rotary table shot blasting machine pricelist

Once inside, the build is automatically raised in stages, allowing the twin, robot mounted blast guns to do their work. Blasting with the removed powder ensures that your components and powder remain undamaged and uncontaminated. ...

... most effective blasting process for removing sand, scale and burrs from heavy or sharp-edged mass production parts that require the robust steel mill design found in our Model MR tumble blast machines. ...

Conventional rotary table blast machines are usually loaded manually. The machines are most frequently used to batch clean cast or die-cast work pieces and to roughen ...

It’s about highly modern machines according to a well-tried principle. Because of many new technical details the new AGTOS drum blast-machines are convincing. This unit type is very capable for treating ...

The LS Industries DB25 Drum Blaster is a quick and efficient machine for cleaning burnt steel drums and barrels. The DB25 can blast the outside and inside of open-end drums in under 2 minutes. The blaster ...

... LSTB8460 Indexing Table Blaster has dual satellite tables to rotate parts into the blast cabinet section. The open front allows for loading / unloading while the other ...

... in position, nozzles moves to first stored position and starts blasting according to the recipe. After blasting is done workpiece is unclamped, unloaded and ready for next one.

Even though machine is designed for manual work, all other features to control the process have been included in solution. That means all components meet shot ...

A 3 – axis automatic machine with full working process control (media flow, shape and size classification, controlled manipulation of parts and peening delivery. Used ...

... manufactures single table and multi table shot blasting machines for processing sensitive components that only need to be blasted on one side, as well as complex, heavy ...

... additional structural work required, the ALFA rotary table blast machines represent the simplest, most versatile and cost-effective solution to your surface treatment issues.

QLX3320A continuous crawler shot blasting machine removes the molding sand on the surface of the workpiece,and eliminates the stress of the workpiece, improves the fatigue strength of the workpiece, and ...

Our rotary drum shot blasting machine enables workpieces to be uniformly cleaned by means of the rotation of a barrel. It is basically used for the shot blasting of small ...

It is designed to work with steel shot (carbon or stainless steel) for cleaning, deoxidation, descaling, deburring, surface finishing for painting and shot peening.

System for automatic processing of rotationally symmetric serial parts of various dimensions. The turntable is completely loaded in the blast chamber; the processing ...

Hodge Clemco purpose-designed and manufactured an internal cyclinder cleaning machine for the leading manufacturer of aluminium gas bottles in the UK. The machine was designed to be both simple to operate ...

Because of their characteristics the rotary-table shotblasting machines can easily be incorporated in diversified machining, adapting to the treatment of various parts of different shape and type. They can be equipped with fixtures and accessories built according to the pieces to be treated.

Browse the massive rotary table shot blasting machine range on Alibaba.com. These machines are useful in critical cleaning. rotary table shot blasting machine are highly efficient machines with lower maintenance costs. They enhance anti-fatigue performance and maintain an adequate surface profile in machine parts.

rotary table shot blasting machine on Alibaba.com can be used in conjunction with other equipment or as stand-alone systems. They are useful in several sectors, including, but not limited to, electronics, construction, and manufacturing sectors. They can process a bulk amount of sizeable machine parts in short periods. They employ an array of cleaning processes like steel shot cleaning, grit cleaning, and so on. They also exhibit a clean-in-place feature for straightforward cleaning. These machines exhibit a high degree of automation with premium logic controllers, making them reliable.

Electricity powers rotary table shot blasting machine and they are power-efficient machines. The turbines and other moving parts are constructed of wear-resistant material. A manganese-steel casing houses the devices to provide them with adequate protection. The cleaning mechanism ensures effective cleaning of parts with deep cores and depressions off scale and sand. Equipment are apt for burnishing, descaling, deflashing, and so on. They can also get rid of rust from the working pieces. They are valuable in extending the steel parts" working life and cutting down labor efforts in cleaning. The abrasive materials are cleaned and recirculated for cutting down operating costs.

Grab lucrative rotary table shot blasting machine deals on Alibaba.com at affordable rates. The listed suppliers sell superior quality products and offer after-sales services like installation and providing spare parts. Buy now and enjoy the of benefits of bulk purchase on the platform.

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

"Based on domestic market and expand overseas business" is our development strategy for Rotary Table Shot Blasting Machine, Steel Plate Automatic Blasting And Painting Line, Tumble Blast Machine With Rubber Belt Machinery, Turn Table Shot Blasting Machine,Blast Cleaning Equipment. Our products are new and old customers consistent recognition and trust. We welcome new and old customers to contact us for future business relations, common development. Let"s speeding in the dark! The product will supply to all over the world, such as Europe, America, Australia,Serbia, Portland,Spain, Stuttgart.Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Swing Table Shot Blasting Machine, In this type of machine casting or forging or aluminium cylinder head, which is to be cleaned must positioned on table and repositioned to assure complete cleaning of full surface.

The basis of the machines is the production at the Grossenlueder site since 1971. Harth & Seifert-Georg Fischer-Schiffmann and Seidl-Oliver Fritz GmbH & Co. Kg with the long-time known contacts.

We sell a used troughed web shot blasting machine from the manufacturer Rump. The machine is in good used condition. It is also equipped with a placement device and suction.

Casting, forging, pressing, heat treatment, finished product, semi-finished product, steel fabrication etc. It is preferred for surface cleaning, pre-coating preparation or revision works. Its distinct advantages are that it enables versatile sandblasting, and that large and small parts with irregular geometry can be sandblasted. With the help of the digital clock we use in our machines, the sandblasting time can be adjusted according to the part type and desired sandblasti...

Wet sandblasting unit, Sandblasting unit - Pressure blasting unit SAPIMasch. No. 43207 Year of construction 1989Canister size 140 litre perm. operating overpressure 10 barAir requirement approx. 3000 litres/min.hose length approx. 8 meter- Valve opens and closes via pneumatic operation at the blasting nozzle- Sandblasting protective hood with compressed air connection- Complete system installed on metal pallet with forklift pockets- Accessories such as connection pieces for blasting nozzles at t...

Compressor Kaeser M36, year 2019 EZ 2020, 23 operating hours, 10 bar, volume flow 4 m³, pressure adjustable 5-10 bar, check valve sandblasting, compressed air treatment G+ (aftercooler, condensate separation, filter combination, heating, bypass), SUB Jet Inverter 230 Volt socket, Ser.Nr.WKA0F1200K7189450

-Dry ice blasting unit SUB Jet 1, year 2020, 5 operating hours, single hose technology with dosing disc, cyclone separator, stainless steel storage tank 25 liters, automatic vibrator for ice loo...

Injector gravitational tumble belt blasting system for blasting series parts with glass beads, corundum, ceramic balls, etc. Due to the gravitational system, the system has 15-20% more blasting power than a simple injector blasting system. The system has a bucket elevator with wind sifting for cleaning the blasting agent. It is possible to store up to 20 programs for various blasting tasks.

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at an acute angle to facilitate the sliding of the material, and an inspection drain for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber w...

The FG 1 fine blasting unit is equally suitable for punctual work on large objects as well as for the extremely precise processing of the smallest workpieces. The built-in dosing vibration allows on the one hand the use of a wide range of blasting media and on the other hand a wide control range, which also allows lowest blasting pressures.

The offered blasting machine is a professional, safe and modern device made by a European manufacturer. The sandblasting machine is equipped with a double, independent chute funnel formed at a sharp angle to facilitate the sliding of the material, and an inspection drain allowing for quick emptying of the chute of the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 800 kg in a chamber with working ...

Equipped with self-cleaning filter cartridges and effective abrasive treatment, the injector blast machine type 75 IN MEDICA is extremely reliable in operation and achieves a high degree of reproducibility.

Offered sandblasting machine is a professional, safe and modern device from European manufacturer. The sandblasting machine is equipped with a chute formed at an acute angle to facilitate sliding of the material and with an inspection trigger for quick emptying of the chute from the abrasive. The use of innovative design solutions makes it possible to process workpieces weighing up to 600 kg in a chamber with working dimensions of 1 350 x 1 740 x 690 mm...

The 75 IN injector blasting system can be used very flexibly with its generous working area and the proven "sandmaster" injector blasting system. Whether it is for parts cleaning, deburring or preparation of the adhesive base, the 75 IN sets new standards in the field of manual blasting technology. The system is suitable for smaller to medium-sized workpieces. As an exclusive representative of sandmaster in the Baden-Württemberg area, we as IS Zubehör GmbH offer the 75IN injector blasting machin...

Offered blast machine is a professional, safe and modern device from a European manufacturer. The sandblaster is equipped with a chute formed at an acute angle to facilitate sliding of the material and with a revision trigger allowing for quick emptying of the chute from the abrasive.

An important advantage of using CLEMCO brand valves and carbide nozzles in our equipment, as well as blasting hoses that carry the material, is the ability to dose any type of abrasive - both quartz sand...

The 115 PB pressure blasting system with its efficient pressure blasting system is especially suitable for work where a high removal rate is indispensable. The optionally available turntables allow even heavy workpieces to be processed without any problems. sandmaster offers the pressure blasting machine type 115 PB as an exclusive representative of sandmaster in the Baden-Württemberg area as IS Zubehör GmbH. "sandmaster" pressure blasting system - pressure blasting system with 25 l boiler - hig...

The parts to be sandblasted move with the help of roller conveyors located at the entrance and exit of the machine. Turbines are placed in the machine body at appropriate angles so that the part surface can be sandblasted from the bottom and top.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

The offered blast machine is a professional, safe and modern unit made by a European manufacturer. The blast machine is equipped with a chute funnel shaped at an acute angle to facilitate the downward movement of the material and an inspection drain for quick removal of the abrasive material form the chute.

Table type shot blasting machine comprises of one/ two rotary table for loading of the constituent. This table straddling on the door swings inside the cabinet, thus it is also called Swing Table Blasting Machine, and the blast wheel on the uppermost cleans the section. The table rotates in a circular and anticlockwise direction to guarantee the blasting surface"s thorough cleaning by the blast wheel.

The table shot blasting machine is commonly known as Swing Table Shot Blasting Machine, which comprises rotary tables for the component loading. This shot blasting table soars on the door swings inner surface the cabin and the blast wheel on the top clean the component.

This table type shot blasting machine comprises a round table over which the ingredients or material to be blasted are kept. The swing table rotates vertically, hence exposing the components to the blast stream by the blast wheel. This blasting machine has an additional table hinged to them to reduce the cycle time. The second part of the table is on another side of the opening that rides and loaded when the blasting is in technique on the first one. Table Shot Blasting Machines are available at a very reasonable price.

It also consist a round table over which, the ingredients to be blasted are placed and the table rotates vertically therefore exposing the components to the blast stream. These machines also have another table hinged to them in order to reduce the cycle time. The second part of the table is on other side of opening which is offloaded and loaded when the blasting is in process on the first one. Our table type shot blasting machines are available at very competitive price.

Quality Space Centre is the premiere table type shot blasting machine Manufacturers are entirely ground-breaking in all the aspects. It has been extensively designed with airless, automatic, and simple handled machines for more applications. At quality space centre, the leading Shot Blasting Machine Manufacturer in Faridabad, India, brings you the finest rotary table machine based on the unique source with the single and double door based on the production rate well the desired output. It is most suitable for the immense to small foundry industries in a more state-of-art way.

Shot blasting machine in India is made in such a way that it suits small to big foundries. Components are loaded on a rotary table and get cleaned either by a portable shot blasting machine or stationary shot blasting machine in India. A swing table shot blasting machine for sale can be supplied in one/ two doors with the table. In the case of a double door shot blasting machine manufacturer in India, one door can be used for the shot blaster and the second door for loading & unloading at the same time & vice versa.

This type of airless shot blasting machine manufacturer is useful where a single side is to be shot blasted at a time. The machine is equipped with a high-performance centrifugal blast wheel. The abrasive media are thrown upon the workpieces kept on the table by this wheel. The abrasives are transferred by a screw conveyor into the boot of the elevator. Clean abrasive gravitate down into the wheel for blasting purposes. Hence the machine is most economical in operation. Dust collector options are available, i.e. fabric, cartridge type. The machine is available with various optional features like abrasive replenishes, rotary screen separators, second door, electronic brake system for blast wheels, program-logic control system, time control, sound reducers, etc.

Shot Blast Cabinet & Liners: The shot blasting cabinet shall be fabricated from thick heavy-duty prime quality mild steel plates supported by strong rolled structure welded construction and engineered suitably for strength and rigidity to ensure the sturdiness of equipment. This robust rolled shot blasting machine manufacturer in India structure with a thick plate foundation shall hold the machine & help to control the vibration. The blast cabinet bottom shall be provided with mild steel perforated floor for the protection against abrasion wear Vestibules shall extend beyond the inlet and exit slots of the blast cabinet of the shot blasting room. The spent abrasive media trapped within the exit vestibule should be returned to the main abrasive system through shot blasting equipment.

The abrasive media for the shot blasting machine manufacturer in India shall get rebounded by the shot blast cabinet direct & indirect manganese steel (11-14% manganese) wall liners of min. 20 mm thick. Provision shall be there for replacement of these liners shot blaster, as and when the liners get worn out.

Provision shall be made to avoid wearing out of fastener heads inside shot blasting machine for sale blast cabinet by providing countersink and manganese hardening of bolt heads. Test certificate for manganese hardening shall be provided from the original shot blasting machine manufacturer in India.

Shot Blaster Wheel Assembly: One No. of shot blaster wheel station shall be mounted on 20mm thick heavy-duty prime quality steel plate and strategically around the cabinet and the pass-line of the work. The unit shall consist of fabricated steel shots casing having the installation of different alloy Mn steel liners(like HUB SIDE LINER, CONTROL CAGE LINER, TOP AND END LINER), rotor, blades, control cage, impeller, and feed spout. The rotor shall be made out of EN grade material duly hardened (test certificate to be provided). The drive system of the shot blaster wheel (rotor) shall have a set of self-lubricated and self-aligning pedestal bearings. The rotor shall be dynamically balanced.

The drive shaft of the shot blaster wheel shall be made out of EN-grade material and duly precision ground to the finest accuracy. The fabricated casing of shot blaster wheel assembly shall be designed for an easy opening through bolts/levers for examination of various liners and parts of the wheel assembly. The shot blaster wheels will generate kinetic energy to strike the abrasive on the job surfaces. The shot blaster wheels shall continuously be in running condition and only abrasive control valves shall be opened or closed at the time of blasting cycle start & stop respectively. The shaft of the shot blaster wheel shall run in self-aligning and sealed bearings which can absorb the extra vibration of the blast wheel.

The shaft of a rotor shall ensure the full safety of the electric motor from any kind of excessive load. Ingress of shots into the electric motor with the passage of time shall be prevented to avoid a short circuit of the electric motor. Shot blasting machine manufacturer follows all instruction which belongs to shot blasting machine in India wheel assembly process.

Abrasive Recycling System of shot blasting machine in India: Bucket Elevator & Media Separator Unit: The transferred abrasives(such as copper slag, steel shot, steel grit, aluminum oxide, glass beads, cut wire shot, plastic abrasive media, tungsten carbide powder, and many others) shall be elevated to the elevator head section at the desired height with the help of seamless buckets mounted on fabric plied rubber belt as a shot blasting equipment. Tensioning arrangement of the elevator belt for removal of tensioned belt length shall be provided at the top portion of the elevator, to avoid slippage of the belt. The elevator head pulley rotation shall throw the abrasives centrifugally to the media separation unit. The separator shall then continuously segregate usable abrasive from unusable abrasive & debris.

Abrasive Controls in shot blasting machine: The abrasive media flow from the storage shot blasting machine price in India shall be controlled by an electro-pneumatic, solenoid-operated valve by a screw regulator, which feeds into shot blaster wheel units through the feed funnel. The rotational movement of the impeller shall constantly accelerate the incoming abrasives and feed them onto the blades of the rotor. In shot blasting machine manufacturer in India, the abrasive at high velocity is then thrown by the rotor onto the job.

The abrasive control valve shall be specifically designed to combat noise arising from the source by sealing the opening to the wheel. It shall have a completely enclosed unit that reduces the noise level of a shot blaster wheel. The abrasive control valve shall also modulate the volume of abrasive flowing to the shot blaster wheel.

Job Tumbling System: In shot blasting machine manufacturer, the components to be blasted are loaded onto the endless rubber belt of shot blasting machine for sale. Load Charging Capacity of Tumbler shall be 500 Kgs. / 10 Cubic Feet (min.). The conveyor belt shall tumble the components gently and ensures adequate exposure of the components in the shot blasting machine manufacturer in India, area for the defined time period.

Dust settling tank: Dust laden air shall pass through a duct connected to series of closed MS tanks -one having a minimum 600litre volume and another having a minimum 300litre volume of shot blasting machine for sale. Both the tanks are filled with water up to 70% of the total volume (called dust settling tank) before reaching the dust collector units per the schematic of the shot blasting machine manufacturer in India provided in the specifications. Heavier size pyrophoric dust gets collected in this dust-settling tank. Dust settling tank shall have inlet and outlet water ports to maintain water level inside this tank. The top lid of the tank shall be the detachable type for cleaning once a month. There shall be provision for water level indication through a sight glass or through a suitable level indicator. A mounting frame shall be provided along with the dust settling tank.

Dust Collection System or Dust Collector for shot blasting machine for sale: (Fabric Bag Dust Collector) The fabric bag type dust collector having a minimum 36 number of tubular filter bags shall be provided. The filter bag shall be of minimum 700GSM quality. The dust-laden air shall enter the dust collector through the side and pass into the settling and equalizing compartment. Heavier dust particles shall get settle down and the fine particles shall get filtered by a filter tube. The clean air shall finally get exhausted through the blower of the shot blasting machine for sale. The filter tubes shall have a mechanical shaking system to remove the accumulated dust from the filter bags. The dust shall get collected in the tray of the dust collector. The filter bags shall be made out of a satin woven filter cloth/Paper.

The seams shall be multiple stitched with heavy cotton thread which is connected to a separate part of the shot blasting machine in India. The shot blasting machine for sale, blower unit of the dust collector shall be dynamically balanced. The dust collector shall be fabricated in modular design and all the joints are perfectly sealed. The pyrophoric dust generated from the shot blasting shall be finally collected in the water-filled SS trays provided at the bottom of the dust collection unit for easy replacement.

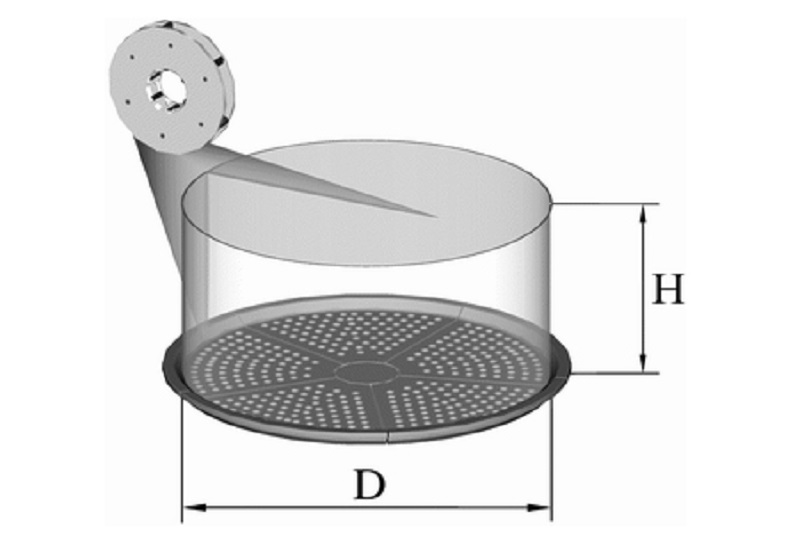

Rotary table shot blasting machine for sale is provided with one and two blast wheels, depending on component size. Regular table component sizes are from 650 mm to 2,400 mm and can process workpieces of a maximum of 1,500 mm height. The standard equipment of larger shot blasting equipment includes PLC, display, timer, automatic or manual mode, automatic starts of shot blasting wheels, working hrs counter, etc.

Tumblast shot blasting machine for sale is used for the removal and segments are loaded against the countless rubber conveyor belt of the tumblast shot blasting machine for sale manually/ with loader composition. Then the entrance is being connected and a Tumblast shot blasting machine in India performance takes position. The abrasive media(such as copper slag, steel shot, steel grit, aluminum oxide, glass beads, cut wire shot, plastic abrasive media, tungsten carbide powder, and many others) with special quickness falls simultaneously the tumbling segments and clarifies them. The rubber conveyor belt or the metallic conveyor shot blasting machinefor sale the segments gently and assures suitable presentation of the elements. After the purification blast cycle is already over, the shot blaster wheel is shut off and doors are removed. The elements are relieved on the trolley bypassing the conveyor belt in a contrary inclination.

Swing table shot blasting machine is applied for shot blasting of different part forms and dimensions, casts also forged components, pressed pieces, ferrous, non-ferrous, steel & metal component made from delicate elements. Shot blasting machine for sale model K does clean outside, desand casting, mix the surface (micro treatment), roughing the exterior surface prior to painting, etc. Rotary barrel shot blasting machine in India is particularly fit for use in small groups & special part production. All swing table shot blasting machine in India are provided with a large loading door which gives easy & quick loading. Components are placed on a swing table. The shot blasting machine in India, installation is strong and preserved with wear-resistant elements. Onward with effective blasting wheels made from wear-resistant materials, the machine is outfitted with a high-efficiency operation for continued rotation and cleaning of the shots.

Shot blasting machine price is low as compared to other, Our maas production of shot blasting equipment decrease shot blasting machine price. We provide all types of portable Shot blasting machine prices all over the world with the best quality. Along with shot blasting machine manufacturer, we are also a manufacturer of sand blasting machine, grit blasting machine, Blast rooms, suction blasting cabinets, acoustic chamber, acoustic chamber dust collectors, and all types of thermal spray gun. Our company has a product portfolio with the best shot blasting machine price in India. Our major market of shot blasting machine price is gulf countries like Dubai, Iran, Iraq, Qatar, Oman, and other countries are Australia, Shri Lanka, Bangladesh, China, Canada, etc.

Airo Shot Blast is the leading Shot Blasting Machine Manufacturer in India and all over the world and supplies shot blasting equipment in all countries. Our mass Production increase quality and decrease shot blasting machine price. Shot Blasting equipment differs from sand blasting machine, because sand blasting machine is operated by air compressor, and shot blasting machine is operated by a shot blaster wheel.

We are one of the affluent manufacturers and suppliers of a wide assortment of Shot Blasting Machine Turn Table Type. This machine is manufactured using supreme grade components under the guidance of skilled team of professionals. The offered machine is widely demanded in foundries, forging plants, automotive, defense, heavy engineering and petrochemical industries etc for cleaning, strengthening or polishing metallic workpiece. In order to ensure its quality and performance, it is stringently tested on various defined parameters. Provided machine is available in various specifications and is widely used in various industries for manufacturing or process of ingot die casting. This Shot Blasting Machine Turn Table Type can be purchased from us at reasonable prices.

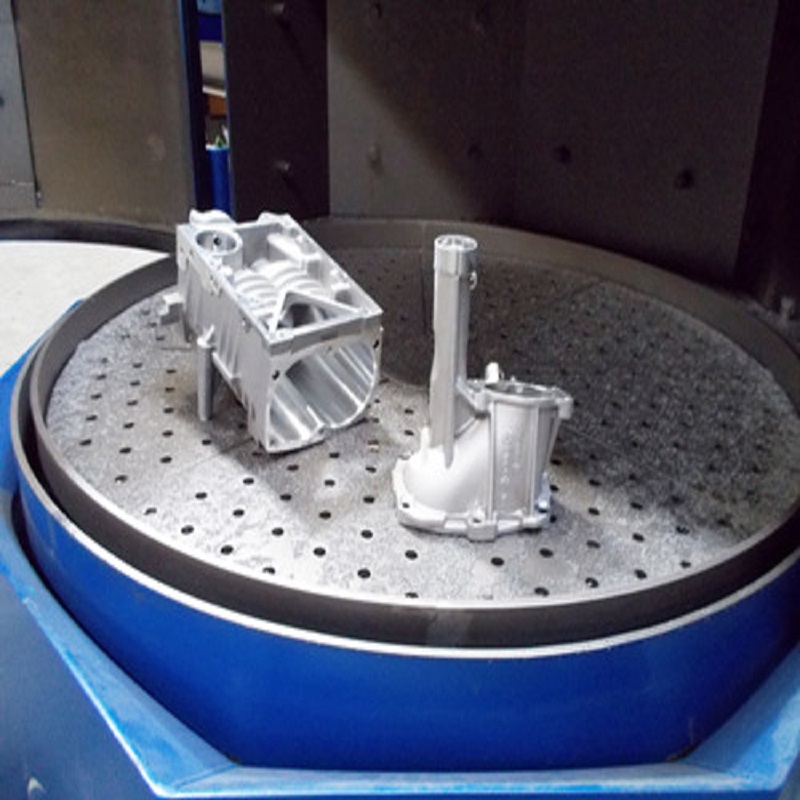

Treated objects are loaded on a perforated rotating table. A big door, provide simple and fast loading. The machine can have the table fitted to the machine"s door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The machine also can be equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the machine.

The machine"s housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand, a magnetic sand cleaner may be installed.

If you are looking forward to cleaning welded structures and fabrications, Aerowheel’s Rotary Table Shot Blasting Machine is the answer to your requirement!

Call it a Rotary Indexing Machine or a Rotary Table Shot Blasting Machine, you are on the right page for gathering more information on it and placing an order for its delivery.

The Rotary Indexing Machine works on the Suction Blasting principle as a Suction blaster. Blast cabinet is fitted with a bearing mounted indexing turntable, with a number of indexing positions. One indexing satellite stands outside the blast cabinet for job loading and unloading while other satellites stand inside the blast cabinet (one in blasting operation and others are in queue) the indexing turntable is driven by a geared drive.

It has indexing movement i.e. after 90 degree or specific rotation, the turntable stops in such a way that the satellite , having a work piece, comes under the blasting area.

After the required finish is obtained, the indexing table rotates again by specified degree so that the next satellite having a new job for blasting to come under the blasting area and the blast job comes to the loading and unloading area.

Treated objects are loaded on a perforated rotating table. A big door provides simple and fast loading. The machine can have the table fitted to the machine"s door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The machine also can be equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the machine.

The machine’s housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand, a magnetic sand cleaner may be installed.

It is suitable for various shapes and dimensions, casts, forged parts, pressed parts, steel, and non-ferrous metal parts and parts made from fragile materials, cleaning surface, removing casting sand and filings, consolidating the surface (micro handling), roughing the surface before colouring, etc.

Because of their characteristics the rotary-table shot blasting machines can easily be incorporated in diversified machining, adapting to the treatment of various parts of different shape and type. They can be equipped with fixtures and accessories built according to the pieces to be treated.

Aerowheel provides its customers with an option of designing the Rotary Indexing machine as per their specification. We have the flexibility of resigning our models in case you want them to adapt to certain specifications as per your need.

Shot Blasting Machine Manufacturers in India often use the term ‘Shot Blasting’ to define various processes such as Grit Blasting, Abrasive Blasting, Shot Peening and Media Blasting. While the process of Shot Blasting remains the same, a shot blasting machine may vary in capacity, size and structural design.

A shot blasting machine makes use of a mechanical method of propelling abrasive using a centrifugal wheel to remove a layer of deposits and impurities from the surface of metal and steel products. There are three basic purposes that require the need to shot blast before finishing the product:

A Shot blasting machine is an enclosed equipment designed for abrasive blasting for cleaning and preparing metal, stone and other surfaces. It is a machine for shot peening, cleaning metal parts such as forging, casting parts, steel surfaces, heavy metal structures, rusted metal parts etc. Shot blasting machine uses blast media on the metal parts in an enclosed chamber to remove surface rust, welding slag and descaling, making it uniform, shiny and improve coating quality of anti rust chemicals. Shot Blasting Machine Manufacturers in Pune, Mumbai, Hyderabad, Faridabad, Punjab, Jalandhar, Jamshedpur, Jabalpur, Bangalore, Coimbatore, Chennai, India offer steel grit blasting machines in various sizes and capacity with the lowest being 80kgs load capacity.

Shot blasting machines have an enclosed chamber for shots and grit blasting purpose and has a bare wheel that continuously rotates at very high speed, blasting media such as steel shots, steel grits or cut wire shots on metal parts for surface finishing purpose. The capacity of each bare wheel goes from approximately 60 kg per minute up to 1200kg/min.

Shot blasting machine also have a dust collection system to prevent tiny particles, contaminant, dust particles etc. from escaping out of the machine into the surrounding. A dust collector connected with a Shot Blasting Machine prevents wastage of abrasives as well as prevents environment. As a leading manufacturer of Shot Blasting Machine in India, MGI manufactures highly reliable, low-cost shot blasting machine that are completely dust and pollution free.

Shot Blasting is the process of cleaning a surface such as iron, steel, cast-iron parts, forgings, rusted pipes, iron bars, engine and automotive parts by blasting abrasive material such as steel shots or steel grits at very high velocity utilizing the centrifugal force generated by high speed rotating disk in a shot blasting machine. Shot blasting machine is also used to alter the mechanical properties or various components, increasing resistance to fatigue for springs, gears, etc.

Compared to sandblasting process shot blasting does not produces large amounts of dust and is much more environment friendly that’s why also called Dustless Blasting. A shot blasting machine is like a closed chamber so the dust particles generated at the time of blasting process remain inside the chamber and does not pollute the environment. Shot Blaster Machines for sale in India are available at competitive price from the best Manufacturer of Shot Blasting Machine.

The door of the machine is opened and components are loaded onto the endless rubber belt conveyor of the machine.The rubber conveyor belt tumbles the components and ensures adequate exposure of the components. The abrasive at high velocity falls upon the tumbling components and clean them. After blast cleaning cycle is over, the blast wheel is shut off and door is opened. The components are unloaded on the trolley by moving the conveyor belt in reverse direction. Always ask the manufacturer of Shot Blasting Machine for the quality of the conveyor belt to ensure long lasting blasting capability.

The rotor of blast wheel assembly unit fires abrasive down on the perforated belt. The spent abrasive from perforated belt top falls into hopper of the cabinet. The abrasive from hopper transferred to the boot of Bucket Elevator which leads abrasive to the Rotary Screen Separator/Air Dynamic Separation System (Optional Accessory). The tensioning arrangement for elevator belt is provided at the top portion of the elevator, hence no spillage of belt. The Rotary Screen Separator/Air Dynamic Separation System continuously segregates usable abrasive from unusable abrasive and debris. The usable abrasives are transferred into the storage hopper for recirculation purpose. The storage hopper entails electronic abrasive level sensor* (Optional Accessory). These sensors are connected to the abrasive replenishing hopper provided at the bottom of bucket elevator. The abrasives from storage hopper are transferred into blast wheel unit through feed funnel. The rotational movement of impeller constantly accelerates the incoming abrasive and pours them on the blades of the rotor. The flow of abrasive to the blast wheel unit is regulated by pneumatic valve operated by pneumatic cylinder and solenoid valve. The blasting media at high velocity are thrown by rotor onto the job.

The fabric bag type dust collector having number of tubular filter bag is provided. The dust laden air enters the dust collector through side and passes into a settling and equalizing compartment. Through expansion in the equalizing compartment, the air velocity drops and flow is distributed over the entire settling area. The air then flows up and away from storage hopper causing the heavier dust particles to settle down, the fine particles floating upward into the filter tube. The clean air passes through the tubes and is exhausted through the blower. At certain interval the tubes are shaken mechanically/manually to remove the accumulated dust from the filter bags. The dust is collected in the tray of the dust collector. The trays are taken out periodically and emptied. The filter bags are made out of a satin woven filter cloth. The seams are multiple stitched with heavy cotton thread. The blower unit of dust collector is dynamically balanced. The dust collector is fabricated in modular design and all the joints are sealed with imported sealing compound. MGI is also known for its high quality dust collection systems and not just as a leading manufacturer of Shot Blasting machines in India.

Shot blasting machine must be used with proper safety measures in place and you find more about the industrial health and safety criteria for abrasive blast cleaning operations.

When we talk about shot blasting ( Airless ) then it is important to remember that we are referring to a shot blasting machine which works by directly converting electric motor energy into kinetic abrasive energy by rotating a centrifugal wheel at a minimum of 60 kg per minute which can go upto 1200 kg per minute.

With such high amounts of accelerated blasting media a shot blasting machine is used to derust, descal, deburr, desand or clean large metal parts or surfaces that cannot be cleaned effectively through other traditional or manual processes.

Difference between shot blasting and sandblasting is simple to understand. In sand blasting compressed air is used to propel the abrasive towards the surface that needs to be cleaned and in shot blasting a centrifugal wheel is used to propel the abrasive toward the surface using an electric motor. Shot Blasting Machine Manufacturers in India for Forging components, Casting components, Shot peening, Grit Blasting Machine and iron parts cleaning.

Flexibility of using various types of abrasive materials that can be used in a shot blasting machine depending on the surface that needs to be cleaned such as glass beads, steel shots, steel grit etc. makes shot blasting the most preferred method of cleaning or preparing different metal surfaces and components.

Maan Global Industries based in Faridabad & Jodhpur Rajasthan India has mastered the process shot blasting and sandblast for effective results in various industries from castings to forgings to fabrication to coatings. We are among the leading manufacturers of Shot Blasting Machine and Sand Blasting Machine in India for over a decade and provide various models of shot blasting machines for different applications such as Portable Sandblaster, Tumb Type Shot Blasting Machine, Blast Cabinet, Cabinet Type shot blasting machine, Spinner Hanger Type Shot Blasting Machine , Blast Room and many other models.

8613371530291

8613371530291