indexing rotary table factory

Indexing tables are used in a multitude of industries and in numerous applications. Their design is optimal for many manufacturing jobs, and they are a critical component in most automated manufacturing systems. Indexing tables are best defined as a machine tool positioning device. They carry components in a manufacturing environment with a repeating process of indexing (rotating) around an axis, stopping, dwelling while an operation is performed, then indexing again to repeat the process. They are usually made of circular steel plates, with one or more spindles, a drive system, encoders, sensors, controllers and slots or mounting holes to hold components.

Virtually any manufacturing operation can be performed on a part held by an indexing table including welding, grinding, drilling, assembly, painting, inspection, testing and more. In order to maximize operational efficiency, the machine doing the operation must also be built for the same intended application as the indexing table for them to work in synch. Similarly the machine that loads the indexing table with parts must also be synchronized. They must have the same capacity and be able to manage to the same dwell time for the system to work.

Industries that use indexing tables include automotive manufacturers, bottling companies, microchip manufacturers, pharmaceutical makers, consumer products companies and many more. They are invaluable to manufacturers pushing for automation and increased efficiency in their factories, turning work that used to take days into work that takes only hours. If a simple assembly task is required on small parts in a factory, there is no better way to complete the task than by coupling an assembly tool and an indexing table.

Rotary indexing table use is widespread in automated assembly machinery and selecting the proper mechanism is essential for both maximizing performance and minimizing the cost of this critical component. This how-to-guide will explore two common devices that can be used for rotary indexing and give advice for proper selection. These two popular devices are cam indexing drives and servo rotary tables.

Cam indexers are a ubiquitous mechanism that have been used for rotary tables for many decades. They are a great fit for applications that will always index the same angle and that require high-precision positioning at a very reasonable cost. A cam indexer uses a mechanical cam to provide the motion control to position the load. A mathematical motion curve is machined onto the cam that provides extremely smooth and repeatable motion.

A cam indexer has two main modes of operation. One mode is referred to as “Cycle-on-Demand”. This indicates that the camshaft will be cycled one revolution at a time to advance the output one position at a time. This is typically achieved by using an inexpensive camshaft sensor package to detect camshaft position and a VFD to stop and start the motor. The camshaft dwell period offers a wide window for the camshaft to stop without affecting the position of the output. To cycle the indexer, a PLC gives a command to the VFD to accelerate the drive motor to a preset speed, the cam rotates one revolution indexing the output, a sensor sends an in-position signal to the PLC, and the PLC signals the VFD to stop the camshaft during the cam dwell position. The table will be in the dwell position for however long is necessary to complete the work at each station. The dwell time can range from a fraction of a second to several minutes or hours depending on the application. This combination allows very accurate positioning with an inexpensive drive system.

A cam indexer can also be run in a more traditional “Continuous” mode where the camshaft spins at a constant speed and the indexing and dwell time is controlled solely by the cam motion profile. Continuous mode is useful when other equipment will be mechanically synchronized with the camshaft timing or when the indexer needs to run at cycle rates faster than a motor can be stopped and started. A continuous indexer can run at rates in excess of 1,000 cpm. The limitation of continuous mode is that it may be impossible to machine a cam that requires a quick indexing motion followed by a long dwell time.

A fully programmable servo rotary table is another common option. There are two specific cases where a servo rotary table is advantageous. The first is when a flexible motion pattern is required. An example is two different products being run on one machine that each require different indexing patterns. The other situation that suits a servo indexer is when extremely fast positioning is required followed by a long dwell period. A cycle-on-demand cam indexer is limited by the need to accelerate the camshaft up to speed during the dwell period before output motion is started. There are practical limitations to how fast the camshaft can be accelerated so there will be a delay before motion is started. With a servo rotary table, the output rotates as soon as the servomotor starts moving. A practical example would be a load being indexed 90 degrees in 0.25 seconds. This is not difficult for a continuous cam indexer or a zero-backlash servo indexer, but a cycle-on-demand cam indexer may struggle with that motion. For quick servo indexing applications, a preloaded gear reducer with zero-backlash is critical to achieving smooth indexing motions with minimal settling time. A zero-backlash RollerDrive mechanism would be an optimal choice to achieve accurate positioning with great dynamic response.

For either style of indexer, application information including moment of inertia, indexing angle, indexing time, and dwell time is required. A reputable manufacture should then be able to properly size the rotary table for the application.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ppr.

The RTBA is a unit manufactured by Kalamazoo company. It is a rotary table with a 6" table index. Furthermore, it has a numerous index combination by changing of index ring on a 36 spaces ...

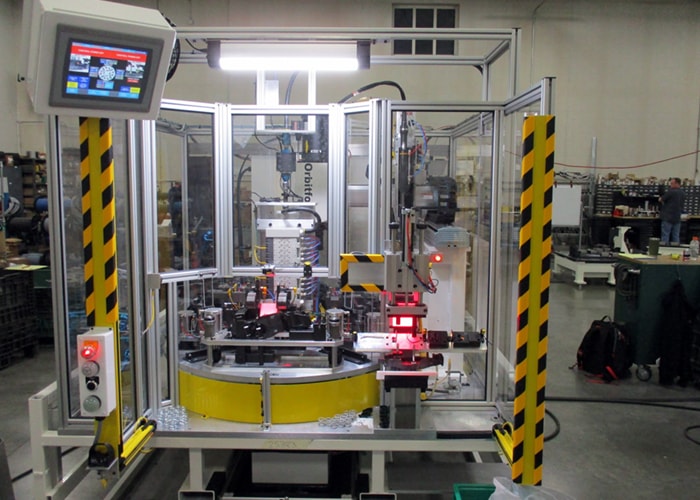

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

We combine rotary index tables with industrial automation systems so each task of your manufacturing process blends seamlessly into the next. For example, in the past we’ve created industrial automation systems that join rotary indexing machines with pick-and-place units for some of our clients. Contact us to see what we can do for you.

Rotary indexers are just one part of the equation when building a custom assembly cell. It’s important to remember the entire scope of the project and be cognizant that the rotary table should be able to move precise distances before stopping cleanly, with no backlash or wobbling. It needs to be balanced and capable of handling the tasks at hand.

Our automation experts have years of experience in consulting with our customers to create machines that suit their needs. We incorporate rotary tables from industry leaders like WEISS, Fibro, and Camco into our machines to create the perfect fusion of form and function. Our dedication to quality is unmatched in the world of custom machinery.

We seamlessly integrate rotary indexing tables into our automated machinery to provide you with custom solutions that work for your business. If you’re looking to take your manufacturing process to the next level, give the custom machine builders at Paramount Tool a call at (616) 582-5300 today. We’re always happy to answer any questions you may have about our rotary indexing machines or the machine building process as a whole. For a free quote, fill out our contact form and we’ll get back to you as soon as we can.

Cam Indexer Technology is Sankyo Automation’s specialty. We’re continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

An indexing table is a rotary table device that uses indexing to position a workpiece. CNC indexing tables are invaluable in milling and other industrial processes that require high precision cutting and shaping. They have a wide range of applications, including machining, positioning, inspection, and automation.

In manufacturing, indexing is the process of exposing a new edge or surface for use. An indexing table is used to convey and position workpieces during a manufacturing process.

The table’s indexing unit rotates the piece a precise distance into a specific position. It remains in place while the manufacturing tool cuts or drills the workpiece. Once the operation is completed, the table indexes the next section of the workpiece into position.

Indexing tables have a wide range of features. A basic indexing tool consists of a precision-machined steel plate with slots or mounting holes to secure workpieces during the machining process. They have either fixed or adjustable indexing angles. Parts can be loaded and unloaded manually or automatically.

There are three types of mounting: vertical, horizontal, and versatile. Indexing tables come with one or more spindles. Drive systems can be powered by pneumatic or electric motors, hydraulic drives, or even manually.

An indexing table is one of the most efficient ways to move and position a piece for precision machining. They can be used with small, medium, or large workpieces. Some of the benefits of using an indexing table include:

CNC indexing tables are used in the machining process for parts and components in a wide range of industrial applications, including food and beverage, printing, aerospace, defense, construction, medical, and automotive.

CNC Indexing & Feeding Technologies has been a premier importer/distributor of quality machine tool accessories such as hydrodynamic magazine-style bar feeders, short bar loaders, rotary tables, high-pressure coolant systems, and oil skimmers since 2007. Our line of TJR Precision rotary and indexing tables turn any 3-axis machining center into a 4 or 5-axis with customized faceplates available. In addition, we offer manufacturers our own CNC Indexing brand of hydrodynamic magazine bar feeders, short bar loaders, and gantry-style autoloaders.

If you’re looking for the best CNC accessories for your manufacturing operations, contact CNC Indexing & Feeding Technologies online or call us at 513-770-4200.

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

Rotary indexing is a process where repeated angular displacement during a machine cycle is followed by motionless dwell. A rotary indexing table is specifically designed to make repetitive moves around a platform. Essentially, they are highly precise work-positioning devices that index parts to be worked or machined in multiple operations.

A rotary indexing table is an integrated motion system. They typically consist of motors and mechanical power transmission devices along with encoders, sensors and controllers. Tables use electric motors for either cam drives or servo tables. Mechanical cam indexers are relatively low cost and only index to set angles, but are capable of precision moves.

Important parameters for rotary indexing tables include the needed resolution of the application (or the smallest increment to move or measure), the required repeatability and accuracy, and other mechanical parameters such as acceptable levels of backlash or hysteresis. Another key parameter is the loading including torque, axial, radial, and moment loads. These can impact the type and size of the indexer used in a given application.

A rotary indexing table can be used in many applications including manufacturing, inspection, and assembly tasks. For instance, assembly, machining, and bottling machines all use indexers. Usually, they take one piece around to work areas or move arrays of relatively small parts around stations for sequential machining or assembly tasks.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

The Peiseler rotary indexing table is at the heart of the rotary indexing machine, which has five stations for drilling and milling processes plus a loading and unloading station. "The key requirements for our design went beyond the need to achieve a maximum power density for highly dynamic indexing times in the smallest possible installation space", says Gronau. "In order to minimise the tolerances present, we had to position each of the two-axis rotary tilt tables as precisely as possible, both as standalone units and in relation to one another". Providing the media required to close, release and monitor the workpiece clamping device was also a complex task. A rotary manifold with eight ports was ultimately fitted for this purpose.

"This rotary indexing table is not only the largest we"ve built to date, but also a customer-specific solution that will shorten cycle times and reduce unit costs in the production of electric vehicle components", explains Gronau. As a high-precision manufacturer of trunnion tables, rotary tables, two-axis rotary tilt tables, swivel heads and workpiece changing tables, Peiseler is helping to build the reliable production processes that will lay the foundations for our future mobility.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

With its products from the Business Unit Rotary Tables, FIBRO has succeeded in becoming well known around the world. In this area, we offer the largest selection of rotary indexing tables available from a single source. Starting with a pneumatic rotary table in 1960, this product line has developed into a programme that today includes more than 150 different models.

Rotary indexing tables from FIBRO are used as swivel axis or axis for positioning as well as workpiece carrier in machine tools as well as in assembly applications. In the mean time, thousands of units have been incorporated as essential components into highly productive machines around the world. The quality, the performance and the large product line meet whatever requirements our customers have.

With its international presence, FIBRO is a partner in your production and provides competent solutions for tasks involving rotary indexing tables and NC technology – worldwide. Experts are at your disposal from as early as the planning phase of a project and continue to work with you as the project progresses.

8613371530291

8613371530291