sherline rotary table manufacturer

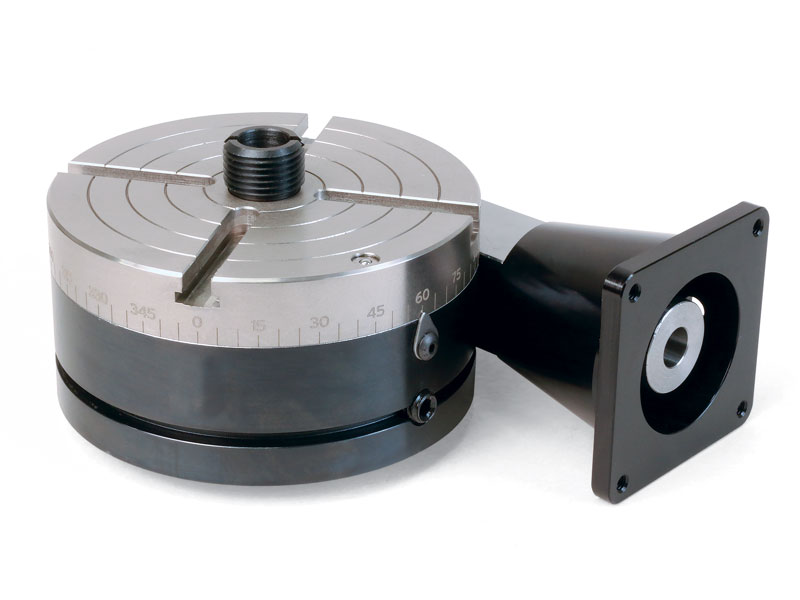

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer. Below are links to the pages on the various versions of the Sherline 4″ rotary table. The table is driven by a worm gear with a 72:1 ratio making each turn of the handwheel equal to 5°. Fifty laser engraved handwheel marks indicate positions 1/10 of a degree apart. A 90° fixture is available to position the table in a vertical position. Our P/N 3750 Tilting Angle Table is also available for positioning at any angle from 0° to 90°.

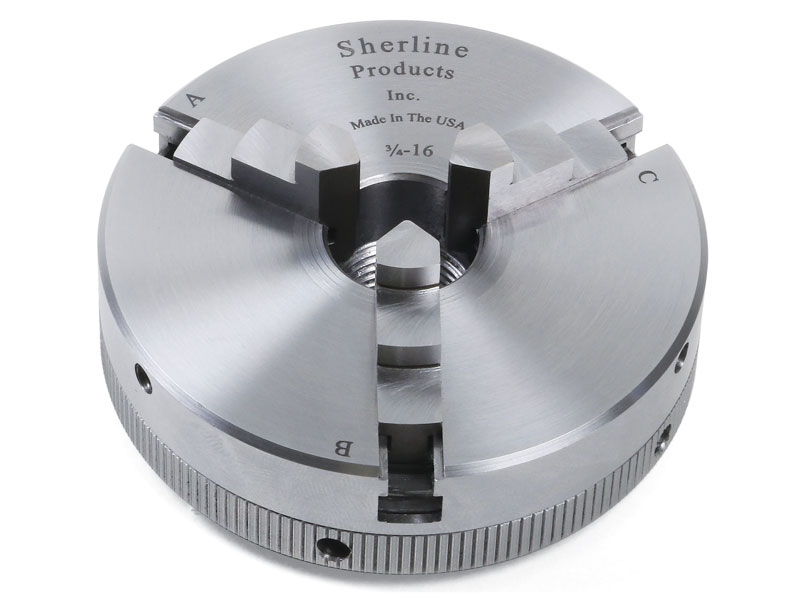

Sherline’s rotary table is one of the most popular accessories in the tool line. Its popularity extends from the home shop to the professional machine shop due to its compact size, solid construction, and long-lasting accuracy. The handwheel is calibrated in 1/10° increments with marks every 5° around the table’s periphery. Included is a set of hold-down clamps, T-nuts, and a threaded center fixture for attaching Sherline chucks with a 3/4-16 center thread. Read more about the Sherline manual rotary table.

P/N 3700-CNC 4″ CNC-Ready rotary table with stepper motor mount: In place of the manual handwheel, a NEMA 23 stepper motor mount is attached, allowing use of the rotary table as a 4th axis on Sherline CNC mills or for whatever CNC application a customer may have where a small but accurate rotary table is needed. Read more about the Sherline CNC-Ready rotary table.

P/N 8730 4″ CNC rotary table with stepper motor mount and NEMA 23 stepper motor: This takes the above rotary table one step further with the inclusion of Sherline’s own NEMA 23 stepper motor already attached to the rotary table and including a 5-pin plug that connects directly to the Sherline 8760 4-axis driver box. Read more about the Sherline CNC rotary table with stepper motor.

Sherline offers the answer to your small rotary indexer needs by providing a programmable control box with its own power supply and driver for running the rotary table. Inputs can be entered by either degrees (to 3 decimal points) or by divisions of a circle (up to 999 divisions). Also programmable are the direction of rotation, the speed of rotation and backlash compensation. In the PROGRAM mode, two different programs of up to 40 blocks each can be entered that control rotation speed, direction and degrees or divisions plus the option to continue or pause at the end of each block. Read more about the Sherline programmable rotary indexer.

For the laser marking industry, Sherline now offers several accessories including three sizes of tooling plates designed for holding parts during scanning. Read more about the Sherline laser scanning plates.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or CNC. It can even be purchased with a controller to be used as a programmable indexer. It’s popular among industrial shops due to its compact size, solid construction, and long-lasting accuracy.

The rotary table also is available with larger, 15/32″ through hole to which you cab mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

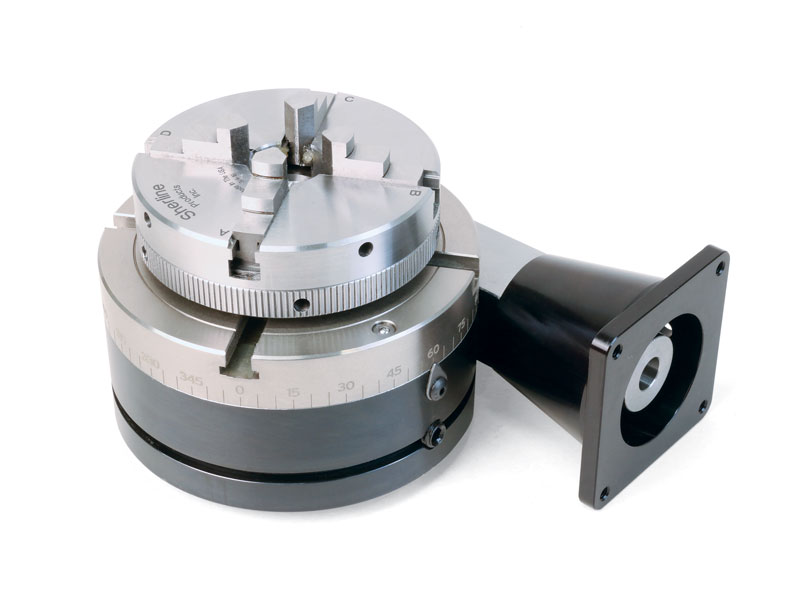

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

Sherline has taken their accurate and reliable 4″ rotary table into the 21st century with the addition of Computer Numeric Control. Clock-makers or anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations.

The rotary table comes with clamps and T-nuts for attaching it to the T-slots of a Sherline mill table. In addition, there are two options available for mounting the table in the vertical position or at other angles:

Right-Angle Attachment—This plate holds the table in the vertical position with a center height of 2.7″. A right-angle tailstock is also available to support long stock held on center in the rotary table.

Tilting-Angle Table—This table holds the rotary table and can be fixed at any angle from 0° to 90°. In the 90° position, the rotary table center is also at the 2.7″ height, which allows the right-angle tailstock to be used with it.

After entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. If an error is made, previous positions can be accurately recalled by hitting another button. Basic resolution is 28,800 steps per revolution, ±0.006° per step. This allows the accurate machining of items like gears with odd numbers of teeth. Computations are made internally to a high degree of accuracy to avoid cumulative errors.

At Sherline, we manufacture the world"s most complete line of precision milling machines, lathes, and chucker lathes (also known as Mini or Micro Mills and Lathes). We manufacture both manual and CNC machines for benchtop or tabletop-size workspaces, along with a full line of accessories to support these machines.

Sherline has taken its P/N 3700 manual 4″ rotary table and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame-size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

On our rotary tables, we finish-grind the tabletop as the last grinding operation for the entire assembly. This means that the overall thickness variation of the assembly is less than (.001″, .0254mm). If you buy this rotary tabletop as a replacement part, the thickness variation of the rotary tabletop (in its machined state) will be .001″ or less. However, the assembled thickness variation may exceed this amount because it is not being finish-ground as an assembly.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part he can design. The only limits are size, not complexity. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines; however, it can be used on any mill whenever the small 4-inch size would be an advantage.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right angle attachment is available (P/N 3701) to mount the table in the vertical position to further increase its versatility. With the table mounted vertically, an optional adjustable right angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines, however, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right angle attachment is available (P/N 3701) to mount the table in the vertical position to further increase its versatility. With the table mounted vertically, an optional adjustable right angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

A ghost view of the rotary table drawn in SolidEdge® by John Costello shows the internal mechanism so you can see how the worm gear drives the table. Ball bearings are shown in dark blue.

The rotary table has a unique table locking mechanism that is positive and does not move the table as it is locked. To maintain accuracy and frictionless movements, ball bearings are used. Worm gears are factory greased and the drives sealed to keep out chips and dirt. An oiler is easily accessible to facilitate lubrication of the table. The appearance is instrument quality with a black oxide base, precision ground finishes, and laser engraved markings.

As with all Sherline tools, the illustrated instructions are very useful. The 8-page manual covers the basics of rotary table use and takes the user through a typical project.

Any machinist desiring to take his capabilities to the ultimate levels should consider purchasing and learning to use a rotary table. The Sherline rotary table is an extremely precise and well-built piece of equipment that is sized to fit with our product line. It can also be useful on larger equipment when its compact size is called for.

The rotary table is also available with a stepper motor mount attached ready for the application of a stepper motor and CNC controls. See P/N 3700-CNC.

NOTE: Because components of the table are ground as a set during production, the P/N 3700 rotary table cannot be upgraded to the P/N 3700-CNC version later on. A new rotary table with stepper motor worm housing must be purchased.

Sherline"s rotary table is a precision piece of equipment that has been designed to work with Sherline"s vertical milling machines; however it can be used on any mill whenever the small 4-inch size would be an advantage.

The table is 2" high and 4" (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds.

The table has been engraved with a laser, giving sharp and precise lines every 5 degrees, numbered every 15 degrees. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel.

The handwheel is divided into 50 parts, making each line on the handwheel 1/10 degree. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The table T-slots are identical to those used on the Sherline mill and lathe,, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline"s 3- and 4-jaw chucks to be mounted directly to the rotary table.

An optional right angle attachment is available (P/N 3701 to mount the table in the vertical position to further increase its versatility. With the table mounted vertically, an optional adjustable right angle tailstock (P/N 3702 can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

The rotary table has a unique table locking mechanism that is positive and does not move the table s it is locked. to maintain accuracy and frictionless movements, ball bearings, ball bearings are used. Worm gears are factory greased and the drives sealed to keep out chips and dirt. An oiler is easily accessible to facilitate lubrication of the table.

The appearance is instrument quality with a black oxide base, precision ground finishes and laser engraved markings. As with all Sherline tools, the illustrated instructions are very useful. The 6-page manual covers the basics of rotary table use and takes the user through a typical project. Any machinist who wants to take his or her capabilities to the ultimate levels should consider purchasing and learning to use a rotary table. The Sherline rotary table is an extremely precise and well-built piece of equipment that is sized to fit with our product line.

It can also be useful on larger equipment when compact size is called for. P/N 3700 Rotary Table Price $250.00 P/N 3700-CNC $300 Right angle attachment, P/N 3701 The rotary table is made even more versatile with the addition of the right angle attachment. This part has been designed to accurately align the rotary table in a vertical position while still maintaining rigidity. Note: The P/N 3750 tilting angle table can be used in place of this accessory when tilted to the 90 degree position.

The Sherline CNC Ready Rotary Table offers a P/N 3700 manual 4 inch rotary table and a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

This table is also available as P/N 8700, which includes a stepper motor and a self-contained CNC controller for use as a stand-alone CNC indexer. The rotary tables can hold more weight when they are not under a continual load.

Sherline’s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures.

NOTE: Because components of the table are ground as a set during production, the P/N 3700 rotary table cannot be upgraded to the P/N 3700-CNC version later on. A new rotary table with stepper motor worm housing must be purchased.

8613371530291

8613371530291