rotary table shot blasting machine free sample

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

Browse the massive rotary table shot blasting machine range on Alibaba.com. These machines are useful in critical cleaning. rotary table shot blasting machine are highly efficient machines with lower maintenance costs. They enhance anti-fatigue performance and maintain an adequate surface profile in machine parts.

rotary table shot blasting machine on Alibaba.com can be used in conjunction with other equipment or as stand-alone systems. They are useful in several sectors, including, but not limited to, electronics, construction, and manufacturing sectors. They can process a bulk amount of sizeable machine parts in short periods. They employ an array of cleaning processes like steel shot cleaning, grit cleaning, and so on. They also exhibit a clean-in-place feature for straightforward cleaning. These machines exhibit a high degree of automation with premium logic controllers, making them reliable.

Electricity powers rotary table shot blasting machine and they are power-efficient machines. The turbines and other moving parts are constructed of wear-resistant material. A manganese-steel casing houses the devices to provide them with adequate protection. The cleaning mechanism ensures effective cleaning of parts with deep cores and depressions off scale and sand. Equipment are apt for burnishing, descaling, deflashing, and so on. They can also get rid of rust from the working pieces. They are valuable in extending the steel parts" working life and cutting down labor efforts in cleaning. The abrasive materials are cleaned and recirculated for cutting down operating costs.

Grab lucrative rotary table shot blasting machine deals on Alibaba.com at affordable rates. The listed suppliers sell superior quality products and offer after-sales services like installation and providing spare parts. Buy now and enjoy the of benefits of bulk purchase on the platform.

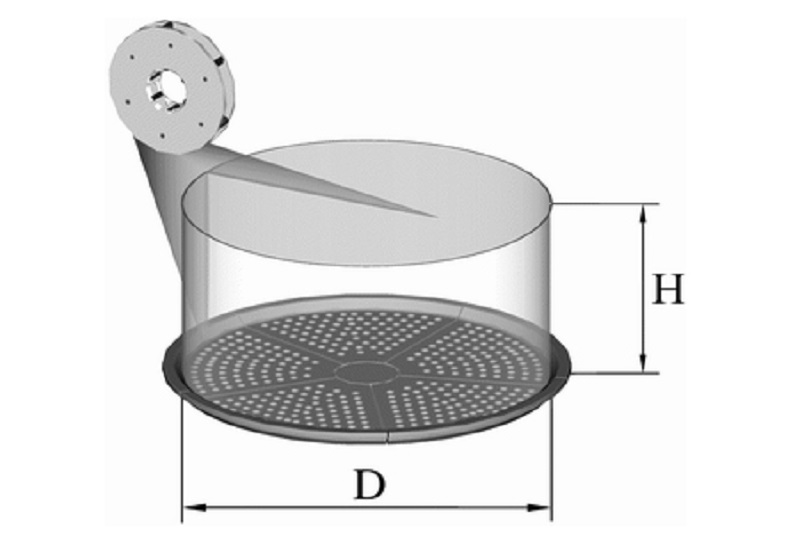

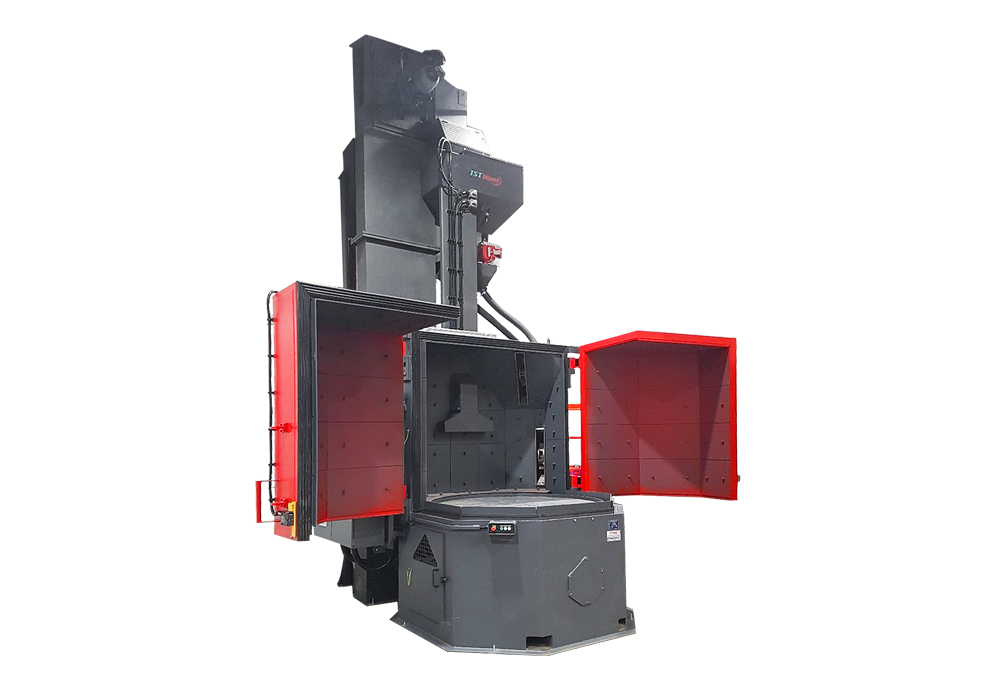

The Rotary Table Shot Blasting Machine is suitable for shot blasting small and medium size parts. This installation is provided with a variable speed drive controlled turbine and a turntable, which has a diameter of 2500 mm. ActOn Rotary Table blast machine is built to be compact, with minimum space being required.GET A QUOTATION

Shot blasting, or abrasive blasting, is an essentialpart of any manufacturing industry seeking tomaintainthe longevity oftheirparts.It is a mechanical method of propelling abrasive using a centrifugal wheel to remove surface contamination, scale,and othersmallimpurities from the surface ofa variety ofsteel applications. For example, this could bestructural steelwhichincludesmassive bridge girders and heavy construction equipment,such aslarge weldments, plate steel, bar and wire steel,and foundry castings.Our shot blasting machines utilize centrifugal force to clean steel utilizing abrasive media. After the steel abrasive hits the surface, the shot blaster recycles the media.Dust and other contaminant particles are removed by an air wash separator within the machine andsentto a dedicated dust collector.This process provides a dust-free operation.In general, blastingbefore moving onto finishing servesa fewprimarypurposes:

When buying a blasting machine, many factors must be considered, such as the dimension of the piece, what it is made of, the volume of production (how many parts need to be finished in one day or hour) and the type of finishing required (cleaning, paint removal, de-rusting, etc.). Thinking of that, we elaborated a guide to blasting machines.This material serves as an instruction to visualize the blasting machine that can meet your need.

It is worth mentioning that this is estimative and, in addition, CMV® blast machines can be customized to best meet your company"s needs. We provide free technical consulting to our customers. We talk and analyze which blasting machine best meets their needs, aiming at the bestcost-benefiton the market.

See the recommended blasting machine by clicking on the item you are interested in below. If you prefer, you can solve your question by talking directly to our sales team by filling out a form.

This is the industry that proportionally uses the most shot peening machines. There is a multitude of aircraft components that are treated with shot peening, including several components of the blast wheels, structural parts and the landing gear.

It is becoming more and more necessary for the industry to prepare the surfaces of castings and aluminum parts. We are prepared for this demand, meeting the needs of our customers and aiming for the best cost-benefit in the market. We have several blasting machines specially developed for surface treatment and deburring of aluminum parts. See some examples:

We have developed a machine specifically designed to blast aluminum rims and wheels. Its capacity is impressive, as the process takes only 6 minutes to complete.

To meet the demand of one of the largest weapons manufacturers in the world, we developed a blasting machine with an indexed table and replaceable planetariums for the various components to be blasted with two B-306 blast wheels with 5 HP each. The blasting time for each part averages 10 seconds.

The equipment used will depend a lot on the parts finishing process. We have many solutions specially developed for the automotive industry. We listed below some examples of parts and blasting machines suitable for the operation:

We have already developed different types of blasting machines with a specific focus on chassis. It is necessary to evaluate each case, but see the example below:

See in the video below the blasting equipment that was developed for the blasting of valves for fuel injection and that performs the production of 70 pieces per minute. The cabinet was without the final finish, as it was in the testing phase in our headquarters.

The stabilizer bar is located on most vehicles on the front suspension and on some models on the rear. It is a fundamental piece of equipment for the stability of the vehicle and, therefore, a shot peening machine with a high precision finish is necessary.

The machine in question has an extremely efficient abrasive recycling system, which makes it possible to obtain a very narrow range of roughness. The new table indexing system ensures extremely accurate positioning of the parts in front of the blast nozzle, providing a uniform finish.

In the case of truck stringers, we recommend using an overhead monorail shot blasting machine. See an example: This blasting machine has 4 blast wheels of 40 CV (30Kw), each with a passing speed of 3 m/min.

CMV® has state-of-the-art technology to treat bars and tubes, regardless of their shape. It is possible to treat different types of bars and profiles in one single blasting machine, due to a vertical support roller that can be installed on the equipment"s table, causing different shapes of bars to advance in a helical way.

This machine has an extremely high production efficiency and can be easily incorporated into automatic or semi-automatic production lines. It meets the central safety and health standards, and it’s available in two models pre-fabrication and post-fabrication.

We are prepared to meet the most diverse demands of the energy industry. Both gas protection and cleaning protection ducts, construction preparation and final coating. CMV® meets all these demands with tube blasting machines. We also have a blast and paint and pipe coating line.

This tumble blasting machine is suitable for blasting and shot peening of forged, stamped, injected and cast parts. This high-efficiency equipment is capable of uniformly blasting several parts at the same time.

There are metal castings that require special attention as they may be subject to impact damage. In this case, the blasting machine with the tumble belt (mentioned above) is not recommended, as the tumble could cause damage. And yes, an overhead blasting machine or even a wire mash blast machine. In both equipments, all the faces of the part are blasted at once, but without the risk of any damage.

No matter what your demand is, we have a shot blasting machine that can meet it. We manufacture both, standard equipment and customized machines. Whatever is necessary to better meet the needs of our customers. From small to large productions, we develop shot blasting machines with the best performance on the market.

Discover our products.If you prefer, talk to our sales team. We provide free technical advice so that we can understand which machine is best for your company.

We are a reference when it comes to the construction of blast rooms for shipyards, having in our experience the manufacture of the largest blasting and painting room in Latin America. A few years later, we developed a paint booth with the largest free-standing door, also in Latin America.

We have blasting machines that work with metal sheets and profiles. It’s possible to purchase only a part of the equipment or the complete line, including conveyor, blowing, drying, blasting, cleaning (sweeping and blowing), painting and drying the paint with gas or electric oven. It also treats the volatiles eventually generated in the process.

Table shot blaster’s essential component is the turntable for handling the workpiece. This kind of machine is best suited to processing symmetrical parts. However, the turntable can be positioned at certain angles to allow the processing of asymmetric parts alongside multiple positioned blast wheels.

BlastKing has developed a variety of table shot blaster to meet the requirements of our customers with regards to their material flow. In addition to the traditionally fixed turntables there are machine types with one or two mobile turntables. These machines reduce process times as new parts can be loaded while others are processed.

Table shot blaster from BlastKing offer total flexibility in your shot blast operations. Whether you are cleaning welded structures and fabrications, cleaning and deflashing castings, or shot peening dynamically stressed components, the Rotary table shot blast machine, can help reduce the production time required.

With extensive experience in the forge and foundry industries, Rosler Metal Finishing understands that no two shot blasting processes and work pieces are alike. With that in mind, we continue our Forge & Foundry Blog Series with an overview of our machines offering excellent finishing for sand castings.

If you demand precise, repeatable results when shot blasting sand castings, consider the following machines. As always, the experts at Rosler are also available to develop a customized machine to accommodate your unique work pieces and challenges.

Work pieces pass through the shot blast area on a wire mesh belt, never touching each other during the shot blast process. The heavy-duty foundry version of the RDGE includes an extra 5/8-in-thick wear lining, special eight-bladed turbines, and a vibratory screen conveyor in place of a media auger.

The RMT’s specially shaped rotary drum optimizes work piece mixing. For foundry applications, a vibratory screen conveyor replaces the standard media auger and a magnetic separator and extra wear lining are added.

The heart of the RMBC batch machine is an endless belt made from rubber or steel slats forming a trough. Work pieces tumble intensively within the trough.

The center of the RROB is a robot, which does the loading/unloading as well as the handling of the work pieces in the blast machine. The robot picks up one, single raw work piece from the staging system (e.g. a conveyor), holds the work piece into the blast chamber while constantly rotating it, and deposits it back on the conveyor.

The RMBS is a specialized machine equipped with a gripper system that rotates and oscillates work pieces weighing up to 11,000 lbs in the blast chamber. Twin robots transfer the work pieces to and from the gripper system.

The experts at Rosler are available to collaborate with you to find the right machine and process for your sand castings. Contact us today to learn how we can help improve your finishing processes and schedule a free sample processing in our test center.

The Guyson Multiblast RSB is equipped with a single rotary work spindle (or table rotating on the spindle) on which the component is placed, usually in a specially designed fixture. The machine can be either loaded by hand or robot.

The RSB model has recently been upgradedand now incorporates roof-mounted servo drives to provide saturation coverage from the attached blast guns across the entire rotating table; allowing full blast coverage to multiple components positioned on the table.

For optimum component blast coverage, the machine can be provided with either horizontal or vertical servo driven gun drives. Both provide 500 mm of precise traversing travel, either across the turntable for full saturation coverage or vertically stroking (up and down) taller components to provide uniform coverage, whilst the part rotates on the turntable.

As standard, the Multiblast RSB comes with two Guyson Model 900 guns, each with its own individual pressure regulator, allowing optimum blast coverage of components on the table. This number can be increased to a maximum of eight guns if the blast application necessitates.

Prospective users of Guyson automated blasting systems are encouraged to submit sample components for free feasibility testing in the company’s extensive Component Finishing Centre at Skipton, England. Contact Guyson now - see contact details at the bottom of this page.

Articulating arm robotics can be added to the interior or exterior of all IPS machines. Normally this type of robotic motion is specific to an application, such as plastic media blasting, or a specific motion that a CNC-gantry robot cannot provide. Articulating arm robots are historically cheaper than CNC-gantry robots, but can be more expensive to repair should wear occur inside the enclosure. Articulating arm robots also require larger enclosure sizes to accommodate the robot motion. The main benefit of an articulating arm robot motion is speed and reach. Systems can also be integrated with other loading robots and multi systems tasking.

Robotic articulating arm machines offer users a fast nozzle motion for larger parts that need quick cycle timers. Customers may choose the robot of choice. Another benefit to some customers is the familiarity of robot programming. Machine enclosures are custom built to allow the robotic arm to fully move to peen or blast the users part.

in the interest of shot blasting equipment from the automotive and aviation industries. A shot blasting machine is a covered piece of equipment used for rough blasting, which is used to clean and shape surfaces like metal, stone, and others. It is a machine for shot peening, cleaning metal parts, such as fashioning and projecting parts, steel surfaces, large metal constructions, corroded metal parts, and so on. Steel shot blasting, aluminium and copper shot pellets are a few of the different types of metal abrasives utilised in this process. Silica sand, glass dabs, industrial materials like sodium bicarbonate (baking soda), and even rural elements like smashed kernels are all used in various shot blasting techniques. A shot blasting machine is a tool used to polish, peen, or reinforce any metal surface, including cast iron, aluminium, and so on.

The Global Shot Blasting Machine Market reached a valuation of US$ 1.1 Bn in 2021. Increasing demand for wheel blast equipment from various end-use sectors is expected to drive sales at a 5.0% CAGR over the assessment period.

To clean the metal surface, the shot blasting machine primarily uses two innovations, such as wheel blasting or air blasting. The shot blasting machine is widely utilised in many industries that work with metals, including the automotive, rail, aerospace, and shipbuilding industries. Shot blasting machines are used for descaling, matting, sanding, smoothing, edge shaping, rust expulsion, and de-glimmering in many types of metal across various industry segments.

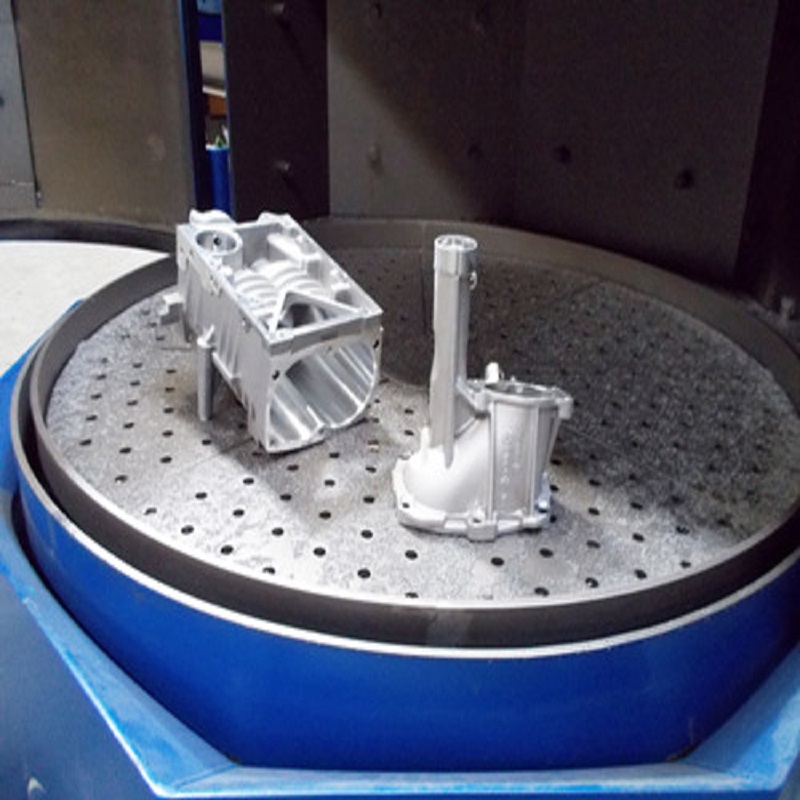

Treated objects are loaded on a perforated rotating table. A big door, provide simple and fast loading. The machine can have the table fitted to the machine"s door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The machine also can be equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the machine.

The machine"s housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand, a magnetic sand cleaner may be installed.

The overarching principle of this exercise is to keep the calculation simple and also to think in the long term versus any brief time period. The second basic principle is to establish an “operating savings account” for blast machine costs, where funds are accrued on an hourly basis but may not be spent for several months or years. If you have a personal Health Savings Account, then it’s very similar and uses the same principle.

To keep this exercise simple, assign a “cost value” to each of the components as follows (again, keep in mind this is a long term cost model, not a pinpoint or snapshot calculation):

Blast Wheel(s) – Use a value of $1.50 per blast wheel, per blast hour, for the average process. Why “per blast hour” you ask? Because the blast wheel is not a significant cost item if it’s not throwing abrasive. Most machines have an hour meter that shows total blast hours (i.e. when abrasive is being fed to the blast wheel or wheels). If your operation is a foundry or other process where high concentrations of debris can be mixed in with the abrasive, then you may elect to increase this average amount to $1.75 or even $2.00 per blast wheel per blast hour. Again, this is a long term averaging calculation, so it can be adjusted a few years from now if you see your “savings account” is either too full of accrued monies or starving for money.

Abrasive Handling and Recirculation Systems -These components sometimes are running even though no abrasive is being thrown, so for estimating purposes, assign a cost value of $1.00 for each hour the machine is available for production. If you want to get a bit more precise on this then install a time meter that runs when the abrasive reclaim elevator runs. If your machine is equipped with 3 or more blast wheels, then consider increasing this accrual amount to $2.00 per available operating hour.

Dust Collection Systems – Commonly referred to as the “lungs of the system”, the dust collector often runs all day long whether the blast machine is running or not. To keep your operating costs in check and conserve energy, we recommend that the dust collection system be tied into the abrasive handling system so they both come on and go off at the same time. If your collector uses standard filters, accrue $1.25 per operating hour to cover the maintenance expense. If you have a more unique collection system, then consider increasing the amount to $1.50 or $1.75 per operating hour.

Work Conveyor/Material Handling Systems – This is a difficult component to estimate costs for since there are a multitude of different material handling methods employed on shot blast machines. In our quest to keep the calculations simple, consider using the following broad categories or types of machines:

Blasting Media (Abrasive) – The range of blasting medias used in airless shot blast machines is very broad, and the cost range is also broad. For illustration purposes, we’ll consider an application where standard steel shot is used and the machine is equipped with two blast wheels, each driven by a 15 HP motor. Assume the steel shot has a cost value of $.60 per pound, including inbound shipping cost.

For general estimating purposes, the typical blast cleaning process will consume 0.4 pounds of abrasive per wheel drive motor horsepower, per blast hour (through natural degradation, carry-out, leaks or other). Some machines or processes consume more abrasive and some less. To get a handle on the estimating process, start here and adjust as needed to arrive at an estimate value that mirrors actual results over time.

Electricity– Probably the easiest cost component to calculate. Total up the horsepower of all the motors on the equipment, multiply by 0.7355, and the result is Kilowatts. Look at an electric bill to get the average cost per kWh (Kilowatt Hour), and then multiply the two components to get the electricity cost per blast hour. For the time period when blasting is not in process (the machine is powered up but abrasive is not being fed to the wheels), use a factor of 25% of the calculated rate. Chart your Blast Hours per Production Day for a few weeks to get an average, and don’t be surprised if the actual Blast Hours rate is less than 50% of the available production time per day.

Compressed Air – Airless shot blast machines consume such a minimal amount of compressed air that it rarely is practical or necessary to develop a cost component for this utility. However, if your machine has a dedicated compressor, then you’ll have to treat it as a part of the machine and assign an hourly cost value. Best bet would be to work with your compressor supplier to come up with this value.

Table 29. Asian and Pacific Economies: Real GDP, Consumer Prices, Current Account Balance, and Unemployment (Annual percent change, unless noted otherwise)

Table 30. Western Hemisphere Economies: Real GDP, Consumer Prices, Current Account Balance, and Unemployment (Annual percent change, unless noted otherwise)

Table 31. Middle Eastern and Central Asian Economies: Real GDP, Consumer Prices, Current Account Balance, and Unemployment (Annual percent change, unless noted otherwise)

8613371530291

8613371530291