3d printed rotary table pricelist

If you"re wondering how much a 3D printer costs. Or, if a 3D printer is worth it. You"re in the right place.The good news is this: These days you can find almost any 3D printer for any budget.

So is it worth it to buy a 3D printer in 2022? If yes, what is the best 3D printer for the price? And are there price range “sweet spots” that you should look out for?

How much does a 3D printer cost? Low-cost 3D printer prices start from $100 to $400. Then hobbyist 3D printers will set you back by up to $1,000. The next level of enthusiast and professional 3D printer prices range between $1,000 to $10,000. After that, the sky’s the limit – with industrial 3D printer prices starting at $10,000 but quickly reaching $100,000 or $250,000 for specialist technologies.

If you"re looking to find out exactly how much Ultimaker printers cost, you can request a quote to find out now.DIY / Low-cost 3D printer price $100 - $400

Low-cost 3D printers are all about the novelty of the technology. They exist for newbies who want to say, "Hey – check out what I just 3D printed!" Almost all will come as kits that the buyer puts together. And while these machines might have beginner-friendly price tags... It won"t be a beginner who can get them to produce a good 3D print. That"s because manufacturing problems are too common to overlook. And these lead to a painful setup and user experience. Also, when asking how much does a basic 3D printer cost? This tier can save you money. But expect to pay more for modifications, upgrades, and repairs down the line. That said, if it"s a choice between "having a 3D printer" and "not having a 3D printer", this tier offers the biggest bang for your buck.

3D printers at this price range can produce some great parts and models. But that"s only after you have set them up and dialed in their settings. In this way, they are aimed at hobbyists. (People who are happy to spend time watching tutorials and tweaking settings to improve their prints.) This also limits your flexibility. Over time, you might be able to 3D print well with a basic material like PLA. But don"t expect to switch filaments too easily. While these machines are often delivered as kits, manufacturing problems are less common.

Up until this price range, almost all the 3D printers will have had an open design. But now you will begin to see more partially and fully enclosed printers that increase safety and print reliability. This also marks the end of the hobbyist range. And the start of 3D printing becoming a useful production tool. Therefore, the enthusiast and prosumer category is great for lower and higher education customers who want to avoid spending time on maintenance. Plus, they present a smart option to 3D print cheaply at home. These machines can 3D print a handful of materials with good reliability. However, these will often be own-brand filaments with carefully tweaked settings. The best enthusiast 3D printers include hardware and software features taken from the professional 3D printer price tier. On which note...

A lot changes at this price point. Instead of being a technology to tweak and adjust, these 3D printers focus on easy use and adoption. They become one tool among many in an engineer"s or designer"s toolbox – giving a growing number of businesses a new way to innovate. And that"s why, at this price point, FFF 3D printing is at its most disruptive. The only way this can happen is for the 3D printer to work – and for it to work hard. Expect a factory-tested machine that you can leave running over the weekend and come back to a finished part on Monday morning. Plus, prints start being repeatable. For example, if you 3D print the same part on the same printer in two or more locations...the part quality should be almost identical. The user also has more flexibility. You can choose to print with a build material and a support material in the same print (called dual extrusion), offering more design freedom. And you gain a growing range of engineering-grade material options. These can include materials reinforced with carbon fiber or even metal.

3D printers that cost tens or hundreds of thousands are made to do a few things at a high level of quality. This includes production technology for specific materials, like high-temperature polymers or metal. 3D printing these materials with a high success rate often requires you to stay within a manufacturer"s material portfolio and software stack. If you are in the market for an enterprise-level machine, this will rarely be the first 3D printer your company buys. And you will know what"s required to make the investment: a strong business case, competitor analysis, and a purchase order. You or your company may be happy to pay extra for increased speed, accuracy, and reliability. But also know that, the higher you go in this price bracket, the more you chase diminishing returns.

If you consider 3D printing as a hobby, 3D printing successfully will largely be paid for with your time and patience. If 3D printing needs to be a tool for you, then you will pay extra for a user experience that saves time and attention.

But it"s also in this second category where 3D printing offers significant business value. And the right 3D printer can end up paying for itself with substantial time and cost savings.

It"s also about the software, accessories, materials, and service that go with it. Together, these contribute to an easy-to-use, time and cost-saving 3D printing experience.

The Ultimaker platform creates a seamless flow between hardware, software, and materialsFor example, every Ultimaker 3D printer works seamlessly with Ultimaker Cura, which is updated every few months. They also ship with a suite of free online tools and e-learning courses. Together these resources transform your ability to click-and-print with up to 239 materials.

So it"s no surprise that hundreds of leading companies – from Ford to L"Oréal – 3D print day and night with the Ultimaker platform to drive innovation and sustain their competitive advantage.

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

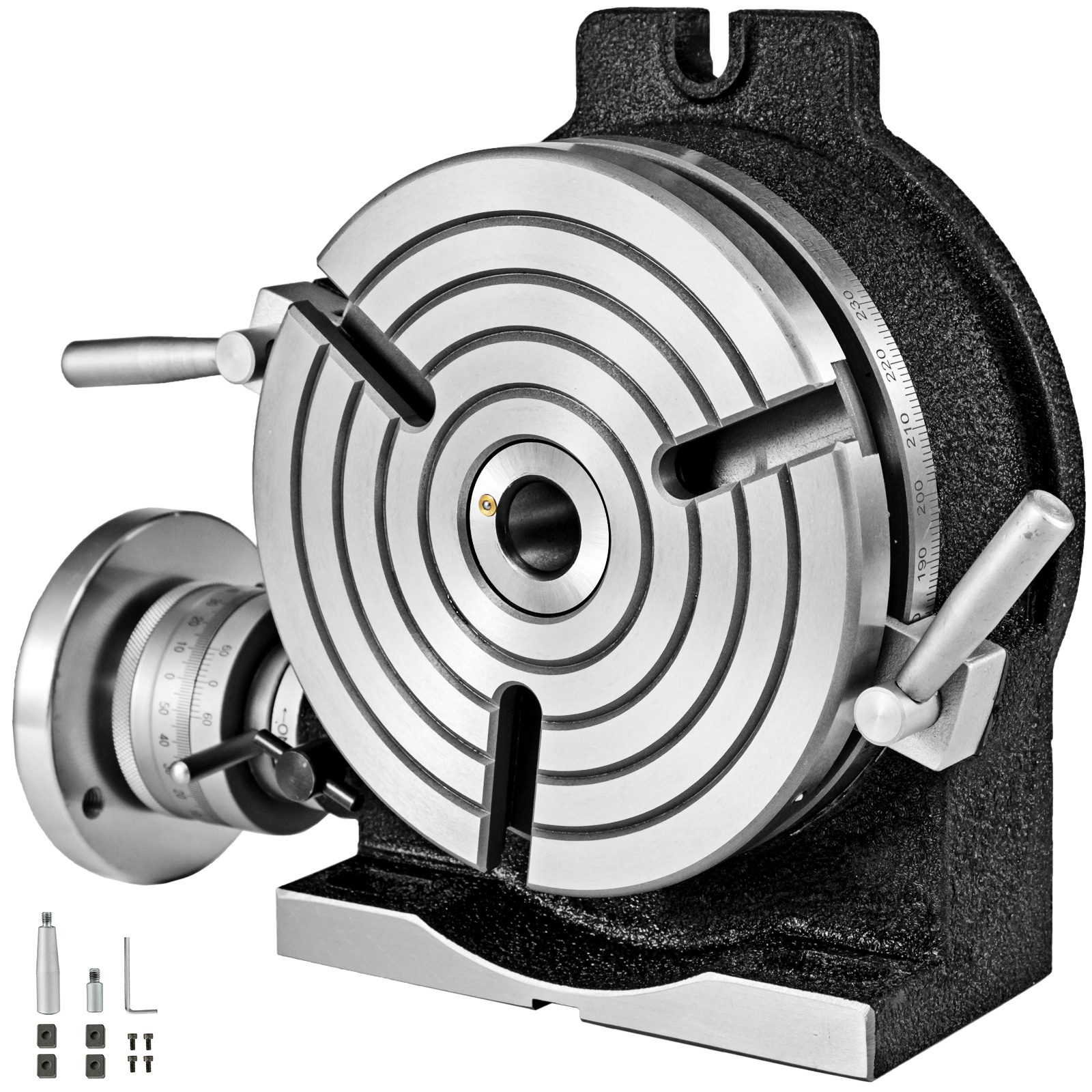

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Designed and manufactured by Shenzhen-based Snapmaker, the Snapmaker 2.0 is a 3-in-1 modular FFF 3D printer with CNC machining and laser engraving/cutting capabilities. Intended as a successor to the company’s debut Snapmaker Original system, the desktop machine started out as a very successful Kickstarter campaign, raising $7.8 million with over 7,000 backers.

The Snapmaker 2.0 is undeniably built for the workshop and provides users with all of the manufacturing capabilities a DIY enthusiast could possibly want. When needed, users can switch out the single 3D printing head for a CNC tool or a laser diode, meaning the sky’s the limit when it comes to creative potential. This isn’t to say the system is inaccessible, however, as all of the setup steps are laid out in the comprehensive instruction manual and all of the necessary hand tools can be found in the box.

With prices starting at a surprisingly affordable $1,199, the system is suitable for just about anyone looking to get their craft on, including professional engineers, designers, educational institutions, and even advanced prosumers.

Seeing as Snapmaker has dedicated itself to 3-in-1 manufacturing systems, the company also offers a number of add-ons for use with the Snapmaker 2.0, including an Enclosure and a Rotary Module. We’ll cover all of these and more in this review.

At its core, the Snapmaker 2.0 is still an FFF 3D printer. Sporting a cartesian coordinate system, the machine features a sleek, notably sturdy anodised aluminum chassis with an open form. The largest of the three models, the A350 variant, comes complete with a build volume measuring 320 x 350 x 330mm. This is significantly larger than the average desktop 3D printer, so it should provide ample leeway for most reasonably-sized engineering projects.

It’s also worth mentioning that the Snapmaker 2.0 is equipped with a Cortex-M4 processor (Quad Core A7 CPU at 1.1GHz) and an Android controller. Recently, we’ve seen a few manufacturers implement Android into their higher-end 3D printers, and it absolutely makes all the difference when it comes to user experience. The 5” full-color touchscreen on the Snapmaker is extremely responsive and provides a beautiful graphical UI, which itself can be used to preview print models, calibrate the bed, load the filament, and manage print jobs. The system also features Wi-Fi functionality, which is always a godsend for remote work.

Instead, once the system deems itself flat, the user can modify the Z-offset via the touchscreen, with increments as small as 0.05mm. While this works well enough to achieve a successful print, the first layer is often flawed and just getting to that point is unnecessarily difficult. Therefore, we advise 3D printing with a raft on this printer. This will help reduce the error of the first layer.

Of course, the Snapmaker 2.0 isn’t just a 3D printer. The 3-in-1 machine also comes complete with its own laser cutting/engraving and CNC Modules, which the user can simply screw on in place of the 3D printing head. Additionally, the system has an extensive aftermarket, meaning there are a plethora of add-ons and extra modules to play around with (more on these shortly).

Firstly, we’ll have a look at the core ‘out-the-box’ modules included with the printer itself – the laser cutter and the CNC. The laser cutter is a blue Class 4 diode, and operates at 1.6W with a wavelength of 450nm. Designed in-house by Snapmaker, the module looks as elegant as the 3D printer head, but it also features an in-built camera to preview designs before engraving.

The module offers four main functions depending on the application: Black and White, Greyscale, Vector (outline cutting), and Text. The laser is compatible with a number of substrate materials, including wood, acrylic, polymers, and even leather. It’s worth noting that the system also comes with a purpose-built aluminum lasering table, which does a great job of reducing reflectivity.

Although the user will have to recalibrate the laser cutter every time a module switch is made, we’re happy to announce that the automatic process works significantly better than that of the 3D Printing Module.

Made of high-quality anodized aluminum, the Enclosure can be used with all three core modules. For the 3D Printing Module, it helps maintain the temperature in the build chamber, which is crucial for printing with higher temperature filaments such as ABS. When used with the laser engraver, the filtering panels help protect the user’s eyes, and with the CNC Module, it can keep swarf and material chippings from flying around the workshop.

Moving on, we also gave the Rotary Module a spin. Much like a lathe, the Rotary Module spins a workpiece in the horizontal plane. Designed to be used in conjunction with the laser engraver or the CNC tool, this optional module works best with cylindrical and rectangular cuboid substrates, whereby images and texts can be engraved or cut all around a continuously spinning object.

Naturally, Luban also has the ability to generate gcode for the laser and CNC Modules, with options for the various manufacturing modes of each. It is compatible with Autodesk Fusion 360 for CNC operations and Cura for 3D printing operations.

Still, we found Luban to be one of the more intuitive slicing platforms we’ve used here at 3D Printing Industry, and everything from the automatic support generation to the default print profiles work as expected. Ultimately, all that’s needed to pick up the intricacies of the software is a little trial and error and a dash of common sense.

It’s time to see what the Snapmaker 2.0 3D printer is really capable of. We start off with 3D Printing Industry’s own benchmarking model in PLA, which consolidates many of our smaller print tests into one comprehensive part.

For this test, we assign each of the individual sections a weighted score based on factors such as dimensional precision, surface quality, and structural integrity. The A350 earned an overall 3D Printing Industry score of 63/100 – a good professional-grade 3D printer is a 60+. Below you’ll find some bell curves depicting the repeatability of the Snapmaker.

The Snapmaker’s performance was around average for this test, as it 3D printed most of the individual sections to a decent standard. Overhangs were printed successfully up to 60° without any problems, and the horizontal bridging test was printed straight up until the 30mm mark. There was some minor stringing in the retraction test but nothing that can’t be removed in post-processing, and the spiked structures themselves are solid with an acceptable surface quality.

However, the leveling process let down the system in the negative precision test, since the printed tubes can’t be removed all that easily – we only managed to pull off three of them. We thought this might have something to do with the flatness of the first layer, seeing as the base of the tubes seem to be stronger than they should be.

We then 3D printed a circular trajectory test to see how the Snapmaker would handle circular structures. By studying the normal distribution of the concentric circles’ diameters, we can say that the printer offers sufficient repeatability when the mean of difference is under 0.1mm and the standard deviation is under 0.05mm. Our measurement devices are accurate to ±0.015mm.

The Snapmaker certainly surprised us with some strong results here, delivering an average offset of just 0.115mm for the X axis, and 0.085mm for the Y axis. This resulted in an average of 0.091mm for all axes. The average standard deviation also came in low at 0.035mm, where 0.05mm is a good target. For context, industrial FFF 3D printers often boast dimensional accuracies of up to 0.1mm, which qualifies them for applications such as high-precision automotive tooling.

Then, we decided to try out the cutting capabilities of the laser with three distinct projects. The Snapmaker-designed gift box and the 3D Printing Industry keychain were done in plywood, while the laptop sticker was cut out of vinyl. All three cutting tests used the ‘Vector’ mode on Luban (the engravings used ‘Greyscale’).

Once again, we were very impressed with the performance of the laser cutter. The gift box was precise enough to be assembled with ease, and the vinyl sticker looks like it was manufactured professionally by a specialist. The 3D Printing Industry keychain even managed to emulate the color scheme of our logo, despite it all being in greyscale.

Happy with the performance so far, we then used the laser engraver in conjunction with the optional Rotary Module, which enabled us to engrave a series of images and texts into spinning objects. The rotary laser tests were as follows: London Bridge on cardboard, manufacturing text on a PLA bullet, a chemicals symbol on a transparent PP beaker, and the London Underground logo on a ceramic mug.

Finally, we combined the CNC with the Rotary Module for four final benchmarking tests. These included an epoxy chess piece, an epoxy lion, an epoxy PolyPearl tower, and a wooden PolyPearl Tower (lime tree).

All we can say is wow. The CNC and the Rotary Module make one hell of a team. Our chess piece and lion came out incredibly detailed, with the passes of the toolhead barely visible to the naked eye. The same goes for the PolyPearl tower torture tests, as the helical geometries were machined with magnificent precision. The Snapmaker 2.0 really exceeded expectations here.

Don’t get me wrong, the machine is far from perfect. The print quality is marginally above average, the 3D printer calibration process needs work, and the day-to-day operation is far too noisy for a close-quarters office environment.

Despite this, the Snapmaker 2.0 simply offers too much in such an affordable package to pass up. We’d go so far as saying the 3D printing capabilities of the system are the weakest, but the laser and CNC Modules carry their weight and then some. As far as optional add-ons go, the Enclosure is an absolute must and the Rotary Module can be a game-changer if you’re in the market for a good old spin.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel.

And its plastic-printed studios and accessory dwelling units (ADUs) are now available for preorder as the startup prepares to ramp up its production line in the Culver City neighborhood of Los Angeles.

Even without the use of recycled plastic, the nascent 3D printing homebuilding industry has already been heralded as a more sustainable and efficient construction method.

And Azure will be no different: The startup says it can build homes 70% faster and 30% cheaper than "traditional home construction methods" by 3D printing the floor, roof, and walls of its models inside its factory.

But no matter the model or size, these units will all be prefabricated and built using connectable modules that can each be printed in under 24 hours.

The floor and ceiling are connected by a flowing wall with curved corners, a trademark of 3D printers. Either side of the unit is then encased with glass walls, giving the studio a clean and futuristic look.

Given its smaller size, these studios can be printed within day one, wired by day two, insulated by day three, and then delivered on-site in two weeks, Maguire told Insider.

"3D printing is a more efficient way of building and it should only get better as we develop the processes, technology, and materials further," Maguire said. "I can only see it becoming more and more prominent in [construction] as we move forward."

Formnext and its exhibitors showcase solutions from the entire process chain of Additive Manufacturing and industrial 3D Printing. From software, technology and materials for all processes, AM production to post-processing and automation in the manufacturing process. The extensive company and product profiles of the exhibitors offer you a comprehensive overview of the latest developments in the Additive Manufacturing industry all year round.

i.materialise is your online 3D printing service. Upload your 3D model, choose from 100+ different finishes and materials, select the size of your print, receive a price quote instantly and let us take care of printing and shipping your products.

Get instant prices for your 3D design seconds after uploading. With no registration or login required, several user-friendly interfaces for uploading, and over 40 accepted 3D files formats, we’ve got you covered.

8613371530291

8613371530291