drill bit, which, in turn, sends the hole deeper and deeper into the ground. The rotating equipment consists of a number of different parts, all of which contribute to transferring power from the prime mover to the drill bit itself. The prime mover supplies power to the rotary, which is the device that turns the drill pipe, which, in turn, is attached to the drill bit. A component called the swivel, which is attached to the hoisting equipment, carries the entire weight of the drill string, but allows it to rotate freely.

Below the drill pipe are drill collars, which are heavier, thicker and stronger than normal drill pipe. The drill collars help to add weight to the drill string, right above the bit, to ensure there is enough downward pressure to allow the bit to drill through hard rock. The number and nature of the drill collars on any particular rotary rig can be altered depending on the down-hole conditions experienced while drilling.

The final component of rotary drilling consists of the circulating system. There are a number of main objectives of this system, including cooling and lubricating the drill bit, removing debris and cuttings, and coating the walls of the well with a mud type-cake. The circulating system consists of drilling fluid, which is circulated down through the well hole throughout the drilling process.

The components of the circulating system include drilling fluid pumps, compressors, related plumbing fixtures, and specialty injectors for the addition of additives to the fluid flow stream.

Rotary drilling, as opposed to percussion drilling, cuts by rotating a bit at the bottom of the hole. In addition to rotation, downward pressure must be exerted and continued as the bit cuts it way through the formation.

Part of the art of rotary drilling is to match the bit type and pull-down pressure with the formation, and the use of drilling fluids to maintain circulation to keep the hole clear of cuttings and the bit lubricated and cool. A rotating table turns the drill string via a kelly bar passing through the table and attached to the top joint of the drill string.

hydraulically driven top-head, top-head unit with pull-down chains (more recent top-head-drive rigs are completely hydraulically driven, eliminating the need for chains or cables to provide pull-down forces); and

When beginning a new hole, and oftentimes during drilling operations, pull-down pressure from the drill rig is applied. This pull-down force is achieved by a screw, cable or chain arrangement, or by hydraulic motors. Hydraulically powered pull-down actions usually are found on more recently manufactured drill rigs, with screw, cable and chain pull-down arrangements more commonly found on older rotary rigs.

The driller controls the pull-down pressure and, thus, the speed of penetration. It must be noted that part of the art of rotary drilling is the matching of pull-down pressure to the formation. Excessive pull-down pressure can damage drill bits, drill pipe and the trueness of the borehole. Thus, applying more pull-down pressure is not always the best drilling practice.

The International School of Well Drilling (ISWD) was established in May 2002 to serve the needs of the water well, environmental and geotechnical sectors of the drilling industry. Since opening, ISWD has trained students both nationally and internationally. These students have included those seeking to enter the drilling industry, and those currently employed at a junior level in the industry, as well as industry regulators and licensed well drillers seeking to further their knowledge.

Since 2005, the ISWD’s focus has shifted to offering training to those already in the water well drilling industry. Continuing education as a requirement for license renewal is required in 27 states. The remaining states are likely to join the majority over time. ISWD is proud to offer continuing education credits for the well drilling industry online.

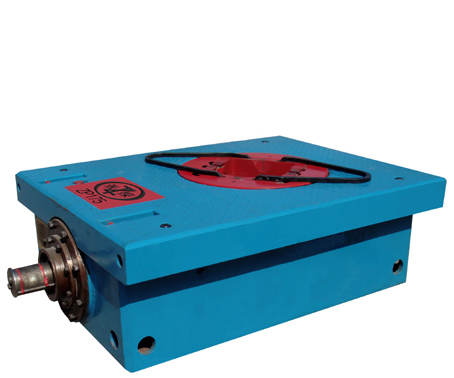

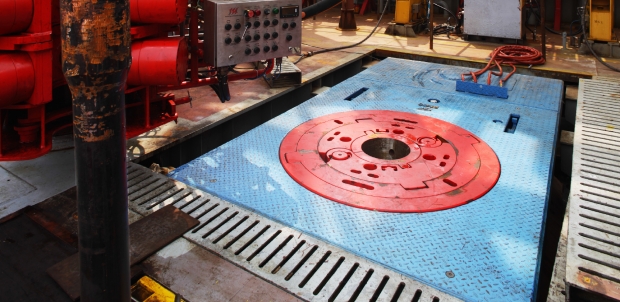

A drilling rig is not complete without the rotary table, a mechanical device that provides a clockwise rotational force to a drill string and enable the drilling of a borehole. The rotary speed is identified as rpm (rounds per minute) the amount of times the device can complete a full revolution per minute. When the drilling process covers the pipe handling operation in the wellbore, it will require a false rotary table for higher chances of success. Shale Pumps provides this device as a hydraulically driven equipment to seamlessly engage tubulars in a wellbore. We manufacture false rotary tables in-house to ensure precision engineering and the highest-quality design and materials.

When it comes to pipe handling, it is crucial for equipment to be seamless and sturdy to be reliable. Shale Pumps’ false rotary table can handle up to 1.3 million pounds of load while maintaining constant operation at a 20 rpm on maximum speed, making it ideal for long drawn and continuous operations. We developed our false rotary tables, like the SP-FRT375 to perform in the most demanding drilling jobs, and we achieve this only with precision engineering and by using advanced materials.

The false rotary table at Shale Pumps is backed by a guarantee for longevity and trouble-free performance. This way, it outperforms false rotary tables offered by other manufacturers. Our device helps you save money and boost productivity in the long run with lower maintenance costs. Every rotary table equipment has been tested in compliance with the latest industry regulations for safety, efficiency, and quality.

When choosing a false rotary table, be sure that it is being sold by a reputable manufacturer and supplier, like Shale Pumps. That way, you can be sure that the equipment has been manufactured and assembled following a strict and proven format, which ensures its quality. Shale Pumps corrects any material defects and problems with assembly immediately and take note of them to prevent them from occurring again.

A rotary table is a mechanical device on a drilling rig that provides clockwise (as viewed from above) rotational force to the drill string to facilitate the process of drilling a borehole.

Most rotary tables are chain driven. These chains resemble very large bicycle chains. The chains require constant oiling to prevent burning and seizing.

Rotary Locks - Virtually all rotary tables are equipped with a rotary lock. Engaging the lock can either prevent the rotary from turning in one particular direction, or from turning at all. This is commonly used by crews in lieu of using a second pair of tongs to makeup or break out pipe.

The rotary bushings are located at the center of the rotary table. These can generally be removed in two separate pieces to facilitate large items, i.e. drill bits, to pass through the rotary table. The large gap in the center of the rotary bushings is referred to as the "bowl" due to its appearance. The bowl is where the slips are set to hold up the drill string during connections and pipe trips as well as the point the drill string passes through the floor into the wellbore. The rotary bushings connect to the kelly bushings to actually induce the spin required for drilling

Xi"an KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL)is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, DST tools and Solid control products.

8613371530291

8613371530291