4th axis rotary table for cnc factory

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

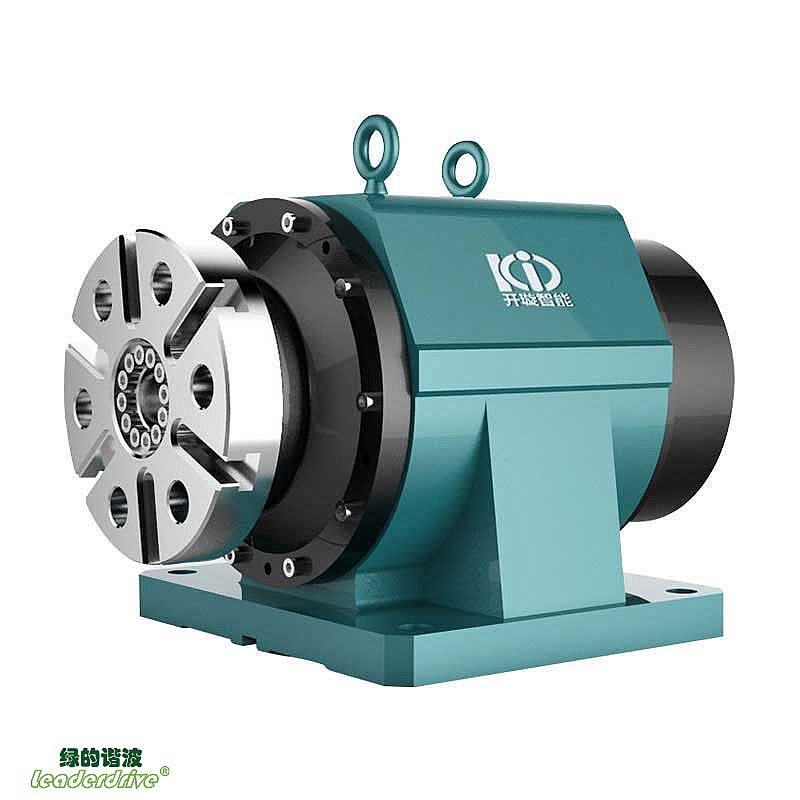

Silvercnc adopts the roller CAM mechanism , one of the finest motion control mechanisms available. The unit is constructed from an input shaft(the roller gearcam) and a turret(output shaft) fitted with roller followers.The roller followers are preloaded against a screw-like input shaft to completely eliminate backlash. Our proprietary adjustment mechanism provides optimum preload. The roller followers planted in the turret use internal roller bearings to transfer torque while rotating. This ensures zero backlash, outstanding precision,and excellent efficiency without causing wear, while providing long-term consistent accuracy, it’s principle below:

The 4th axis rotary table is Widely used in large machining centers. Compared with other structures rotary table, the four axis have the following characteristics and advantages:

Through the roller and CAM rolling contact, no forward and reverse back gap problem, greatly improve the roller CAM ultra-precision characteristics, reduce the rate of defects, improve the quality of precision machining technology is a breakthrough.

Roller CAM type turntable in rolling way conduction, reduce wear, conduction efficiency is high, high speed operation, conduction efficiency is up to 90% above.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Furniture industry: various types of doors, windows, cabinets, shelves, tables, chairs, sofas, couches, stools, benches, beds, desks, night stands, bunks, cupboard, tea boards Decoration industry: door frames, handrails, building columns, pillars, table legs, chair legs, photo frames, mirror frames, screens, lights, holiday decorations.

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts.

PRO4896 CNC uses a PRO rack and pinion system with linear guides to guide the X and Y-axis machine movement. Y-axis is driven by two stepper motors to prevent it from racking.

The control system from Avid CNC is plug-and-play compatible, it houses a 32-bit CRP5056 stepper motor driver and uses an Ethernet SmoothStepper breakout board.

Avid PRO4896 CNC router is greatly customizable, while buying you have the option of choosing stepper motors, spindle, controller, gantry width, and Z-travel of your choice.

Avid provides many upgrade options for the PRO4896 CNC. The Rotary Axis attachment is the one you need to achieve fourth axis capability on this CNC router.

Avid also offers software-guided alignment for the rotor. It"s fully integrated with their Auto Z and corner-finding touch plate and will work seamlessly with Mach4 software.

Their post-processor uses inverse time feed rates that prevent the production speed from slowing down during programs with combined linear and rotary motion.

The rotary axis is highly versatile, it can be mounted to the PRO4896 CNC router parallel to the X or Y-axis and can be recessed to the machine to help maximize the workpiece diameter.

The 49" rotary axis used in the Avid PRO4896 CNC router can be mounted with a maximum workpiece length of 34" if mounted parallel to Y-axis, and 28" if mounted parallel to X-axis.

Avid CNC"s post-processor for rotary control is available for all the Ventric software products and for the Autodesk Fusion 360 software. It can be downloaded either directly from the Avid CNC website.

They also have detailed instructions on assembly, different mounting options, and the electronics of the rotor axis. It is available on the website and in the user manual.

Avid offers various accessories like a leg kit, auto Z and corner finding touch plate, proximity sensor kit, composite nailer, dust shoe, plasma kit, and a rotary axis.

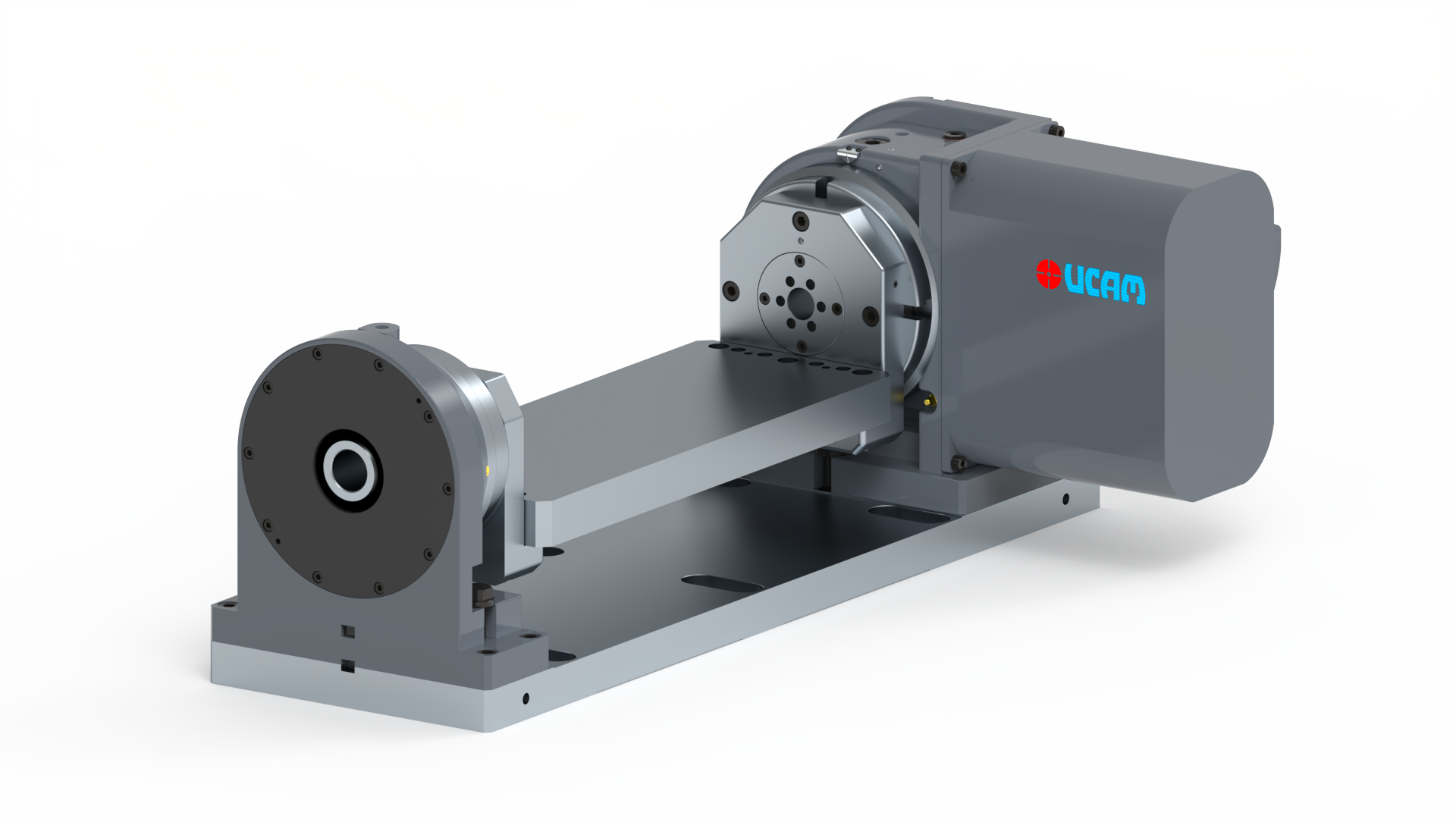

The chuck and tailstock of ShopSabre"s 4th axis system don"t come attached to a frame, so each can be mounted on the worktable in different configurations.

ShopSabre 23 has a wide list of accessories like the 4th axis kit, braille kit, computer mount, digitizing touch probe, laser sight, tool measure switch, tabletop, vacuum pump, warning light bar, and wireless pendant.

ShopSabre has community discussions happening on Facebook groups, YouTube, and Router Forums. No live discussions are happening and most of the time they are inactive.

GDAE10 6040 CNC router is the best budget-friendly 4-axis CNC router on this list. It comes with a rotary axis that can be attached along the Y-axis to attain 4-axis control.

The fourth axis control in GDAE10 6040 CNC is achieved through a rotary system with a 3-jaw chuck and a tailstock. It comes with a belt, tailstock, rotary axis, and five wrenches.

There are a lot of videos on youtube on cutting different materials using GDAE10"s 4th axis, you can refer to them to get a visual idea of its operation.

The 6040 CNC router comes pre-assembled and is ready to work right out of the box. The only work for you is to connect everything to the respective slots.

The 6040 CNC router has a large user base because of its low price. It is a great introductory 4-axis CNC to many people trying to come into 4-axis CNC machining.

The iQ CNC has a footprint of 39 1/2" x 50 1/2" with an effective work area of 24" x 36". It provides a Z-travel of 6" and the machine weighs around 425 lbs.

You can use any CAD/CAM software of your choice for working with the iQ CNC. Some of my recommendations would be VCarve Pro, Aspire, RhinoCam, Mozaik, and Enroute FAB Advanced.

For control operations, you"ll have to export and feed the G-code file to the CNC through a USB flash drive. The CNC can operate without a computer connected to it.

The iQ CNC router machine can be upgraded with the Laguna Fourth-Axis Attachment for achieving 4-axis control. It helps you machine complicated designs.

The 4th axis attached to Laguna iQ can work on workpieces having a length ranging from 12" - 26" and a maximum diameter of 7" depending on the optional table size you opted for.

You can use 4-axis G-codes generated from any G-code generator directly on Laguna iQ through a USB flash drive and iQ CNC can operate without a computer.

Next Wave CNC"s Shark HD520 is a popular choice among small businesses and many woodworkers. It can do 4-axis machining with a 4th axis rotary system installed in its work area.

The machine comes with a spindle mound and Next Wave CNC recommends using spindles like Bosch1617, DeWalt DW618, or NWCNC’s water-cooled spindle with the machine.

The Shark HD520 CNC can be upgraded with the Shark Standard 4th axis rotary system. The rotary system provides 4-axis machining capability to your HD520 CNC router.

You can place the 4th axis driver board on the controller slot by facing the pins out of the box, then you"ll have to tighten it with provided screws to hold it in place.

The 4th axis post-processor can be downloaded from the Next Wave CNC"s website. These post-processors are used to process and convert designs and toolpaths to CNC readable G-Code.

You can add the post-processor to the V-Carve Pro software that you get with the Shark HD520 CNC router. It can also be used with software like Aspire which supports post-processor integration.

In most cases, a 4-axis router kit is used to achieve 4-axis machine movement but to control this additional axis you"ll need to have a 4-axis compatible controller.

To put it in a simple form, the standard 3-axis together with the A-axis gives you a 4-axis setup. A-axis is the rotational axis that turns the workpiece.

4-axis machining brings in a great deal of flexibility to your CNC machining process, enabling you to create some of the complex designs that otherwise would not be possible.

4-axis CNC machines are costly because there is a lot of research and development going into building all these machines. You require 4-axis supported controllers, software, and CNC machines to do 4-axis machining.

Also, 4-axis designs require a high precision system to design those models. To make high precision systems you need to use a rigid machine built with well-calibrated electronics. As there are more moving parts in the machine, the operating complexity increases, and a lot of support systems are required to keep the machine running.

In 5-axis machining, two rotational axes operate separately to rotate the workpiece in many different angles with respect to the cutting tool. The machine may utilize either A-axis or B-axis with the C-Axis to achieve this feat, all these are rotational axes.

In 4-axis CNC machining only one rotational axis is there, but with 5-axis machining you can achieve two rotational axes that can operate independently. It brings in a great deal of flexibility in your CNC machining.

Yes, due to the advanced system, a 4-axis CNC requires specialized software to control the movement of the fourth axis. It requires CAM and control software that supports 4-axis machining. To control the machine properly, the software must understand the geometry of the 4th axis and how it relates to the other axes.

Let"s first have a look at the background of the video. In the video, the 4 axis multi head cnc router EA-1825RMS10 is milling 3D furniture parts with solid wood. There are two procedures in total: roughing and finishing. Two types of bits ( 12.7mm straight flute bits and 6mm V-shaped bits) and two pieces of toolpath files are used. Now you probably have a question:

A: For the exact design in the video, it takes 6 hours to finish. We got 10 pieces in 6 hours since 10 spindles and 10 pieces of the 4th axis work together. By calculation, we can know that each piece costs 0.6 hours on average.

Its biggest advantage comes from its dual-application working platform, a dual exchange table system for rotary and flat milling. The two platforms can be switched at will according to actual production requirements. One end of the rotational platform is a mobile carriage; when the flat platform is required, the mobile carriage can be pushed to the rear part of the machine and leave space for the flat table. So, we can get the flat table installed there and execute flat machining.

Since the flatbed size (2000x2500mm) is relatively large, if it is designed as one piece, it seems impossible for us to install it manually. Our strength is not enough to lift it.

Therefore, we divided it into two pieces, one on the front and one on the back. The size of each piece is 2000x1250mm. As shown in the picture below, this is what it looks like after the rear piece is installed.

In order to make the installation easier, we installed several small pulleys under the flat table. Same as the rotational table, it is supported by the heavy-load round linear guides as well.

• The electrical part is designed with the most reliable performance standards. As shown below, the machine uses a total of 6 sets of Yaskawa servo motion systems; both the headstock and the Y-axis are dual-driven; It also uses 10 inverters, so that each one controls an electric spindle; this combination is undoubtedly the most reliable one since one control one is more stable than one control couple.

• The multi-head 4th axis cnc router machine is equipped with a WEIHONG 4-axis simultaneous motion controller based on the windows system. This is because multi-head router machines are mainly used for engraving, and the tool path files of such machining are often very large; a computer is prior to a handheld DSP unit on the performance of both reading and running files.

It is ideal for the European-style furniture production industry engineered to process mass 3D carving, complex 3-dimensional leg curve patterns, curved parallelogram shapes, cabriole, and 2.5D relief sculpture engraving operations of solid wood elements.

A: Seeing from the users" feedback, EagleTec CNC strongly recommends the water-cooled constant-torque electric spindles; this type of spindle is the most durable one and has a lifespan of 2 to 3 times longer than regular water-cooled spindles.

A: This machine has 10 spindles, and they are often worked simultaneously, so the load on the Z-axis is relatively heavy. If the machine uses the same Z-axis transmission structure as the ordinary machine, this part will soon stop working. In addition to the use of servo motors and dual-balanced cylinders, EagleTec CNC has also made a reasonable transformation of the connection between the motor and the ballscrew, which offers splendid durability in the Z-axis.

A: Based on the dimension of this machine, we will have to take the gantry down before loading. Because the door width of all typical containers is 2.35m, our machine width is much larger than this size. SKD packing way would be the solution for this.

A: It"s a 12-months warranty since the departure. Under warranty, you’ll enjoy free replacement for any broken parts except Vulnerable parts. After that, we provide you with constant free online support as well; spare parts replacement will be charged based on raw materials cost.

8613371530291

8613371530291