kitagawa rotary table free sample

Used in CNC machining and metalwork, rotary tables, also known as indexing tables, provide fine control of a workpiece in order to cut work at specific intervals around a fixed axis. Simply put, it needs to control and rotate the workpiece that is being machined. Since precision and accuracy are so important in the CNC machining process, picking the right machine that fits your needs and requirements is so important.

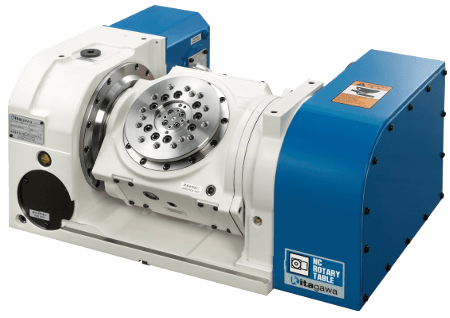

Kitagawa Rotary Tables feature proven technology with high clamping torque, accuracy, and rigidity. With a wide range of tables to choose from, there is a huge amount of flexibility on offer to meet whatever needs your machine shop may require. Choosing a Kitagawa rotary table is a quick, easy, and inexpensive way of increasing the capabilities of your machining centre, allowing you to increase accuracy, decrease cycle times, and machine more complex parts.

So what are the different types of rotary tables and which is best for you? This greatly depends on what you need to get out of it and your budget. Fortunately, Kitagawa provides some of the best rotary tables on the market and supply a wide range of models for both big and small projects.

Kitagawa’s GT Series are 4-axis rotary tables that offer a higher clamping torque than standard, making them extremely capable of withstanding high cutting loads. Productivity is further enhanced by the tables’ robust yet compact design, which allows maximum metal removal rates to be combined with high indexing accuracy and repeatability. The GT Series also features a rapid clamping action for reduced cycle times and maximum production throughput.

Kitagawa’s TT Series is an example of 5-axis, ball drive rotary tables that feature tilting rotary indexers. These allow for more complex workpiece and machining configurations and make it easy to add 4th and 5th axes capabilities to standard machining centres.

All Kitagawa 5-axis rotary tables are available with a built-in rotary joint if required, simplifying the pipework that would be needed for using a power chuck. When combined with the range of rotary tables, Kitagawa’s extensive range of power chucksallows for a huge amount of flexibility in your machining environment.

Perfect for large scale projects and businesses looking to improve their productivity and efficiency, the multiple components with multiple operations simultaneously, it still possesses all the characteristics of any other 5-axis indexing table.

If you would like more information about Kitagawa Rotary Tables, you can contact us on 01725 512517 or enquiries@1mta.com and arrange a FREE visit with one of our technical representatives. We look forward to hearing from you.

A series of new workholding and machining equipment – including the IEMCA Automata 2.5, Kitagawa TW2180 twin spindle rotary table and JFT-S100 stationary grip meter – will be exhibited for the first time in the UK by Kitagawa Europe on Stand 5148 in Hall 5 atMACH 2008, which takes place at the NEC between 21st-25th April. Kitagawa’s new products at MACH will be complemented by examples from the company’s extensive range of machine chucks and rotary tables, as well as demonstrating a number of special purpose models.

INSERTING POSITION WORK DIAMETER LARGE ~ HIGH-SPEED ROTATION STABLE CHUCKING OUTER DIAMETER INSERTION OF WORK IMPOSSIBLE GRIPPING POSITION_ GRIPPING POSITION MAINLY OIL WELL PIPE - Flange Work INSERTING POSITION WORK DIAMETER LARGE ~ "WORKING LATHE" -Flange Work -SKIP PORTION SMALL - -SKIP PORTION LARGE - UNCLAMP STATE STABLE CHUCKING STABLE CHUCKING Long stroke - Flange Work GRIPPING POSITION, "ROUND FIGURE GRIPPING POSITION. SK-The contents in this chart are subject to change without notice for further improvement, etc.

Universally recognised and trusted brand offering proven technology For over half a century, KITAGAWA products have inspired confidence in customers all over the World. The Kitagawa series of chucks is wide- ranging and so technologically advanced that we can offer solutions for all machining conditions, no matter how punishing. Manufacturing systems with exceptional quality controls ensure the production of highly precise and superior products, which guarantee trouble-free operation. Our unique innovations in workholding solutions, supported by highly specialised design teams and a proven...

Standard Chuck Cylinder series exclusive From our standard chucks and cylinders through to our most advanced, this extensive line up combines excellence with performance, and caters for all KITAGAWA chucking.

Large Thru-Hole Power Chuck Stable Machining for Large Work Pieces Universally recognised standard chuck Dimensional Drawings Gripping Characteristic Graphs I DImBnSlOnS * Blank draw nut equipped.

Large Thru-Hole Power Chuck Stable machining even for large diameter bar material Universally recognised standard chuck •Standard Soft Jaw can be used for B-200 series as well •Large through-hole Dimensional Drawings Gripping Characteristic Graphs SKWlth standard blank soft top law.

Quick Jaw Replacement Chuck Suitable for small and large batch production Quick & smooth Jaw Replacement 2types of easy replacement jaws, Serration and Tongue & Groove, are available as options. Jaw can be replaced quickly and easily by handle ■Suitable for small and large batch production Resuced set up time by Quick and Easy Jaw ■Interchangeable mounting dimensions Kitagawa"s B-200 and BB200 series can be easily replaced with QJR large thru-hole power chucks. Dimensional Drawings Gripping Characteristic Graphs The models above are Including Chuck body, 1 sat of Base Jaws and 1 set of Soft...

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

CNC MATRIX 2,Strokes 2000 x 820 x 720 mm,table 2500 x 820 mm,spindle speed 18000 rpm,table weight 1700 kg,magazine 48 tools,spindle center watering 15 Bars,preparation RENISHAW OMP 60,central separation,4 th Axis KITAGAWA,Conveyor

DMG Mori NLX 2500Y/700 CNC Turning Centre with DMG Mori Ergoline Touchscreen Control, 12 Position Tool Turret, Incl. 10 Tool Holders (2 Driven), Max Spindle Speed 2500rpm, Renishaw RP3 Tool Setting Arm, Kitagawa BB212 3 Jaw Chuck, Coolant System, Swarf Conveyor, Filtermist Oil Mist Extractor, Machine Weight 6,140kg. S/No. NL256160939 (2016) Hydrafeed MSV80 Barfeeder Mounted on Linear Rail. S/No. S02-18E149 (2018)

The rhizomes and roots GM were purchased from Yanbian Puhe, China in March 2006 and authenticated by Prof. Hui-Zi Lv of College of Pharmacy, Yanbian University. The rhizomes and roots of GM (1 kg) were extracted three times with methanol (10 L) and boiled under reflux for 4 h at 40°C, and then the percolated was concentrated in a rotary vacuum evaporator followed by lyophilization. The yield (w/w) of extract was about 22.35%. The freeze-dried extract was used in both chemical analysis and pharmacological studies. GM extract was analyzed on HPLC to confirm the presence of gentiopicroside (Figure (Figure1).1). The content of gentiopicroside was 2.48% in GM extract. The extract was pre-solubilized in distilled saline for the in vivo studies.

HPLC chromatograms of Gentiana manshurica Kitagawa (GM). Column: Diamonsil C18 (250 mm × 4.6 mm); Flow rate: 1 mL/min; Mobile phase: Methanol and H2O (35:65).

8613371530291

8613371530291