large rotary table manufacturer

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

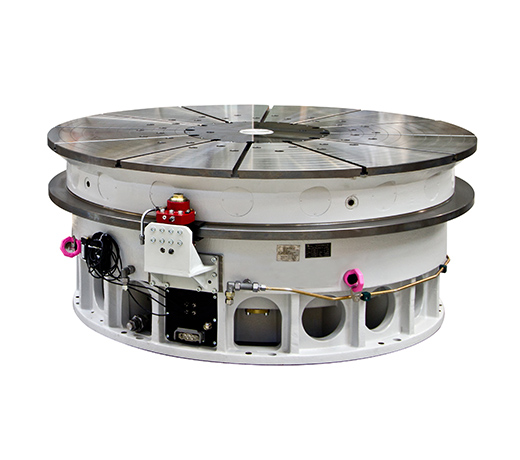

Ganro Industrial Corporation offers large rotary tables in their standard DR series configuration. The large rotary tables are available in a range of 1000mm (40”) to 2500mm (98”) in faceplate diameter. They can be utilized as a full rotating axis incorporated into a machine’s control or as indexers with Ganro’s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions to give manufacturers maximum flexibility. These large rotary tables and indexers utilize a hydraulic brake system to reach high clamping torques. All Ganro DR Series rotary tables and indexers use Ganro’s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary table models, accessories and spare parts. We have certified service technicians for installation and repair of all Ganro and Golden Sun rotary table and indexer models. Please contact us today to learn how adding a Ganro rotary table or indexer can help improve your manufacturing process.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

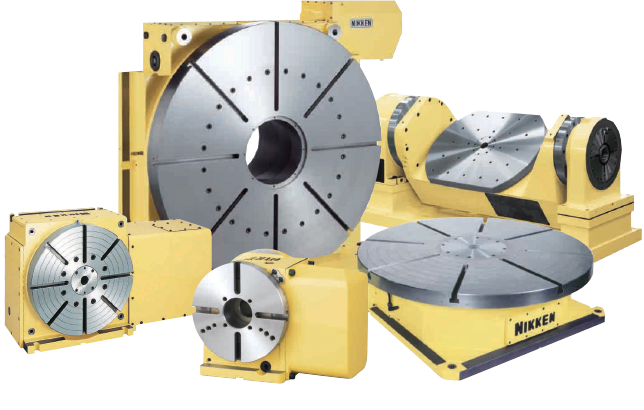

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

The TR210 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale feedback on the ...

... . and more utilize the free standing column design. The column design floor turntable uses a large diameter slew ring bearing and center column for supporting the load. Table deflection ...

This is the Hollow Rotary Table model number GSN60-05K-SV with table size 60mm gear ratio 1:5 for servo motor. GIGAGER Hollow Rotary Table also called ...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Our rotary, tilt and carousel rotary tables set a clear mark due to the extremely robust design as well as a high level of precision in the micrometre range, speed and repeatability. A suitable solution can be designed for every application case. We speak with our customers about requirements and work pieces, which are to be processed on the rotary tables. We create the right solution based on our experience from more than 600 projects. Our high-precision rotary tables can withstand a bearing load of up to 500 tonnes. If such masses are being moved, this requires high torques. If these masses need to be accelerated quickly, then they need to be braked quickly, and they need to be precisely positioned with accurate repeatability.

Whether a hydrostatic linear or rotary axis, roller bearing axles or also a combination with both, we have all the solutions in our portfolio. Hydrostatic guides help to avoid wear surfaces, for example at very high loads, and the tables are thus suitable for processing with the highest requirements and the highest accuracy. The best damping properties allow for longer tool lives and high-precision work piece processing. The decisive factor for the durability and precision of the rotary tables is not only the possible loading, but the largest possible bearing diameter in relation to the worktop size. The machine bed itself is very compact and space-saving. It is well-protected under the steel cover. All the necessary regulation and control elements are easily accessible in an power box located in the rotary table. Thanks to the standardised, plug-in-ready interface, the rotary table can easily be connected to all machine tools.

In addition to rotary tables for positioning work pieces for milling work (also in interpolation operation), patented tilting tables with additional axes, for example, are among the repertoire. Due to the standard angular adjustment of up to 10°, these are suitable for milling large an heavy components and, for example, are used in wind energy technology. Pallet changing systems are used to automate machining centres due to the multiple pallets and the ability to set up during main working hours. Thanks to a powerful drive train design, our carousel rotary table achieves very high machining torques, which makes a very good machining performance possible. In addition to the milling, it is also possible to turn and grind work pieces.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

... models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with excellent dynamics whereas the hydrostatic tables ...

The tilting tables are designed and produced for 5-axis operations on complex work-pieces requiring accessibility to the most unreachable surfaces thus ensuring fast swarf removal at the same time.

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

Additional rotary and tilting axis for your machine. High accuracy and high loading capacities make Rusach International tilting rotary tables suitable for machining and metrology applications. Ideal for milling machines, horizontal boring machines, vertical machines. We can design and manufacture larger sizes for the largest gantry and bridge type machines.

Preloaded axial-radial roller bearings with high loading capacities in both horizontal and vertical planes. Sensitivity and fine positioning ensured on all Rusach International tilting rotary tables.

Modular construction provides the widest possible freedom for application variations with our tilting rotary tables. Worm gear drive specially configured for maximum torque and minimum (adjustable) backlash. We offer several different styles of tilting rotary tables to cover all possible applications.

The A-688 direct drive rotary table with air bearings provides extremely high resolution and geometric performance. The angular resolution of this high precision air bearing spindle is 0.0015µrad (0.00003 arcsec), and flatness and eccentricity are specified better than 175nm and 300nm, respectively. This is made possible by high resolution, absolute measuring feedback encoders, and low-cogging frameless and slotless torque motors. The A-688 rotary table can be used in any orientation. Air bearing spindles guarantee a virtually unlimited service life with no wear, and zero required maintenance. As with all PI air bearings tables, the A-688 spindle is clean room compatible and requires no lubrication.

PI uses EtherCat based, high performance motion controllers ideally suited for closed-loop control of the rotation tables. Advanced algorithms are available to deal with changing load conditions and to suppress external disturbances.

8613371530291

8613371530291