accumulating rotary table quotation

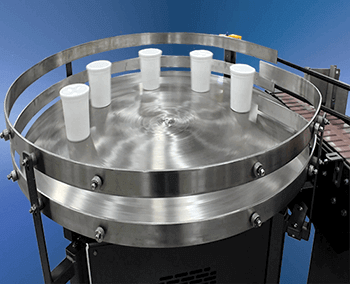

Our Rotary Accumulation tables can be used at the end of production lines, as an infeed to a conveyor, and as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Rotary accumulation tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

Our SNEED-PACK Rotary Accumulation tables can be used at the end of production lines, as an infeed to a conveyor, and as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Rotary accumulation tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

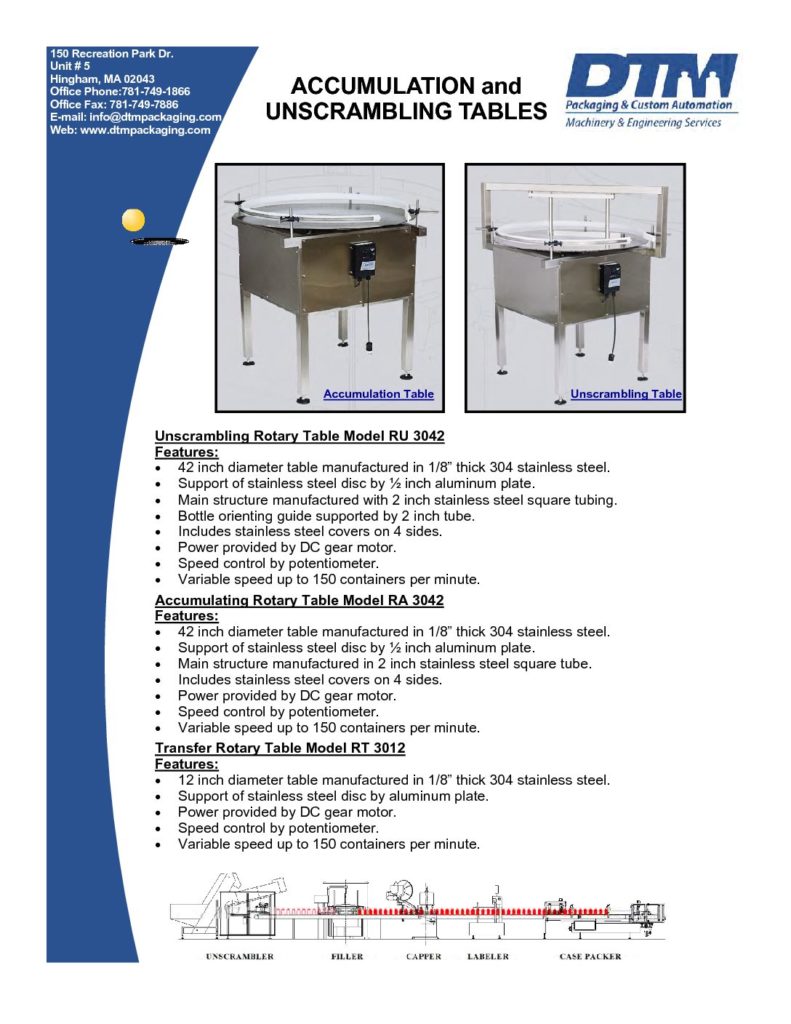

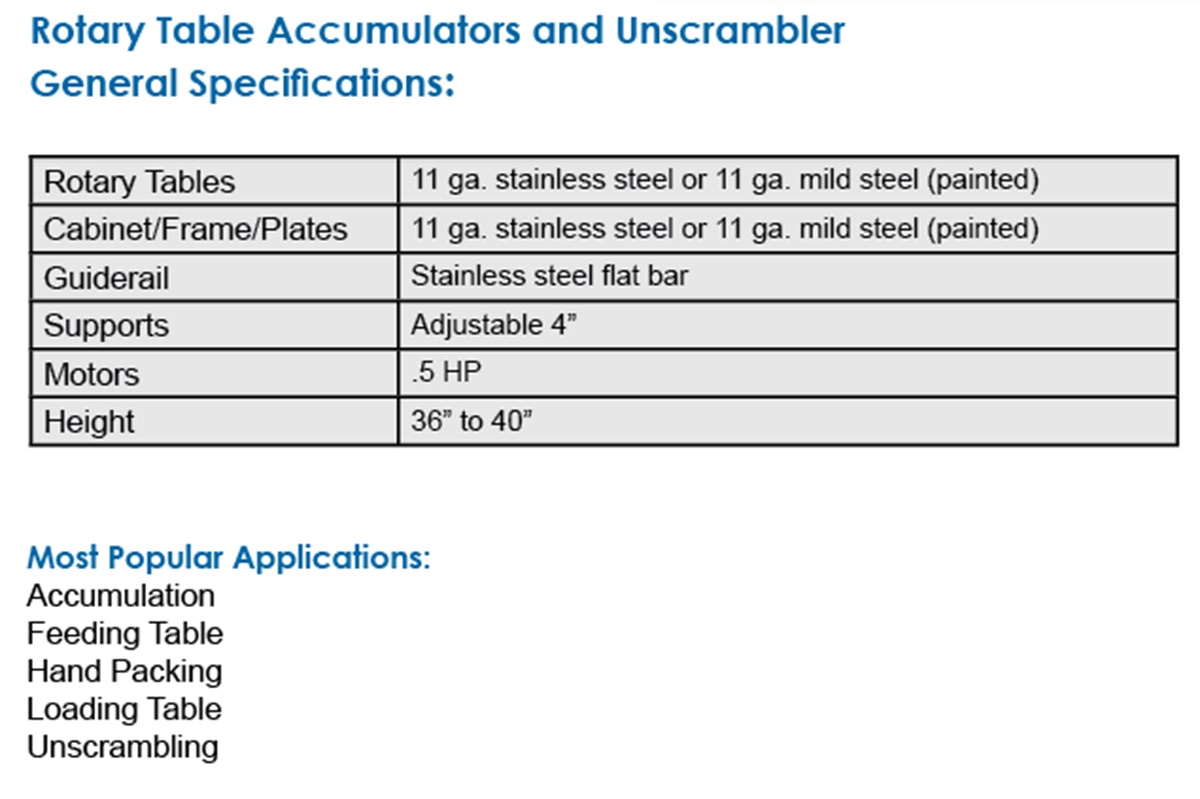

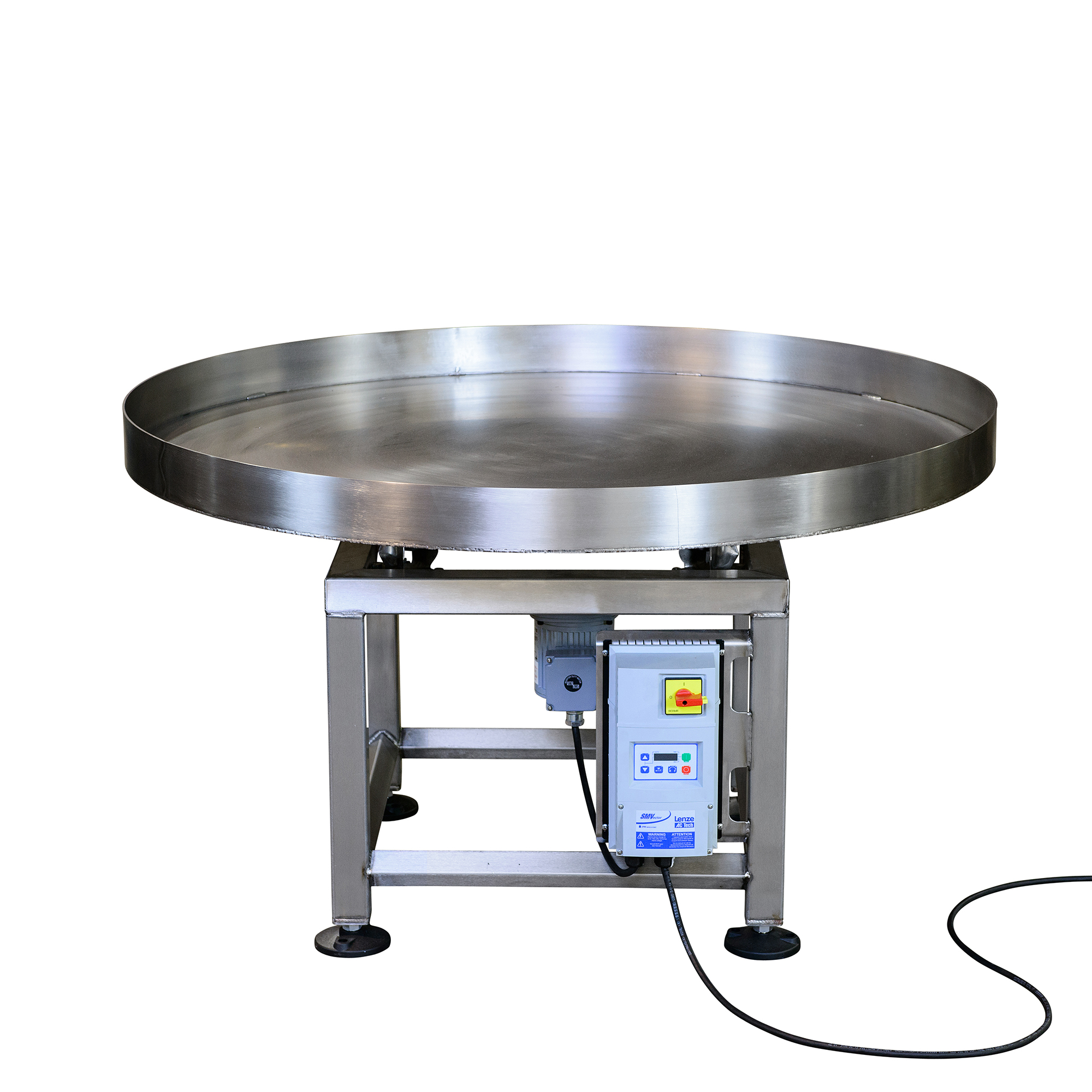

One of the earliest designs for accumulation or unscrambling is the rotary table. Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Standard (non-custom) diameters are 36", 48" and 60”. Top discs are stainless steel with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers. A smooth edge bowl top is available for hand packing applications.

Rotary accumulation tables are a small footprint conveyor solution designed for accumulating and unscrambling products at various points during the conveying or packing processes. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped. This accumulation solution is also ideal for end of the production lines accumulation needs with limited floorspace. Rotary accumulation tables are often used in conjunction with bulk round, flat-bottom products to be off-loaded in a single-file line.

Variable Frequency Drive (VFD) speed control sets the optimum table rotation speed. Nercon’s rotary accumulation table is designed to handle extremes with ease reducing wear and tear on the motor that can otherwise lead to early motor burnout. Temporarily off-loading product flow due to inconsistent speeds between processes maintains production schedule and decreases downtime.

Height adjustable to integrate seamlessly into current production lines, the adjustable supports also allow for leveling on uneven floors to keep the rotary accumulation table stable.

Rotary Work Tables were designed to accept product flow from discharging belt or other general material handling systems. The rotary table or some times called spinning table is a robust design, which is engineered to take demanding punishment from an industrial environment. The rotary table is the key component in designing a flexible work cell for jobs requiring manual inspection, degating, assembly or packing. In typical applications, the product is conveyed on to a the table to allow multiple operators can efficiently handle tasks or allows multiple products (sub-assemblies) to be conveyed from multiple machines to one location and have one operator handle multiple tasks without added effort or ergonomic strain.

The Globaltek rotary tables can be used to unscramble product and feed a conveyor, also as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

Rotary unscrambling tables and accumulating tables are used to orient or feed bottles on a production line. We are suppliers of used rotary turntables and used accumulation tables for sale. Unscramblers and rotary indexing tables are available in a variety of sizes including 36-inch rotary tables (36” diameter), 40-inch rotary tables (40” diameter), and 48-inch rotary tables (48” diameter). We also stock automatic plastic bottle unscramblers from OMEGA, PACE, KALISH (Kalisort), NEW ENGLAND MACHINERY, and KAPS-ALL.

Rotary unscrambling tables and accumulating tables are used to orient or feed bottles on a production line. We are suppliers of used rotary turntables and used accumulation tables for sale. Unscramblers and rotary indexing tables are available in a variety of sizes including 36-inch rotary tables (36” diameter), 40-inch rotary tables (40” diameter), and 48-inch rotary tables (48” diameter). We also stock automatic plastic bottle unscramblers from OMEGA, PACE, KALISH (Kalisort), NEW ENGLAND MACHINERY, and KAPS-ALL.

Mini-Mover Rotary Table Accumulators (RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining. These types of units are also called “accumulation tables” or “lazy susans” in the industry

Our RTA units are well suited for various applications in metalworking, assembly and packaging, such as cycle tolerance inspection, surge table on production lines and staging for manual or pick & place case packing.

This table top accumulator was developed to be a simple and effective rotary table replacement or turntable accumulators replacement. The patented Infinity™ RX 36” can out-feed products faster than a traditional rotary table and with less pressure and no damage. This rotary accumulation table replacement uses virtually the same footprint as a traditional rotary table, with greatly reduced pressure and noise. The Rotary Table Replacement allows conveyors to eliminate virtually all vial damage with also accumulating vials effectively.

Alibaba.com offers 310 rotary accumulation table products. About 62% % of these are other packaging machines, 4%% are other machine tools accessories, and 3%% are table.

A wide variety of rotary accumulation table options are available to you, such as wood, plastic and glass.You can also choose from food & beverage factory, manufacturing plant and food shop rotary accumulation table,As well as from automatic, semi-automatic rotary accumulation table. and whether rotary accumulation table is 1 year, 6 months, or 1.5 years.

CM Machine Services offers stainless steel rotary tables commonly used for product accumulation, manual packaging, and case filling applications. Due to the fact it is completely made in house, there is the ability to make the table customized based on customer requirements. Examples of what can be customized: casters, length, width, height, etc.

CM Machine Services offers stainless steel rotary tables commonly used for product accumulation, manual packaging, and case filling applications. Due ...Read more (+)

The beginning of a production line (infeed) application facilitates the introduction of empty containers. Workers load containers onto the table and the table transfers the containers onto the production line in a single file.

The end of the production line (outfeed) application facilitates the removal of full containers. Containers accumulate on the table and workers unload the containers from the accumulation table into secondary packaging (boxes, pallets, cases, etc).

An additional benefit of the Bevco Rotary Accumulation Table is that it provides temporary storage spaces for products. When normal production flow is interrupted due to temporary product blockage, machine malfunctioning, or adjustment, the Rotary Accumulation Table allows operators time to attend to correct problems without the need to fully shut down the line to maintain productivity.

Select a categoryBakeryBlendersDepositorsMixersBowlsOvensBerry EquipmentBeverage EquipmentBlowersBoilersBreweryChocolate/CandyCleaning EquipmentCoffee EquipmentConveyorsAccumulation TableAuger/Screw ConveyorBelt ConveyorBeltsBucket ElevatorFood-Grade ConveyorIncline ConveyorIndexing ConveyorRoller ConveyorVibratory and Shaker ConveyorsWire ConveyorDairyElectricalControl PanelsTransformersEnrobing & CoatingFarm EquipmentSilosFillersAuger FillersNetweigh FillersVolumetric FillersFiltersFruit and Vegetable EquipmentFryers, Skillets and CookersGeneral EquipmentCompressorsDust CollectorsForkliftsPumpsVacuumsGeneral FacilityAir Conditioning and RefrigerationLightingPallet RackingGeneratorsGrindersHeat ExchangersHoppersKettlesLab EquipmentMeat EquipmentBowl CuttersDicers / SlicersSausage FillerSmokersMetal DetectorsPackagingAdhesive MelterBag SealersBox SealersCap SealerCartonersCase PackerCup/Tray SealersDate CodersFlow WrappersHFFSL-Bar SealersLabellersBagBottleCanPalletizer / DepalletizerPouch FillersShrink WrapperThermoformerVFFSPartsBearingsDrivesElectric Motors5 HP & Under50 Hp & OverOver 5 HPGearboxesValvesPharmaceuticalProcessingBulk-Feed ProcessorCentrifugesDryersHomogenizersIQFSiftersTumblersProduct HandlingBin, Buggy & Tote DumpersBins, IBCs, TotesBuggiesRestaurantScalesBench ScalesCheckweighersLinear ScalesMultihead ScalesSeeds/GrainsTablesTanks2,001+ Gallons201-500 Gallons50 Gallons & Under501-2,000 Gallons51-200 GallonsDairy TanksJacketed TanksSS TanksUncategorized

8613371530291

8613371530291