rotary table vise in stock

AV-R-4 Rotary Vise is a precise solution for your rotary clamping needs. Combining the features of our Table Vise that is designed for 4th axis machining. A unique T-Hook allows the jaws to disengage in an open position for rapid changeout. Our one touch open and close feature provides consistent and repeatability clamping. Ease of integration without the need to modify existing fixturing or labor-intensive set ups. The pneumatic AV&W Rotary Vise offers substantial time and cost savings while increasing consistency.

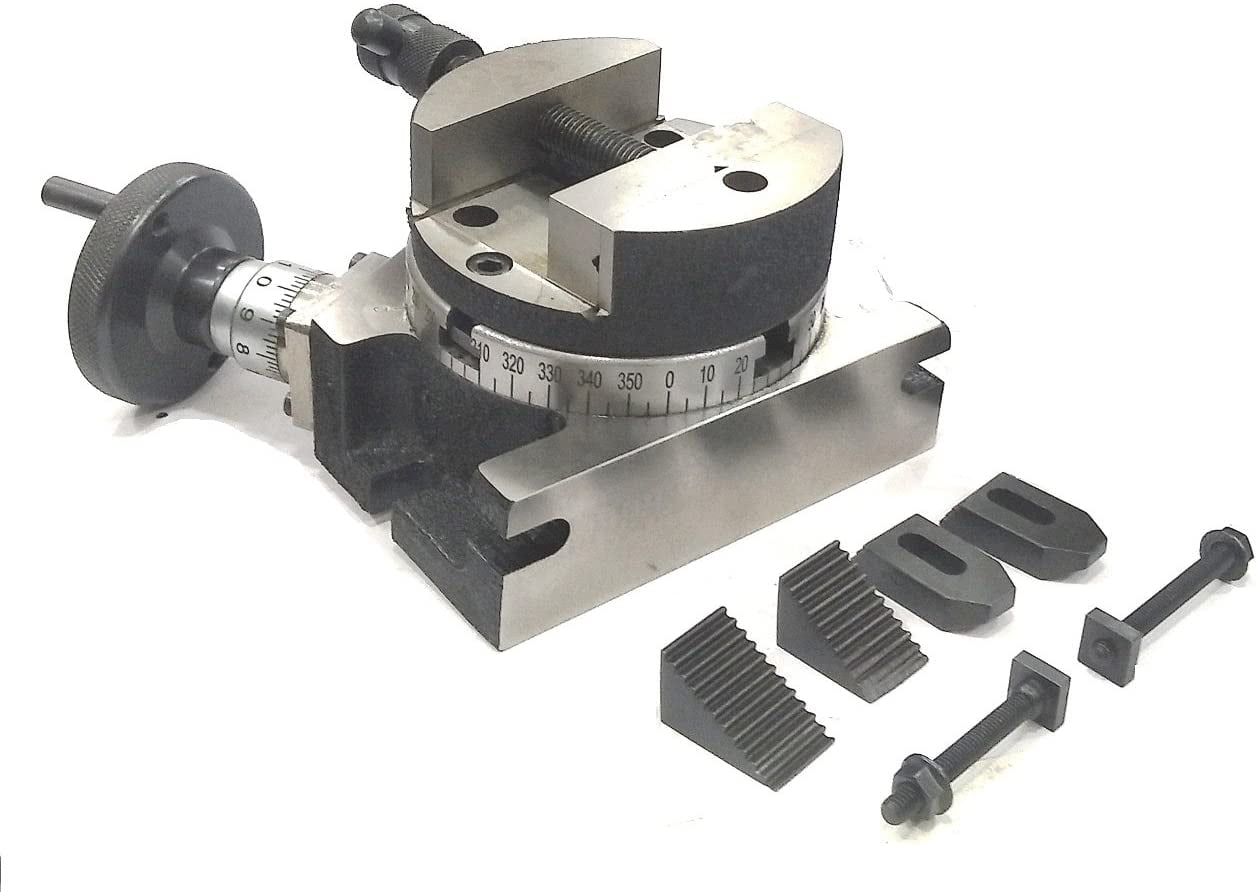

816-1511 - Includes the Positional Rotatory Table (great for general work at the bench this 8" steel work base offers drag screw resistance, optional positioning and a 360 degree rotation) plus a mounted vise in the center for ease of positioning. Made in USA

Simply put,a tailstock is NOT needed. Because of the compact length, rigid materials and parts held closely to the rotary table face, tailstocks have no effect on performance. We"ve rigorously tested the RotoVise for over four years and have cut aluminum, steel, stainless, cast iron and hardened alloys with excellent results and surface finishes at aggressive feed rates (250-600 ipm depending on material) without the need for a tailstock.

As previously mentioned, we"ve machined aluminum, steel, stainless, cast iron and hardened steels during the two year development of the RotoVise. In fact, most components of the RotoVise are made on the RotoVise! For comparison, we machine the ductile cast iron sliding jaw carriers at 300 ipm, .750" doc and .050" woc with a 4 flute 1/2 inch diameter carbide endmill with amazing results.

The RotoVise is designed to bolt to all brands of rotary tables that use 4 or 6 t-slots platters as well as all Haas Automation UMC models. For best results, only use rotary tables that have integrated pneumatic brakes that provide a minimum of 100 ft-lbs (136 Nm) of brake torque. Manual rotary tables also work well as long as they have a manual brake.

Each jaw station grips with up to 5,000 lbs of clamping force. Let"s think about this... a good conventional 6 inch vise clamps with about 8,000 lbs. With only 3 inch wide jaws, the RotoVise has an equivalent clamping force of 10,000 lbs on half the width compared to 6 inch vises. Furthermore, the RotoVise uses a fine pitch 16 tpi lead screw to exert more clamping force for the same torque input. We"ve designed this to minimize torque placed on the rotary unit without compromising clamping force.

45 foot lbs maximum.The RotoVise uses a finer pitch lead screw (16 tpi) than traditional vises (10 tpi). This means the same amount of handle torque applies 60% more clamping force than a standard vise. For this reason, only the 3-arm handle supplied with the RotoVise should be used because the shorter handles limit the amount of torque applied to the brake and gears of the rotary unit.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. The dial is graduated in divisions of 1 min. and the vernier scale allows readings down to 10 seconds.

8613371530291

8613371530291