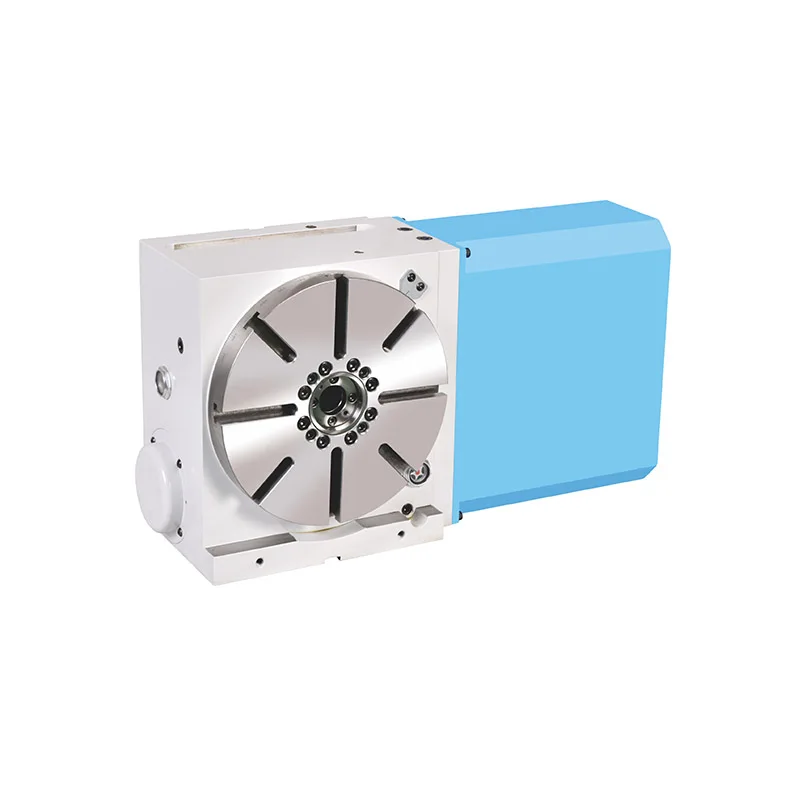

haas 4th axis rotary table made in china

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

5) After Sales Service and Technology Assistance --- Company provides after sales service and technical assistance as per customers requirement and need Tilting Rotary Tables Contact us: Shandong Sishui OLI Machine Co. 4 Could you produce non-standard products9 Yes,we can 5. Why Choose Us 9 1) Cost Control---Lower your cost in products purchase and insurance 2) Quick Respond---offers & solutions send within 48 hours 3) Fast Delievery---universal & interchangeable parts delivery within 30days 4) Genuine Products with Excellent Quality---Company has always proved the 100% quality products it provides with genuine intent. 5) After Sales Service and Technology Assistance--- Company provides after sales service and technical assistance as per customers requirement and need 6)15 years OEM manufacture experience

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

Haas Automation, Inc is an American machine tool builder headquartered in Oxnard, California. The company designs and manufactures lower cost machine tools and specialized accessory tooling, mostly computer numerically controlled (CNC) equipment, such as vertical machining centers and horizontal machining centers, lathes/turning centers, and rotary tables and indexers. Most of its products are manufactured at the company"s main facility in Oxnard.Haas F1 Team and in NASCAR the Stewart-Haas Racing Team.

Gene Haas founded Haas Automation in 1983machine tool accessory tooling. The company entered the machine tool industry with the first fully automatic, programmable collet indexer.

In 1987, Haas Automation began developing its first vertical machining center (VMC), the VF-1, a machine designed to perform operations such as milling, drilling, tapping, and boring. The first VF-1 prototypes were completed in 1988,Chicago, Illinois.

2019: Haas purchases 279 acres of land in Henderson, Nevada for $27.4 million to expand its business, planning to build 4.3 million square feet of commercial space with 2.3 million square feet intended for a $327 million manufacturing facility

VF series mills are a range of 3-axis vertical machining centers, which can be outfitted with 4th and 5th axis drives if so configured. These mills are available in different sizes, ranging from VF-1 to VF-14.

The VF in the name stands for "Very First" as the first machine Haas produced was the VF-1 ("Very First One"). One of these machines was restored by an employee, gifted to Gene Haas, and now resides in Haas"s demo room in Oxnard, CA.

The Haas DT series was originally introduced as a 30 taper high-speed machine, ideal for operations where high speed and small footprint are required, but the ability to handle large axial cutting loads is not needed. Eventually, the DM series was introduced as a 40 taper variant of the DT machine, but does not offer the 20,000 RPM spindle option.

The CM is focused on machining small parts where high accuracy is required. The CM is a 20 taper machine, with spindles from 30,000 to 50,000 RPM. Haas only offers one machine in this series, the CM-1.

Gantry Series mills feature a static bed, a bridge that moves along the Y axis, and a head that moves along the X axis. The two primary use cases for GM series machines are large molds. GM series machines feature a more substantial casting with improved chip management as opposed to the GR series. The GM-2-5AX is also available, which is simply a GM-2 featuring two extra axes affixed to the head.

VR Series machines are based on the VF series, but include a special head to allow A and B axis capabilities. VR machines are able to machine larger parts than would be possible on a VF machine outfitted with a 5th axis trunnion, as the head is able to span the entire X and Y axis travel, rather than being constrained by the smaller work envelope of a trunnion.

Haas Automation is an ISO 9001 certified company. All machine tools carry the ETL Listed mark, certifying that they conform to the NFPA 79 electrical standard for industrial machinery and the Canadian equivalent, CAN/CSA C22.2 No. 73.CE mark to its products.

Products are distributed worldwide through a network of independently owned franchised local "factory outlet" businesses that provide sales, service, and applications support for Haas machine tools. Introduced in 1999, with the first outlet established in Torrance, California, it was applied to the company"s existing worldwide network,Europe.

To enable the 4th and 5th axis code, set the right machine configuration for the ABC axis for the specific machine being used. The machine configuration can be found in the onOpen() function:

Range: Specifies the angular range for the axis in degrees as a 2-element array ("[-120, 120]"). You can also specify a single number to create an axis for an aggregate.

Resolution: Specifies the resolution. In degrees for rotational actuator. The default is 0. Note: If there"s only need for a 4 axis setup, delete the other axis beginning with "var bAxis” and “var cAxis” or disable them by typing two slashes “//” in front of the line that needs to be disabled.

This line creates a new machine configuration as defined previously by using the given variables for each axis (in that case: aAxis, cAxis). Only use the variables inside the parenthesis. If an axis has been removed or disabled earlier for a 4 axis machine setup, remember to remove the disabled axis variable here as well.

In order to participate in the auction, all BIDDERS must provide AUCTIONEER a 25% deposit in cash, cashier’s check, or company check accompanied by a bank letter of guarantee of unqualified payment to AUCTIONEER, or a wire transfer (with a wire transfer fee included) of BIDDER’S maximum expected spending inclusive of taxes and fees. Credit cards are not acceptable form of payment and will not be accepted.The final payment in full of BIDDER’S invoice must be received by AUCTIONEER within the first banking day 24 hours after the auction or BIDDER will be in default of AGREEMENT. AUCTIONEER will charge BIDDERS a taxable surcharge BUYERS PREMIUM on AUCTIONEER’S invoice to BIDDER. BIDDER shall provide proof satisfactory to AUCTIONEER of BIDDER’Sentitlement to claim exemption from sales tax. BIDDER’S proof of any claimed tax exemption must be representative of the same industry as the LOTS purchased. In the absence of proof satisfactory to AUCTIONEER, BIDDER shall pay all taxes. AUCTIONEER is not responsible for any Department of Motor Vehicle fees, taxes, registration, licensing, penalties, smog certificate, or any other fees. Certain vehicles as announced and/or noted in the auction catalog or on BIDDER’S invoice will be sold “AS IS” with a Bill of Sale only. Each titled item will be charged a $75 title transfer fee. If available to AUCTIONEER, titles will be sent to BIDDER approximately 7-30 business days after receipt of payment from BIDDER to AUCTIONEER. Sales tax on Motor Vehicles is the responsibility of BIDDER to be remitted to BIDDER’S appropriate state Department of Motor Vehicles. All vehicles are sold “AS IS, WHERE IS, WITH NO WARRANTIES EXPRESSED OR IMPLIED”. It is the BIDDER’S responsibility to inspect the vehicle to verify accurate description, model, year, mileage, condition and any and all details pertaining to the vehicle. AUCTIONEER is not responsible for any inaccuracies regarding LOTS of any kind INCLUDING THE DESCRIPTIONS ON THE FINAL INVOICE.

Should any pits, floor bolts or hazards of any type exist after removal of equipment, it is BIDDER’Sresponsibility, at BIDDER’S cost, to reasonably safe guard these areas using generally accepted safety practices, such as safety tapes, pipes or bars welded in place or suitable safety barriers acceptable to AUCTIONEER. All floor bolts and/or anchoring fasteners are to be cut flush to the floor and the area left broom clean and all debris removed. It is the responsibility of BIDDER to be sure that power to the LOTSis off and then to safely disconnect all electrical wiring and utility piping from the LOTSand to cap at the first electrical or air junction of the LOTS.

8613371530291

8613371530291