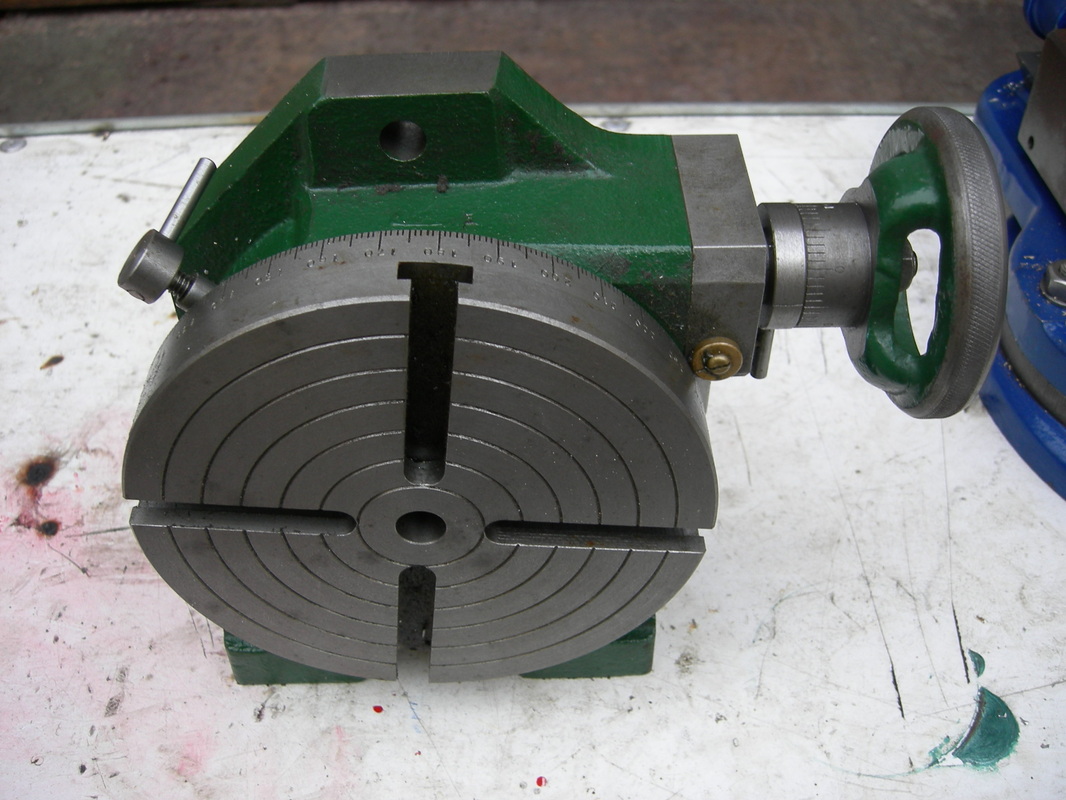

enco rotary table made in china

All is not lost. Look your rotary table over and make the needed changes like add a seal of two. Make sure all the parts fit and things are parallel etc. If they aren"t make them so.

Buying cheap while expecting perfection baffles me. One of the reasons you bought that rotary table so cheap is because the maker didn"t bother with the final fitting and refinements. This is the stage that quadruples the cost of precision machine tool accessories. You will have to perform this work yourself if you want a good product. I"ve bought any amount of cheap import stuff and it never failed: I had to spend time and material to bring what ever it was it up to usability. I"m out the time and material but that part was cheap. I have plenty of both. Now I have accurate vises, three jaw chucks, concentric mill adaptors, mikes, angle plates, etc and on the cheap.

I am thinking of adding an 8" horizontal/vertical rotary table to my PM935 mill setup and need some suggestions. The candidates I have seen so far are Yuasa, Vertex, and Phase II. Their are other but these seem to be the most readily available in 8".

I have an eight inch that I ordered from Enco but it looks different (has two vertical mounting lugs and two horizontal lugs). Mine also came with the dividing apparatus and a 17 - 47 hole set of plates. It IS very heavy, as you mentioned, and I have made a small roll-around platform for mine so that I can move it around the bench during setup. I"m considering a crane to move mine, too, but in the meantime, here"s what I do:

After I get the table set up to my liking, I lower the mill table so that it is an inch or two lower than my workbench. Placing a plywood ramp between the workbench and the mill table, I roll the rotab down to the mill and carefully slide it off the little wheeled platform onto the table. To get it back on the workbench, reverse the process only raising the mill table an inch or two above workbench level.

Mine hasn"t seen extensive use but works well ... I"ve made a couple of large milling cutters from 1-1/2 diameter drill rod and a number of smaller projects. (I even used it for a couple of woodworking projects with my home-made router spindle attached to the mill quill.) The cool thing about it is that the backlash in the worm can be completely adjusted out. Frankly, I"ve thought about a smaller table (for convenience) but the argument for the bigger table is that more mass prevents chatter and makes for a smoother cut. If yours doesn"t come with dividing plates, you might consider that as one of your first projects.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

as gear plate A is supported , the rotation plate rotates smoothly and accurately without vertacal moving error. *when gear plate a completes indexing ,gear plate C goes up to match gear plate A and B ,clamping the index table. *gear plate C has sufficient space to completely match gear plate A and B ,the pressure angle of 30 degree of each gear focuses gear plate A and B accurately ,keeping high accuracy even after long term using.

Mini Drilling Milling Machine 600W Motor Extra Wide Cross Table $ Free shipping Make Offer Mini Drilling Milling Machine 600W Motor Extra Wide Cross Table Power Feed X Axis 150 LBS Torque Power Table Feed Milling Machine For Bridgeport $ Free shippingWhen you think of Bolton Tool s milling machines you think of high quality mills at very low pric We at Bolton Tools are known for our impressive quality mill/drill machine tools We guarantee our milling machines will be the best value on the market HANDS DOWN We take great pride in the workmanship of our milling machin مزيد من المعلومات

The handle of the drilling and milling machine is mainly used to adjust the rotation speed of the head of the drilling and milling machine There is no difference The two handles are the most common on the market today and the customers say the milling and drilling machine with two handles is in good quality and high precision Structure Features Enco Model ZX 40 Bench Top Drilling Milling Machine All the specs are in item specifics and are my best guess going off another similar machine It has a Power Cross Feed on table set of collets Vise Hold down set Drill chuck and a few cheep milling cutters It is 220 1ph power for macine and 110 120 1ph for power cross feed مزيد من المعلومات

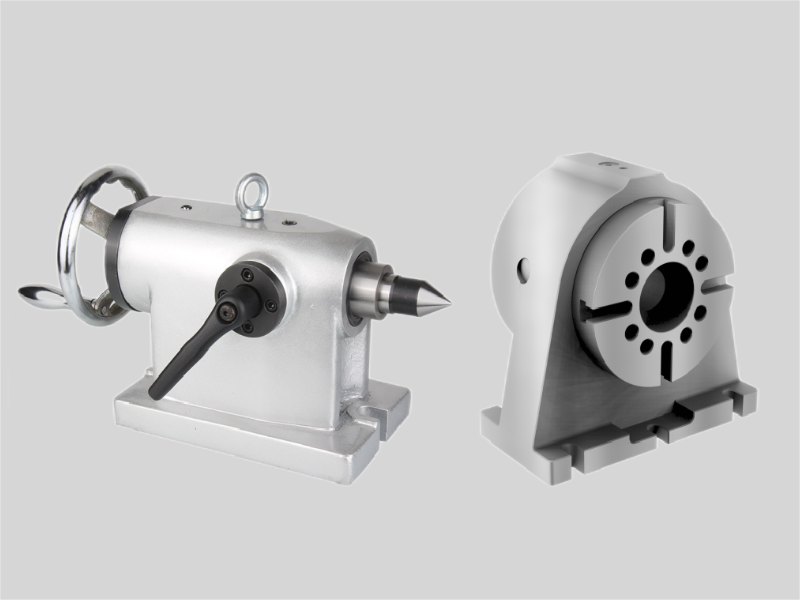

Machine suitable for processing metal wood and other materials Consists of bed headstock drilling and milling units work table tailstock and motor Incorporates turning thread cutting drilling and milling in one machine Includes free stand Other features Uses milling X and Y power feed Mill drill machines are used for accurately boring drilling milling or tapping into a workpiece Their spindles are designed to handle side cutting loads and feature rigid milling tables with X Y movementMill drill machines are lightweight and used where space is a concern مزيد من المعلومات

Jet machines are quite functional A milling machine is the heart of a machine shop If this is your first milling machine expect to spend and equal amount on the tooling you will need to make it work A clamping kit an assortment of end mills chucks and holders a vice a rotary table an indexing head3 in 1 Mill Drill Lathe View All This drill lathe mill combo will save space in small home shops and garag Separate motors run the lathe and mill for longer machine life Digital readouts help you get precise results Read more about 3 in 1 Mill Drill Lathe 3 in 1 Mill Drill Lathe مزيد من المعلومات

Come to Grainger when you need vertical milling machines to expand your operation or replace aging equipment You’ll find vertical mills in a variety of sizes to handle a wide range of drilling boring cutting and tapping applicationsThe M is a variable speed mill/drill machine And the ground dovetail precision column makes it easy to change tools That’s because there’s no need to re register the spindle’s centerline each time Who Is the Fox Model M Milling Machine For This is a tabletop mill drill and a good choice for anyone who has a spare sturdy surface مزيد من المعلومات

8613371530291

8613371530291