high precision rotary table factory

The assembly tables with reciprocating movement rotate on the horizontal plane. They are used to equip semi-automatic or automatic loading stations. Incorporated fine pitch stop screws made of hardened ...

... SA conceived these electric rotating tables for an integration in automatic rotating machines, for transport and assembly where precision and dynamism are asked.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages are ...

RTGA Series motorized rotation stages provide precision angular positioning accuracy combined with high load capacity. There are three stage sizes with center aperture ...

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

... guaranties high temperature stability, lightweight of 8MRL80 stage and excellent long period kinematics without drift of its performance. Compact crossed roller bearing provide perfect ...

... open access to the load. When two BG stage are stacked together, the sample rotates about a common pivot point. These DC motor goniometers are suited for applications that require smooth motion, high ...

For the past fifty years, TRT has been the most frequently used rotary table. TRTs are electric, driven by fully CNC Brushless motor with precision reducer. Position and rigidity are ...

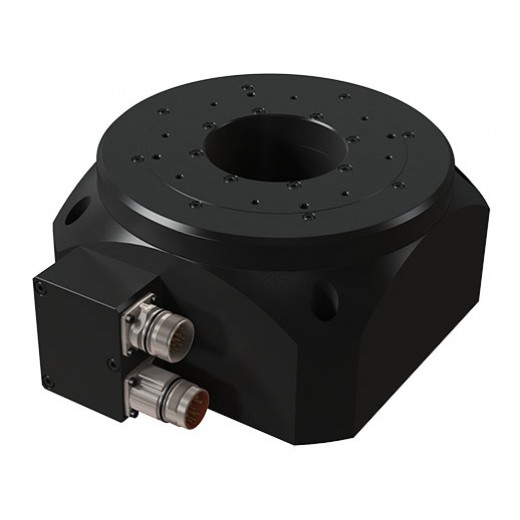

Jenaer Antriebstechnik GmbH"s HRT-100 Series of hollow-shaft rotational tables feature n x 360° rates, mechanical and electrical connection readiness, and integrated ES Series motors. They feature hole ...

The Rotating rotary table DSH-S Series is manufactured by Isel Germany. The product has a compact and durable design; it is made of stainless steel that has protection class of IP 65. ...

The RT series of our precision rotation stages is used where rotation-symmetric components and assemblies are measured with highest accuracy or for positioning. The free from float pre-stressed ball bearings ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

... acoustics Remote-operated Turntable HRT I is used for automated orientation-dependent acoustic measurements, allowing to rotate the device under test to specific angles in the measurement field.

This is the Hollow Rotary Table model number GSN60-05K-SV with table size 60mm gear ratio 1:5 for servo motor. GIGAGER Hollow Rotary Table also called ...

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

The basic version, M-035.50 rotating table, is equipped with a micrometer drive and a zero-backlash magnetic coupling. The micrometer provides a positioning range of ±9.5 degrees.

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements. They can be selected in either English or metric mounting. They are found in virtually all industries where intermittent part indexing, part scanning, skew adjustment, or precise angular alignment is required. At the heart of these tables is a rugged main support bearing which is comprised of two preloaded angular contact bearing races. It is designed for high load capacity and smooth, flat rotary motion. The drive is a precision worm gear assembly which is preloaded to remove backlash. The top and base are constructed of high quality aluminum with an attractive black anodized finish. The top and bottom mounting surfaces are precision ground to assure flatness.

Our rotary tables are ideal for indexing, milling and boring with your milling machine. Suitable for vertical and horizontal positioning for a high degree of accuracy and precision with your work.

Rusach International has continued an on-going program of design and development, benefiting from years of experience in the design of special purpose Rotary Tables, Pallet Automation Systems and Metrology Products,from our Eimeldingen years. An increased product range through acquisitions and product development has enhanced the company"s work on high accuracy rotary tables. A natural progression was the introduction of retrofitting pallet automation systems in 1976. These have subsequently been supplied in "stand alone" and FMS form to suit a wide range of machining applications, also over the last few years supplying rotary and tilt CNC tables fully integrated onto slideways or as full bases for various machines.

Designed and manufactured to the highest level of quality, our rotary tables feature distortion-free active clamping with roller bearings for high-resolution rotation. The rigid design and solid components make loading capacities of up to 100+ tons possible.

Rusach International has been awarded the ISO 9001:2008 Management System certificate by Perry Johnson Registrars, Inc., for the Design, Assembly and Service of Metal products for various Industries. This goal further insures that our customers receive consistent high quality products and services.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new high precision rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement high precision rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new high precision rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

This compact, high speed, direct-drive rotary table is equipped with a direct-drive 3-phase brushless motor and optical direct-metrology encoder (sine/cosine) for high position resolution and repeatability.

The M-660 precision rotary stage employs PILine� ultrasonic piezo ceramic motors that act on a ceramic drive ring attached to the platform. This piezo direct drive principle is the basis for the compact design and low profile of the rotary stage. An integrated optical direct-metrology encoder offers closed-loop precision position control with up to 4 �rad resolution. There are no gears or mechanical parts that can contribute to backlash. The integrated ultrasonic motors provide a maximum velocity of up to 720 �/second. The maximum load is 2 kg.

These directly driven, low-profile air bearing rotary stages provide superior angular positioning accuracy along with high velocity constancy and minimized eccentricity. The brushless and slotless motor features a very low cogging torque. These air bearing rotary stages are designed to applications such as high precision optical inspection, wafer metrology, beam line instrumentation and nanotechnology research and manufacture.

M-06x series high precision rotary stages are equipped with ultra-low-friction, spring-preloaded worm gear drives allowing unlimited rotation in either direction. Models M-060 feature a 60mm diameter turntable, models M-061, a 100mm table and models M-062, a 120mm table.

M-116 rotary stages are equipped with low-friction, spring-preloaded worm gear drives allowing unlimited rotation in either direction in an extremely compact package.

Yukiwa precision rotary tables and index tables are high-speed indexing tables which have the built-in precision couplings. They are most suitable for precision machining for the automobile parts, etc., interlocking with the machining centers and the special purposes machines.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

SAN JOSE, CA, Jan. 25, 2022 (GLOBE NEWSWIRE) -- With the expansion of its line of RTMB high precision indexing tables, ETEL now offers the new RTMB+, enabling large-diameter manufacturing applications that require higher torque than previously provided. This is achieved through an expansion to four new table size options, and two new diameters with two heights per. Also, with the key integration of a new water-cooling feature, users can expect an up to 30% indexing gain compared to its equivalent air-cooled version.

All of this makes the RTMB+ rotary axes the ideal solution for all rotary machining applications where high repeatability and short indexing times are required, such as in back-end semiconductor, electronics, automation, or printing industries.

It is important to note that the RTMB+ benefits from the best motor constant on the market (Nm/√W) since it integrates ETEL’s TMB+ direct drive torque motors which allow very high acceleration during indexation with low power dissipation. And the new water-cooling feature can be utilized with or without the option of a closed cooling jacket to enclose the liquids.

A unique internal encoder-bearing solution provides the RTMB+ with the best torque-to-volume ratio in the industry, with the position feedback based on a high-resolution encoder from parent company HEIDENHAIN. This solution offers an optimized hollow shaft size to accommodate various customer cables and tubing.

Alone or coupled with ETEL’s force-controlled short stroke actuators and AccurET controllers, the RTMB+ is an especially notable solution for applications in back-end semiconductor manufacturing, such as in MEMS testers, die bonders, pick-and-place testers, turret testing handlers, and more!

ETEL S.A. is based in Switzerland with exclusive North American distribution through HEIDENHAIN CORPORATION in San Jose, CA and Schaumburg, IL (www.heidenhain.us). As a leading international supplier of direct drive and motion control components and integrated systems, ETEL supports high tech industry with linear motors, torque motors, positioning stages, and motion controllers/systems.

8613371530291

8613371530291