drill press rotary table pricelist

I usually don"t review stuff but I thought I would mention a little about my experience with my table.I made a wide guide for my table...2"x1" that slides side to side with a locking clamp to hold items to be drilled. I had never used a pressure clamp using the tracks. I used the other day and both tracks popped out of the slots. The T-track was secured using 3 small 1/2" screws and no glue. Guess I"ll have to fix that before using it again!!!

I bought this a while back because I always wanted a bigger table for my drill press. I was disappointed because the fence isn"t square to the table. It"s 90.6° to the table and the small insert sits 1/32" below the rest of the table. Things that could have easily been fixed during manufacturing instead me having to shim things.

I found the drill press table to be a great table for the price. The only issue I noticed is you need be sure your setup takes into account the position of your drill press handles.

I ve been using this table for my table mounted drill press for over 5 years espacially useful when I am making PSI pens since I use the PSI self centering jig . This table adds the nice sliding fence and stop for Perfect repeatable drill bit alignment. So I just bought another for my Larger free standing drill press. Installed in a flash.

Great extension for any bench top drill press (or floor model)at a very affordable price. Quality, detail, and value are excellent especially with the included free hold down clamps.This is not an extremely heavy duty table but will accommodate most drilling activities very adequately and precisely. As such, avoid over-tightening plastic parts, particularly the attachment to the drill press table. Fence could have included a metal T-Track to accommodate the stop block and flip stops but again, price would be a factor. All in all, a very functional table at a great price. Highly recommend.

*** MLCS NOTE: This table includes T-Tracks, but does not usually include T-Track Hold-Downs which are sold separately except during special sale promotions. Please review the description of the item and included extras when ordering. ***

I have a full size Jet drill press (JDP-17DX). I needed something to hold down wood when drilling and liked the idea of a fence and stop block. Contemplated making my own, but saw the sale on this table and the free hold downs and figured it was worth saving time and materials. This is my first purchase from MLCS. Table is MDF and has a no-frills look. Can"t yet speak to the durability as I just got it. Had to look at the website to find a picture (found on the jumbo table entry) on how to use the bottom clamps to hold it to my table. Not complicated but would have been nice to include. Table is narrower front to back than the drill"s table and longer by about 3" on each side. My fault for not measuring the drill table and comparing to the specs. Not a big deal since I needed more side to side space than front to back. Perhaps the jumbo would have been a better choice. If you have a bench top drill, this would definitely be additional space. Fence slides smoothly, but it"s up to you to square it up. Also, the fence track for the stop block is not aluminum - it"s routed out of the MDF. Don"t know how durable that is in the long run. Free hold down clamps were a nice bonus, but I was disappointed to discover that their design (a C shape) limits them to clamping straight down onto the track. This means that if what you"re drilling isn"t long enough to reach the T-track (7-8"), you"re out of luck. Looks like I"ll have to buy a different kind of t-track hold down that can be angled. Final thoughts - the table is ok, especially for smaller drills. I definitely would not pay full price for it. And honestly, I would have been better off building my own.

After reading the reviews, I had some concerns about the lack of a metal track in the fence. I called tech support and they said that with a metal track in the fence you could damage a Forstner bit if you inadvertently hit it. I still thought I"d like a metal track in the fence for durability of the table set up. For $13 MLCS threw in a metal track. It was easy to install. One pass on the router table with a 3/4 bit at the proper depth made the perfect mortise for the track. The included track was about an inch too long but the aluminum was easily cut. The track does not come with screws. As with other reviews, I found that I had to remount the mounting bracket. The existing bracket is aligned for a very small drill press table. I used a 1 1/2 Fostner bit to counter sink the mounting plates in their new position. This whole table could be made in your own shop but when you consider the time it would take to make it, the cost of the materials and MLCS adding the free T-track hold downs, you can"t beat this deal. Also, the free hold downs fit a standard T"track so they can be used on other equipment. I used them on the fence for my Kreg router table to hold stop blocks. The table is a nice size. When it"s mounted on the drill press you can still easily reach the adjustments under and behind the table.

My experience tallies with those of several other reviewers: nice enough table, but it does not come close to fitting my Jet model JDP-15M drill press. Reading through other reviews leads to the conclusion that re-drilling the mounting holes is a frequent issue impacting several brands... and a pain. Redesign of the mounting system, anyone?

****MLCS NOTE: The mounting instructions will vary based on the configuration of the many different drill presses on the market. Our woodworkers are happy to assist with specific set-up questions via toll-free phone or email.***

They say it fits most drill presses, but not my Craftsman table mount (small)drill press. You have to move the MLCS table way forward so the height crank can rotate, and you have to remove one of the three arm handles on the press to lower the drill. On small work the chuck hits the fence. Still, its way better than not having this table. I was able to accurately drill multiple parts in the same location, which is what matters most. I will cut down the fence in the middle to accommodate the chuck. Makes my drill press much more accurate. It"s worth dealing with the rest.

One problem a had was with the fence. The bolt holes on the fence were about 1/4" wider than the t-track.I had to grind down the heads on the hex head bolts and drill over size holes in the fence in order for it to fit in the track. Now I can move the fence without it binding. Other than that it looks like a nice table and should work better for wood working.

Drill Press Table to my Shop Fox 1668 Oscillating Drill Press. I hade to make some modifications by re-locating & re-drilling the two mounting holes. This was easy using a 1 3/8" Forstner Bit then using a 3/8" drill bit for the recess. I also routed out the fence MDF and mounted a metal T-Slot. Piece of cake, however MLCS should consider using a metal T-Slot in the fence instead of the MDF to prevent tear out if you happen to over-tighten the stop block. I recommend this table to anyone who owns a drill press. I also recommend purchasing the two hold down clamps to go with the table. With just a couple of simple modifications it"ll work like a champ.

Wonderful item, some drill press tables holes must be elongated for base,missing M8 3 9/16 bolt (back plate hold down bolt), bought at hardware store.

Just received this table today. Installation was very straight forward. The Hold Downs are a must. One area of concern is the Fence. The T-Slot for the stop block is routed in the MDF which if you are not careful looks like potential damage to the fence can be caused if over tightened. My plan is to route it out and install a Metal T-Slot. Other then that is is a great table!

I bought this table a year or so ago and I still use it today. Unfortunately, I had to mount mine with and intermediate table. BEFORE YOU PURCHASE THIS ITEM, READ the compatibility note and be sure you know your drill press. This unit does not mount directly to many drill presses.

MLCS NOTE: This item is designed to mount directly to as many drill presses as possible. However, it is not universally compatible due to the wide variation in drill press designs. We provide the compatibility note so customers are aware before purchasing of any potential mounting issues based on the specifics of their drill press.

I ordered one of these for my new Ridgid drill press I recently purchased and it arrived in excellent shape and was easy to mount and put together. I do have 1 major complaint though. The metal T slots on the table were not routed deep enough so they are above the surface and as I slide something around on it to drill it gets hung up on the metal runners. If you slide it on top of the protruding runners you are now drilling a hole off of 90 degrees square. Why they couldn"t have routed the channels a bit deeper so the metal T slots were even with the table top, or even a little below, is beyond me. When I get a chance I am going to take them out and re rout to a better depth. Also be aware that the stop block channel has no metal T track so if you over tighten the stop block there is a chance you will break out the MDF. All in all it is worth the price with the free shipping if you want to take the time and make it right.

I like this table. I did have to re-drill the table"s mounting T-cap nuts to accommodate my Delta DP 350"s wider table. The two holes were easily accomplished using a 1 3/8 inch Forstner bit and standard drill bit for it"s center hole. The available T-Track Hold Down clamps are a must although somewhat pricey. I would recommend these products.

I have owned this table for over a year now and it never comes off my drill press. It is very functional and easy to use. A great value for the price. I have also made custom inserts for my drum sanders which make it even more useful.

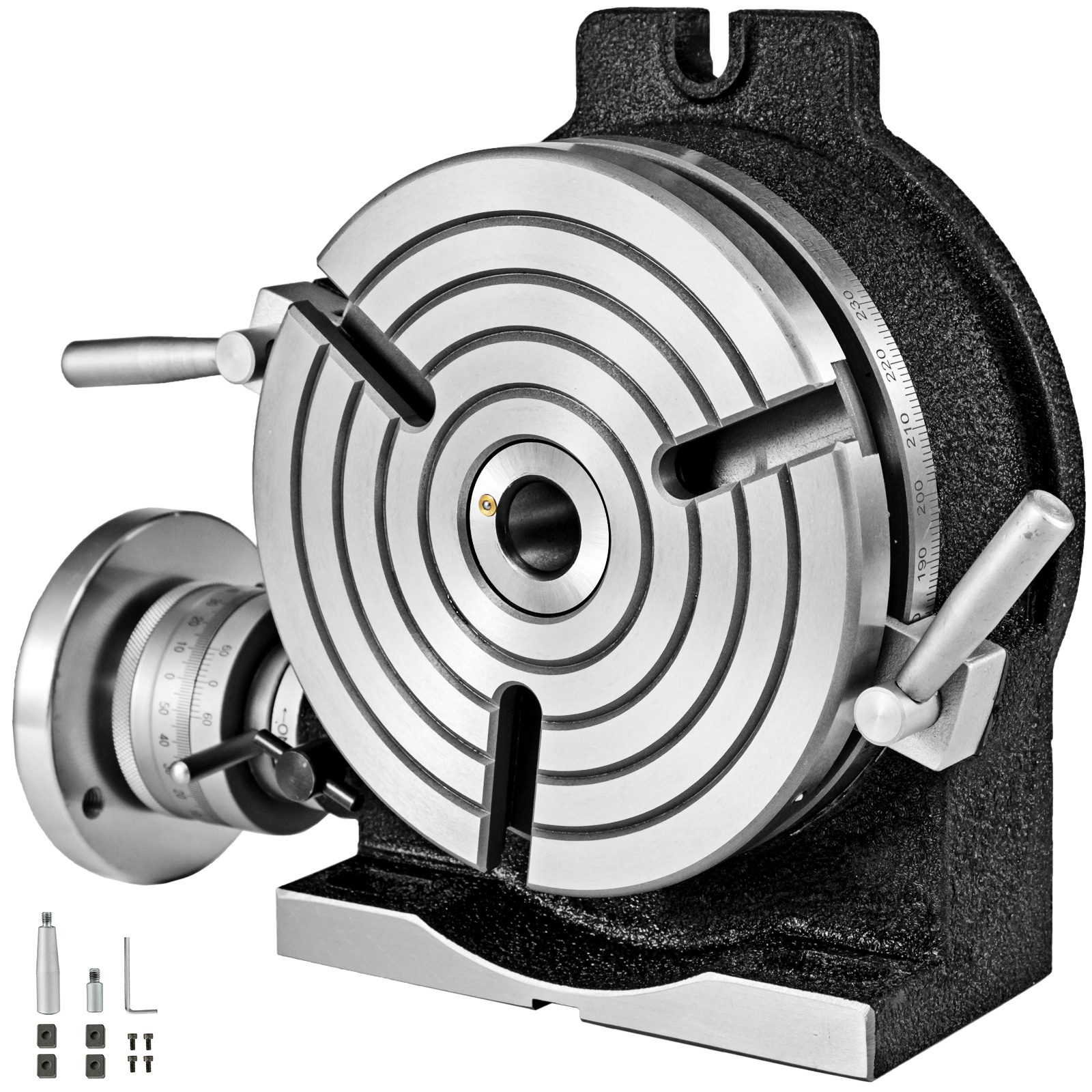

The vertical & horizontal rotary table, one of the main accessories of the milling machine, is a precision work positioning device. This machine is widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis.

It can be mounted "flat," with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. Or, mounted the rotary table on its end (or mount it "flat" on a 90° angle plate) so that it rotates about a horizontal axis. In this configuration, a tail stock can also be used, thus holding the workpiece "between centers."

It"s not difficult for you to adjust the rotary table milling machine. What you should do is to adjust the handle to the position where you want because the precise scale is marked on the dial.

Except for the 5.9""(150 mm) rotary machine table, we also offer you four locating blocks. The center can be corrected quickly and accurately by the Key guide block.

Widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis. Great for circular cutting work, boring, spotfacing, and similar work.

The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on.

Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice!

Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work.

It"s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial.

If you purchase our product, we are going to give you a free wrench, 2 positioning keys and screws. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences.

This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working.

A drill press, especially one like you describe, is not really made for milling. Milling puts a lot of radial stress on the quill bearings while drilling is mostly axial stress. So drill presses are not made for milling.

8613371530291

8613371530291