kitagawa rotary table made in china

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

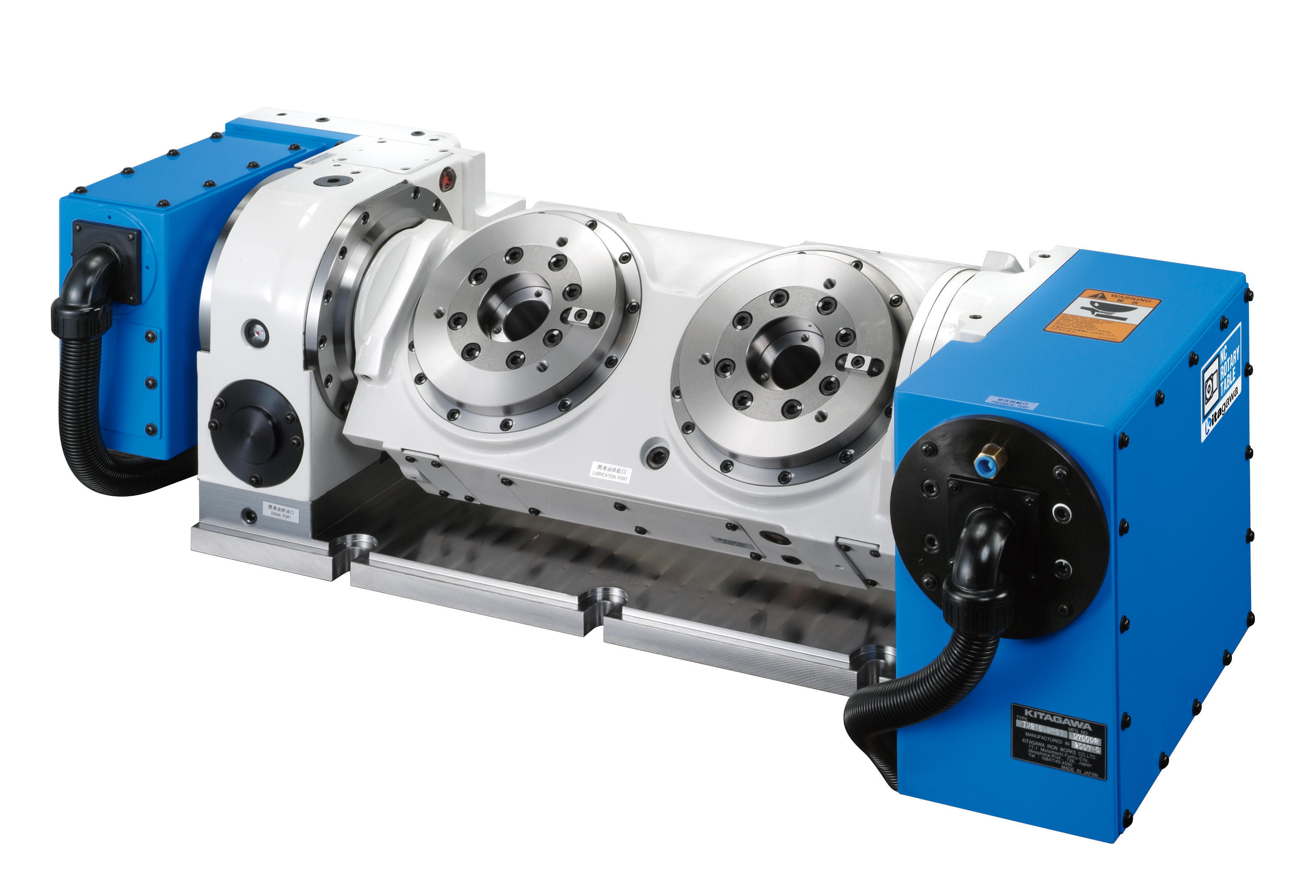

As the oil, gas and aerospace markets have grown, so too has the size of workpieces those industry segments require. Machining of tubes and pipes, for example, calls for NC rotary tables with sizeable through-holes to accommodate large-diameter stock. The Kitagawa-NorthTech TP530 was developed to deliver the requisite through-hole diameter in a more compact overall size than comparable rotary tables so this type of work can be performed on smaller machines.

The TP530 has a 20-inch-diameter face plate and offers a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a 31.5-inch face plate. It is said to be four times smaller than conventional 31.5-inch versions as well as 484 pounds lighter while providing the same through-hole capacity. This design enables work to be performed on smaller-sized machine tools.

The rotary table also offers a low Z-axis centerline height. Bringing the centerline of the workpiece closer to the table minimizes machining vibration and workpiece deflection. Plus, it enables large-diameter work to be performed on machines that don’t have significant Z-axis travel, which, in some cases, can preclude the purchase of a bigger machine. In addition, shorter, stouter tools can be used because the distance from the top of the rotary table to the workpiece is less than conventional rotary tables. Shorter tools are less prone to deflection and enable shops to realize more aggressive cutting operations. This feature complements the rotary table’s high clamping torque of 4,499 foot-pounds.

Affordable indexers and fourth-axis rotary tables greatly enhance the capability of vertical machining centers. It’s almost as good as having a horizontal machining center.

Kitagawa Corp is the diversified machinery manufacturing company based in Japan. It is specialised in three core businesses: the production and development of casting and machining techniques of metal raw materials; supplying power chucks and numerically controlled rotary tables to the global machine tool industry; constructing custom-made concrete and recycling plants as well as providing construction machinery for various projects, including bridge erection and self-propelled multi-floor parking. The company has an operational presence across the United Kingdom, the United States of America, China, Taiwan, Australia, Germany and other regions.

Our fine quality tilting tables has marked their place in the national, as well as international markets for their extended service life, dependability and fine finish. The offered assortment is specially designed by our industry experts in accordance with the needs, requirements and specifications of our valued clients.

CNC MATRIX 2,Strokes 2000 x 820 x 720 mm,table 2500 x 820 mm,spindle speed 18000 rpm,table weight 1700 kg,magazine 48 tools,spindle center watering 15 Bars,preparation RENISHAW OMP 60,central separation,4 th Axis KITAGAWA,Conveyor

DMG Mori NLX 2500Y/700 CNC Turning Centre with DMG Mori Ergoline Touchscreen Control, 12 Position Tool Turret, Incl. 10 Tool Holders (2 Driven), Max Spindle Speed 2500rpm, Renishaw RP3 Tool Setting Arm, Kitagawa BB212 3 Jaw Chuck, Coolant System, Swarf Conveyor, Filtermist Oil Mist Extractor, Machine Weight 6,140kg. S/No. NL256160939 (2016) Hydrafeed MSV80 Barfeeder Mounted on Linear Rail. S/No. S02-18E149 (2018)

We handle lathe chucks, design chucks, NC rotary tables, grippers (robot hands), and other machine tool products that are indispensable for machining.

This is the 2-jaw standard chuck with the highest gripping accuracy in the history of Kitagawa Corporation, and is ideal for high-precision machining of irregularly shaped workpieces on a lathe.

Gripping accuracy, which is directly linked to workpiece machining quality and safety during machining, is 0.01mm T.I.R. or less. Moreover, the chuck"s reduced jaw-lift compared to the conventional standard chuck ensures stable machining quality.

Chucks hold the key to machining accuracy. Although Japanese-affiliated manufacturers understand the importance of chucks and the Kitagawa brand has a large share of the industry, its share is only 10% on a global scale, which still requires aggressive publicity. On the other hand, the demand for Kitagawa chucks in the Chinese market has been increasing in recent years. This is due to the growing awareness that even if the performance of the machine tool (lathe) is not high, the quality of the chuck can achieve high precision, and there is a growing demand, especially among Chinese manufacturers and trading companies, to reduce costs and improve product precision.

Kitagawa Corporation is the only Japanese-affiliated chuck manufacturer with a branch office in Thailand and has the largest sales network (bases) among manufacturers handling chucks.

If you are looking for a high-precision lathe chuck in Thailand, or if you are interested in other machine tools (NC rotary tables, grippers, etc.), please contact us using the form below.

8613371530291

8613371530291