trunnion rotary table made in china

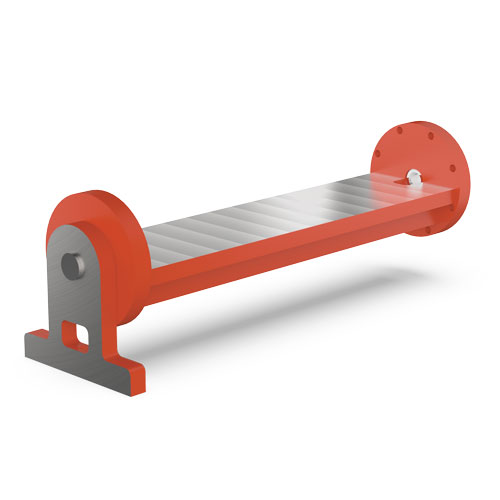

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

Benefit from one of AMROK"s complete 4th axis solutions through dramatic increased efficiency of your vertical machining center and rotary table. The Stallion Trunnion Table is made from Class 35 cast iron, making it a rigid and robust solution to your CNC machining needs. The Stallion Trunnion Table can be made in a variety of shapes and sizes, ranging from 10" to 10" in length and from one to eight faces. The 4th Axis fixture can also be integrated with all of your favorite workholding devices, including Schunk, AME, Mitee-bite, Triag, Jergens, and more! Scroll down to find your perfect 4th axis workholding solution.

The combination of the Shelf Unit Trunnion Table and AMROK Dovetail Vises provides a simple, small, and affordable workholding solution that takes the productivity of your rotary table to the next level. Still made from Class 35 Cast Iron, these smaller Trunnion Tables are still as rigid and durable as their big brother, the Stallion Trunnion Table, but are better for smaller machines, smaller parts, and smaller rotary tables.

The smallest standard trunnion table size, made 100% from Class 35 Cast Iron, is designed for smaller machine tools and rotary tables. Riser blocks and braking systems are available to accommodate for your machining needs.

The 9/23 Stallion Trunnion Table is designed to hold a double station 6-inch vise and features a through hole to open/close workholding device of choice. The outboard support is customized to the center height of your indexer along with faceplate dimensions.

The 9/35 and 10/30 trunnion table fixtures feature heavy bracing for the most demanding cuts. Large face mills are not a problem. The outboard support is customized to the center height of your indexer along with faceplate dimensions. Hydraulic and Pneumatic braking systems are recommended at this size.

The Stallion 12/48, the largest standard trunnion table, is highly engineered for rigidity and accuracy. This 4th axis fixture is made for the largest rotary tables and machine tools. At this size, our hydraulic and pneumatic braking systems are highly recommended.

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

The trunnion consists of a fixture that turns around an axis (A). The rotation is made by using a rotary table with a support (motor-support), or 2 rotary tables (double motor system). Thanks to this trunnion fixture, at Ibarmia we offer the possibility of machining 1, 2 or 4 faces, with a smooth surface with clamping holes, T-slots, and the possibility of integrating zero points in the tooling, which facilitates the automation of the part change.

Many machines and applications have been approached, from trunnions mounted on the fixed table to machines with no table and a design adapted to the tooling. Depending on the transversal stroke of the machine, one or two trunnion tools can be mounted for pendulum cycle work. It also includes the possibility of integrating a plate between the two central rotary tables, connecting the fixtures on both sides to change from a double to a single workstation.

In short, we are talking about a concept tailored to our Z SERIES moving column models in which the longitudinal travel is the key feature, introducing an added rotary axis for the machining of long and extra-long parts that do not require large transversal stroke.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Five-axis machining is a powerful tool for reducing set-up time and increasing accuracy for complex parts, but investing in a 5-axis machine tool can be prohibitively expensive, especially for smaller shops. The TR200Y dual-axis trunnion rotary table from Haas Automation, Inc. (Oxnard, CA) puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility. The TR200Y is designed to mount in the Y direction (front to back on the table) of a mid-size VMC. At less than 27 in (686 mm) wide and only 20 in (508 mm) deep, this rotary table easily fits on one end of the machine’s table, freeing up the remainder for additional fixtures or vises. It has a 200 mm (7.87 in) T-slot platter and will swing parts up to 8.1 in (206 mm) diameter. The maximum platter capacity is 80 lb (36 kg). The trunnion provides ±120 deg of tilt and 360 deg of rotation for full simultaneous 5-axis motion, or to position parts to almost any angle for machining. Yet it can easily be removed when not needed.

Powerful brushless servomotors provide 150 ft-lb (203 Nm) of spindle torque on both axes of the TR200Y. Brake torque is 300 ft-lb (407 Nm) on the tilt axis and 100 ft-lb (136 Nm) on the rotary axis, speeds are 130 deg/sec on the rotary axis and 100 deg/sec on the tilt axis. The trunnion’s precision-ground platter of heat-treated 4140 alloy steel has six standard 5/8 in (16 mm) T-slots equally spaced at 60 deg for easy fixturing. Plug-and-play compatibility makes connecting the TR200Y to a Haas mill with 4th-axis and 5th-axis drives a breeze, and the available programmable servo control makes it easy to interface the rotary to almost any machine. Built in the U.S., the TR200Y is backed by the worldwide network of Haas Factory Outlets for extensive support and service.

#cncmachining #cncmanufacturing #manufacturing #indianmanufacturing #machinist #metalcutting #5thaxis #5axis #cncmill #cncmachine #5axismill #machineshop #5axiscnc #rotarytable

About UCAM: We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others.

Mr. Straessle is pL Lehmann product manager at Exsys Tool. He says that while five-axis machines have become more affordable, they still can be two to three times the cost of a three-axis VMC, depending on the model. Therein lies one advantage to rotary tables, which, when installed on the bed of a three-axis VMC, combine a rotational C axis and a tilting A axis to enable the machine to perform either five-axis positioning work (aka 3+2 machining) or full five-axis contouring. Three-axis VMCs outfitted with two-axis rotary tables are commonly smaller than five-axis machines, too, saving valuable floor space. Unfortunately, they also tend to have tighter work envelopes, meaning a sizeable rotary table will be more restrictive of a machine’s movements.

A compact rotary table preserves work envelope space, providing more room for spindle and tool movement. Plus, shops have the option to use just the rotary table, mount standard vises next to it or remove the rotary table altogether, which is made simpler when the rotary table has a zero-point-type locating system to eliminate the need for alignment when it is removed and then remounted.

That said, Mr. Straessle says compact rotary tables still must possess design elements that enable them to perform effectively for a range of work. Here, he details four such features inherent to the pL Lehmann 500 series of modular-designed rotary tables, available in North America through Exsys Tool.

1. Load capacity. The compact 500 series provides load capacities that, in the past, were only available with larger rotary tables. For instance, the 3-inch rotary tables in this series are generally half the size of comparable units, but can handle workpiece loads as heavy as 400 pounds, he says.

2. Speed and torque.Rotary tables commonly use either direct-drive or gear-driven technologies, the former able to achieve high rotational speeds and the latter offering high torque. The 500 series uses the company’s pre-loaded gear drive (PGD) design, which is said to offer the best of both worlds in terms of high speed and high torque while being as much as four times as rigid as direct-drive systems. Plus, it enables the rotary tables to generate rotational speeds as fast as 160 rpm with virtually zero backlash.

3. Spindle clamping power.Once a rotary table is oriented to the desired position, an effective spindle clamping system is needed to securely hold that position during machining operations. Some rotary tables use an external intensifier or some other type of standalone hydraulic unit combined with disc braking to achieve necessary clamping forces. Conversely, the 500 series features an integral unit that converts air pressure into hydraulic holding power, using a

4. Monitoring system.The 500 series features a self-contained, internal monitoring system used to track and record vital rotary table information, including temperature, rotational speed and clamping force. It also detects internal pressure decay.

In addition, the rotary tables have USB ports to enable users to download monitoring data to log the operational history of the table. Not only does this data highlight crashes or malfunctions, but it also facilitates more effective preventive maintenance by offering early warnings to possible issues so users can avoid unplanned downtime. Plus, the monitoring system activates a series of LED warning lights when it recognizes a potential problem. For example, a blinking orange light is an alert to a situation that can be addressed before it becomes serious, while a continuous red light means immediate attention is needed. Because these rotary tables integrate with all the common machine tool CNCs, users can have warnings displayed on the control screens, too. By connecting a laptop running software such as pL Lehmann’s TeamViewer, users can also solicit assistance via the Internet from a company technician who can log on to assist in troubleshooting.

Mr. Straessle says the company guarantees the spindles on its standard rotary tables to achieve runout of 5 microns and its high-accuracy models to achieve runout of less than 3 microns (the latter is commonly used in grinding applications). In addition, glass scales provide ±1-arcsecond positioning capability for the C axis. These rotary tables are also sealed to prevent internal contamination that could hinder performance and feature a motor housing internally pressurized with oil to achieve an IP67 rating.

The 500 series is available in four standard, single-fourth-axis models. The smallest is the EA 507, offering a 3-inch face diameter and a spindle nose load capacity of approximately 240 pounds, while the high-speed EA 511 model is said to deliver twice the speed of the standard models. Each model can be configured as a two-axis system that provides 180 degrees of A-axis tilt with full C-axis rotation, as is the case with the series 500 T1 (trunnion-style) and TF (cantilever-style) units. They can also be ganged together with multiple spindles/C axes.

8613371530291

8613371530291