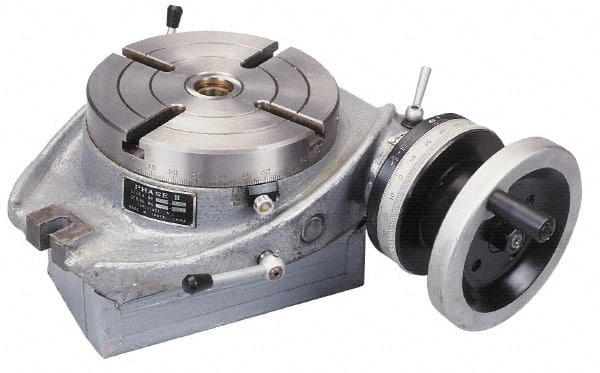

phase ii rotary table quotation

The stage includes an optical rotary encoder with a digital TTL output signal. After 400x interpolation, the resolution of one encoder count = 0.07 arc-sec (0.33 µrad). Very fine encoder resolution is necessary to enable smooth velocity control by the servo system.

Of utmost importance to this application was the very low error motion of the air bearing. Measurements were taken using a master ball and a capacitance probe. The master ball was mounted 50mm above the air bearing tabletop. Total radial runout error motion measured was less than +/-25 nanometers.

TEX-VA: (Texas and Virginia? Me too. Grew up in Charlottesville, moved to Austin.) I like those tables. I have the same LMS table as you. Unfortunately, the LMS table I have is horrid. Even after tuning it and lapping the gears, it would go from 0 to 0.5 degrees of backlash as it rotated. And it was worse before! I even tried to shim the ring gear before I finally gave up on it.

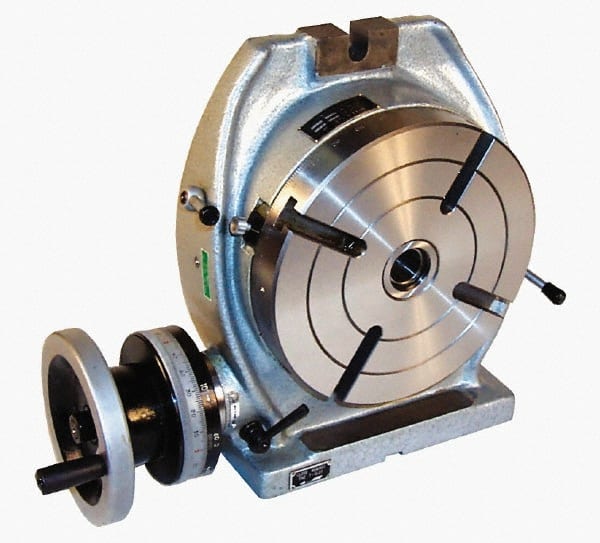

GMFoster : Why do I want zero backlash on the rotary? CAD/CAM. Unlike manual programming, a good CAM program makes it easy to program all sides of a part in a single operation, using the rotary table axis of rotation as the center of the part.

Then I can just stick metal in the rotary table and let the machine go to work making the part. But this is dependent on the 4th axis being a very rigid setup that can resist large cutting forces. This means good bracing and minimal backlash.

A cheaper table would be fine for gear cutting or similar operations. But when the toolpaths get more complex, the cutting forces will try to rotate the table against the backlash. That can ruin parts and tools.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

The Convex Rotating Table, unlike the Concavo rotating table, has the particularity of collecting the products deposited in the center of the tray, by means of a conveyor belt or slide, and convey them towards the outer edge. Located at the end of the packaging line, they act as an “accumulation tank”. They facilitate the unloading phase of the product leaving the packaging machine and facilitate the operations of picking up and boxing the operator.

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

8613371530291

8613371530291