tsudakoma rotary table pricelist

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

A new line of high accuracy, high rigidity, energy saving and zero maintenance rotary tables from Tsudakoma. The TBS Series rotary tables are built using the new ball drive system featuring advantages like zero backlash, improved cycle times, energy conservation and a lifetime adjustment-free transmission system.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Koma Precision showcases the dual platter Tsudakoma TWM-250 five-axis rotary table. This high precision unit has two 10" platters that can be equipped with rotary unions for hydraulic or pneumatic work holding actuation. The unit can be setup for 12-16" between platters, which Koma says enables for a variety of work holding and workpiece shapes and sizes.

The TWM series is said to be ideal for high-production single or dual spindle VMC’s that require five-axis machining. The TWM series unit can be setup for simultaneous five-axis movement or 4+1, enabling the machine to get around five sides of the workpiece. The hydraulic brake on the tilt axis reportedly provides 3100 Nm of brake torque, which enables the machine to take heavier cuts at more aggressive speeds and feeds while maintaining the accuracy of the part. According to Koma, the machine tool is only as accurate as the work holding and rotary table; therefore, the rigidity is critical to the entire throughput rate and quality of the cutting process.

X2F says the addition of a rotary table to its machine reduces cycle times and opens up higher-volume production possibilities—up to four million parts per year.

The Third-Party Rotary provision provides access to the rotary parameters in the Haas control, allowing you to use a third-party single- or two-axis rotary table on your Haas machine. The option supports full simultaneous machining up to 5 axes, and is compatible with Dynamic Work Offsets and Tool Center Point Control. It is the responsibility of the customer and the third-party manufacturer to troubleshoot and fine tune the different parameters. Requires the purchase of the 4th-Axis Drive option to operate a single-axis rotary, or the purchase of both 4th- and 5th-Axis Drive options to operate a two-axis rotary.

Precision rotary table tiltable type UT300, precision rotary table can be used horizontally and vertically, for milling, drilling, grinding and marking work.

1 pair of prismatic blocks without clamping brackets, suitable for clamping round material, prismatic incision 90°, made of special cast iron, supplied in pairs

Clamping tables, swivelling ±45 degrees in both directions, with rotating plate rotatable through 360°, type HAP, with reinforced construction in special cast iron.

Precision rotary tables HOMGE type HHV, universal dividing head for milling, drilling, boring, grinding and marking work, for horizontal and vertical use.

ZENTRA precision rotary table RT with a gear ratio of 90:1 / for milling, drilling, boring, grinding and marking work is horizontally and vertically versatile.

Precision rotary table dividing head ZENTRA type RT-DF, mounted lathe chuck for milling, drilling, boring, grinding, scribing work, for horizontal and vertical use.

ZENTRA indexing disks for precision rotary tables type TS for the production of precise, indirect graduations as for example in gear milling ✅ buy now!

One thing that is sorta misleading about the CNC tables unless you"re seen one first hand is just how big they are. I"ve got a Tsudakoma THNC-301, which is a 320mm (12"+) table thats rotary powered and manually tiltable from horizontal to a bit past vertical. It weighs somewhere between 400 and 450 lbs, and I guess the new cost now is somewhere north of $16,000. They have positioning accuracy within a few arc seconds, and are capable of holding accuracies like this with a part that weighs a couple hundred pounds and cutting forces that can generate several hundred ft-lbs of torque.

Pricewise, assuming my 16K current estimate is accurate, that would work out to a bit less than $40/lb, because it definitely weighs over 400#. For comparison, a 10" Kitagawa power chuck for a lathe retails now for about $4000, and although I"ve never weighed one, I guess they weigh less than a hundred lbs from picking one up a "few" times. So that puts the chuck at over $40/lb. If you ever have cause to take one of these chucks apart, they are surprisingly simple. They"re accurate and repeatable, and everything is hardened and ground, but they"re still simple, especially when compared to a rotary table. A good sized collet chuck from Royal to fit an A-8 spindle nose on a lathe weighs barely over 40 lbs and costs close to $2500. Once again, its all hardened and ground, but this is the price of a pullback type chuck which is just one single piece of steel with no moving parts whatsoever, yet it sells for over $60/lb. When you compare the rotary tables and their size and complexity to other machine tool parts of similar complexity and quality, the price begins to look not so far out of line, even though its still not cheap by a long shot.

The NC combines robustness and durability with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute value encoder and a drive cam with constant pitch. For applications requiring extreme precision, weread more...

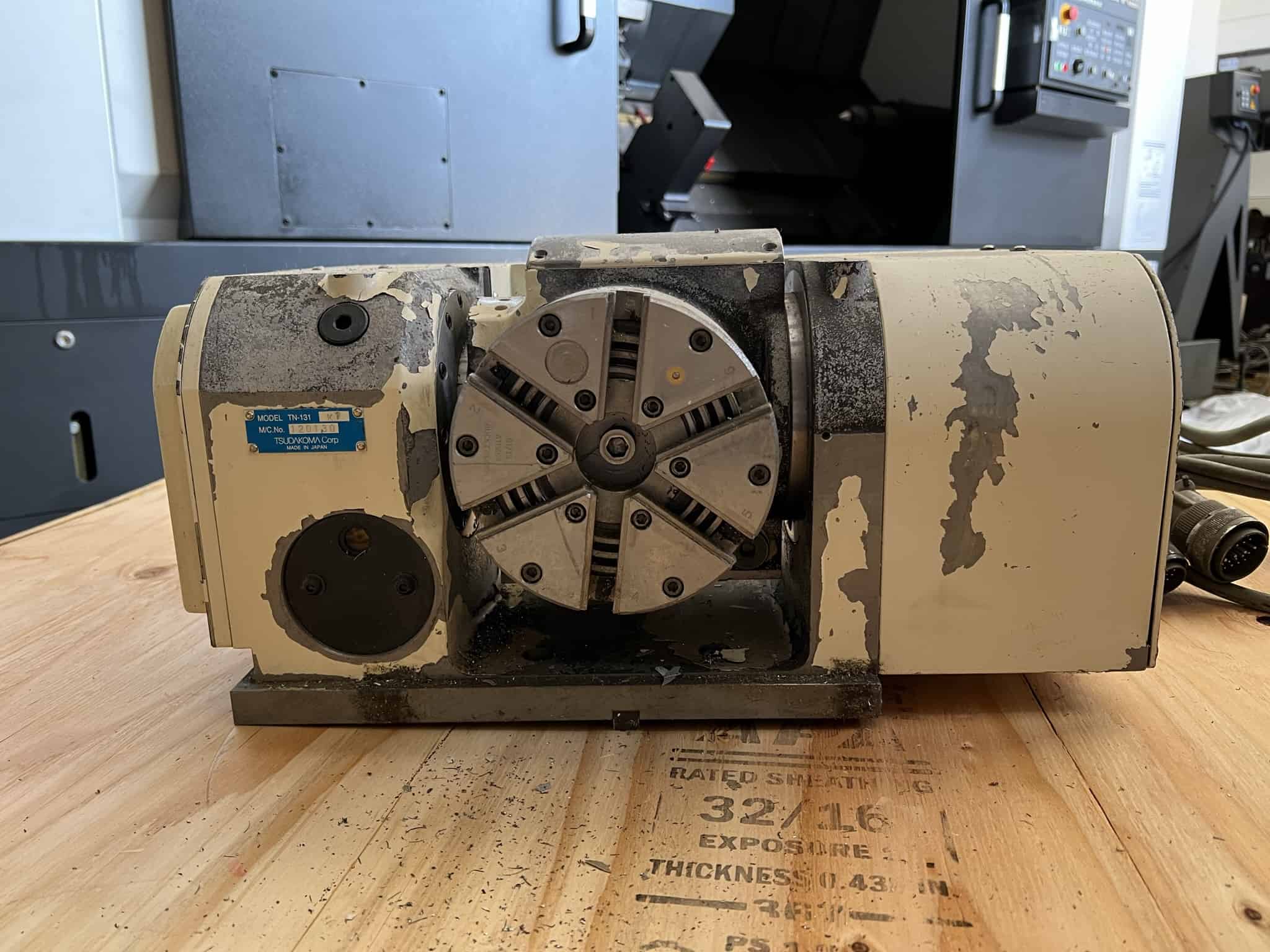

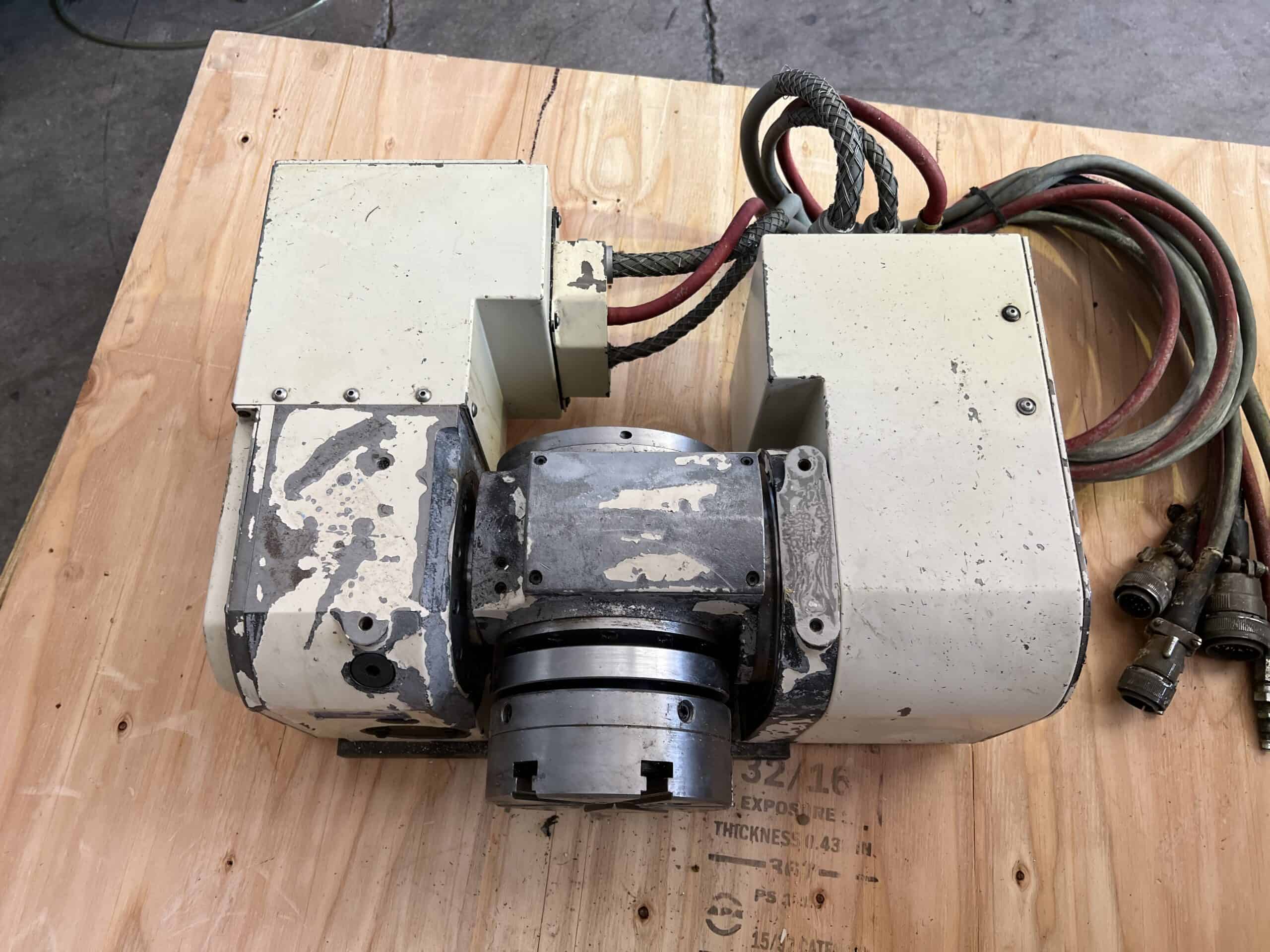

The latest TN tilting range from Tsudakoma, with major developments over earlier models with major increases in speed and power transmission, with high power pneumatic clamping system. The unit has a 55mm spindle nose location with a generous location depth of 15mm with 35mm directly through the table and a has a centre height of 150mm in the vertical position (90 degrees) and 210mm in the horizontal position (0 degrees) without faceplate, 235mm with faceplate. This device is around 524mm in overall width which would ideally suit a wide range of machine tool bed widths and an overall height of 235mm. The unit has a tilting range as standard of -17 to + 107 degrees. An excellent carrying capacity of 20kg through the whole tilting range and 35kg horizontally or between centres and speeds of up to 41. 6rpm in the rotary axis and 16. 6rpm in tilt dependent on motor selection. Net weight of this device is 80kg. The Tsudakoma TN-131 CNC rotary tilting table without motors, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th / 5th ;axis interface” in the machine) and machine interface costs (if you do not have the additional axes fitted). Rotary axis motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the tilt axis motor is mounted in a rear facing direction on the far side of the device and should not have any bearing on traverses. This range of Tsudakoma devices now come with dual lead full depth worm and wheel, which means that there is less load on individual teeth improving wear and torque performance over and above the conventional standard gear. Tsudakoma is one of the oldest and original manufacturers from Japan and in our experience build a very fine device with a very long service life, probably greater than those we have experienced from other Japanese makers. Tsudakoma products carry a standard one year parts and labour warranty and have a full working partnership with CNCROTARY. COM. This device may take from 2 to 3 weeks to configure as required.

Tsudakoma RNCM-250R 4th Axis 10" Rotary Table with Tailstock . Tsudakoma RNCM-250R 4th Axis 10" Rotary Table. Gear Hobs, Lathe Chucks. Bore Gage setting Rings ( 10mm - over 300mm 1/4" - 13"). Tool holders (CAT50, CAT40, BT50, HSK, VDI, Morse Taper) . Tsudakoma RNCM-250R 4th Axis 10" Rotary Table with Tailstock Nice Clean condition as shown from a working environment Fright Shipping cost is upto buyer Item can also be picked up from OHIO 44090 Please See All Photos If you have any questions or would like any extra photos please contact me the items shown in the photos is the items you will receive I go to the post office at everyday at 1.00pm Monday - Friday if an item is bought and paid for before then the item will be shipped the same day if any later it will be the next day A place to receive friendly, reliable , full service at an affordable price. We hold each of our customers as a top priority.Our promise from our business to our customers is high standards ,quality and best prices at a fast shipping pace secured & insured! "NO" question asked return policy!!!! (within the 14 days of item arrival. ) Please see terms & condition policy. Inventory Machinist Lathe Tooling of all brands, Gear Hobs, Lathe Chucks, Tool holders (CAT50, CAT40, BT50, HSK, VDI, Morse Taper) , Capto,Kennametal , Bore Gage setting Rings ( 10mm - over 300mm 1/4" - 13"), Height Stands, All types of Gages , Inspection Equipment and more!!! 14 Day No Hassle Returns Policy Please subscribe to my eBay Store For Great deals Thank You For Viewing

Condition: Used, Condition: Good used condition as shown from a working environment, Manufacturer: Tsudakoma, Brand: Tsudakoma, Model: RNCM-250R, MPN: 8798644, Tsudakoma RNCM-250R 4th Axis 1: Tsudakoma RNCM-250R 4th Axis 10" Rotary Table with

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

8613371530291

8613371530291