rotary table drilling supplier

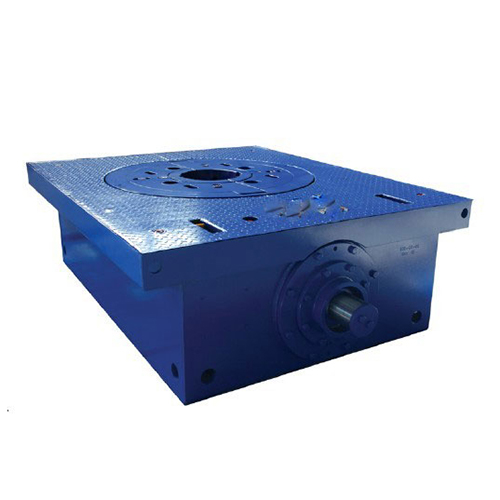

American Block offers a complete line of drilling rotary tables that range from 17 ½ to 60 ½ . These tables are designed to withstand the harshest drilling conditions. All rotary tables feature a fabricated frame, heavy duty main thrust bearing and precision machined spiral bevel gear that results in superior strength, toughness and durability.

American Block can also provide unitized rotary table assemblies (IRD). Our unitized skid packages are ideal for new builds or can be retrofitted to existing rigs. Featuring a heavy-duty oilfield skid and an extend life transmission. The rugged design ensures that when the equipment is mounted it remains rigid during operation and rig moves. Other rotary table options include hydraulically operated tables and high torque tables (25% more torque), which are ideally suited for top drive operation.

Because the rotary table links the rig"s power source to the drill string, it may be described as a clutch. Most rigs have a rotary table as the prime mover for the

the drill string have replaced the rotary table, the kelly bushing and the kelly drive in some rigs, due to changes in trenchless construction requirements.

The rotary drive table is prevalent in top-drive rigs, that is, those which have their drive motor at the top of the rig. Drill string sections are first attached to the bottom hole assembly. As drill string sections go into the bore, additional sections of drill string are attached to the top drive motor and to sections in the bore, building the drill string from the top. These sections of drill string screw together using a clockwise motion. The rotary table -- which turns clockwise -- is used to tighten the segments of the drill string.

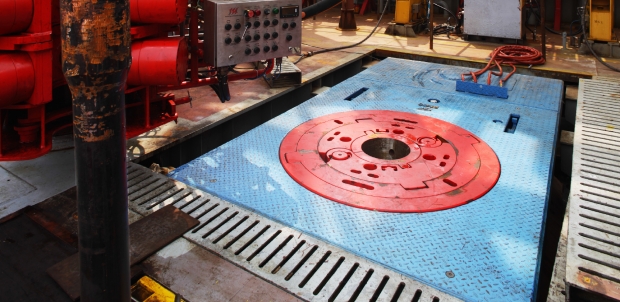

A drilling rig is not complete without the rotary table, a mechanical device that provides a clockwise rotational force to a drill string and enable the drilling of a borehole. The rotary speed is identified as rpm (rounds per minute) the amount of times the device can complete a full revolution per minute. When the drilling process covers the pipe handling operation in the wellbore, it will require a false rotary table for higher chances of success. Shale Pumps provides this device as a hydraulically driven equipment to seamlessly engage tubulars in a wellbore. We manufacture false rotary tables in-house to ensure precision engineering and the highest-quality design and materials.

When it comes to pipe handling, it is crucial for equipment to be seamless and sturdy to be reliable. Shale Pumps’ false rotary table can handle up to 1.3 million pounds of load while maintaining constant operation at a 20 rpm on maximum speed, making it ideal for long drawn and continuous operations. We developed our false rotary tables, like the SP-FRT375 to perform in the most demanding drilling jobs, and we achieve this only with precision engineering and by using advanced materials.

The false rotary table at Shale Pumps is backed by a guarantee for longevity and trouble-free performance. This way, it outperforms false rotary tables offered by other manufacturers. Our device helps you save money and boost productivity in the long run with lower maintenance costs. Every rotary table equipment has been tested in compliance with the latest industry regulations for safety, efficiency, and quality.

When choosing a false rotary table, be sure that it is being sold by a reputable manufacturer and supplier, like Shale Pumps. That way, you can be sure that the equipment has been manufactured and assembled following a strict and proven format, which ensures its quality. Shale Pumps corrects any material defects and problems with assembly immediately and take note of them to prevent them from occurring again.

TSC RT series rotary table is provided with high reliability and serviceability. The rotary table structure has been designed to provide maximum strength to ensure larger load, increased safety and well-fit between bearings and gears. The table assembly was greatly simplified so it can be installed into the rotary housing and is easy to maintain. The RT series can be designed to meet the requirements of various drilling operations and work environments.

RDE"s 22K Hydraulic Rotary Table is designed to add high speed, high torque rotational capacity to snubbing units. This unit is mounted above the snubbing unit’s hydraulic cylinders. A pneumatic or hydraulically actuated slip assembly (supplied by others) can be bolted to the rotary’s top mounting flange to accommodate both pipe pulling (tension) and pipe snubbing (compression) operations.

RDE"s features a roller type thrust bearing instead of a thrust bushing. This bearing provides enhanced performance in applications where pipe must be “snubbed” into the well while rotating for extended periods of time. Such applications may include shallow drilling, milling, window cutting, and side tracking.

The Rotary Table’s large bore design 11.06 inch ID will readily allow the passage of large downhole tools. This feature significantly reduces tripping times when compared to other systems which must be removed when large diameter tools such as mills, packers, or side pocket mandrels are encountered.

Four single speed hydraulic motors with Three piece shafts directly drive the Rotary Table to provide high torque capacity in a compact package. High efficiency Rineer MO-15 vane type motors are powered by the snubbing unit’s hydraulic power supply to eliminate the need for additional power units. Precise speed, direction, and torque control are achieved by means of pilot operated control valves (supplied separately). Note: A two speed motor option is available. Motors are interconnected by welded supply and return manifolds with split flange O-ring connections to provide optimum reliability in service.

Tensile loads (pulling pipe) are carried by a lubricated roller bearing. Compressive loads (snubbing pipe) are transferred through a composite self lubricating thrust bearing assembly. For extreme drilling applications, long term heavy compressive loads will be encountered with simultaneous high speed rotation. Lubricated bronze bushings absorb any radial loads resulting from eccentric slip assembly loading.

Don’t let a bad rotary table put you in a twist. Your rotary table is at the center of your drill floor – make sure it’s a piece of equipment you can trust. Bridges Equipment carries new and rebuilt rotary tables from the most trusted brands on drilling rigs around the world, including:

Rotary tables are the spinning section of the drill floor that applies torque to turn the drill string in the borehole. Problems with your rotary table can cause safety issues and long, costly drilling delays. When you buy a new or rebuilt rotary table from Bridges, you know it has been broken down to its elements and completely rebuilt to OEM standards, then tested to ensure it will exceed the highest standards of safety and performance. Don’t settle for a fresh coat of paint when your project is on the line.

Bridges Equipment can be found on drilling projects around the world, and for good reason. More than 35 years of experience and expertise in the oilfields of the Permian Basin, and across the globe, have earned us a reputation for speed, service and quality.Â

A rotary table is a mechanical device on a drilling rig that provides clockwise (as viewed from above) rotational force to the drill string to facilitate the process of drilling a borehole.

Most rotary tables are chain driven. These chains resemble very large bicycle chains. The chains require constant oiling to prevent burning and seizing.

Rotary Locks - Virtually all rotary tables are equipped with a rotary lock. Engaging the lock can either prevent the rotary from turning in one particular direction, or from turning at all. This is commonly used by crews in lieu of using a second pair of tongs to makeup or break out pipe.

The rotary bushings are located at the center of the rotary table. These can generally be removed in two separate pieces to facilitate large items, i.e. drill bits, to pass through the rotary table. The large gap in the center of the rotary bushings is referred to as the "bowl" due to its appearance. The bowl is where the slips are set to hold up the drill string during connections and pipe trips as well as the point the drill string passes through the floor into the wellbore. The rotary bushings connect to the kelly bushings to actually induce the spin required for drilling

Xi"an KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL)is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, DST tools and Solid control products.

8613371530291

8613371530291