kitagawa rotary table manufacturer

TMX160 Heavy Duty Rotary Table with increased rigidity for demanding applications. The internal air hydraulic booster gives extremely high clamping forces.

TMX160 Heavy Duty Rotary Table with increased rigidity for demanding applications. The internal air hydraulic booster gives extremely high clamping forces.

TUX200 Rotary Table with top mounted motor suitable for horizontal machines. Integrated air booster provides high clamping torque from a standard air supply.

Used in CNC machining and metalwork, rotary tables, also known as indexing tables, provide fine control of a workpiece in order to cut work at specific intervals around a fixed axis. Simply put, it needs to control and rotate the workpiece that is being machined. Since precision and accuracy are so important in the CNC machining process, picking the right machine that fits your needs and requirements is so important.

Kitagawa Rotary Tables feature proven technology with high clamping torque, accuracy, and rigidity. With a wide range of tables to choose from, there is a huge amount of flexibility on offer to meet whatever needs your machine shop may require. Choosing a Kitagawa rotary table is a quick, easy, and inexpensive way of increasing the capabilities of your machining centre, allowing you to increase accuracy, decrease cycle times, and machine more complex parts.

So what are the different types of rotary tables and which is best for you? This greatly depends on what you need to get out of it and your budget. Fortunately, Kitagawa provides some of the best rotary tables on the market and supply a wide range of models for both big and small projects.

Kitagawa’s GT Series are 4-axis rotary tables that offer a higher clamping torque than standard, making them extremely capable of withstanding high cutting loads. Productivity is further enhanced by the tables’ robust yet compact design, which allows maximum metal removal rates to be combined with high indexing accuracy and repeatability. The GT Series also features a rapid clamping action for reduced cycle times and maximum production throughput.

Kitagawa’s TT Series is an example of 5-axis, ball drive rotary tables that feature tilting rotary indexers. These allow for more complex workpiece and machining configurations and make it easy to add 4th and 5th axes capabilities to standard machining centres.

All Kitagawa 5-axis rotary tables are available with a built-in rotary joint if required, simplifying the pipework that would be needed for using a power chuck. When combined with the range of rotary tables, Kitagawa’s extensive range of power chucksallows for a huge amount of flexibility in your machining environment.

Perfect for large scale projects and businesses looking to improve their productivity and efficiency, the multiple components with multiple operations simultaneously, it still possesses all the characteristics of any other 5-axis indexing table.

If you would like more information about Kitagawa Rotary Tables, you can contact us on 01725 512517 or enquiries@1mta.com and arrange a FREE visit with one of our technical representatives. We look forward to hearing from you.

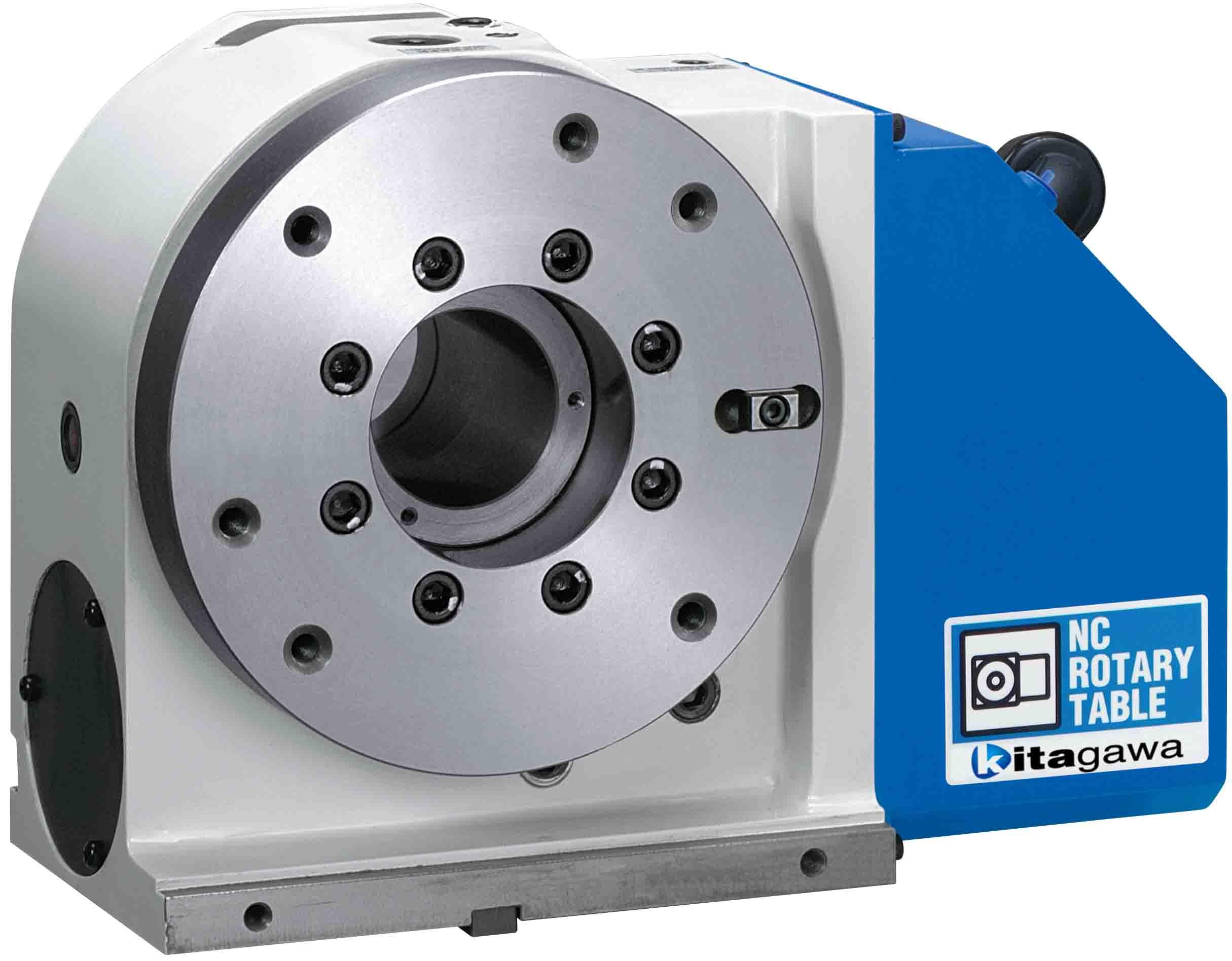

With thorough expertise and understanding of this industry, we are enormously involved in offering a quality assured range of Kitagawa MK200RAV00 NC Rotary Table.

Kitagawa Corporation (KITAGAWA)KITAGAWA manufacture and supply standard power chucks, rotary cylinders, NC rotary tables, vices, work grippers, as well as other peripheral equipment for machine tools such as turning centres and vertical machining centre.

Eastec 2019: Kitagawa NorthTech will be displaying its Nobel brand of workholding chucks for vertical turning lathes (VTLs), available up to 3.5 m (11.48 ft.) in size.

Kitagawa NorthTech earlier this year absorbed Itex Workholding operations, which previously held the distribution rights for Kawatatec Nobel Chucks in North America.

PMTS 2017: Kitagawa-NorthTech, a manufacturer of chucks, cylinders, steady rests and workholding accessories, provides custom turnkey workholding services.

Kitagawa NorthTech offers its Digital Grip Force Analyzer software and kit (PC version) designed to enable users to easily, accurately and quickly analyze and measure grip force performance of their CNC lathes and turning centers via a desktop PC, laptop or tablet.

Featuring robust construction and powerful clamping for high accuracy, Kitagawa’s TT-series NC tilting rotary tables are designed to handle a range of applications including shaft work requiring large through holes.

Well-suited for oilfield work, this compact rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a much larger face plate.

Workholding product manufacturer Kitagawa-Northtech (Schaumburg, Illinois) has established a strategic business solutions team to accelerate and streamline customer support.

At this Chicago-area manufacturer, quick-change chucks from Kitagawa added to the benefits of moving from multiple setups on multiple machines to producing parts in a single setup on Mazak turn-mills.

While the lack of young people coming into manufacturing industries has been a concern for years, the situation has yet to improve, says Bill Graham, marketing manager for Kitagawa-NorthTech. Mr. Graham believes the industry as a whole needs to better support teachers who are interested in teaching technical skills and dispelling myths about manufacturing.

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Last year the Japanese manufacturer Kitagawa introduced the first in a new range of compact, general purpose rotary tables, the MK-series, for adding a rigid fourth CNC axis to a 3-axis vertical machining centre.

Most notable improvement on the MK250 is the 1,000Nm, pneumatically actuated clamping torque, making it more than four-fifths stronger than the first model. As with all Kitagawa tables, this torque is determined by the point at which the force on the worm wheel causes it to displace by 30µm. In contrast, some manufacturers quote the slipping torque as a maximum, which can cause inaccuracy or even failure.

If a Kitagawa TSR181A tail spindle with integral clamp, also available through 1st MTA, is added for securing a component or tooling column horizontally between centres, clamping torque increases to 1,600Nm. The result is even faster, heavier duty, more productive machining. As the table has a small footprint, loss of bed area and working volume in a machining centre is minimised.

Kitagawa has both stronger and more compact rotary tables of similar capacity in its product ranges, for example the GT250 and CK250 respectively, but Kitagawa asserts that the MK250 meets 90% of all customer requirements.

The type of the faceplate is specified by the customer, either with T-slots or pre-drilled holes. The advantage is that a chuck, trunnion or other workholding device can be mounted directly onto the rotary table, reducing the distance from the spindle bearing. Such compact assembly lessens the load on the bearing, increasing rigidity and longevity. Cutting torque is 480Nm and the spindle through-hole diameter is 70mm.

The table design minimises accumulation of chips around the base, reducing cleaning time and ensuring the absence of interference to the workholding arrangement – an important consideration in automated production cells.

Compact, built-in, 7 MPa rotary joints may be selected from 4-, 5- and (6+1)-port types, the latter having a 12.5mm diameter, multi-purpose hole through the centre for additional hydraulic or pneumatic services to actuate workholding. The hole can also be used as a duct for cables feeding signals back from fixture sensors confirming correct workpiece seating, enabling the design of the workholding configuration to be improved and its capabilities enhanced.

1st MTA will alternatively provide a high pressure 25MPa, four-port or six-port rotary joint instead of the standard 7MPa variety, allowing a further reduction in fixtures sizes as well as improved clamping speeds.

8613371530291

8613371530291