velmex rotary table quotation

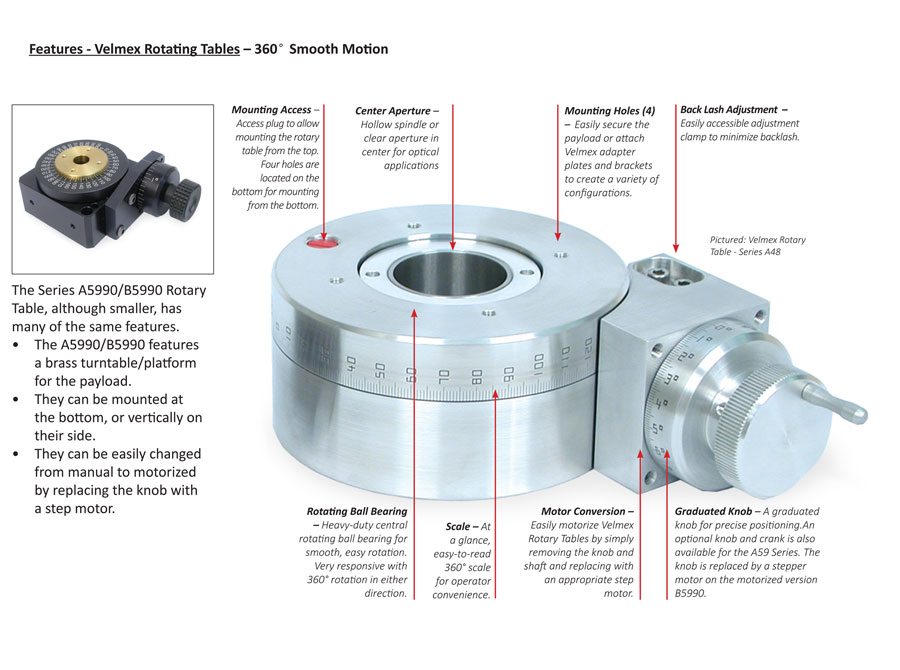

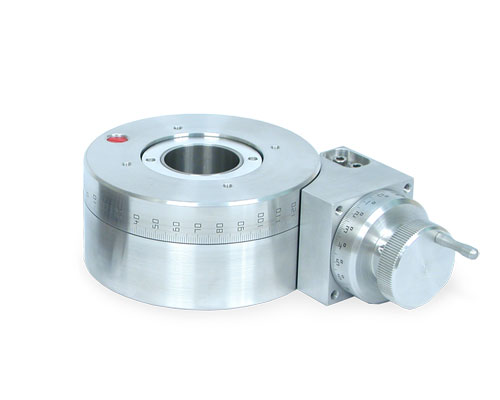

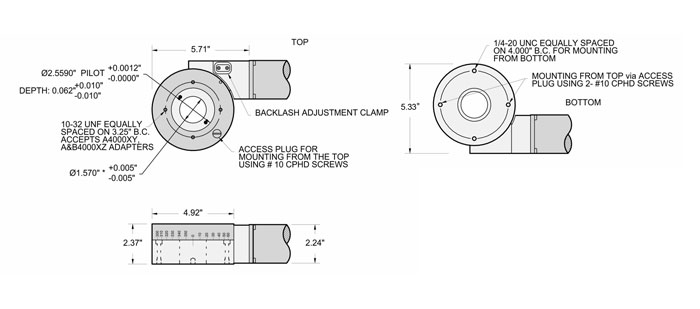

Velmex offers two series of Rotating Tables – the A4800 in three different gear ratios (18:1, 36:1 and 72:1) and the A5990 with a 90:1 gear ratio. The A4800 Series of Rotary Tables has a load capacity up to 200 lbs. (90.7 kg.) horizontally and 25 lbs. (11.3 kg.) vertically. The A5900 can handle 50 lbs. (22.6 kg.) horizontally and 5 lbs. (2.3 kg.) vertically. They easily integrate with Velmex UniSlides®, BiSlides® and XSlides™ in a array of configurations.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Velmex products, including, without limitation, product features, specifications, designs, availability and pricing, are subject to change by Velmex, Inc. at any time without notice.

All Velmex products, whether standard or custom are built-to-order. While we do have standard items, we do not have "off-the-shelf" items. We want to ensure you get the configuration you need with the travel distance, lead screw pitch, drive, etc. that you require for your application.

All Velmex manufactured products are made in the US and can be purchased from Velmex directly. For our customers" convenience, we do have distributors throughout the world. Please refer to our Distributors page.

Cancellation of orders consisting of standard products, for any reason, is subject to a 15% cancellation charge. Cancellation of orders for special products and nonstandard UniSlide®, BiSlide® or XSlide™ Assemblies are subject to a cancellation charge to be determined by Velmex, Inc.

Returned products should be well packed to prevent damage. All returned goods are subject to inspection for use or damage on receipt. Credit is subject to the inspection results. Return of special and custom systems is at the sole discretion of Velmex depending upon the level of customization

If you need to return a product to Velmex for repair, please contact us for a Return Materials Authorization (RMA) number before returning the product. Please complete theRMA Request form and we will assign an RMA and give you instructions on your next steps. Include a written explanation of the problem, along with your contact information. We will inspect the unit and notify you of the cost, if any, before any work is performed or if we"ve determined it is not cost-effective to repair the unit. The charge for non-warranty work will be billed at the current Velmex hourly rate. Please review Velmex"s Warranty Policy.

Should the bearing pads wear out after long periods of use, replacement pads can be laminated to the slider at a nominal cost. Please contact us via phone at 800-642-6446 or +1-585-657-6151 or via email at info@velmex.com if you would like a Velmex product reconditioned. If you are returning an item for reconditioning that is not covered under warranty, please complete a Modification Request form and include it with the product you are returning for reconditioning.

Replacement parts including lead screws, carriages (sliders), locks, cranks, joysticks, motors, etc. are available from Velmex. Please specify your Assembly model number and, if applicable, motor model number when ordering replacement parts.

Velmex has the ability to modify our products to a customer"s specifications. This includes but is not limited to custom lengths, additional or different hole patterns, adding customer-purchased motors that are different than those offered by Velmex. (Nominal costs may apply.)

If you would like to modify a Velmex product, please contact a Sales Application Engineer via phone at 800-642-6446 or +1-585-657-6151 or via email at info@velmex.com or complete our Request Assistance form. Once you place your order, please complete theModification Request form and include it with any items you are sending to Velmex to be incorporated on the product.

Cross Sections – The cross sections of the Velmex linear stages are a key differentiation. While the three Velmex linear stages all have bases with dovetail ways, they each have a different cross-section profile. (images above) The sliders (carriages) each ride on the ways differently.

Most Velmex linear stages can be mounted on their ends and used as a stand alone Z axis. The load in this case is often considered a cantilever load. When mounted in combination with multiple stages in X or XY axis other factors need to be considered to calculate load including the weight of all the components. Which assembly and the dovetail profile of the carriage can also make a difference in the load the slide can carry. (See the load questions below.)

Yes, all Velmex stages can be used in either the vertical (Z) or inverted X or Y position. However, inverting the stage puts restrictions on the load it can carriage. See the FAQ that follows on loads and how to calculated the permissible load.

Most Velmex linear stages can be mounted to other stages in the same product line in XY, XZ, XYZ configurations. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems to meet a wide range of requirements and applications.

Velmex has several thousand standard configurations of linear slides when you include the options, accessories and the multitude of sizes. However, our standard offering does not always meet every requirement. Our sales application engineers can design a custom solution to the meet a customer"s specification. Custom systems could include design, mounting and testing charges; and contain custom, externally-fabricated components.

All of the above assume a single axis stage. You also need to consider the number of axes in the system. If it entails more than one axis, the weight and orientation of each subsequent stage and any required adapter plates or gussets need to be considered. Combining slides or rotary tables in XY or XYZ configurations can create a cantilever load. In these configurations the X axis carries the weight of the Y axis and/or Z axis (and/or theta axis), any components and the attached payload.

Additional design factors can be incorporated to accommodate larger payloads such as going up in stage size, adding additional carriages to the slide, or looking at tandem or parallel Velmex slides.

Load calculations for Maximum and Normal (in Horizontal Center and Vertical Center), along with Load Thrust and Cantilevered Loads are found under the specifications for each brand of Velmex stages.

Cantilever loads and the load on the stage when mounted inverted or on the stage"s side are also affected by gravitational forces that pull the payload and the carriage down. The rating for a Cantilever type load is always going to be less than that of a normal load. How to calculate the allowable load and illustrations of each follow. The profile of the carriage and the dovetail way the carriage is nested in also affects the tensile strength the stage has to support the weight of the payload when placed in a cantilever, suspended (gantry) or inverted position. Depicted below is the load calculation for Velmex UniSlide Linear Assemblies.

Velmex products are primarily manufactured from hard-alloy aluminum. Lead screws are either 303 stainless steel or nickel-plated steel depending on the pitch. The BiSlide and XSlide assemblies have black anodized bases. Black anodizing is an option for UniSlides. They also can be hard coat anodized or nickel-plated for an additional charge.

BiSlide assemblies can easily be converted from a manually-operated slide to a motorized version. See the BiSlide Owners Manual for the instructions on converting the stage. UniSlides, XSlides and Velmex Rotary Tables cannot be converted. You should purchase the version you require at the onset. It is possible, however, to buy Velmex stages pre-configured for both manual and motorized operation with a double shaft stepper motor.

Options and accessories like revolution counters can be added to Velmex assemblies after the fact. However, because of special adjustments, possible cutting or turning and additional hardware that may be required, the assembly needs to be returned to the factory to properly fit the additional component. There is a nominal charge for reconfiguring assemblies.

Below is a chart showing the available lead screws and pitches. Followed by the lead screw code for each Velmex brand. The code can be found after the base lengthin the model number. See the Model Number explanation that follows.

Velmex products are used in many industries for a variety of applications. Both manual and motorized versions are used in single and multiple axes configurations. A few examples:

• Velmex stages have successfully been used in environments including: clean rooms; outdoors; underwater; in a vacuum; attached to aircraft; on naval ships; and in outer space.

Yes, Velmex products can be used in vacuum or specialty environments with modifications or material substitutions. What is required depends on the environment. For more information on material substitutions, outgassing and other environmental considerations, please check theVacuum Environments page.

Lubrication is important for motor-driven systems or wherever you want maximum life and the lowest friction. Only a few drops are required to keep your device running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your Velmex device for recommendations.

• Normally, the worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole.

• An adjustable expansion gib controls the fit of the UniSlide carriage. Adjust by tightening the Allen head screws located at the end of the slider.

• Adjustments on the carriage on a BiSlide may be necessary after break in period and less frequently thereafter. The Lead Screw Nut (StabilNut™) has an adjustable mesh to minimize backlash. Carriage fit can be adjusted by tightening the bolts on the carriage surface.

Yes, the drive nut tension can be adjusted all Velmex linear slides. An adjustable mesh minimize backlash on each of the drive nuts. Refer to the product Owner"s Manual for instructions and frequency.

• UniSlides and XSlides use a tension adjustable drive nut made of Delrin AF®. The UniSlide has one adjustment location the top of the drive nut. The XSlide adjustment in located from the side of the slider.

Step motors are very common in linear positioning because of their ability to operate within very precisely defined increments. They work efficiently when there is frictional load to dampen them. Velmex assemblies have friction, and a polymer lead screw drive nut which absorbs step vibration. Velmex lead screws have low inertia relative to the motor inertia, making very fast accelerations and decelerations possible. Step motors reach full torque in just one step.

Step motors, when controlled with Velmex Controllers, do not miss or lose steps. Step motors run synchronously to their phase switching speed. When an external motor load exceeds the running torque of the motor, the motor may stall and lose a position greater than one step.

Velmex step motor controllers remove the problems of low speed motor resonance by utilizing half-stepping and controlling the current. The VXM switches the motor drive amplifiers directly, eliminating the sensitive pulse to motor translator link.

Proper motor sizing and operating the motor in a range that provides a torque reserve will ensure reliable operation. Review the motor speed/torque curves to determine the maximum reliable operating speed. Our Sales Application Engineers can help you determine the right motor size to operate the Velmex slide efficiently and effectively.

In order to program the VXM Controller for your specific application, it should be connected to a PC, Laptop, Tablet or PLC. However, the VXM-1J Control has a simple jog and auto-reverse functioning and does not require a computer to program.

Yes, if you have your own motors and controllers, you can use them with Velmex motor-ready products. The VXM Controller, however, has been specifically designed to optimize stepper motor control. Its a very dependable and low cost solution for high precision positioning requirements.

The Velmex VXM for step and direction has been designed to work with other motors, specifically motors with built-in controllers, if the motor can take step pulses. With this VXM version, you gain "smart control" of the motor. .

Velmex motorized stages, motors and the VXM Motor Controller come as a complete system, ready to plug in. See the Controllers Page for more details and specifications.

Yes, encoders can be used to determine payload positions on Velmex slides and tables. We offer inductive and magnetic encoders for UniSlide and BiSlide linear stages and rotary encoders for the Rotary Tables and the compact XSlide. You would also need a readout like the VRO™ to interpret the data being transmitted by the Encoder.

Because the carriage rides on the outside of the ways as opposed to the inside it"s difficult to tell where the carriage is positioned in relation to the travel distance. A rotary encoder fixed to the lead screw at the end of the XSlide is a better solution.

Yes, Velmex offers an number of options in addition to the linear and rotary encoders to measure travel. In most cases, these options would be used with manually-operated stages. They include:

The VRO can provide a readout from linear and rotary encoders for one or two axes. The axes can be configured in X, XY and XZ. An XYZ or other multi-axis configuration would require additional VRO Readouts.

The VRO can report position in either Imperial English or metric. It can count revolutions. It also can report in degrees when connected to a rotary encoder.

Velmex has over 4,000 possible sizes and configurations of linear and rotary stages. Please contact one of our Application Sales Engineers about your needs and your product specification requirements. They can aid you in selecting the proper stage and configuration at the lowest cost.

We build every Velmex product to order. A typical lead time is 2 to 3 weeks after receipt of the order for standard products. Custom configurations will usually take longer. Please contact us for a precise lead time.

We manufacture all Velmex products in our facilities in upstate New York. You can buy direct through us or through one of our international distributors. We ship worldwide.

The KP1-V single-axis turntable with vertical rotational axis is used for direct workpiece positioning or as a modular base. It is available with a payload ...

The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with ...

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

Microplan"s TR rotating tables are designed and manufactured out of 2 granite disks each, moving on pressure/vacuum air bearings in ways to obtain highest possible stability. These apparatuses exhibit ...

These rotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives. Low maintenance ...

... distributed brushless RotoLinear motoring modules provide high positioning stiffness during rotary indexing and when installed on moving XY tables.

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

... roller bearing provide perfect resistance to load in vertical direction. Rotary Stage of series 8MRL80 can be prepared for clean rooms and vacuum up to 10-3 torr with minor changes.

... versions of TRV rotary table involve electric rotation via double Brushless motor with precision reducer instead. In these big TRV tables position and rigidity are granted by Hirth coupling ...

The HRT-160 rotational table from the portfolio of the modular rotary table system is designed as a complete unit ready for connection. The rotational ...

... mount and flat table applications. The compact design features a wide through hole for utilities occupying less space than other servo indexers for space constraint applications.

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

Table size form size 1,000mm to size 2,000mm can be manufactured in both Vertical/Horizontal position. With high accuracy and high loading capacity which are suitable for heavy machining and metrology ...

The KESSLER Table line includes single-axis rotary tables and dual-axis rotary tilt tables. It incorporates the renowned KESSLER know-how for superior ...

Manual Linear UniSlide® Assemblies For Nearly Four Decades Velmex... positioning equipment has been used to produce linear and rotational motion in scientific, research, machine, instrument and industrial applications. Hundreds of thousands of UniSlides and BiSlides are in use providing simple, rugged, reliable motion. Velmex applications are limited only by your imagination. For example: measurement, alignment, inspection and QA/QC, optical focusing, antenna alignment, film and animation work, medical and biological analysis, for moving probes, sensors, components, and thousands of other uses. If you need precise, versatile movement in one, two or three dimensions, do it more efficiently and less expensively with a Velmex UniSlide®, BiSlide® or XSlide™. UniSlides are available in nearly 1000 standard models, including Free Sliding, Screw Drive, Graduated Knob and Scale with Vernier. Read position from 0.025” to 1 micron using mechanical or optical mechanisms. Finally, our Rapid Advance models save time. That is an impressive array of products, but the real versatility of UniSlides is their amazing flexibility. Every UniSlide is built to order. Customers are not limited to off the shelf products — you can customize your UniSlide to meet your exact requirements. Rapid/fine motion, thumb screw locks, special finishes, way covers, revolution counters, position encoders or some other feature? We can do it. BiSlide, XSlide and UniSlides Assemblies from Velmex, we’ve put quality into motion. Manual Introduct

UniSlide Features BiSlide Features • Rugged I-beam design • Integrated T-slot system for mounting and configuring XYZ systems • Manual and motorized versions • Corrosion resistant anodized finish • In stock Widths from 1.5” to 9” Lengths from 3” to 93” Weight capacities to 400 pounds Resolutions to 0.00005” Manual and motorized versions More compact than ball screw-driven stages Lighter weight-high strength aluminum alloys Low friction adjustable Rulon® sliding element eliminates lubrication, greatly decreases wear Resistant to impact loads Corrosion resistant Fewer parts Lower cost...

www.velmex.com Table of Contents Manual UniSlide® Contents Examples and Application Photos 1.4 Actual Size Cross-Sections 1.6 Selecting the Right UniSlide 1.8 TA Rapid Advance UniSlide with Linear Encoder 1.52 B Series Dovetail Base 1.54

Examples and Application Photos Here are examples of UniSlide® stock and custom positioning equipment. Many more examples are shown on our website. For help, please call our engineering staff, fill out the RFQ/RFA form on our website or the Fax-a-Quote form on page 1.58. Example 1: A manual rotary table that rotates a small, motorized slide. Example 2: A three axis system including an elevating table, all with a black anodized finish. Example 3: A four axis system to measure travel distance for medium-sized payloads. Manual UniSlide

www.velmex.comChoose a Size or SeriesActual size cross sections of the 5 different UniSlide Assembly Series. Drive nut diameter will vary. A15 Series See page 1.9 for details. Travel Distances and Load Capacities of Manual UniSlides Width Series Travel Horizontal Cantilevered Vertical Range Central Load Central * A25 Vertical Central Load Capacity with a 10 pitch (W1 and P10) screw is 30 lbs/15.5 kg. to due to a stronger thrust bearing design. Also, for greater base stiffness, Series A25, A40 and A60 are available in deeper cross sections. See the B Series Bases on page 1.54 for...

www.velmex.com Introduction All Series A15 UniSlides are 1.5” wide. Lengths vary by Type. There are 9 types. Each Type offers you specific features and benefits to satisfy your requirements. The UniSlide Model Number specifies the Type and other char-acteristics. Series A15 Series A15 Common Dimensions and Load Capacity 1.187" 0.62" T LEAD SCREW EXTENSION END BEARING BLOCK ASSEMBLY LEAD SCREW EXTENSION DIA. 0.218" FOR B & P20 0.231" FOR C & P40 0.250" FOR K1 & Q1 0.250" FOR K2 & Q2 S is the slider length. The standard length is 1 1/2.” Optional longer 2” and 3” length sliders are...

Manufacturer of standard and custom linear and rotary motion-control positioning equipment for scientific, research, machining and industrial applications. Products include manual, lead screw and electric motor driven mechanical slides, stages and actuators. Includes x-y, positioning, rotary, elevating, micrometer, pan and tilt, motorized, indexing and scanning tables. Slides include anti-friction, motorized, dovetail, electric, instrument, lead screw and linear slides. Systems include AC and DC motors and controllers, adapter plates. Machine bases and frames are available.

Velmex, Inc. is a premier US manufacturer of standard and custom linear and rotary motion-control and positioning equipment for scientific, research, machining, instrumentation and industrial industries. Established in 1967, Velmex manufactures UniSlide®, BiSlide® and XSlide® manual and motor-driven assemblies; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM motor controls and VRO digital readouts. Velmex offers precise, modular-designed slides, stages and actuators available in a variety of configurations and a very broad range of sizes and payload capacities at reasonable cost. Velmex products are useful for precisely moving a probe, sensor, antenna, transducer, components or other objects. Common applications include light manufacturing, research, automation and prototyping.

Velmex offers thousands of configurations in simple single-axis slides to complex multi-axis systems. Velmex slides include anti-friction, dovetail, electric, lead screw and linear slides. Table configurations include X-Y and -Z positioning; rotary; elevating; micrometer; pan and tilt; indexing and scanning tables. Complete systems with motors, controls, adapter plates, frames, bases, software and additional options and accessories are available. Although a myriad of standard assemblies are offered, each is built to order to match the customer"s exact requirements. Velmex application engineering and R&D can be utilized to develop custom systems. Less

Since 1967, Velmex, Inc. has manufactured linear and rotary motion-control positioning systems for scientific, research, machining, instrumentation and industrial applications. Velmex produces UniSlide®, BiSlide® and XSlide™ manual and motor-driven stages; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM™ motor controls and VRO™ encoder readouts - all, American-made. All providing a variety of precise, yet simple, modular configurations to satisfy a broad range of positioning applications where high precision and value are essential. Common applications include manufacturing, research, automation and prototyping. Services provided include custom machining and controller integration.

A roller table is a small, stiff, limited linear guide device with an integrated cross-roller guide. Electrical or mechanical drive systems are frequently used to move a roller table, making it easy to transfer heavy loads...

A new report released by Market Research Update is Torque Motor Rotary Tables Market 2023. This report provides up-to-date information on the market and also pinpoint all the opportunities for Torque Motor Rotary Tables market growth. The report begins with a market outlook and offers market basic introduction and definition of the worldwide Torque Motor Rotary Tables industry. The overview part of the report contains Torque Motor Rotary Tables market dynamics which includes market growth drivers, restraining factors, opportunities and Torque Motor Rotary Tables current trends along with the value chain analysis and pricing structure study.

Torque Motor Rotary Tables market is segmented by region, players, by Type, and by Application. Players, stakeholders, and other participants in the global Torque Motor Rotary Tables market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region, by Type and by Application in terms of revenue and forecast to 2029.

The report also includes the effects of the ongoing global crisis. COVID-19, on the Torque Motor Rotary Tables Market and what the future holds for it. It provides an analysis of the impact of the pandemic on the global economy. The epidemic has directly disrupted demand and the supply chain. The report also analyzes the financial impact on businesses and financial markets. This Torque Motor Rotary Tables report have gathered information from several industry delegates and have been involved in primary and secondary research to provide customers with data and strategies to address market challenges during and after the COVID-19 pandemic.

Top Key Players of the Torque Motor Rotary Tables Market:Hiwin Corporation, Motor Power Company, Velmex, Tecnotion BV, PARKER, SMC Corporation of America, Kitagawa, FIBRO INC, Techsystem, Magtrol, Sherlineipd, Newmark Systems Incorporated, Sankyo Automation, ZOLLERN GmbH & Co. KG

The global, regional, and other market statistics including CAGR, financial statements, volume, and market share mentioned in this report can be easily relied upon in light of their high precision and authenticity. The report also provides a study on the current and future demand of the Global Torque Motor Rotary Tables Market.

With the present market standards revealed, the Torque Motor Rotary Tables market research report has also illustrated the latest strategic developments and patterns of the market players in an unbiased manner. The report serves as a presumptive business document that can help the purchasers in the global market plan their next courses towards the position of the market"s future.

Torque Motor Rotary Tables market competitive landscape provides details and data information by players. The report offers comprehensive analysis and accurate statistics on revenue by the player. It also offers detailed analysis supported by reliable statistics on revenue (global and regional level) by players. Details included are company description, major business, company total revenue and the sales, revenue generated in Torque Motor Rotary Tables business, the date to enter into the Torque Motor Rotary Tables market, Torque Motor Rotary Tables product introduction, recent developments, etc.

In the end, the Torque Motor Rotary Tables Market report includes investment come analysis and development trend analysis. The present and future opportunities of the fastest growing international industry segments are coated throughout this report. This report additionally presents product specification, manufacturing method, and product cost structure, and price structure.

Scissor lift tables are pallet loading stations that are located at the end of a conveyor. Rotary Indexing Satellite Table Machines - wheel technology. i 36" Stainless Steel Rotary Accumulation Table / Turn Table It is designed with a center height of 167 mm, and bearing size of 180 mm x 110 mm. The line of stainless steel conveyors by MCE is pre-engineered, allowing us to provide a modular design, saving you time and money. Shaft for for ELC Rotating Tables. This content and associated text is in no way sponsored by or affiliated with any company . The quality control team carries out the salt spray and high-temperature withstanding test on the food tray to check its corrosion resistant capacity and temperature resistance. Table & Lazy Susan Conveyors. The frame is constructed of carbon steel. Fax: 870-483-7049 The Globaltek rotary tables can be used to unscramble product and feed a conveyor, also as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. $690.00. Consult the Factory to Discuss Your Application. feed force: FX = 12000 N Basic. Rotary Tables; Gap Transporters; Belt Conveyors; Unscramblers; Guard Rails and Brackets; Contact; 732-203-2077. We"ve got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Rotating Table, Conveying Pipe, Conveyor Belt Skirt, Conveyor Belt Machine, Portable Screw Conveyor. Precision Link Conveyor High accuracy and robust design. by MTC - Material Transport Company, Temple, TX. Contact Tel: 870-483-7631. China Rotating Conveyor Supplier, Rotating Platform, Metal Spraying Machine Manufacturers/ Suppliers - Wujiang Shuanglongsheng Automation Equipment Co., Ltd. . Because the table tops rotary action is powered by sew motor there are no breaks in the top surface and it offers an unprecedented level of personal safety. Carousel oven, Oven with rotating table. from a foot pedal for manual load indexing to automatic photocell control of the lift for automated indexing up or down. VIC . Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. Last used in a major food plant. guide load: FZ = 95000 N Max. speed: v = 1,0 m/s Max. The finished package is sent to the work height level for manual packing or to continue the automated packing system, rotating stacking table to receive and accumulate bags from the bagging line before the case packing. acceleration: a = 20 m/s Max. Turning Cross Conveyor. When using a rotary table conveyor, the products gently accumulate on the tabletop where they can be collected by a packer for further processing or boxing. Click to . Linear Servo Actuator . Quick Links. Rotary accumulation tables are a small footprint conveyor solution designed for accumulating and unscrambling products at various points during the conveying or packing processes. Emerson hp drive, 208-230/460. View Listing. long. We work tirelessly to ensure that all of products are in high standards. A Carousel conveyor oven is a simple concept which saves valuable space and allows the product to be loaded and unloaded at the same spot. If you"re interested in rotary tables, JG Machine Works has the perfect products for you! Join 10,740,000 engineers with over 5,340,000 free CAD files. The transition section can be reconfigured to make 90 turns at the intersection of two gravity conveyor lines. much easier and more ergonomic. * Adjustable speed control knob. Rotary Tables. LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. It has robust construction. The units automatically adjust the height of pallets as boxes are added or removed. These conveyors work for both rigid and flexible types of packaging. Home. They make loading/unloading pallets at conveyors, packaging stations, workbenches, loading docks, etc. It has an adjustable height to suit your operator or existing equipment. These types of units are also called "accumulation tables" or "lazy susans" in the industry Diamond Member Since 2019. Can be used at the front of a line for packing on applications or at the end of a line for packing off finished products. The table provides a simple and cost-effective method for the hand packaging of bottles. Stainless construction. Accumulation Conveyor, Brand Lanpac, Dimension 7400mm L x 1470mm W x 740mm H Unit is a product accumulation conveyor. The CAD files and renderings posted to this website are created, uploaded and managed by third-party community members. Stainless Mobile Scissor Lift Carts. The accum. Place a Free Classified Ad. Transfering .more .more 36. The table top is manufactured from 3mm galvanised steel. Accraply Stainless Rotary Table. motor-driven rotary table ZASD Series. Both configurations can handle multiple container sizes and materials. for conveyors rotating A turntable is a machine used to perform changes in direction on a transportation line maintaining the direction of advance of the load. 2. $88.00. Only a few left! Top discs are s. Learn More. Rotary accumulation tables rotate clockwise or counter clockwise and collect, release, regulate travel speeds, hold or even halt production of products & materials. Search. Louisville, KY, USA. CALL TOLL FREE. Motor and Gearbox for ELC Rotating Tables. For over 60 years, JG Machine Works has produced quality filling and conveying equipment. Linear Motion. Agricultural Equipment (4,562) Airport . Adjustable speed drive with electric overload clutch, panel is recessed under the support frame. 4 Ways to Rotate Product 1. 30" food grade belt. Machine disc material: 304#,Strong solid, good appearance, durability. Once on the rotary plates, the components are blasted by two high-performance . For ultimate hygienic and product-friendly material handling, ACL rotary tables are constructed in stainless steel and include a food-grade, ultra-high molecular weight, low friction plastic bed. The design and construction for temperature from 40C (100F) to 400C (750F) that will fit to any of your processes: Several independent heating zones as well . 4" tall perimeter rail to aid in part containment white polyurethane lined work surface Powder coated industrial finish Five year system warranty Contact our Customer Service Team at 800-435-6979 or sales@macautomation.com Mac Products Conveyors * Turntables Made of Durable Aluminum. The table then unloads the bottles during gaps in the conveyor until the table is emptied. Quality stainless steel components are easy to clean and result in a low maintenance, durable piece of conveyor equipment. While moving, it collects pouches from the packaging machine. All of the Q lifting tables can be supplied with driven or non-driven roller conveyor, and with various levels of controls, e.g. safe and healthy. Step 1: Intro and Getting Started. Model LPTG is a heavy duty turntable featuring a 1912 gravity roller top and concave transition sections (2 included) that can be used in a pass thru conveyor line. Turntables take up less floor space than other accumulating conveyors and can be customized to suit particular product and space requirements. This machine has three satellite turntable inserts (multiple table options are available on request), each with a diameter of 1000 mm, which are integrated into the main table level (diameter 2500 mm). SS top, 48 in. Sometimes referred to as a Lazy Susan. The DTZ-P 2040 Turntable (or Rotary Conveyor) from mk North America comes in a wide variety of standard sizes with an array of design options for making the most out of this accumulating conveyor. They are ideal for use within the food industry or within pack houses. Rotary Turntables Description E-PAK Rotary turntables can dramatically improve the efficiency of your production. * Max weight for all sizes 200 lbs. motor-driven turntable TTP 1012 horizontal for conveyors rotating Diameter: 1,760 mm electric rotary table Drive Specifications: Ball Screw. Model #MTCB-30-07. Call 1-800-236-7960 or Contact Us Online Technological rotary table for conveyor | 3D CAD Model Library | GrabCAD. The tables use a rugged worm and gear drive design with a central rotating ball bearing. A heavy duty chain driven live roller may be mounted on turntable platform and rotated to orient product at specified intervals allowing operator to perform a variety of tasks, such as blasting, rinsing, cleaning, and blow-off. This self-clearing table provides a space-effective solution for accumulation and works as either a pack-off . The finished products are mainly packed by the packing machine and transported to the disk material handling machine for packing. Rotating tables can help in maximising space and . Call an ACG Conveyor Expert. No Obligation & Toll-free at (866)403-5232 . Smart Weigh | easy-operating rotating conveyor table order now Smart Weigh undergoes a thorough test on its quality safety. tall. Depending on how many degrees it turns, you can find turntables . Simply install a Rotary Accumulation Conveyor Table between your infeed and discharge conveyor to cost effectively manage your product throughput. China Self-Service Rotary Hotpot Table Double-Track Rotating Conveyor, Find details about China Food Machine, Kitchen Appliance from Self-Service Rotary Hotpot Table Double-Track Rotating Conveyor - Wujiang Shuanglongsheng Automation Equipment Co., Ltd. It is a great way to learn something new, rehash simple skills or just create a rotating table, something you need, with ease. Cover panels made from sheet metal or polycarbonate can be easily attached. Applications : Industrial FDA and EU food quality End of production lines Collecting table Pharmaceutical industries Food and beverage industries Chemical Industries Structure : Rotary 304 stainless Steel Frame 304 stainless Steel with accessories polyamide Load Up to 30 KG Speed Up to 30 RPM Dimensions Various siz KAPS-ALL model FS-U-48. Rotary Table Dyco"s Rotary Table is designed for all shapes and sizes of either full or empty containers. Mini-Mover Conveyors > Rotary Table Accumulators (RTA) Mini-Mover Rotary Table Accumulators ( RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining. We have included as standard a variable speed control that offers a range of 2 to 7 RPM. Our rotating unscrambling and accumulation tables, which are built to attach to the beginning and end of your conveyor respectively, are designed to maximise your production whilst minimising the reliance on human contact for the unscrambling and accumulation of all self-standing and stable containers. MTC Stainless 30" x 7" Long Incline Food Conveyor. It is simple and easy to use. Only a few left! Top-notch after sale support. Serial #089250. Categories. These transfer tables allow you to conveyor a load in a number of directions and therefore they are usually used at the end of your conveyor systems. Kids Wooden Kitchen Retro Toy Pretend Play Set Children Food Cooking Cookware D2. We offer a variety of rotary conveyor sizes made to accommodate different product sizes. Bearing Type: Ball/Roller Bearing. 80/120/160/240mm link size. This approach is used to slide, merge, divert, sort, turn and transfer products as required. Traditionally placed in the final part of the packaging line, they have the function of accumulation, facilitating the unloading phase of the output product from the packaging machine and facilitating the operations of collecting and boxing of the operator. The table is 1.82 metre in diameter. Your Best, Conveyed Better Tell us about your product transfer and product turning needs! Arrowhead Conveyor Company rotary accumulation table. Rotary tables consist of a round and driven table top made of laminate, stainless steel or another function-specific material. Previously u.. POA NSW - Delivers Nationally . Main Features Choice of table diameters - 800mm, 1000mm, 1200mm and 1500mm Plastic or stainless deck option Low maintenance Easy wipe down surfaces Typical diameters are 30, 36, 42" and 48". 0:30 2. Rotary accumulation tables are also ideal for hand packing stations or feeding and loading tables. It mainly uses for collecting, rotating & temporarily stacked the bagged food from finished conveyor and waiting for the further packaging processing operation. Starting with the pallet at the same height of the conveyor, the table top drops down as the bags are manually stacked on the pallet. C-Mac"s Rotating Table Features. Standard (non-custom) diameters are 36", 48" and 60". The stainless steel rotating table is.. $3,800 Ex GST. This Rotary Accumulation Table is made of stainless steel. Direct Conveyors LLC USA Home Order) Download product information FEATURES Static plough guides to suit your product Other special guides or modifications catered for 25mm upstand fixed to edge SPECIFICATION fotoconic White Electric Motorized Rotating Turntable Display Stand with LED, 10 Inch / 25cm Diameter, 20 Lbs Centric Loading for Shop Display 1,632 $36 99 Above $50 Dailydanny Aluminum Heavy Duty Lazy Susan Rotating Turntable Bearing Swivel Plate Hardware for Dining-Table (24 inch (16mm)) 30 $75 99 MORE RESULTS tilting for machine tools NC. Equipped with simple speed adjustment. Standard units are designed for a 3,000 pound load capacity. New Flamingo Stainless Steel Feed/ Collect . Here at UPM we have developed various different sizes of rotary tables/lazy susans to cater for the accumulation of product, allowing operators time to inspect and pack. The base frame is built from Series 40 profiles as standard and equipped with height-adjustable levelling feet. Rare earth magnet mounted on discharge end. The rotary table is highly efficient in manual secondary packing and assists in streamlining the entire process of lifting packets manually. Rotary Table Conveyor A rotary table is a round table that typically rotates in a circular motion at slow speeds. This project dispalys describes a simple and quick design for a rotating table that anyone from hardware beginners (such as I) to experienced hardwarers can recreate. More details 1 Submit Newsletter Sign-up? Snap these ball transfers together like jigsaw pieces to create a custom ball transfer plate, or use them unconnected to create your own pattern for rotating and positioning material. The 360 degree revolving table top allows the easily positioning of the bags without the operator twisting his back. LPTG25 - LOW PROFILE TURNTABLE WITH 2500 SERIES GRAVITY CONVEYOR Loading turntables assist operators with feeding round containers to your filler. The rotary design is flexible and effective. Xinyan Sushi Train Rotary Sushi Toy Track Conveyor Belt Rotating Table Kid Food Train Set DIY Sushi Making Family Sushi Party : Amazon.co.uk: Toys & Games New New New. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished . Potentiometer for ELC Rotating Tables. Need More Information? Pallet Positioners help you build or break down pallet loads with a minimum of bending, reaching, stretching or walking around. Price On request. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped. Contact Supplier . rotary food delivery table feeding dinning restaurant conveyor hot sale in USA with computer control box and sushi train system $425.00/ Meter 1 Meter (Min. Quality stainless steel components are easy to clean and result in a low maintenance, durable piece of equipment. Dual Conveyor Product Turner This type of rotation is done using two conveyors on a single frame, moving at different speeds. A rotary table is a type of rotating conveyor table that is used for product accumulation. Machines & Equipment. Velmex offers two series of Rotating Tables - the A4800 in three different gear ratios (18:1, 36:1 and 72:1) and the A5990 with a 90:1 gear ratio. diameter x 36 in. The Roach Model IPT Heavy Duty Indexing Powered Turntable conveys heavy unit loads in numerous manufacturing applications. This creates sufficient backlog that enables your filler to run at maximum production capacity. The stainless steel rotary tables are made according to the specific needs of . Transfer Conveyor Auto Rotating Collection Table For Sale , Find Complete Details about Transfer Conveyor Auto Rotating Collection Table For Sale,Transfer Conveyor,Rotating Collection Table For Sale,Collection Table from Other Packaging Machines Supplier or Manufacturer-Shanghai Bindi Mechanical Equipment Co.,Ltd 480mm~unlimited length. They have magnets embedded in the frame, so you can mount them on any flat magnetic metal surface and rearrange them as your operations change. Please see the general specifics below and individual product specifics in the product chart below. The stainless steel rotary tables are made according to the specific needs of each client and in . Stainless Steel Table Top for ELC Rotating Table ELC-CT1200. With a lift and rotate module, conveyors can efficiently rotate products without disrupting the manufacturing process. . The distance it will take to rotate the product depends on the size of the product and the speeds of the belts. Diameter: 100 mm - 500 mm. CS Series. Dyco"s Rotary Pass-Through Accumulation Table utilizes strategically placed bottle-diverting arms which guide bottles and empty the table. This is together with a choice of outer ring heights and . Stainless Lift Tables & Pallet Positioners. 4-Axis Rotary Table Featuring high-speed, a compact size and an oversized bore, the RS Series is ideal for small sized machining centers and taping machines. Simply install a rotary table between your infeed and discharge conveyor to cost effectively manage your product throughput. 877-860-3620. Rotary Tables manufactured in the UK Rotary accumulation tables are normally positioned at the end of a process line to give additional packing time as required. . AU $17.99 + AU $1.39 postage + AU $1.39 postage + AU $1.39 postage. Address 808 Highway 463 N. Trumann, AR 72472. Machines in Used Conveyor / Accumulation Table. $5.00. Rotary Table Conveyors: Accumulation and Unscrambling One of the earliest designs for accumulation or unscrambling is the rotary table. Food Rotary Table Sushi Conveyor Sushi Dining Table Custom and so on. Description: Linear table size 30 as a unit with counter- rotating screw with 2 carriages, ball screw and ball guiding rail: Max. 23 offers from $52.54 FDSF Sushi Train Rotary Sushi Toy Track Conveyor Belt Rotating Table Kid Food Train Set DIY Sushi Making Family Sushi Party B 1 1 offer from $13.99 FDSF Sushi Train Rotary Sushi Toy Track Conveyor Belt Rotating Table Kid Food Train Set DIY Sushi Making Family Sushi Party A, White (500074350A1) 1 offer from $38.98 Search for manufacturer, modal, category or keyword. Stainless Steel Equipment. Available in either stainless or painted steel, the rotary table comes with a variable speed motor which allows for different line speeds. Machines in Used Conveyor / Accumulation Table. The ZASD 125 is available in A-axis, and C-axis. Spare parts , Maintenance contracts Rotary tables or rotary conveyors are used for accumulation or unscrambling in processing lines. The standard colours are green, blue and grey, but the lifting tables, like all other Q . wide x 12 in. 5 watchers 5 watchers 5 watchers. MFG. Rotary tables enable the collation and accumulation of products from conveyor lines and packing areas creating a buffer zone on a low speed line and also providing accumulation at the end of a production line. Give us a call to learn more about . You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website. Rotary Tables : Loading and Discharge Conveyor Tables 2016 28,641 views Jun 2, 2016 Rotary Tables for conveyor product handling which have all been custom made for our clients. Ball transfer tables are used at packaging and assembly stations where the product needs to be rotating or moved in more than one direction. Side pack-off 24 in. Sushi Train Rotary Sushi Toy Track Conveyor Belt Rotating Table Kid Food Tr O1F7. They are a convenient, accurate method of quickly positioning a payload. The A-xis version provides 500 revolutions each minute. Simply relocate the pin to do this. The rotary tables are placed in the final part of the packaging line and they have the function of accumulation, facilitating the unloading phase of the output product from the packaging machine and facilitating the operations of collecting and boxing of the operator. . Suppliers with verified business licenses. This creates an efficient end-of-line accumulation solution for a wide range of products that . Learn More. The Rotary Tables Turn at Slow RPM"s Minimizing Part to Part Contact. Direct Conveyors can Construct Small Rotary Accumulation Tables that can be Used to Store and Protect Parts Exiting a Process. Order) CN Jiaozuo Kecheng Trading Co., Ltd. 4 YRS 5.0 (1) | "Fast delivery" Contact Supplier 1 / 6 Good Working Movable Roller Table With Conveyor $100.00-$1,000.00/ Set 1 Set (Min. Conveyors with this feature simply lift the product or pallet above the belt and rotate the surface on which the product rests, effectively rotating it 90, 180, 270, or 360 degrees as needed. * 110V Electric 5 amp Motor. Industrial Kinetics turning roller conveyor is commonly used to reorient a load on a conveyor by picking it up and rotating it 90, 180, 270, or 360 degrees.

8613371530291

8613371530291