rotary table automation supplier

Cam Indexer Technology is Sankyo Automation’s specialty. We’re continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

Unimec SA conceived these electric rotating tables for an integration in automatic rotating machines, for transport and assembly where precision and dynamism are asked.

... powdered sugar, cocoa powder, chocolate sprinkles, nuts or almonds, chocolate beans or pine nuts. whether turntables for manual or fully automatic sprinkling powder drums series PTR, the sprinkling of ...

This device also operates for the collection of single containers on the rotating table to prevent jam issues. In addition, this filled container collection system runs on a 380 ...

The turntable machine model R 703 from Krautzberger is used for the automated coating of small to midsize series of different work pieces. The preferred geometry of the parts is rotation-symmetrical.FunctionalityThe ...

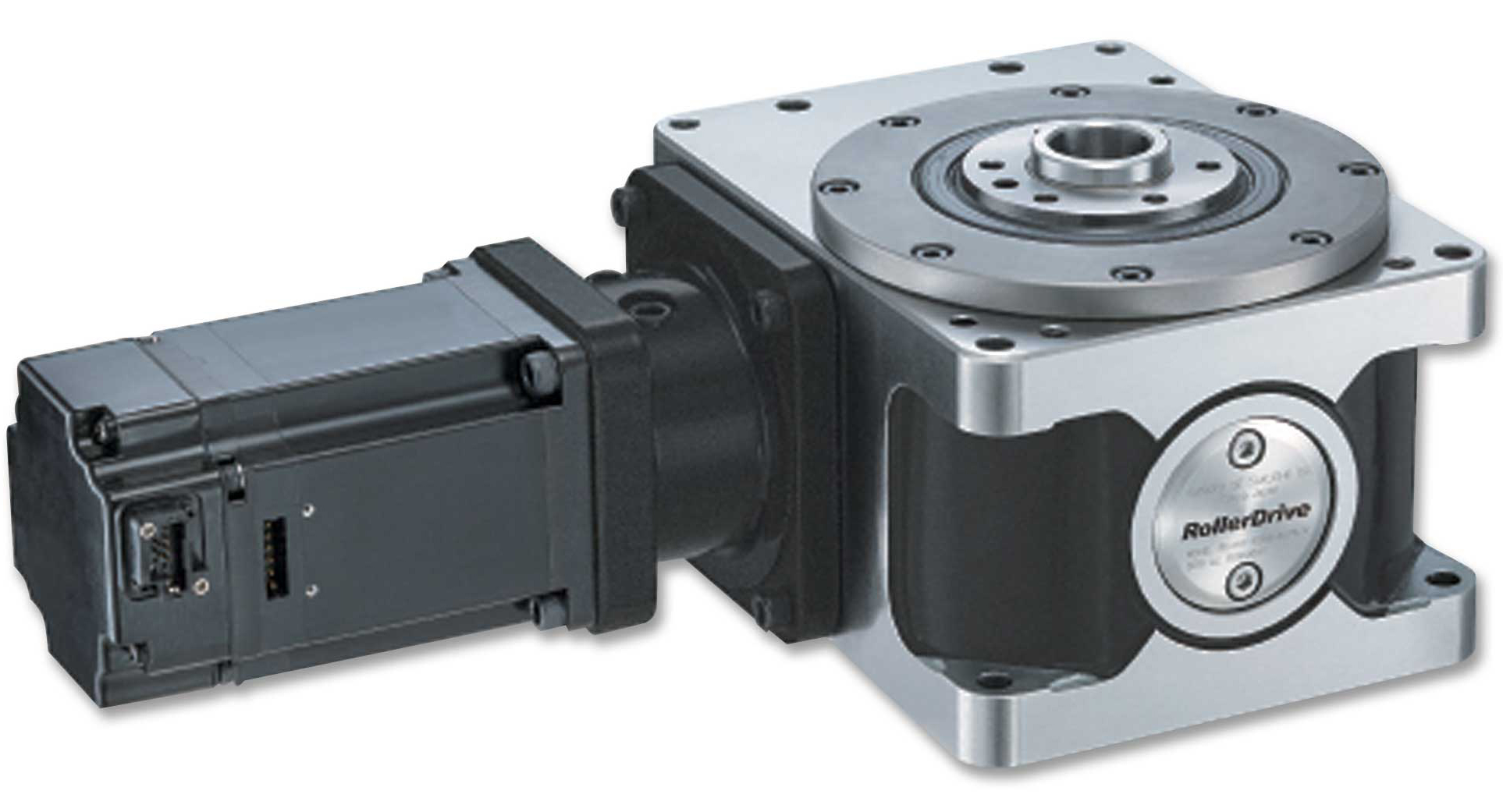

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.

For over 50 years, Pfiffner has been developing rotary transfer machines that offer high precision and flexibility, marketing the most cost-effective solutions for high-volume workpieces. Thanks to our solution-oriented approach, well-developed expertise in the market, and a passionate innovative spirit, we"ve established ourselves as a leading partner for innovative industry sectors all around the world. Our success is based on a clear vision: We always remain a leap ahead of the times, ensuring satisfied customers every single day.

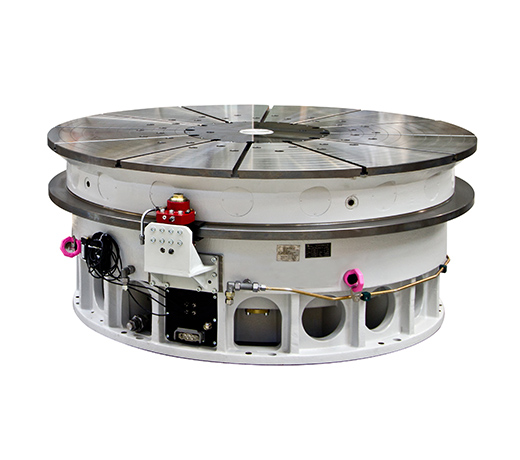

Boasting a 1300 mm footprint, the TO1300 suddenly makes larger scale applications possible that previously seemed out of reach− as current direct-drive tables are relatively small and limited to a diameter of 750 mm. Additionally the TO1300’s high-tech drive operates predominantly without mechanics or gearboxes.

For challenging tasks of this nature, a mechanical heavy duty table is typically the logical choice. Due to their gearing ratio, however, these tables don’t fare well in service life calculations for use at such high speeds as the needle bearings simply suffer from too much wear.

The correct alternative is a direct drive; which inspired the development of the TO1300. With a direct drive, only one bearing is under load which is virtually free of backlash. The table is low-wear and easily capable of delivering the desired dynamic performance requirements.

Unique to the TO1300 is that customers can customize it to their individual requirements. For example; they can make a modular selection between bearings, encoder and motor, and thereby alter the following table characteristics:

Configured in a uniquely robust design, the TO1300 offers new possiblities for high-speed automation applications such as: lighting, automotive, cleanroom, small gear assembly, switches/sockets, and electronic components.

A specialist in automation, WEISS also offers many sizes for the TO series direct-drive rotary indexing tables; ranging from small to very large. Optimal solutions for specific application challenges can be achieved from the series wide range of options. Each TO model is also available in a version with a cleanroom certificate.

Corporate Profile: An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

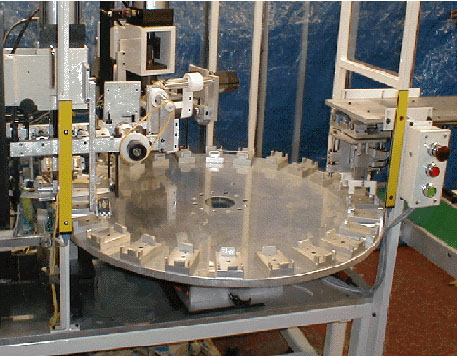

Indexing tables are used in a multitude of industries and in numerous applications. Their design is optimal for many manufacturing jobs, and they are a critical component in most automated manufacturing systems. Indexing tables are best defined as a machine tool positioning device. They carry components in a manufacturing environment with a repeating process of indexing (rotating) around an axis, stopping, dwelling while an operation is performed, then indexing again to repeat the process. They are usually made of circular steel plates, with one or more spindles, a drive system, encoders, sensors, controllers and slots or mounting holes to hold components.

Virtually any manufacturing operation can be performed on a part held by an indexing table including welding, grinding, drilling, assembly, painting, inspection, testing and more. In order to maximize operational efficiency, the machine doing the operation must also be built for the same intended application as the indexing table for them to work in synch. Similarly the machine that loads the indexing table with parts must also be synchronized. They must have the same capacity and be able to manage to the same dwell time for the system to work.

Industries that use indexing tables include automotive manufacturers, bottling companies, microchip manufacturers, pharmaceutical makers, consumer products companies and many more. They are invaluable to manufacturers pushing for automation and increased efficiency in their factories, turning work that used to take days into work that takes only hours. If a simple assembly task is required on small parts in a factory, there is no better way to complete the task than by coupling an assembly tool and an indexing table.

Automated Expert rotary tables & index drives help expedite line production with products for more constant motor rotation in fabrication or assembly processes. EXPERT® (formerly EXPERT-TÜNKERS) is recognised as a world leader in production efficiency with highly dynamic drives for rotating, lifting and traversing operations.

A long trusted Romheld Automation provider of line production essentials, EXPERT is an excellent supply partner for index drives, rotary tables, trunnion drives, conveyors, lifting axes, shuttle systems and complete transport solutions. If you’re looking for Expert-Tunkers products, we can get them.

As a rule, the rotary tables are driven by a factory installed shaft-mounted gear motor. The indexing time is defined by the gear ratio. The rotary table can be delivered without drive and directly integrated into machinery drive chains.

EXPERT globoidal rotary tablesare used for packaging machines, assembling machines, textile machinery, automated handling systems, conveying systems, welding machines, machinery for glass-making and fabrication processes in which extremely short cycle times are required due to high output.

6.1. North America Automated Rotary and Indexing Table Market Size (US$ Mn) and Volume (Million Units) Analysis & Forecast, by Configuration, 2017‒2031

Leaders in the manufacture of advanced technology solutions including Multi-Tasking, HYBRID Multi-Tasking, 5-axis, milling, turning, CNC controls and automation.

Leaders in the manufacture of advanced technology solutions including Multi-Tasking, HYBRID Multi-Tasking, 5-axis, milling, turning, CNC controls and automation.

8613371530291

8613371530291