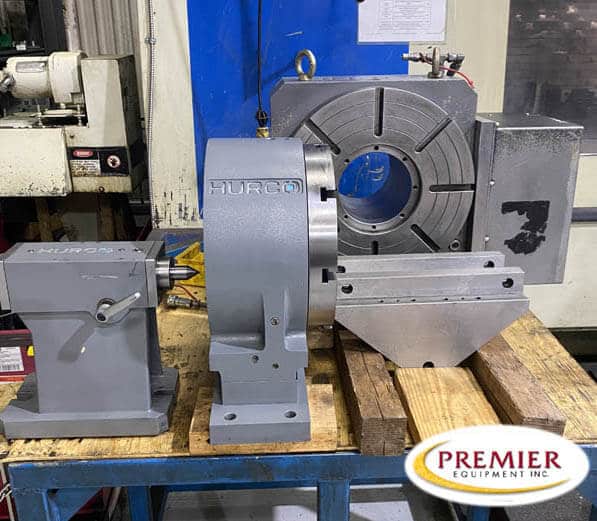

hurco 4th axis rotary table in stock

The Hurco VMX50i w/4th Axis is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

2004 Haas TM-2 with Brushless 4th Axis Drive/Wiring, 10 Station Automatic Tool Changer, Rigid Tapping, USB, Intuitive Programming System, On Our Floor, On Our Floor, Under Power, Grand Rapids Michigan

Kitamura HX300iG CNC HMC, 12" x 12" Pallets, Full 4th Axis Table, 18.1" x 20.1" x 22.0" Travels, CAT40 BIGPLUS Taper, 15000rpm Spindle Speed, 50 Station ATC, Work Probe, Laser Tool Probe, Through S...

Haas Mini-Mill, 6000rpm Spindle, 16" x 12" Travels, CAT-40, Brushless 4th Axis Drive and Ready, Rigid Tapping, Coordinate Rotation and Scaling, Quickcode, 10 Station Tool Changer, Coolant Pump, Wor...

Haas VF-6 CNC VMC with Through Spindle Coolant, 4th and 5th Axis Drive/Ready, Chip Auger, 40 Station Tool Changer, 10000rpm Spindle Speed, 2-Speed Gearbox, 30HP Spindle Motor, Remote Jog Handle, Hi...

Lots of Options, Wireless Probing, 4th Axis Drive and Ready, 5th Axis Drive and Ready, Through Spindle Coolant System, Chip Auger with Dual Internal"s, Programmable Coolant Nozzle, High Pressure Fl...

21" x 16" x 19" X/Y/Z Travels, 10000rpm Spindle Speed, CAT-40, 20 Station ATC, Full 5-Axis Rotary/Trunnion Style Table, Hurco WinMax CNC Control, Loaded with Hurco Software Options!

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

The Hurco VMX60SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

Tool Center Point Managementeliminates the need to account for the machining center’s centerlines of rotation. Instead, you simply use the solid model zero location. Post the program independent of where the stock is fixtured on the table.

Transform Plane calculates the other locations for each of the rotary moves after you locate part zero. The control software only needs you to define part zero one time, and it figures out all of the other part zero locations automatically.

At Hurco, we are immersed in 5-axis technology. We have carved out a niche in this arena because we made a commitment fifteen years ago to focus on 5-axis. We determined this type of machining center, combined with the capabilities of our control, would make our customers more profitable. Similar to the transition from manual mills to CNC mills, we believe the time is right for shops across the country to increase profit margin by investing in 5-axis.

Because we listened to our customers’ reservations about switching from a 3-axis process to 5-axis, we assembled a 5-axis applications team with a dedicated phone number and email to help. If you do NOT OWN a 5-axis machining center, the most important message you need to know: 5-sided machining on a 5-axis machining center will increase the profit margin of the parts you are producing on your 3-axis machining centers. The Hurco control makes programming easy for 5-sided—NO CAM needed!

According to benchmark data from Modern Machine Shop magazine, 24% of the highest performing shops in the U.S. are using 5-axis positioning. Hurco has carved out a niche in the 5-axis arena due to years of research and development. When we decide where to invest our resources at Hurco, our primary criteria are customer productivity and profitability. We evaluate the past, the present, and the possibilities of the future to determine what technology will benefit our customers the most. Nearly a decade ago, we determined that 5-axis machining warranted our attention and set a path to become the experts. We continue to lead the industry in developing control technology that optimizes the process for full 5-axis and 5-sided (3+2).

As our industry transitioned from manual to CNC milling, many shops got left behind. The transition from 3-axis to 5-axis may prove to be a similar situation. At the very least, you should evaluate the benefits of integrating 5-sided processes into your operation. With 5-sided, also called 3+2, you reduce setup time, increase accuracy, and expand your shop’s capability for future simultaneous 5-axis work.

When you invest in a Hurco 5-axis CNC machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center via powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Hurco CNC has been in business since 1968 and has always been cutting-edge with both machining and process-control technology. Some key dates for their equipment include 1986, when they introduced the 3-axis machine, In 1997 they introduced the VMX CNC mills, In 2003 the VM series and VTXU 5-axis were started and lastle 2004 the TM slant-beds hit the market. In 2006 their business expanded rapidly with the introduction of the SR Series 5-axis machining center and the WinMax software. The TMXMY series started in 2010 and was rebranded to include the "i" in 2012. This includes the HSi series which stands for High Speed along with the Ultimotion.

Hurco machines with trunnion tables have integrated tables instead of simply sticking a trunnion table on a 3-axis CNC machining center and then calling it a 5-axis. This allows for more clearance on the Z-axis. This series is ideal for machinists experienced in 3-axis machining, but ready for the benefits of 5-axis. You still machine in a linear fashion, but just machined more sides with this type of CNC. The trunnion 5-axis mill by Hurco allows for better undercut, larger work volume, and more torque.

Since 1984 when Hurco CNC introduced the dual-screen console, Hurco has been focused on designing controls that are easy to use and intuitive. They were early innovators in conversational programming aimed at making machining simple, however, this did not mean that they could only make simple parts.

Hurco Supports ISO/EIA standards that are common with Fanuc or Siemens programs, so you can use existing NC programs on a Hurco. The control also offers Full Macro B support and most G & M cores that an NC programmer uses.

When selecting a Hurco to meet your needs, it is helpful to understand the Series naming standards. The VM represents Vertical Milling, then there are typically two numbers representing the number of inches travel on the X-axis and another letter designating special features.

The VMX line ( Hurco VMX 30t) is the most popular of the 3-axis machining centers. The first two numbers in the name represent the X travel. We have used Vertical Milling Machining Centers in this line going back to 2003.

The SR Series (Example: VMX60SRTi) of 5-axis mills has a swivel head with either an A or C style rotary table. The extra size of the rotary table allows for versatility for secondary operations or 3-axis work. In this example, the travel is 60 x 26 x 24 with a spindle speed of 12,000 rpm and tool capacity of 40 CAT 40.

The HTM series (Example: HTM30i) is the toolroom mill designed with an open bed for easy access to the table. Its equipped with UltiMotion. In this example, the machine is 30 x 16 x 18 with 8,000 rpm and 16 tool max.

The BX series (Example: BX40i) features a high-speed double-column bridge design machining center. This highly stable, the high-weight machine provides exceptional accuracy and outstanding surface finish capabilities. In this example, the travel is 40.2 x 27.6 x 19.7, the spindle speed 18,000 rpm and machine weight is over 20,000 lbs. If a U is added to the series name (BX40Ui), then a trunnion table is mounted along the Y-axis.

The HM series (Example: HM1700i) is a line of horizontal mills equipped with pre-tensioned, dual ballscrews for excellent rigidity. It has large front and side access doors ergonomically designed for operator use. If an R is added to the series name, the model comes with a rotary torque table (HM1700Ri).

The VC Series (Example: VC500) is a cantilever 5-axis machining center. The 500 has a travel of 20.5 x 17.7 x 15.8 and a spindle speed of 10,000. The 600 has a larger travel and 12,000 rpm making it a larger more powerful machine than the 500.

The VM_U series are 5-axis trunnion table machining centers with an integrated trunnion table. Like the VMX line, the first two numbers represent the X-axis travel. For example, the VM10Ui has a travel of 21 x 16 x 19 with a spindle speed of 10,000 and tool capacity of 20 CAN 40.

8613371530291

8613371530291