fanuc rotary table pricelist

Table Model • Several options available for motor mounting position, including right side, left side, back and top • Highest weight load capacity in its class Table Model • Compact design • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application • Excellent full 5 axis contouring capabilities • Compact design Table Model • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application Table Model NIKKEN KOSAKUSHO EUROPE LTD - PRECISION HOUSE -...

The Perfect Solution for Your Manufacturing Needs Nikken’s Rotary Tables are known worldwide for their longivity, rigidity and quality. Our range of rotary tables are designed and built to provide extreme accuracy and to increase your work productivity. Fanuc Robodrill is an intelligent high-speed CNC drill with versatility which offers application solutions to meet a wide variety of machining needs. Nikken’s Rotary Tables seamlessly become part of the machine to create the perfect solution for each and every manufacturing requirement. The result is simple: maximum productivity and...

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

Need to get a down FANUC-controlled CNC machine up and running fast? Looking for control or integration advice on a CNC machine purchase or upgrade you are thinking about? Our engineers are here to help.

With 400 combined years of experience with FANUC controls and expertise in control, electrical and mechanical aspects of CNC integration, we can help you quickly find answers to your questions.

Our engineers have built an extensive library of FANUC manuals and other documentation to help you. Our collection of Case Studies & Tech Resources includes videos and other content to answer the most common questions we hear. And live support is just a few clicks away.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

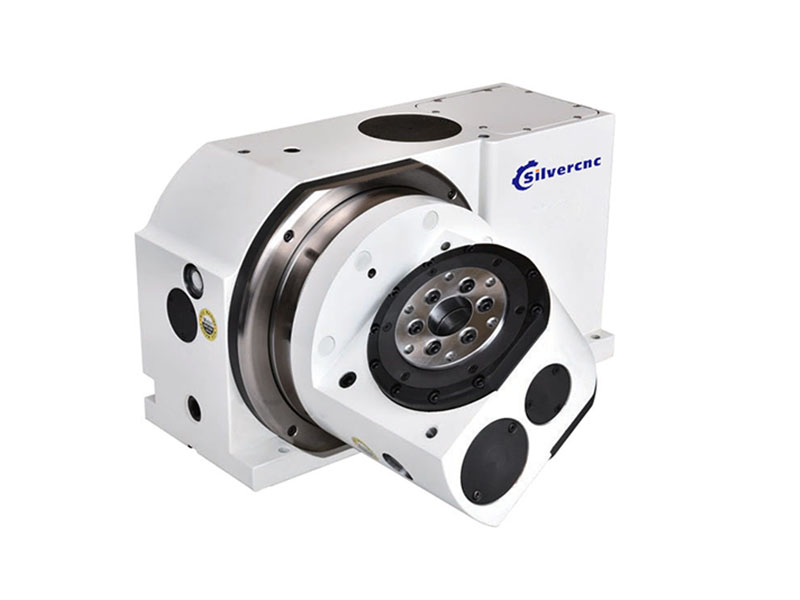

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

Fast delivery date and favorable price – these are the benefits of used rotary tables. Before delivery, each rotary table is subjected to a special quality control. pL LEHMANN also provides a 6-month warranty on each system.

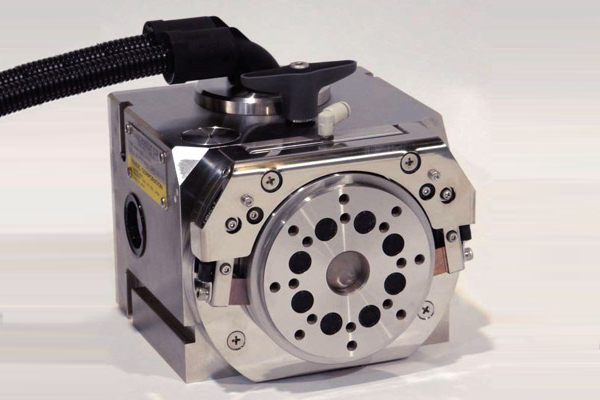

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

This eliminates the need to repost a program from the CAM system when the programmed and the actual workpiece locations are different. The Haas CNC control combines the known centers of rotation for the rotary axes (MRZP) and the location of the workpiece (e.g., active work offset G54) into a coordinate system.

TCPC makes sure that this coordinate system remains fixed relative to the table; when the rotary axes rotate, the linear coordinate system rotates with them. Like any other work setup, the workpiece must have a work offset applied to it. This tells the Haas CNC control where the workpiece is located on the machine table.

TCPC G-code is programmed from the tool tip. The control knows the centers of rotation for the rotary axes (MRZP), the location of the workpiece (active work offset), and the tool length offset. The control uses this data to calculate the position of tool tip relative to the active work offset and maintains a static tool tip position through rotary feed moves.

The Haas CNC control combines the known centers of rotation for the rotary table (MRZP) and the location of the workpiece (e.g., active work offset G54) into a coordinate system. TCPC makes sure that this coordinate system remains fixed relative to the table; when the rotary axes rotate, the linear coordinate system rotates with them. Like any other work setup, the workpiece must have a work offset applied to it. This tells the Haas CNC control where the workpiece is located on the machine table.

TCPC is invoked in . The Haas CNC control knows the centers of rotation for the rotary table (MRZP), and the location of the workpiece (active work offset G54). This data is used to produce the desired machine motion from the original CAM-generated program. The machine follows an interpolated X-Y-Z path to create this edge, even though the program simply commands a single-axis move along the Y Axis.G234 (TCPC) On and the B and C Axes Rotated

Invoking G234 (TCPC) rotates the work envelope. If the position is close to the travel limits, the rotation can put the current work position outside of travel limits and cause an over travel alarm. To solve this, command the machine to the center of the work offset (or near the center of the table on a UMC), and then invoke G234 (TCPC).

8613371530291

8613371530291