servo rotary table manufacturer

TMX160 Heavy Duty Rotary Table with increased rigidity for demanding applications. The internal air hydraulic booster gives extremely high clamping forces.

... rotating units of the DT series comprise of stainless steel and aluminium. They are available in many different designs. The rotary tables DT 80/100 or DT 100/140 are designed for motor-powered operation. ...

JVL introduces a highly effective, modern turntable that can be fully integrated in modern automation systems. TurnMaster Turntable is supplied with integrated electronic control and modern servo ...

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

These rotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives. Low maintenance ...

The HRT-160 rotational table from the portfolio of the modular rotary table system is designed as a complete unit ready for connection. The rotational ...

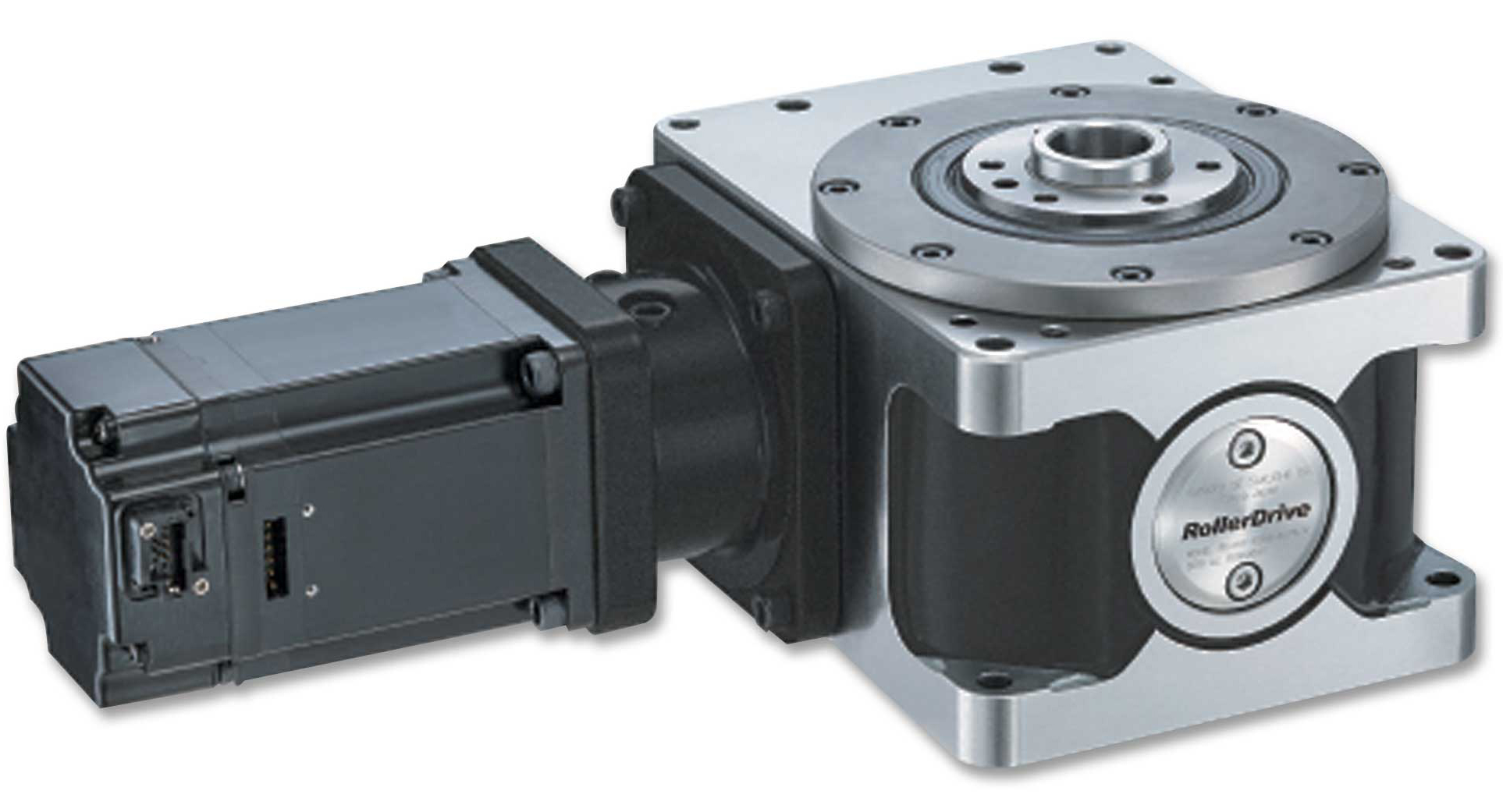

... series compact gear drive servo-mechanical positioners deliver high torque for demanding payload applications with large inertia moments. The GTB units are orientation independent for flexible mounting ...

The Rotating rotary table DSH-S Series is manufactured by Isel Germany. The product has a compact and durable design; it is made of stainless steel that has protection class of IP 65. ...

... Tuenkers, and is a versatile rotary table that is equipped with a trunnion drive. The drive module has been specifically developed for the realization of versatile motion applications ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

... a heavy duty 310 mm servo rotary table designed for a myriad of machining applications. The HRT310 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide ...

... the Hollow Rotary Actuator model number GSN130-18K-CS with table size 130mm gear ratio 1:18 and closed loop stepper motor. The CS type of GIGAGER Hollow Rotary Actuator is a line of ...

DESTACO’s CAMCO GTB rotary tables are the lightest, most compact, high-accuracy servo positioners available. The exceptional low profile high-torque output design supports the demands of typical high load inertia applications. These models are available in four sizes, horizontal or vertical mounting configurations, and are lubricated for life. The large thru-hole diameter is designed for space constrained machine applications. The GTB is 34% lower in height and 64% lower in weight when compared to competitive models, while being able to deliver 1.4 times more torque.

IntelLiDrives manufactures a large selection of rotary tables including direct-drive tables that use brushless torque rotary servo motors, as well as precision motorized worm-gear and belt-driven rotary actuators. These rotary stages are available with many different size apertures, table diameters, and mounting options to provide the ideal solution for your industrial automation application. IntelLiDrives rotary tables are used in industrial robots, fiberoptics and photonics, vision systems, machine tools, assembly, semiconductor equipment, medical component laser machining, electronic manufacturing, and other high-performance industrial automation applications.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

Motorized rotary tables incorporate an aluminum housing with bearing and precision ground worm or pinion gear drive. Multiple choices of gear reduction are available. Features no backdrive with minimum backlash.Supplied with stepper motors or brushless servo motor/encoder combination

High speed, large aperture and low profile motorized belt driven rotating actuators. Cost effective alternative to direct drive rotary servo tables. Supplied with NEMA23 stepper or brushless servo motors with encoders

Rotary tables incorporate ABSOLUTE RING ENCODERS with industry standard SSI, BISS-C and Fanuc interfaces. Absolute positioning information is maintained during power-down. No homing required upon power-up

Low profile rotation stages 22 to 42 mm. Light-weight and compact, these rotary actuators are best suited for integration with XY tables to minimize system stack-up height and errors

Direct drive air bearing rotation stages with axial and radial air bearings. Frictionless and maintenance-free rotary tables best suitable for cleanroom environments

Rotary tables with protection against ingress of water and particles. IP65,IP66and IP67 rated. Direct drive rotary servo tables and motorized actuators

Low profile and small footprint (40 mm to 115 mm) rotary stages. Designed for the confines of laboratory and production environment. Available in vaccum compatible versions

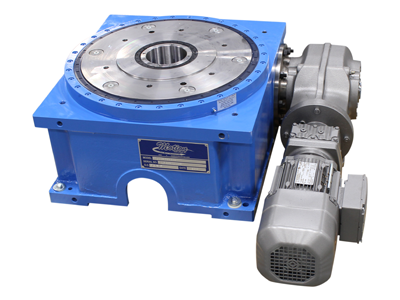

GOIZPER INDEXERS offers solutions to suit your applications. Servo rotary tables (or rotary indexing tables), flexible tables for welding cells, hemming, assembly and control. Ourrotary tables for automation systems can be used as rotating or positioning shafts or for a wide range of assembly applications. With a very high output rate and the shortest possible cycle times in addition to the highest standards of accuracy, they can increase the efficiency of your production processes for any application.

Our ZPGI range of servo rotary indexing tablewith heavy load positioning are ideal for dynamic, precise positioning of parts and large heavy equipment. Several versions of our cam operated servo driven rotary indexing table are available.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

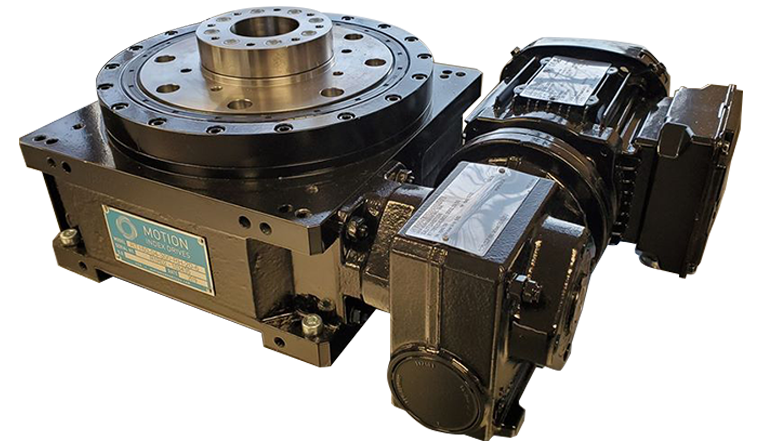

The Motion Index Drives RTX Series Servo Rotary Index Tables encompass a large range of sizes, ranging from our model RTX100 up to our RTX1250. In addition, special cam-driven devices can be custom made to order for your automation needs. Our servo rotary indexer is offered with a servo motor or standard AC brake motor with absolute hiperface or incremental encoder. The RTX Series Flexible Rotary Index Table is one of world’s most accurate barrel cam indexers. Motion Index Drives servo rotary indexer are constructed with strength and reliability in mind. Robust design and components ensure this device will maintain precision in intense factory settings.

M-036 high performance series of closed-loop servo motor driven precision rotation tables provide the highest resolution, excellent repeatability and minimum wobble. The stages are equipped with double rotational ball bearings for minimum backlash and high load capacity. Both the rotation platform and the scale ring (graduated in 2-degree increments) can be independently coarse positioned over 360 degrees and then be locked by screws.

The basic version, M-036.D0, is equipped with a DC servo motor drive providing a rotational range of ±10.5 degrees. A set of limit switches eliminates the possibility of overtravel.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

To achieve rotary motion, Cross Company pairs a rotary table with a servo motor, drive and control to create a complete rotary actuation system. This allows greater flexibility for your rotary positioner because you’re not tied to just one or two positions. Some examples of rotary actuation that Cross Company has worked on recently include:Robotic cells which require precise rotary indexing for manufacturing stations

Cross Company’s Automation Group works with several different manufacturers of motors, drives and rotary tables. We work with you to understand your application and then we size and specify the best combination for your particular need. We have literally decades of experience working with rotary actuators, so we can specify a robust solution optimized for the application.

Cross is proud to represent the following manufacturers of rotary positioners:Parker:Worm gear-driven precision rotaries, manual stages and direct drive rotary servo motors which are suitable for light to medium industrial precision positioning

In virtually every industry, a right-sized rotary solution increases the throughput and efficiency of your process. By working with Cross Company, we can help reduce the risk of incorrectly sized and specified equipment, delivering a complete solution perfectly tailored to your application. Contact the experts at Cross to discuss your rotary positioning needs.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

Servo rotary table HRTJ200 also called as freely programmable indexers, heavy duty hollow rotary table which has large central opening reach to 90mm, it is quite convenient for engineers to wiring and piping in automation rotary motion and provide more options for engineers.

Sango HRTJ200 servo rotary table is making better performance than HRT200, more output torque but keep same positioning accuracy, bigger designed loading than HRT200.

Sango Automation provide multiple options of servo rotary table, from small size HRT62, to big size HRT280. HRTJ series includes 130, 200 and 280 version, which are reinforced model on the same dimension.

A CNC (Computer Numerical Control) rotary table is an automation tool used in a milling machine to perform complex machining operations. It consists of a circular disc, mounted on an axis so it can rotate around its circumference and provide multi-axis machining capabilities.

The rotary table enables users to produce workpieces with cylindrical surfaces, multiple faces, and holes located off-centerlines on any angle through indexing. This makes it possible to perform intricate machining operations such as face grooving, drilling and boring that would otherwise be impossible or require extensive setup time with the standard x-y axis milling machines.

Moreover, using CNC in combination with the rotary table provides even greater flexibility since commands are automatically sent from the computer software directly to the machine for precise movement without operator intervention or supervision during operation. In other words, this allows operators to program sequences of motions not normally done by hand which increases speed and accuracy significantly; thus increasing production efficiency overall.

CNC rotary tables are commonly used in industries like aerospace manufacturing where parts often require precision cutting for aerospace components that need fast completion times along with accuracy within tight tolerances. The versatile nature of this system also makes them suitable for use in all types of industries including automotive engineering where they are frequently used in creating molds or forming dies into specific shapes depending on part requirements while still maintaining a high level quality control. All these qualities make CNC rotary tables a great asset when striving for higher productivity levels while still achieving high quality results every time!

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new servo rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement servo rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new servo rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

Smaller versions can be used to power joints in robots for automation, powering pick-and-place applications, material handling, packaging and handling as well as servomechanism applications

8613371530291

8613371530291